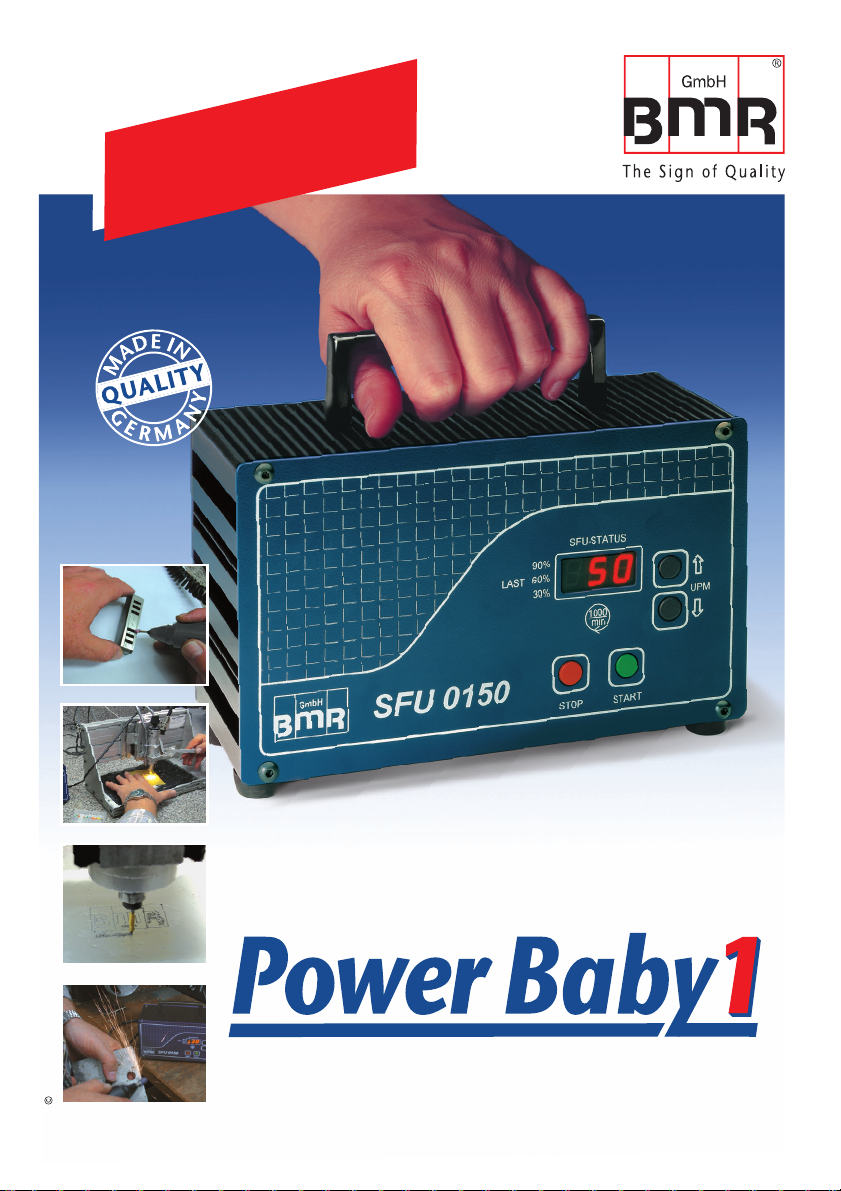

BMR Power Baby 1 User manual

MANUAL

Power Packet

in a small Size:

Handheld High Frequency Converter SFU 0150

BMR GmbH 2008

SFU 0150

2

Plea e read

thi manual carefully

before the fir t u e

Version 06.April.2009

Congratulation

for purchasing a BMR-GmbH product.

We thank you for the decision for

choosing a BMR-GmbH device

and wish you much success.

