Boehringer 3930 User manual

User Manual

Boehringer Laboratories, LLC

300 Thoms Dr.

Phoenixville, PA 19460

800-642-4945

Model 3930

Vacuum Assisted Venous

Drainage Controller w/

WAGD Suction Flowmeter

3930.003 Rev C P/N 34031 1 of 9

Released July 2014 User Manual VAVD Controller

WELCOME

Congratulations on your purchase of the Boehringer VAVD Regulator. We consider our regulators

to be the best in the world. We are confident it will provide you with reliable, trouble-free, safe

patient care and low cost of operation. This product is intended for use by clinicians properly

trained in the use of vacuum assisted venous drainage for cardiopulmonary bypass. The product is

intended for use on the order of a physician. Please read these instructions carefully.

Definition of Terms...................................................................................................................3

Indications ................................................................................................................................3

Contraindications......................................................................................................................4

Safety Information....................................................................................................................4

Operation/Features ..................................................................................................................5

Theory of Operation .................................................................................................................6

Installation ................................................................................................................................6

Pre-Use Check.........................................................................................................................7

Mode Selection.........................................................................................................................7

Clinical Use...............................................................................................................................7

Maintenance.............................................................................................................................8

Cleaning & Disinfection ............................................................................................................8

Troubleshooting........................................................................................................................8

Specifications ...........................................................................................................................9

Warranty and Repair ................................................................................................................9

Contents

3930.003 Rev C P/N 34031 2 of 9

Released July 2014 User Manual VAVD Controller

Parts .........................................................................................................................................13

VACUUM Air or other gases at a sub atmospheric pressure typically expressed as mmHg.

SUCTION A use of vacuum that causes a fluid or solid to be drawn into an interior space or to adhere to a

surface because of the difference between the external and internal pressures.

Alerts the user to the presence important operating and maintenance instructions in the

literature accompanying the device.

WARNING Alerts user to actions or conditions that could result in injury to user or patient.

CAUTION Alerts user to actions or conditions that can cause damage to the device or may result in

substandard performance of the device or system.

IMPORTANT Indicates an action that is emphasized to ensure proper operation of equipment.

OFF Supply suction is off and patient circuit is vented to atmospheric pressure.

REG Supply suction is on and regulated output is controlled to prescribed setting.

Lo Spike: Accuracy of regulation depends primarily on the ability to provide a consistent level

of vacuum under changing flow conditions.

Involuntary pneumatic biopsy, or tissue damage, can occur when high levels of vacuum are

applied to delicate tissue. With a Boehringer regulator, you can depend on very low “spike”

compared to our competitor’s models.

"Spike" is the variation in indicated suction as flow in the collection circuit changes from an a

free flowing condition to an occluded condition. We measure spike as the change in indicated

suction from full flow to a no flow condition using a typical collection circuit with a 14 French

catheter. To test, set the regulator to 50 mmHg flowing, and then allow occlude the 14Fr

catheter. The change in the indicated suction level is "Spike".

Boehringer regulators are checked on the assembly line to meet a specification of less than

10% of the indicated setting, for example 5mmHg spike at a 50 mmHg setting.

An evaluation of a regulator’s spike allows one to determine whether the device is truly

“regulating”. A safe and reliable regulator should regulate to its set position regardless of

variable flow conditions.

PARALLAX Inaccuracy caused by observational position of an indicating element (pointer) to a reference

element (scale).

This product is intended for use by or on the order of a physician. It is to be used by individuals who are properly

trained in the use of Vacuum Assisted Venous Drainage during Cardiopulmonary Bypass.

The Boehringer VAVD Controller was designed to provide accurate control of wall suction from 15 - 60 mmHg

for use in vacuum assisted venous drainage and the removal of waste anesthetic gases in cardiac surgery. The

VAVD provides a redundant safety device that vents excess negative pressure > 95 mmHg and positive

pressure > 10 cmH2O.

Definition of Terms and Symbology

Indications for Use

3930.003 Rev C P/N 34031 3 of 9

Released July 2014 User Manual VAVD Controller

This device is designed and sold for use only as indicated

This product is intended for use by or on the order of a physician. It is to be used by individuals who are

properly trained in medical suctioning procedures. Please read these instructions carefully.

