BMR SFU 0156 User manual

Frequency Converter SFU 0156

SFU 0156 M a n u a l

E 2015-10-15

2

Content

1 Description and Features

2 Technical Data

3 Safety and Caution Instructions

4 Connections, Plugs and Pin Assignments

4.1 Power Supply Connection SL4

4.2 Spindle Connection SL3

4.3 Inputs and Outputs SL2

4.4 USB Interface

4.5 Serial Interface SL5

4.6 Adapter Cable

5 Description of Functions and Operation

5.1 Start and Stop

5.2 Set Value of Rotational Speed

5.3 Outputs

5.4 LEDs

6 Example for I/O Wiring

7 Safety Functions

8 EMC

9 Power Supply Set (as option)

10 Remote Control

11 Drawing and Mounting

We thank you for choosing a BMR-Product !

This product was carefully developed and manufactured in Germany

at BMR-GmbH

>Please read this manual carefully before first operation!

SFU 0156 M a n u a l

E 2015-10-15

3

1. Description and Features

•Operation of AC spindles and BLDC spindles

•The frequency converter SFU 0156 allows speed frequencies up to 100.000Upm with 2-

pole spindles.

•The core of SFU-0156 is a digital signal processor (DSP) which produces all output

parameters and collects signals.

•High-precision sinusoidal output signals with a low distortion factor and low

deformation allow for optimal rotation qualities in AC motors of all operating conditions

•All parameters like power, voltage and frequency are collected in real time and are

regulated by the implemented vector control depending on the load.

•High operating safety: All operating conditions like acceleration, operation with nominal

rotation speed, braking are controlled and critical conditions are intercepted.

•Short circuit protected

•on board chopper resistor

•Protection against excess temperature.

2. Technical Data

Power Supply SL4 Logic Supply: 24V / 0,25A DC (max. 30V)

Spindle Supply: max. 80V / 6A DC pluggable screw terminals 4mm2

Fuses FS1:T250mA recommended Littelfuse 0477.500XP

FS2:T6,3A recomm. Littelfuse 0477 06.3XP / SIBA 179200 6.3

Power 400VA

Spindle Connection SL3 4-pin: U, V, W, PE pluggable screw terminals 4mm2

Output Voltage depending on the spindle characteristic: max. 3 x 60V

Output Current electronically limited and matched to the corresponding spindle

Output Frequency AC: 1.667Hz / max 100.000 rpm

Control Inputs SL2 Pin1 / DI - digital in: Start / Stop ( 0 / 24V ) "0": 0..7V, "1": 18..24V

Pin3 / AI - analogue in: Set Value Rotational Speed ( 0..10V )

Control Outputs SL2 Pin9 / DO1 - digital out: free configuration: open collector 45V/0,5A

Pin7 / DO2 - digital out: free configuration: open collector 45V/0,5A

Pin10 / DO3 – digital out: free configuration: open collector 45V/0,5A

PIN6 / AO - analogue out: Output Load ( 0..10V )

Operating Status

Indicators Converter Ready: LED green Converter Overload: LED red

Interface SL5 - RS232: 115.200Bd, 8Data 1Stop Bit, No Parity

- USB Interface (USB-Mini)

Dimensions Approx..132 x 111 x 43 L x B x H (mm) open frame style

Chopper Resistor 47Ohms / 10W

Operating Conditions 10°C bis 40°C / Rel. Humidity max. 80%

- Maximum Surrounding Temperature: 40°C.

- The inverter shall be installed in a pollution degree 2 environment.

SFU 0156 M a n u a l

E 2015-10-15

4

3. Safety-Precautions and Warnings

•This device produces dangerous electrical voltages and is used for the operation of fast

spinning tools. Because of their high rotational speed, it may be dangerous in case of

improper handling. For this reason, only professionally trained and qualified personnel

should be allowed to work with and setup this device!

•Any maintenance to the device must be carried out after the supply voltage has been

disconnected, only!