3

Content

1. ntroduction

2. Description and Features

3. Technical Data

4. Safety Precautions and Warnings

5. Connections, Plugs and Pinouts

5.1 Remote Control Connector

5.2 Spindle Connector

5.3 Mains

5.4 Mains Switch and Fuse

6. Functions, Setup, Operation

6.1 Front Panel

6.2 Setup of Rotational Speed

6.3 Starting and Stopping the Frequency Converter

6.4 Setup of Direction of Rotation

6.5 Operation

7. Safety Functions

8. EMC (Electro Magnetic Compatibility)

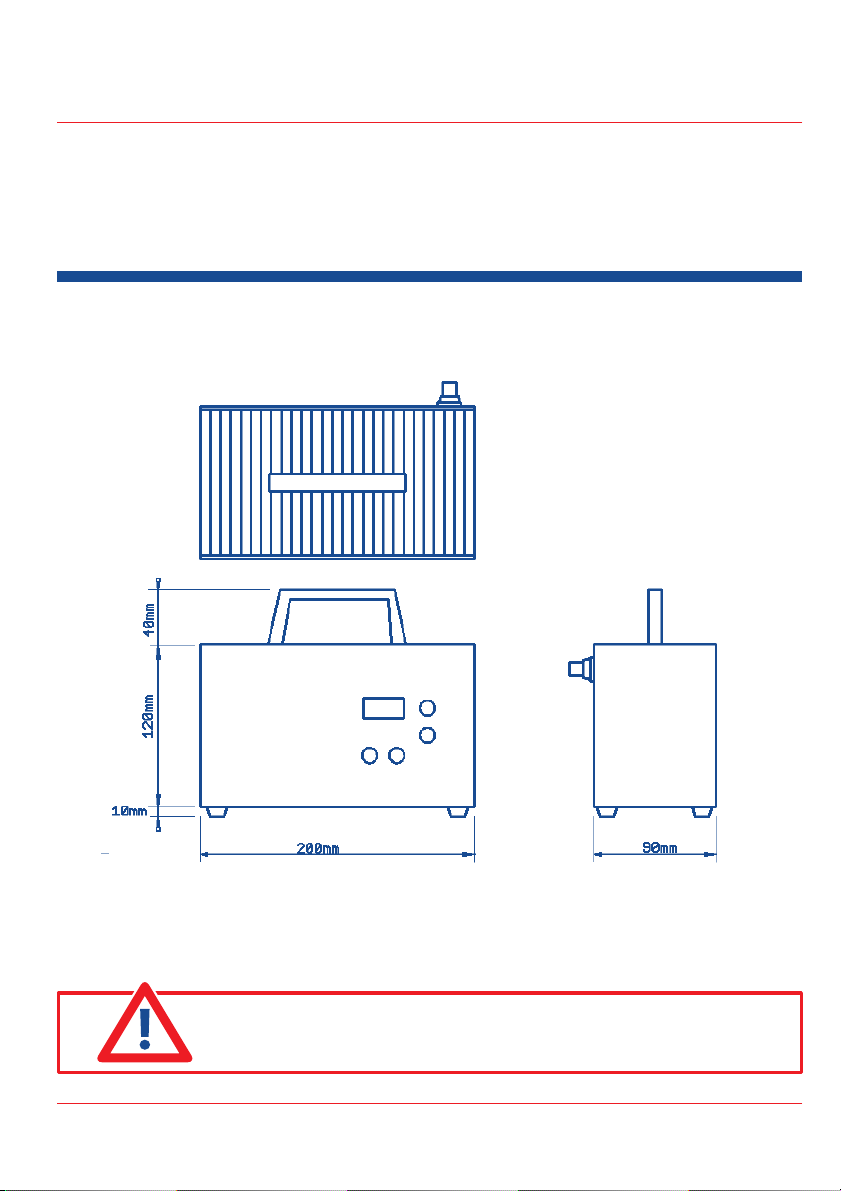

9. Dimensions SFU0150

10. EG-Declaration of Conformity

11. General Hints

12. Warranty

4

5

6

7

8

9

9

9

9

10

10

11

11

12

12

13

13

14

15

16

17

SFU 0150

4

Depending on its construction, the speed of a three-phase A.C. motor is directly dependent

on the number of poles and the frequency of the network. n a 3ph 380V/50Hz network, with

a 2-pole motor, the rated speed would be 50 U/s * 60 = 3000 Upm.

With D.C. motors (brushless motor D.C.), the speed is dependent on the voltage applied.

Three-phase A.C. motors provide numerous benefits in industry, such as brushless motor

operation, long life, favourable performance/weight ratio, high-speed capability, and much

more. These motors can be used in many different application areas, such as milling and

grinding spindles, or with drilling machinery.

n these mentioned applications, three-phase AC motors are operated using special control

gear - frequency converters. These frequency converters convert the fixed 50 Hz network into

a 3-phase network with variable frequency and voltage. This greatly reduces the start-up

problems and the high starting currents that are unavoidable when high-capacity three-phase

A.C. motors are connected to a fixed network. The motor is controlled according to a special

characteristic curve until its rated speed has increased, or it has been stopped.

The SFU 0150 - series high frequency converter has been specially designed for use in these

high frequency applications, offering excellent safety, performance and reliability, the result

of years of experience in the design and construction of frequency converters, together with

the use of the latest materials and the most reliable components. t can be used in many

different applications and is as suitable for use as a replacement device in existing systems

with older type series as it is in pre-planned applications as a cost-effective solution, helping

to prolong the useful life of tools.

1 Introduction

5

2 De cription and Feature

For the operation of A.C. spindles.

The high frequency converter SFU 0150 allows peed frequencie up to 50,000rpm with

2-pole A.C. spindles. Maximum High output power i (150VA) in a compact de ign.