A High Flow Bubble Barb fitting is provided to connect the regulator to a central suction source. Braid

reinforced tubing must be used to preclude the possibility of suction tubing collapse during extended

periods of use. The hose supplying suction to the regulator should have a vertical orientation to reduce

the possibility of kinking over time. Any deformation of this tubing may be indicative of a reduction in

flow to the suction regulator and accompanying patient circuit.

Always verify the regulator is attached to an appropriate source of suction, and that suction is present,

before attaching a patient collection circuit. This can be verified by turning the control valve to REG, and

adjusting the control knob to increase suction. The presence of suction can be audibly heard from at the

patient port of the regulator.

Suction regulators must only be attached to vacuum systems. Do not attach to compressed air,

nitrogen, or oxygen sources.

Do not cover, obstruct, or occlude the inlet of the interrupter where it is labeled ‘Do Not Occlude Vent’.

Do not attempt to calibrate this safety device. Return to the factory for appropriate service.

When used in conjunction with a venous return reservoir for cardiac bypass surgery: ensure that all air

detection and control devices are in proper working order, have all field suction pumps clear and

operating and monitor and control the fluid levels in the reservoir to prescribed limits.

When used for the purpose of vacuum assisted venous drainage for cardiac surgery, ensure proper

placement of cannulae and verify that venous drainage is properly occurring.

Suction catheters, collection canisters and suction tubing must be carefully evaluated and selected to

ensure adequate function for the specific clinical environment and intended field of use.

Always verify regulator operation (Spike, see page 4 for details) before use on a patient. Verify

operation by establishing the desired vacuum level with the collection circuit and suction catheter

attached to the regulator. Occlude the suction catheter and note that the indicated vacuum does not

rise by more than 10% of the original setting.

The Suction Flowmeter of the 3930 uses the facility’s medical-surgical vacuum source for Waste

Anesthetic Gas Disposal (WAGD). As such, flammable anesthetics or other flammable vapors are

required to be diluted below the lower flammable limit prior to disposal into the medical-surgical vacuum

system per NFPA 99-2012 (5.1.3.8)

Safety Information

WARNING!