•Before the first commissioning can be carried out, it should be ensured that the spindle

and the tool are fixed properly, to eliminate all dangers because of uncontrolled

movement of the spindle.

•Safety regulations being valid for the country where the device is used, have to be

adhered to where any work is carried out on the device.

•Maintaining EMC (electromagnetic compatibility) limits is the responsibility of the

manufacturer of the machine or device. The inputs and outputs on this device are fitted

with filters, to increase the interference immunity and reduce emitted interference,

making it possible to use this device in an industrial environment.

•The EMC of a machine or device is affected by all connected components (motor

spindle, length and type of cables, wiring, etc). Under certain conditions the use of

additional filters can be necessary to maintain the current laws.

•For the reasons listed above, installation and connection of the device should be carried

out by qualified personnel, only.

Attention:

Please verify that all power supply voltages are correct in polarity and value

Attention:

Please ensure to have the proper characteristic selected, always!

The operation of a spindle with a wrong characteristic may harm the spindle

severely!

Attention:

In case of replacing the fuses, please ensure to use types only, which are

mentioned in 'Technical Data'!

SFU 0156 M a n u a l

E 2015-10-15

5

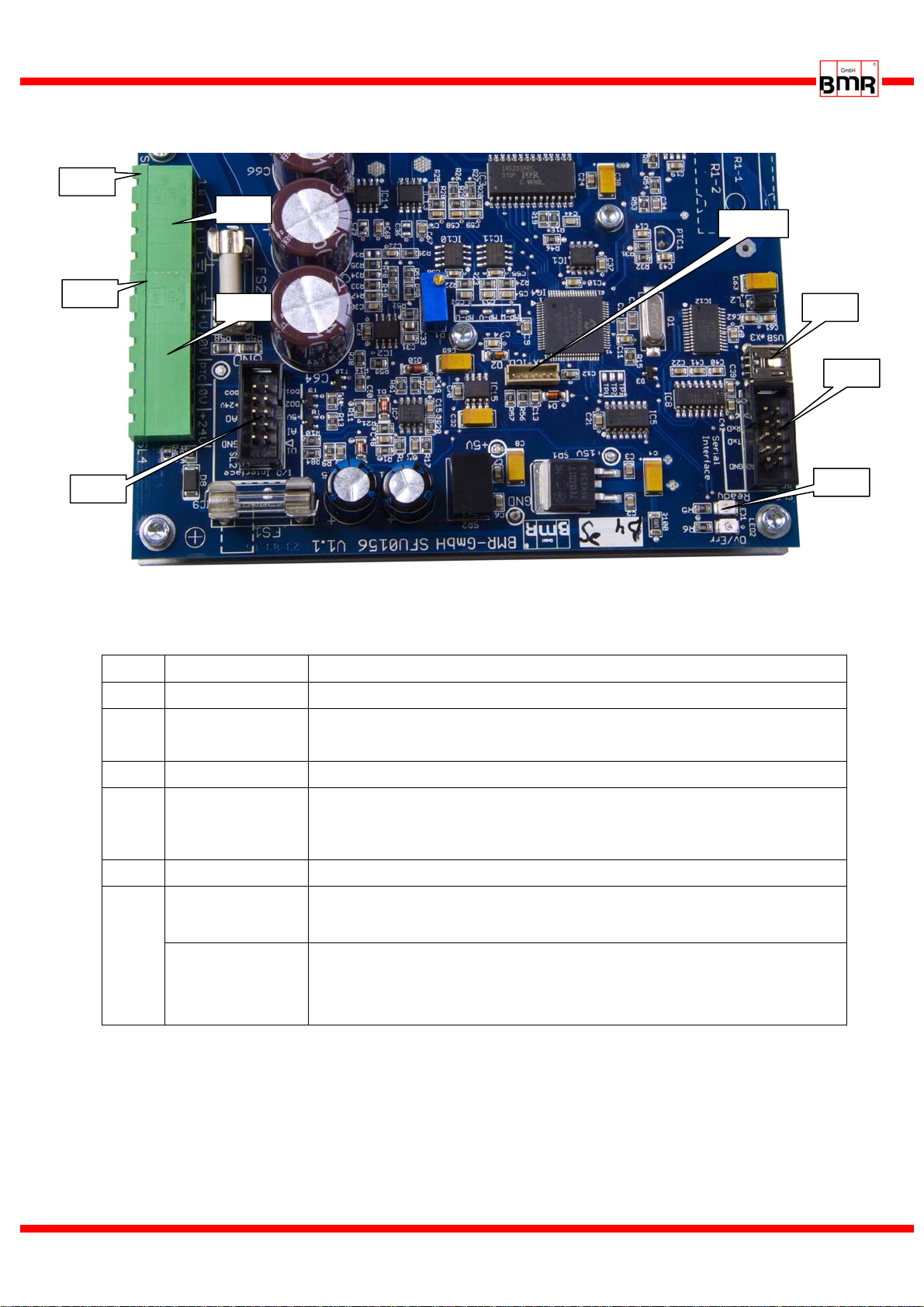

4. Connections, Plugs and Pin Assignments

* X-ICD for internal use only

4.1 Power Supply Connection SL4 (pluggable screw terminals)

Pin Function Description

1 PE Protective Earth, is internally connected to mounting bracket

2 +80VDC + Supply Voltage for spindle -> Fuse FS2 6,3AT

ÎAttention, not protected against voltage reversal

3 0V (80V) Voltage Return for spindle supply

4 PTC / KTY Temp sensor Spindle

Îavailable at HW V1.1 and to be configured with SFU-Terminal

> V6.25

5 0V (24V) return for controller supply (internally connected with PIN3)

6 +24V (max 30V)

+ Supply voltage for control logic -> Fuse FS1 250mAT