The core of the SFU 0150 is the Digital Signal Proce or (DSP) which generates all output

signals and captures all input signals.

All parameters, such as current, voltage and frequency, are captured in real time, and are

adjusted according to load condition by Vector Control Mode.

The highe t efficiency of motors at both low and high frequencie is made possible.

Highe t level of operational afety: All operating states such as acceleration, operation at

rated speed, and deceleration, are monitored and critical situations are intercepted and

brought under control automatically.

Di play of Rotational Speed: current load condition and converter status message on

three 7 segment LEDs.

Control: The high frequency converter can be controlled manually using 2 push buttons on

the front panel or via the control input on the rear panel.

Galvanic i olation: spindle voltages and electronics using a mains transformer

Short-circuit-protected

Over-temperature-protected

SFU 0150

6

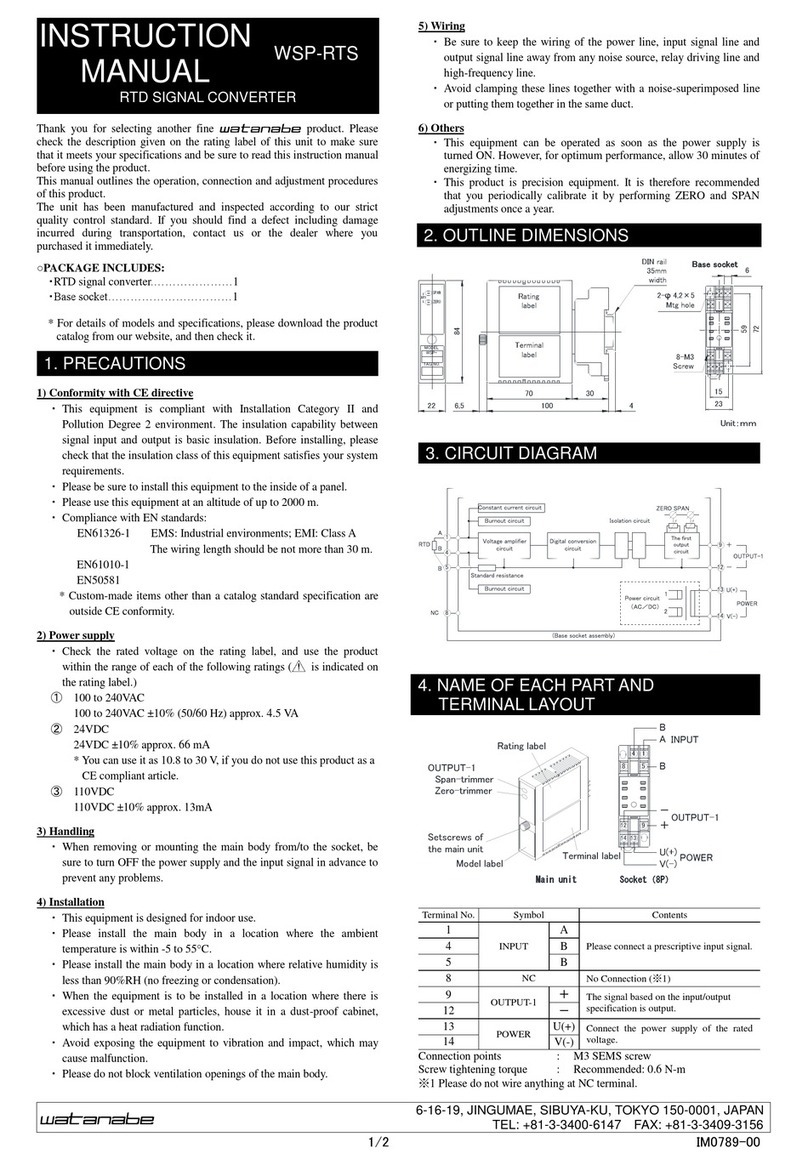

3 Technical Data

230V, 50Hz, 1PH / 115V, 60Hz, 1PH as option

ON/OFF Switch in combination with a resettable

thermo protection switch as mains fuse 1A/250V

150 VA (max 5 min)

3 prong U, V; W,

3* 36V

Electronically limited

AC: 833Hz /50,000 rpm

Start/Stop with a galvanically isolated contact or a B.M.R foot

controller.

On 3 x 7 segment LED

On 3 x 7 segment LED

As bar graph on 1st 7 segment LED

200 x 120 x 105 W x H x D (mm)

App. 2,5kg

P20

ambient temperature 10°C...40°C, max 80% humidity content

Mains connection

Mains Switch

Fuse

Output Power

Spindle Connection

Output voltage

Output current

Output frequency

Control input

Display of rotational speed

Display of status

Display of load condition

Dimensions

Weight

Protection

Operating conditions

ATTENTION: Make sure that the setup for mains voltage is in

accordance to the power line used.