Contraindications

3930.003 Rev C P/N 34031 4 of 9

Released July 2014 User Manual VAVD Controller

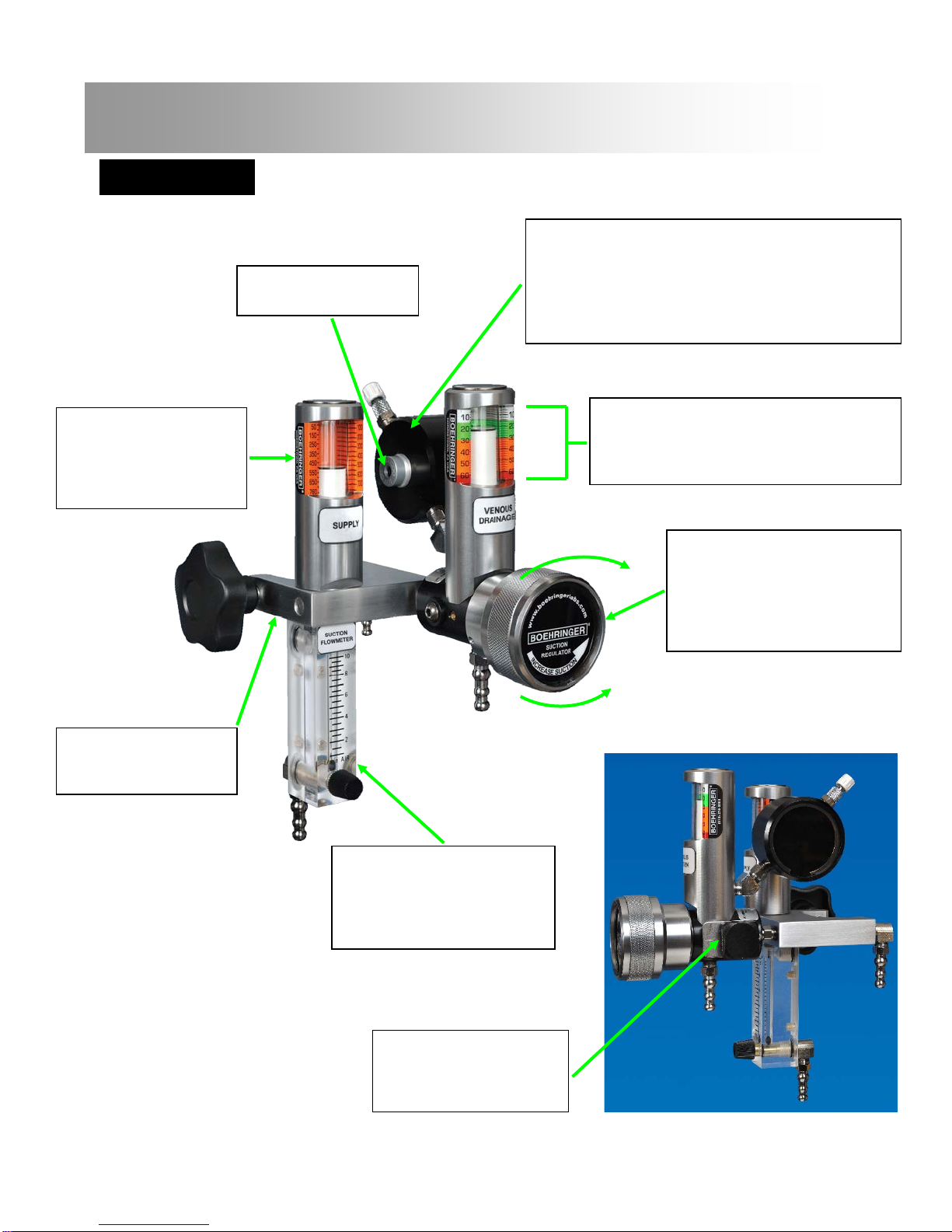

Operation

FEATURES

Mode Selector Valve:

Square knob to easily switch

between operating modes

(OFF/REG).

Adjusting Knob:

Extra large, easy grip knob turns

COUNTER-CLOCKWISE (direction

of arrow) to increase suction setting

and CLOCKWISE to decrease

suction setting

Independent Safety Relief:

1. High Negativity Safety Vent:

Safety mechanism limits maximum suction to less

than 100mmHg.

2. Positive Pressure Relief:

Safety mechanism vents excess positive pressure.

WARNING! – Safety Port:

Do Not Occlude

Patented Linear Gauge:

Allows accurate readings from 180° field of view

and never requires calibration. Each range has

unique color-coding

Integral Supply Gauge:

Supply pressure drop allows

for quick identification and

correction of open caps or

kinks in tubing.

Adjustable Bracket:

Allows mounting to vertical

poles.

WAGD Suction Flowmeter:

For attachment to the scavenger

port on the membrane oxygenator

via the provided WAGD tubing with

safety vents.

DECREASE

INCREASE

3930.003 Rev C P/N 34031 5 of 9

Released July 2014 User Manual VAVD Controller

The VAVD regulator incorporates a 2-way selector valve for selecting no suction or a preset level of suction.

REG Mode: With the vacuum regulator attached to the vacuum system and a vacuum capable venous reservoir

attached to the vacuum regulator, rotating the control valve on the side of the vacuum regulator will place the

vacuum regulator in the REG mode. Vacuum can now be regulated from 15-60 mmHg or shut off by turning the

knob all the way clockwise.

With the control valve in the REG position, wall vacuum may be controlled to a specific level by turning the large

adjusting knob in the direction indicated. A spring opposed diaphragm assembly precisely controls the level of

suction provided at the lower inlet port of the regulator. This assembly senses changes in the venous return

circuit and makes appropriate adjustments to maintain the vacuum level that has been selected. Vacuum level is

adjusted by turning the large knob in the direction indicated. Regulated settings are verified with the large, easy

to read gauge.