protected against voltage reversal with Diode D8

NC Version SFU0156 with onboard +24V logic supply

In this version the logic supply voltage is directly generated from the

spindle supply voltage (Æ9. )

SL3

SL4

SL2 LEDs

X-ICD*

PIN1

PIN1

SL5

USB

SFU 0156 M a n u a l

E 2015-10-15

6

4.2 Spindle Connection SL3 (pluggable screw terminals)

4.3 Inputs and Outputs – I/O Interface SL2 (2.54mm Header)

Pin Function Description / default function

1 DI Digital Input Start/Stop

3 AI Analog Input Set value for rotational speed

2,4 Ground Ground Ref for Pin 1,3,5,7,8,9,10 (internally connected with SL4.3/5)

5 +5V /10mA

max auxiliary supply(1)

6 AO Analog Out Output 0…10V ( free configuration)

default setting: Load Percent

7 DO2

Open Collector 2 Output (for free configuration)

default setting: Overload

8 +24V /10mA

max auxiliary supply(1) (internally connected with SL4.6)

9 DO1

Open Collector 1 Output (for free configuration)

default setting: Converter Ready

10 DO3

Open Collector 3 Output (for free configuration)

default setting: Duty Speed Reached

The scaling of the analog input can be modified, as well as the function of the open collector

outputs can be defined freely. The noted functions are the factory default setup.

On option a remote controller is available which can be connected directly with the

I/O interface at SL2. (Æ10.

4.4 USB Interface (alternative with RS232 Æ4.6)

The SFU 0156 has an USB Mini connector for easy access to "SFU-Terminal" configuration

program. You have the options to setup and configure the converter. The USB interface is

using the same interface channel as the RS232 interface (4.5) so that either one of both can

be used, only.

Pin Function Description

1 W Spindle Phase W

2 V Spindle Phase V

3 U Spindle Phase U

4 PE Protective Earth of spindle and cable shield

SFU 0156 M a n u a l

E 2015-10-15

7

4.5 Serial Interface RS232 SL5 (2.54mm Header) (alternative with USB Æ4.5)

Pin Function

1,2,4,6,7,8 NC

3 RxD

5 TxD

9 GND

10 NC

4.6 Adapter Cable for SL2 and SL5

For easy connection to SL2 and SL5 a standard(2) ribbon cable connector with Dsub9 fem is available

as option.