7

This device produces dangerous electrical voltages and is used

for the operation of dangerous moving mechanical parts.

For this reason, only professionally trained and qualified personnel

should be allowed to install and work with this device!

Any maintenance or repair work on the device must only be

carried out when the mains supply plug has been disconnected!

Before the first activation can be carried out, it should be established

that the tool is installed correctly and securely, to eliminate the

possibility of uncontrolled movement of the motor.

Safety regulations that are valid for the country where the device

is used, must be applied when repair or maintenance work is

carried out on the device.

Maintaining EMC (electro magnetic compatibility) limits is the

responsibility of the manufacturer of the machine or device. The

inputs on this device are fitted with filters, to increase the

interference immunity and to reduce emitted interference, making

it possible to use this device in an industrial environment. The

EMC of a machine or device is affected by all connected

components (cables, wiring, etc.) and for this reason, installation

and connection of the device should only be carried out by

qualified personnel.

4 Safety Precaution and Warning

SFU 0150

8

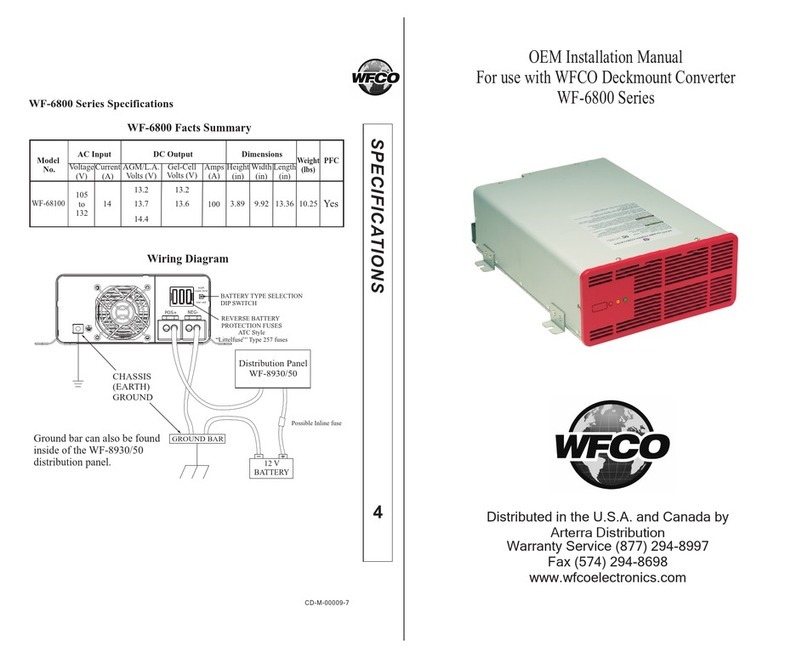

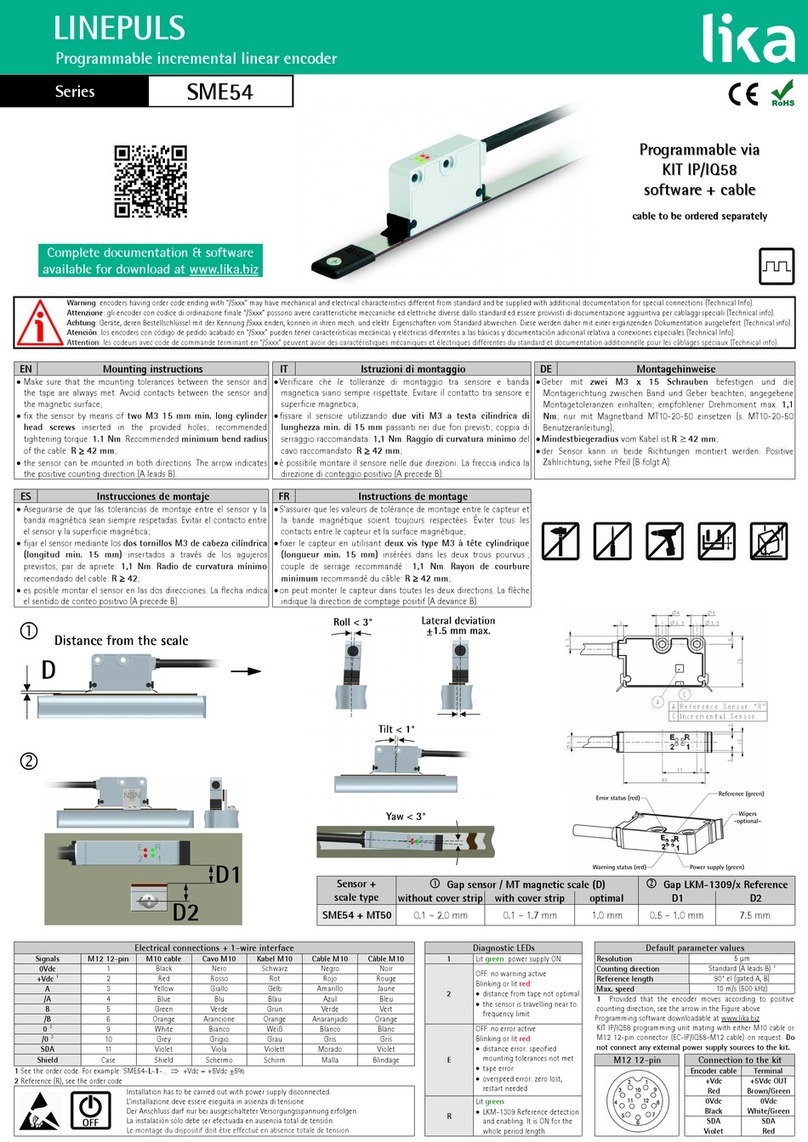

5 Connection , Plug and Pinout

Spindle Connector

Remote Control

Connector

ATTENTION: Plea e do not connect any external

voltage to the remote control pin !

On/Off Switch in combination

with a resettable fuse

9

Off Position On Position

Pin 1 = to FSW, B.M.R Footcontroler or contact

Pin 2 =

Pin 3 =

Pin 4 =

Pin 5 = to FSW, B.M.R Footcontroler or contact

5.1 Remote Control Connector (5 Pin)

Operation with footswitch

BMR vario footcontroler

Galvanically isolated contact

= ON/OFF.

= ON-OFF- Variable rotational Speed.

= Remote Control by a external PLC

3 pin butterfly mains connector.

The mains switch is realized as a combination between a push-push button mains switch

and a thermo protection fuse for 1A. Exeeding the rated current will trigger the thermo fuse