OFF Mode: When the vacuum regulator is on the OFF position, the vacuum return circuit reverts to atmospheric

pressure.

The model 3930 regulator is supplied with a high flow bubble barb for attachment to wall suction. Only braid

reinforced tubing suitable for suction service should be used when connecting this to a central suction supply.

Inappropriate tubing could lead to a reduction in flow and compromise patient safety. The tubing should exit the

fitting in a downward vertical orientation to minimize the possibility of kinking the supply tubing over time.

Connect the externally reinforced clear tubing to the WAGD connection (below). This line is meant to conduct

waste gases without applying negative pressure to the blood or gas inlet of the oxygenator.

The patient connection must be connected to an appropriate cardiotomy reservoir, do not draw patient materials

directly into this line, the use of a disposable vapor trap between the suction regulator and the cardiotomy

reservoir is recommended.

INSTALLATION

THEORY OF OPERATION

3930.003 Rev C P/N 34031 6 of 9

Released July 2014 User Manual VAVD Controller

1. With the selector valve of the unit in the OFF position and the valve on the suction flowmeter fully closed

(clockwise), verify the supply gauge reads > 500 mmHg. If a minimum of 500 mmHg is not available,

check the incoming supply tubing, or check the suction inlet to confirm it is compliant with the NFPA 99

standard.

2. Adjust the WAGD suction flowmeter all of the way open (counterclockwise) verify the flowmeter

registers the flow and that audible suction can be heard. Ensure the supply gauge registers > 400

mmHg with the suction flowmeter all of the way open. If a minimum of 400 mmHg is not maintained,

VAVD may not be effectively applied, resulting in patient risk. Check the incoming supply tubing, or

check the suction inlet to confirm it is compliant with the NFPA 99 standard.

3. Connect the VAVD Controller to the cardiotomy reservoir. Turn the control valve to ON and adjust the

output to 20 mmHg. Ensure suction can be audibly heard and the unit maintains the 20 mmHg set point.

If the unit is unable to pass the pre-use criteria, please contact Customer Service 800-642-4945 to have

the unit returned for needed service / calibration.

Follow venous reservoir manufacturer’s instructions regarding proper set up and use.

Ensure that all air detection and control devices are in proper working order. It is recommended that over

pressurization and vacuum relief valves are used in conjunction with the venous reservoir. It is recommended

that the pressure inside the venous reservoir be monitored by the clinician.

Attach the externally reinforced clear tubing (WAGD Tube Assembly) to the vent port on the membrane

oxygenator. The tube is bidirectional and either end may be connected to the vent port as well as the WAGD

connection on Suction Flowmeter. Do not block or occlude the vent holes that are at both ends of the tube.

Follow membrane oxygenator manufacturer's recommendation for suction flow settings.

Connect the reservoir connection port to the venous reservoir. It is highly recommended to use a disposable

vapor trap between the vacuum regulator and the venous reservoir

OFF: With control valve in the OFF position, suction is off and the collection circuit is returned to

atmospheric pressure by an internal vent port, a special feature of the Boehringer design. Any additional

positive pressure or negative pressure in excess of 100mmHg will be vented from the patient collection

circuit.

REG: With control valve in the REG position, wall suction may be controlled to a specific level by turning

the large adjusting knob in the direction indicated. A spring opposed diaphragm assembly precisely

controls the level of suction provided at the lower port of the Regulator within the range of the gauge. This

assembly "senses" changes in the patient collection circuit and makes appropriate adjustments to maintain

the suction level that has been selected. Regulated settings are verified by the large, easy to read gauge.

MODE SELECTION

CLINICAL USE

PRE-USE CHECK

3930.003 Rev C P/N 34031 7 of 9

Released July 2014 User Manual VAVD Controller

Your VAVD Controller has been designed with the highest quality materials and to the strictest production

tolerances. Unlike common hospital suction regulators, the VAVD controller has precision low suction output

and redundant safety features to limit excess negative pressure and positive pressure. Given the critical nature

of the clinical interventions for which the VAVD Controller is employed, and the inherent risk involved in applying

unregulated suction during these procedures, only factory service and calibration may be performed on this unit.