(1) Attention, with using and wiring these auxiliary voltages particular care is required and lies under the

responsibility of the user! These voltages may be used as auxiliary voltage but are not especially

fused. +24V is directly connected to FS1 and +5Vdig is directly connected with the DSP and all other

ICs. So, potential errors at the wiring may harm the board severely!

(2) Attention, On request a non standard cable is available with a special wiring which makes OC3

accessible at PIN7 of the 9Pin D-Sub

DSub-Pin SL2-Pin Funktion an SL2

1 1 Digital Input1

2 3 Analog Input1

3 5

+5Vdig (1)

4 7 Open Collector 2

5 9 Open Collector 1

6 2 GND

7 10 GND

8 6

Analogue Out

9 8

+24V (1)

7 10(2) Open Collector 3

DSub-Pin SL5-Pin Funktion an SL5

1 1

2 3 RxD

3 5 TxD

4 7

5 9 GND

6 2

7 4

8 6

9 8

SFU 0156 M a n u a l

E 2015-10-15

8

5. Functions, Setup, Operation

5.1 Start / Stop

There are two possibilities to start the spindle:

digitally with a digital control signal at digital input1 Start/Stop at SL2.1.

The switching levels for "OFF=0" are 0...7V and for "ON=1" 18...24V,

voltages between 7V and 18V are undefined.

ÎAs soon as this is initiated, the spindle will be accelerated to the set value of the

rotational speed which is pre-selected as voltage at analogue input1 Set Value of

Rotational Speed at SL2.2.

analogue with a voltage at analogue input1

Precondition is a valid "ON" signal at digital input1 Start/Stop

ÎAn input voltage of 0V makes the spindle stop, and a voltage higher than 0,29V

starts the spindle up to a rotational speed according to the scaling.

5.2 Set Value of Rotational Speed

There are two possibilities for scaling the rotational speed

•0-10V / Min-Max: The default scaling for the analogue value is according the

Min/Max values of the rotational speed from the spindle characteristic

e.g.: set values are Min: 5.000rpm, Max: 60.000

This results in a formula for the control voltage u: u = set value * 10V/60.000rpm

A voltage of u<0,8V realizes standstill, a voltage of 0,8V sets the minimum speed of

5.000rpm and 10V sets the maximum rotational speed of 60.000rpm.

•Another option of the input scaling is 1V/10.000rpm.

5.3 Outputs

Digital Outputs:

As feedback signals to a PLC or another control there are 3 open collector outputs

available. They indicate the current operational status of the converter. (Æ6.)

The functions can be setup freely, factory default is listed below

DO1 / SL2.9 default Converter Ready . In this case, the PIN is drawn to ground

DO2 / SL2.7 default Overload. In this case, the PIN is drawn to ground

DO3 / SL2.10 default Duty speed reached. In this case, the PIN is drawn to ground

Analogue Output:

As a default function the output load condition is output as a voltage between 0..10V at

the analogue output AO / SL2.6. with a scaling of 1V/10% . Other function values are

available and can be setup with SFU-Terminal.