to switch in the OFF Position

Pin 1 = R

Pin 2 = S 3 Phase for Spindle

Pin 3 = T

5.2 Spindle Connector (3 Pin)

5.3 Main

5.4 Main Switch and Fu e

SFU 0150

10

6 Function , Setup and Operation

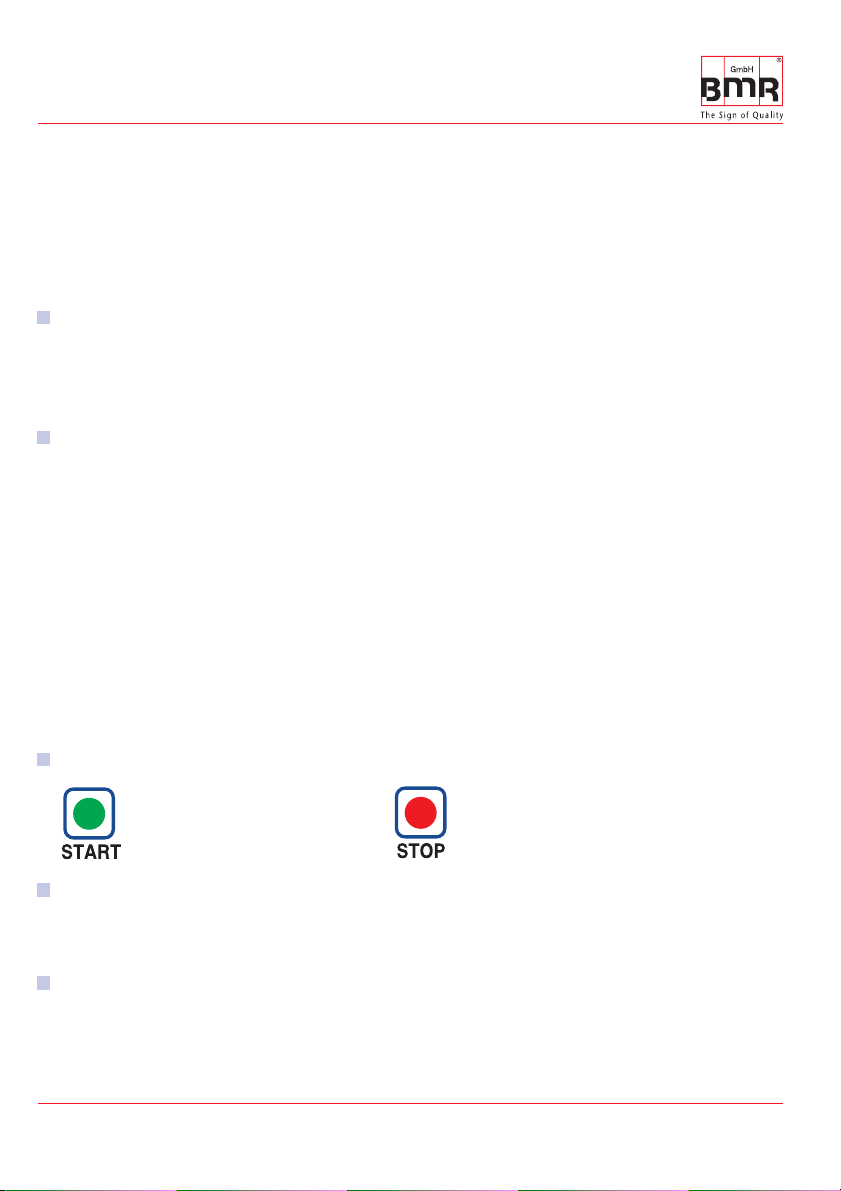

6.1 Front Panel

4 Po ibilitie for Operation:

Manually with the buttons on the front panel

Operation with footswitch = ON/OFF

BMR Vario foot controler = ON / variable rot. speed / OFF

Galvanically isolated contact = remote control

ATTENTION: Plea e do not connect any external

voltage to the remote control pin !

11

6.2 Setup of Rotational Speed

The rotational speed of a connected spindle or the frequency of the output voltage at the

spindle terminals can be set up in several ways.

Pre election manually via rpm button on the front panel

The needed speed of rotation can be adjusted with the buttons on the front panel and is

displayed on 3 digits on the LED-Display. During operation of the spindle the speed of

rotation is displayed with 2 digits.

Start, Stop and Setup with the B.M.R foot controler

The maximum value of the rotational speed wished can set with the buttons on the front

panel. From zero position (OFF ) up to the maximum equivalent with the preselected

rotational speed . The rotational speed can be increased or decreased depending on the

pressure applied to the foot controller. For example for the max. rpm the foot pedal has

to be pushed completly down.

6.3 Starting and Stopping the Frequency Converter

Because of multiple requirements the frequency converter SFU0150 can be started and

stopped in several ways.

Manually with the help of the pu h button at the front panel

With a galvanically i olated contact

f Pin 1 and 5 of the remote plug is shorted, the converter is started and the rotational speed

is setup according the preselection displayed at the front panel

With foot controler

f the footcontroler is actuated beyond zero position, the speed of rotation is set up according

to the position of the foot controler pedal. f the pedal is brought into stop position, the

converter is stopped.

Stop with the

red button

STOP

Start with the

green button

START

SFU 0150

12

The direction of rotation may be changed before the start. To achieve this, the push buttons

STOP and START have to be actuated simultaneously for about 5 sec (press Stop first, then

Start) n this configuration mode it is possible to change the direction between clockwise