Factory calibration is recommended - -

•Any time fluid has entered the VAVD Controller.

•Any time there is physical damage noted to VAVD Controller.

•Any time the VAVD Controller fails a pre-use test.

•A minimum of every 24 months.

WAGD Tube Assembly (Model 3947) - -

It is recommended to replace the WAGD Tube Assembly every (3) three months or sooner if it has any sign of

being damaged or visibly contaminated. Additional WAGD Tube Assemblies (Model 3947) are available for

purchase.

Please call Customer Service at 800-642-4945 to obtain an RMA prior to return or to order additional WAGD

Tube Assemblies (Model 3947). Once the unit has been received you will be contacted with an estimate of any

service charges. Units will be serviced within five days of receipt of charge authorization.

After patient use, wipe all exterior surfaces of the VAVD Controller with an appropriate surface

disinfectant. Appropriate disinfectants are:

•3M Quat®

•Cavacide®

Your VAVD regulator has been designed for years of trouble-free service. Should you experience difficulty that

is not the result of damage to the instrument, the most likely cause is aspiration of dirt and/or fluids into the

Regulator.

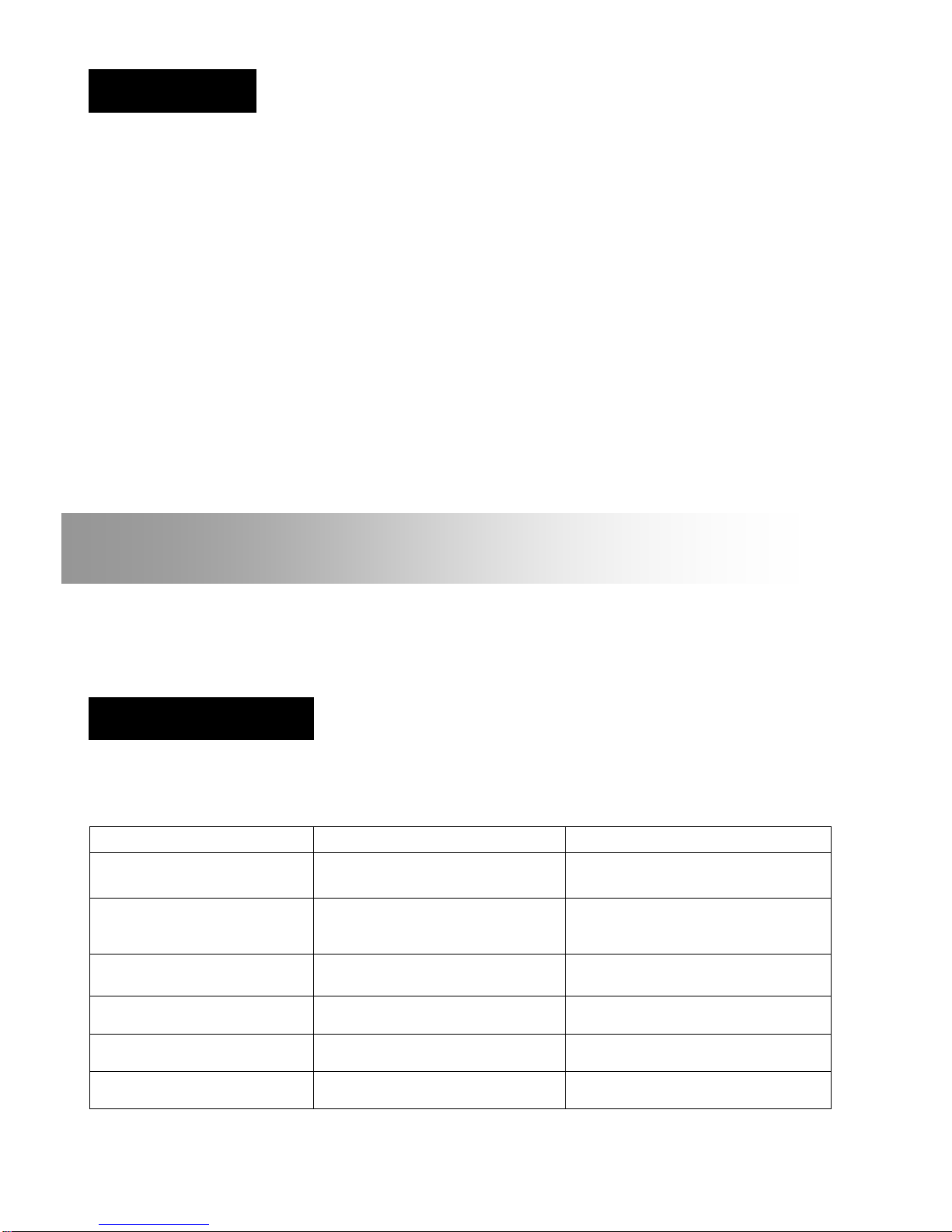

Symptom Probable Cause Solution

Instrument fails to provide suction at

the patient port.

The supply or patient fittings are clogged,

or the incoming suction tubing is collapsed

or kinked.

Replace or clean the fittings. Replace the

incoming suction line.

Gauge doesn't respond to changes in

suction (via control valve or

adjustment knob)

Gauge diaphragm is improperly sealed on

the gauge piston and/or view tube Reference Boehringer Tech Bulletin

3700.044.

Gauge piston is discolored. Material has entered the inside of the

device. Instrument is contaminated. Please return to

the factory for service.

Instrument will not shut off or exhibits

high spike. Dried fluids may have cut the quad ring

seal. Please return to the factory for service.

Instrument fails to regulate suction Piston/Stem surface is binding with foreign

matter Please return to the factory for service.

Audible sound coming from safety

port on safety interrupter Material has entered the inside of the

device. Instrument is contaminated. Please return to

the factory for service.

TROUBLESHOOTING

MAINENANCE

Cleaning & Disinfection