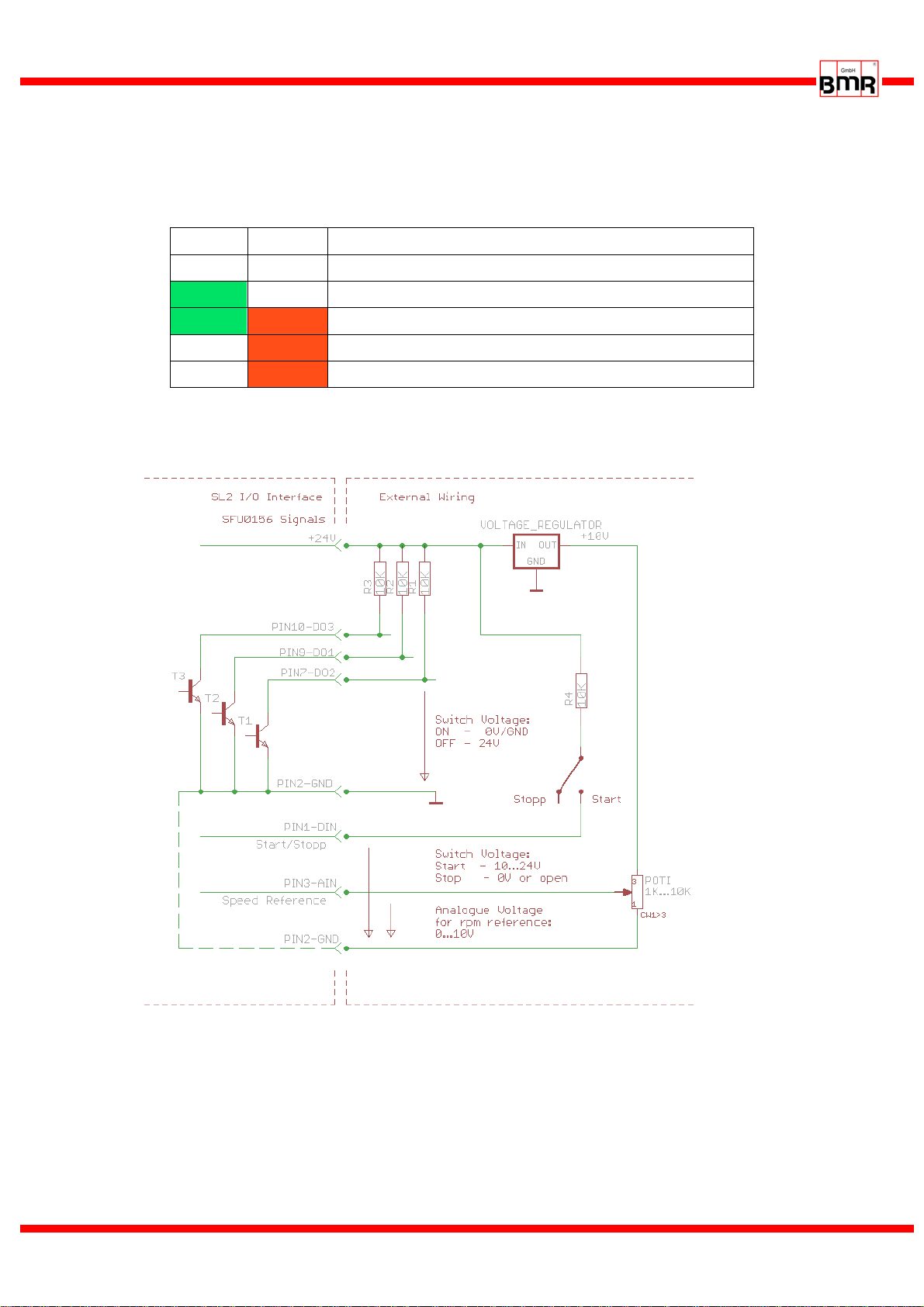

Analogue input circuit

SFU 0156 M a n u a l

E 2015-10-15

9

5.4 LEDs

Likewise the open collector outputs, there are LEDs indicating the current operational

status of the converter.