(displayed: rE) and counterclockwise (displayed: Li) with the help of the RPM push buttons.

f the push buttons are left un-

pressed for more than 10 sec,

it is switched back to operating

mode.

f the converter is started and the spindle is spinning, the speed of rotation is displayed at the

right LED digits. The horizontal bars of the left digit serves as display of current load condition.

Some display examples: The converter is set to 10-thousand rpm each

idle running or load <30 % load 30 % - 59 % load 60 % - 89 %

load 90 % - 100 % overload >100 %

cut-off after 10 sec. of load

excess temperature of the

converter

cut-off after 10 sec. of load

6.4 Setup of direction of rotation

6.5 Operation

13

7 Safety Function

A controlled pindle top according to the preset acceleration data is carried out because

of the events listed below.

Converter switch-off, if maximum power consumption is exceeded constantly.

n this case the thermofuse with the ON-OFF switch is triggered.

Stop because of exceeding the max. internal temperature of the converter after a time

delay of 10sec.

Stop because of exceeding the max. nominal output load of the converter after a time

delay of 10sec.

mmediate-Stop because of exceeding maximum spindle current.

This device was developed for use in industrial environments. For trouble-free operation

and to reduce emitted interference, the following should be observed during wiring of the

equipment:

The EMC of a machine or device is affected by all connected components (motor spindle,

length and type of cables, wiring, etc.). Under certain conditions, the use of additional

filters can be necessary to maintain the current laws.

The ground and shield connections of all devices used in conjunction with the frequency

converter should be as short as possible and have as large cross-section as possible.

Control devices used with the frequency converter (PLC, CNC, PC, ...) should be connected

to an earth terminal bar.

For mechanical installation, use serrated lock washers to guarantee good electrical contact

with the housing.

All connections both to and from the frequency converter should be shielded cables.

The shield must be completely connected to ground.

Supply cables, motor cables and control cables should be mounted separated from each

other. Where crossing points cannot be avoided, cables should be laid at 90° to each other.

The control cable should be laid as far away as possible from the spindle cable.

8 EMC Electro Magnetic Compatibility

SFU 0150

14

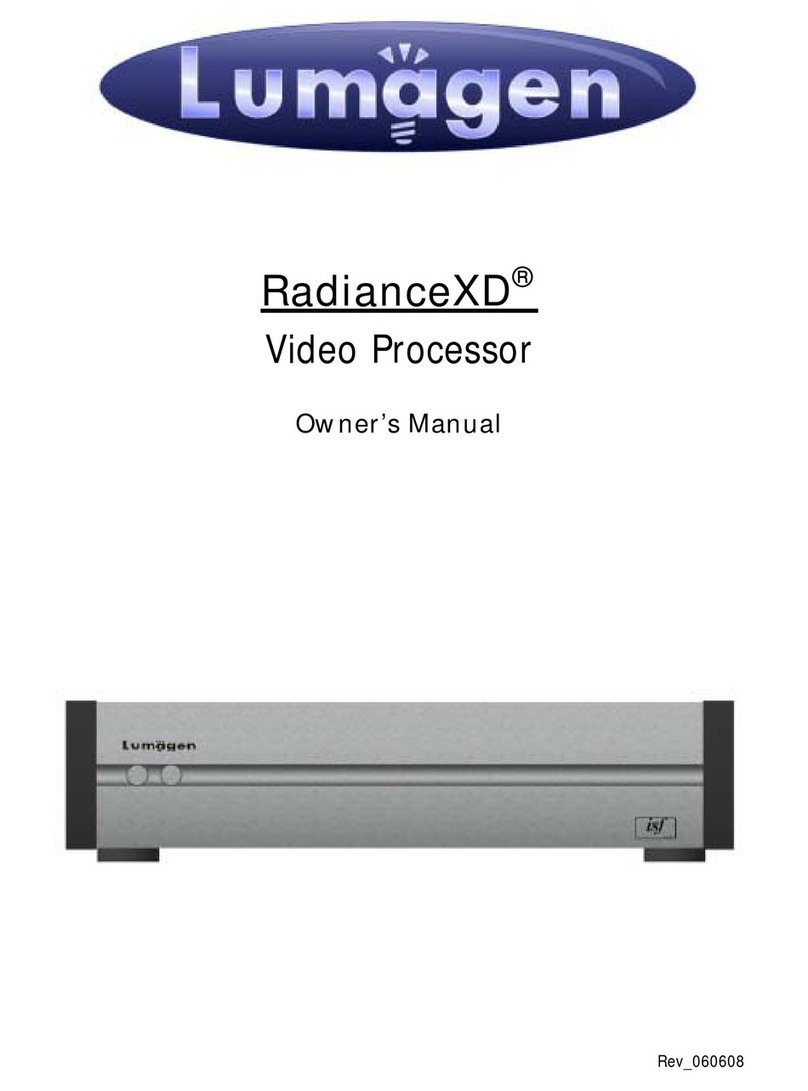

9 Dimen ion SFU 0150

Subject to technical changes.

Edition: April 12, 2008

ATTENTION: Old electric and electronic device mu t not

be placed into the dome tic wa te but have to be di po ed

eparately!

15

10 EG Declaration of Conformity

Manufacturer:

BMR GmbH

Unterreichenbacher Str. 1

90455 Nuernberg

Product:

SFU 0150

The above mentioned products comply with the regulations of the following European

guidelines:

89/336/EWG approximation of legal regulations on EMC"

The adherence to the above mentioned guidelines requires an installation into the

total unit according to the EMC.

The following tandard are applied:

EN 61800-3

C3 tandard which are al o complied with:

VDE 0839 Teil 6-4, EC 61000-6-4

VDE 0160 Teil 100, EC 61800-3

VDE 0847 Teil 4-8, EC 61000-4-8

VDE 0847 Teil 5-5, EC 61000-4-5

VDE 0875 Teil 11 + Bbl. 1, EC / C SPR 11 (C SPR TR 28)

VDE 0847 Teil 4-6, EC 61000-4-6

VDE 0847 Teil 4-2 +A1, EC 61000-4-2 +A1

VDE 0847 Teil 4-11, EC 61000-4-11

VDE 0847 Teil 4-3, EC 61000-4-3 +A1

VDE 0839 Teil 6-2, EC 61000-6-2

VDE 0847 Teil 4-4, EC 61000-4-4

Nuernberg, April 12, 2008

Rudolf M. Brittling,

executive director

Electric drives with variable rotation speed

EMC product standard including special

test procedures

SFU 0150

16

11 General Hint

Before the first activation of the device, verify if it is in a faultless optical condition.

f it was damaged during transportation, it must not be used and not turned on.

During the installation the safety regulations must be observed.

Before the converter is turned on for the first time, it should be verified that

connected parts cannot carry out uncontrolled movements.

The frequency converter must not be operated close to heating devices or

magnetic devices.

Sufficient air circulation around the converter should be ensured.

Fluids should be prevented from intruding into the housing.

f it seems to have happened, the converter has to be switched off immediately.

f the converter is connected to a remote control, it should be verified that the

switch is in the OFF position before connecting.