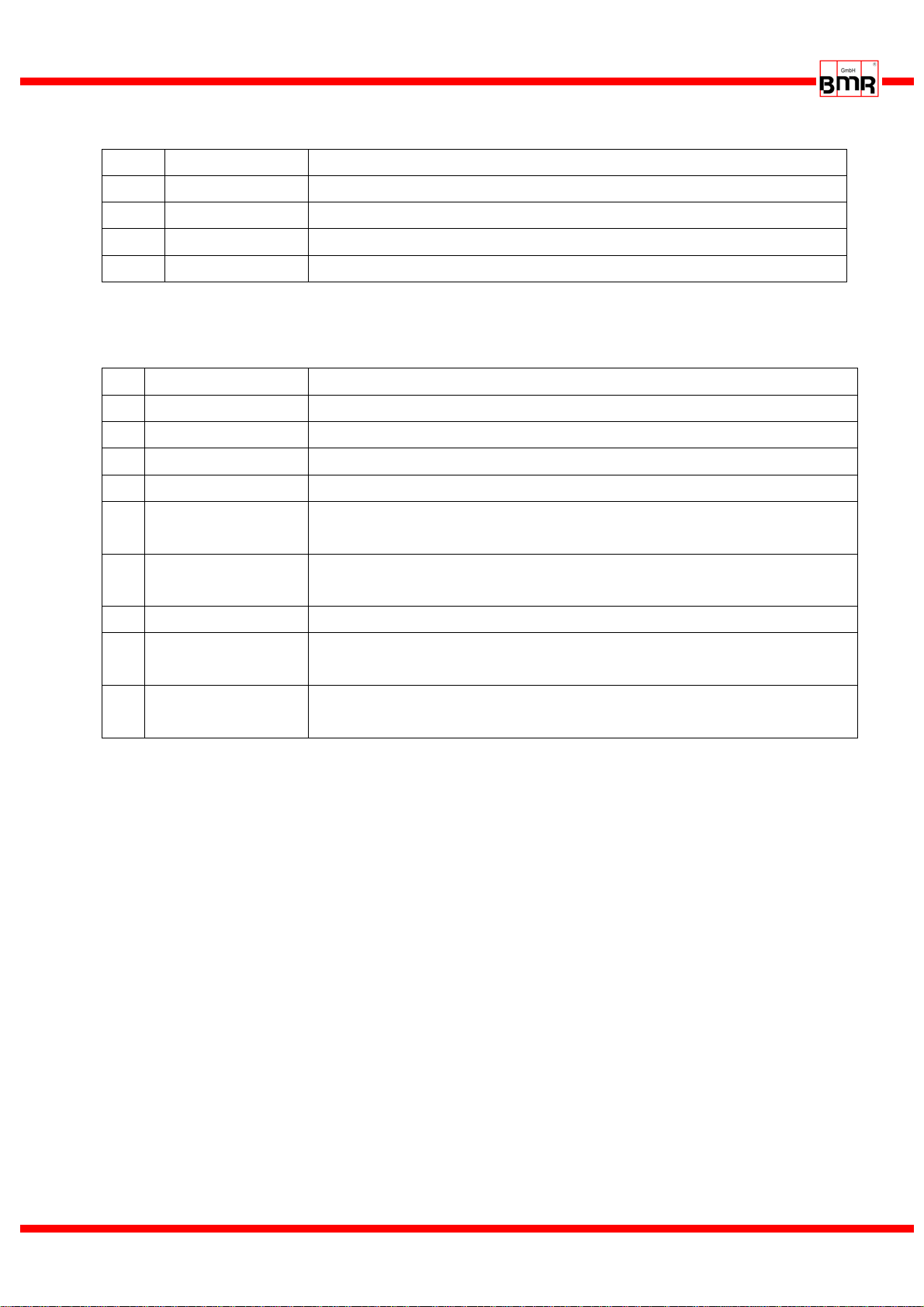

6. Example for I/O Wiring

example for wiring the I/O Interface

A successful start of the spindle the analogue voltage at PIN3 as reference for

the duty speed hast be higher than the minimum voltage (Æ5.2) .

With using a potentiometer for dialing the rotational speed it should be wired to

10V, so that the required range from 0…10V can be covered, representing the

speed range.