All repairs and maintenance on our converters must be carried out by skilled and instructed

persons, only.

All repairs and maintenance on the converter and the relating accessories must be carried

out by skilled and instructed persons in the OFF-state only. To ensure this, the mains plug

should be pulled out. n doing this, both the terms of regulations for preventing accidents

and the general and national rules for mounting and safety have to be applied.

Our high frequency converters are highly valuable precison devices. Please take care of

them with the necessary attention, to preserve their high precision, high power ability,

and long lifetime.

These devices leave our company only after a quality test and a load check have

been carried out. Before mounting and use please read the attached manual carefully and

pay attention to the points listed below.

Our common hint can give only a rough guideline because it is not possible for BMR

to deal with every specific situation. The compliance with the limits of EMC demanded

by law is the responsibility of the manufacturer of the unit or machine. By doing controls

and tests in our own laboratory, BMR can guarantee that our products comply with the

corresponding standards if they are installed and used in an appropriate manner.

17

12 Warranty

With exclusion of additional claims we give a warranty on our high frequency converter for

1 year on errors due to material, mounting and construction.

We commit to repair or replace the parts without any costs which seem to be

defective by our estimation and which are not damaged by not appropriate handling.

Warranty claims have to be sent to us in written form. The customer has to pay the costs to

send the defective device back to BMR within the time of warranty. f this is not complied with

or if we detect an external intrusion into our control unit, we withdraw our duty of warranty.

Our duty of warranty is limited to the repairing or replacing of the defective parts.

We refuse claims of responsibility or warranty for direct or indirect consequential

damages, caused by faults of our products.

Changes in construction may be carried out without any message or notification.

Our common terms of business conditions apply.

Subject to technical changes.

BMR GmbH is a dynamic and flexible company. We take into account specific

requirements of our customers as well as demanding solutions in design. These

are integrated according to qualitative and functional aspects maintaining of

course our high quality standard.

Our company is working according to the highest economical and ecological

standards which are mirrored at BMR in all areas. Especially in manufacturing

we try to improve our ecological standard constantly. t has been and is our

constant purpose to comply with these demands.

18

The company BMR GmbH was founded in 1978.

We develop, construct and manufacture electronic devices

and electronic drive units.

Nearly all the steps of the manufacturing process are carried

out within our company.

The development department designs all our printed circuit

boards first in a schematic form and then as a layout. They

furthermore develop the firmware for the microcontrollers and

DSPs and even the Windows PC Software for our devices.

The manufacturing department solders and mounts

all the components. And finally in the quality and test

department the devices are tested and set up according

to the customers requirements.

We have established "short ways" between the departments in

order to guarantee a constant level of high quality and to be able

to realize changes fast and in a flexible way.

By keeping the manufacturing processes within our company,

we have gained years of knowledge and experience,

offering this further to our customers as an extra service.

Our goal is a quick,

flexible und reliable execution of orders.

With our long-time experience, especially in manufacturing

frequency converters, we have gained a strong position in the

market. This becomes evident especially in our

growing presence in domestic and overseas markets.

19

High frequency converters for industrial use

Drive units for Electroluminescence displays

ntelligent lighting controls

Control units for domestic appliances

Acoustic test units

Motor controls

Accumulator charger

Time controls, for example grease controls used in

automotive applications

Development of oem controls

Manufacturing of electronic devices using wire-through

and surface mount technique

We also work as an extended workbench for

well known companies

Our pre ent

product profile:

Our trength

i called quality!

The quality sign "Made in Germany" is the synonym for preci ion,

reliability and innovation.

BMR GmbH feels commited to these values. With two decades of

experience in the sector of developing, constructing and

manufacturing electronic devices and controls this was and still is

the prescription for our success.

Our policy of "short ways" ensures constant high quality. This makes

it possible to react rapidly, in time and flexible with changes and

requirements for our products.

This concept is valued by our customers and becomes evident in

our steadily growing presence in the market at home and abroad.

f you are interested in our products and accessories, contact us or

visit us on our website:

www.bmr-gmbh.de

BMR GmbH

Unterreichenbacher Strasse 1

90455 Nuernberg-Katzwang

Germany

Phone: .. +49(0)9122 / 63148-0

Fax:........+49(0)9122 / 63148-29

e-mail: [email protected]

www.bmr-gmbh.de

Our Partner in the U.S.A.

HPT DRiVE SYSTEMS

HPT Preci ion Spindle & Drive Inc.

110 Newport Center Drive

Suite 200 Newport Beach, CA. 92660

USA

Tel. ............(001) (949) 719-1145

Fax:............(001) (949) 719-1150

e-mail: sales@hpt-drivesystems.com

www.hpt-drivesystems.com

This manual suits for next models

1

Table of contents

Other BMR Media Converter manuals