GREEN RED Function

Off Off Converter Not Ready

On Off Converter Ready

On On Overload or Error Warning

Off On Converter not Ready, Switch Off because of Error

Off blinking internal Error

SFU 0156 M a n u a l

E 2015-10-15

10

7. Safety Functions

The following safety functions bring about controlled stop of the spindle according

predefined deceleration times:

•Safety stop because of converter excess temperature after delay-time of 10s is exceeded

•Safety stop by overload and time delay exceeded (default 10sec)

•Safety stop will occur immediately by exceeding the maximum admissible spindle

current.

8. EMC

This device was developed for use in industrial environments. For trouble-free operation

and to reduce emitted interference, the following should be observed during wiring of the

equipment:

•The EMC of a machine or device is affected by all connected components (motor

spindle, length and type of cables, wiring, etc.). Under certain conditions the use of

additional filters can be necessary to maintain the current laws.

•The earth and shield connections of all those devices used in conjunction with the

frequency converter should be as short as possible and have as large a cross-section as

possible.

•Control devices used with the frequency converter (PLC, CNC, IPC) should be

connected to a common earth/earth terminal bar.

•Supply cables, motor cables and control cables must be completely isolated from each

other. Where crossing cannot be avoided, cables should be laid at 90° to each other.

•The control cable should be laid as far away as possible from the load cable.

SFU 0156 M a n u a l

E 2015-10-15

11

Green

Vout: 24V/120mA

Red

Vin: 28-95VDC

Blue

0V/GND

9. Power Supply Set (as Option)

As option a power supply set is available, consisting of a switched mode power supply

for the 48V and a DCDC voltage converter for the 24V supply. With the help of this set

it is possible, to generate the required DC-supply voltages for the SFU0156.

•48V Power Supply for Spindle Voltage Supply

Dimensions (WxHxD in mm): 115x50x216

•24V DC-DC Voltage Converter as separate solution

This DC-DC voltage converter generates the voltage for the 24V logic supply directly

from the spindle voltage. It has a wide band input range and a regulated 24V output.

Dimensions (WxHxD in mm): 20x15x30

Cable length: 160mm

0V / GND Mains connection

88-264 VAC

124-370 VDC

+48VDC Output

SFU 0156 M a n u a l

E 2015-10-15

12

48V Switched Mode Power Supply

24V Voltage Converter

SFU

•Connection Diagramm of Power Supply

(1) Cable Colours of the 24V Voltage Converter

•Version with onboard +24V logic supply

Attention: All these works handle with dangerous voltages and have to be

carried out by skilled persons only.

Please verify before connecting that the mains voltage is switched off!

24V/Green

(1)

Spindle Connector

48V

0V / GND

0V / GND

Blue*

48V / Red

(1)

Spindel spindle

connector

spindle- and logic supply

connector

on board +24V logic-

supply module

SFU 0156 M a n u a l

E 2015-10-15

13

10. SFU0156 with Remote Controller

On option a remote controller is available which can directly be connected with the

I/O interface at SL2.

By this, the required duty speed can be adjusted with a potentiometer and the

converter can be started and stopped with a rocker switch.

The status of the digital outputs is indicated on LEDs

All required voltages are generated within this adapter, so the converter can be

controlled and tested very easily.

A quick test and setting into action of the converter becomes possible even without

external control signals.

SFU 0156 M a n u a l

E 2015-10-15

14

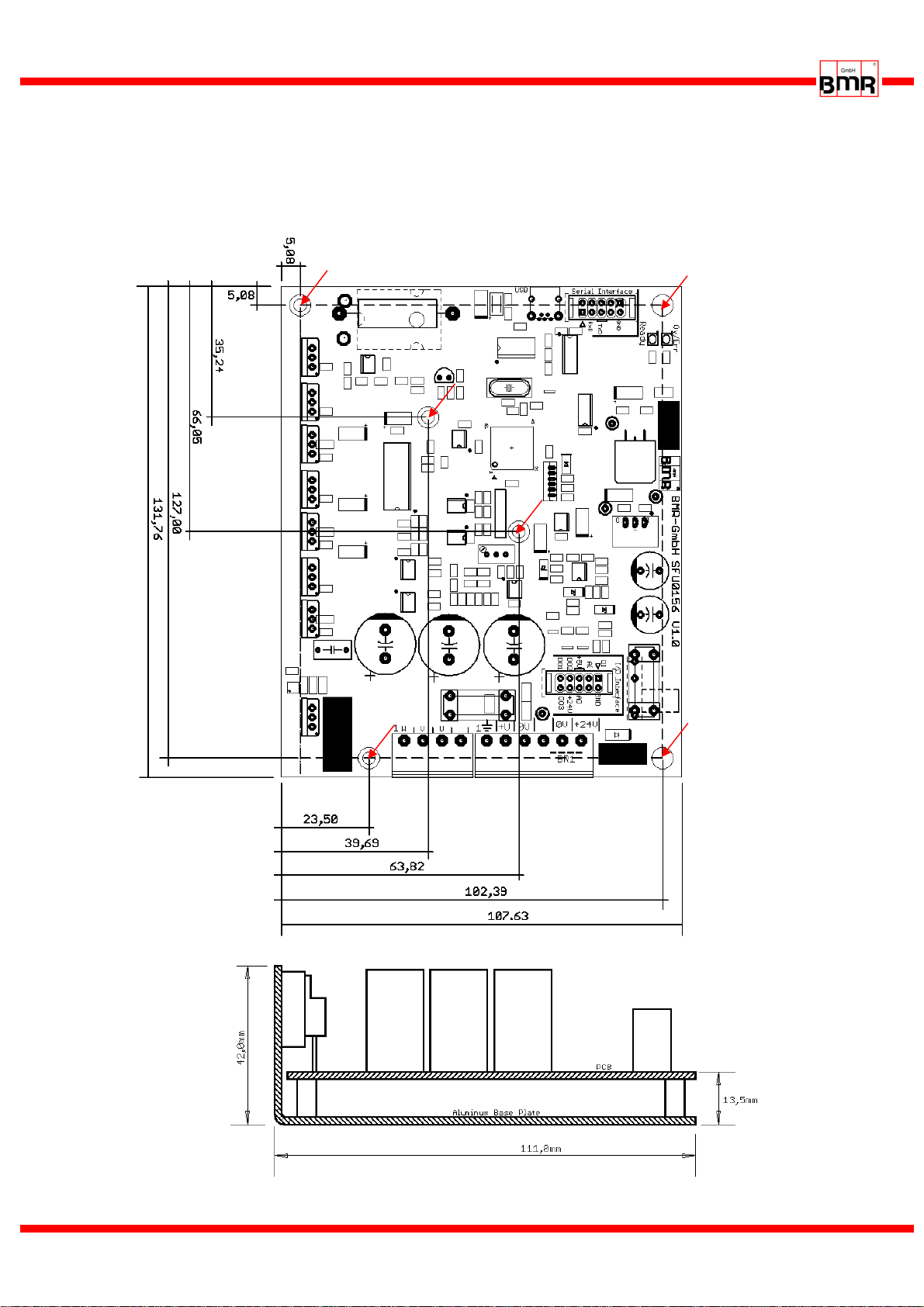

11.Drawing and Mounting

For mounting purpose there are 6 nuts with a 3mm thread provided, being pressed into

the at the bottom side of mounting bracket.

view from side

view from to

p

SFU 0156 M a n u a l

E 2015-10-15

15

this page is left blank intentionally

SFU 0156 M a n u a l

E 2015-10-15

16

Walpersdorferstr. 38

91126 Schwabach

Tel.: +49 (0)9122 63148-0

Fax.: +49 (0)9122 63148-29

Internet: www.bmr-gmbh.de

Subject to technical alterations.

2015-10-15

Other manuals for SFU 0156

1

Table of contents

Other BMR Media Converter manuals