3930.003 Rev C P/N 34031 8 of 9

Released July 2014 User Manual VAVD Controller

•Inlet and outlet fittings: 1/8 NPT, High Flow Bubble Barb (P/N 2469)

•Gauge accuracy ANSI Class B, ± 5% FS (± 3 mmHg)

•Regulation Accuracy: ±10% FS from full flow to zero flow with 14 FR catheter attached.

•Leak rate in OFF position: less than 1 cc/min

•Materials: polycarbonate, hard-anodized aluminum, stainless steel, Buna rubber, acetal copolymer.

Model

Regulation Range

User Selectable Modes

Wt. (lb)*

H x W x D (in)

3930 15 - 60 mmHg Off & Regulated Control 3.40 lbs 101/4” x 7½” x 81/2”

Operating and Storage Limits

We recommend that Boehringer Suction regulators be operated and stored at controlled conditions that typically

reflect the medical facility environment.

Boehringer Laboratories, Inc. guarantees your VAVD regulator for FIVE years from the date of manufacture.

Boehringer Laboratories, Inc. warrants to the original purchaser, new suction regulators purchased directly from

Boehringer Laboratories, Inc. or from an authorized dealer or representative. This warranty guarantees the

suction regulators to be free from functional defects in materials and workmanship. We also guarantee that our

suction regulators will meet our published specifications.

All regulators returned for repair shall be clean and free from contamination prior to shipment. This requirement

is for the safety of our employees as well as to comply with Federal Law prohibiting the shipment of unmarked

biohazard materials. If units are returned contaminated, a cleaning charge may result.

A service charge may be assessed on any unit returned that shows evidence of gross abuse.

Boehringer Laboratories, Inc. is the only authorized warranty service center for your VAVD regulator.

This warranty excludes acts of God, fire, flood and acts of war, terror or insurrection.

Boehringer Laboratories’ sole and exclusive remedy under this warranty is limited to repairing and/or replacing

the suction regulator. There are no other express or implied warranties beyond these warranties set forth above.

At Boehringer Laboratories, we are committed to lowering your suction regulator costs of operation!

A Return Material Authorization Number (RMA) must be obtained prior to returning a unit for service. Please

contact Customer Service at

SPECIFICATIONS

Warranty and Repair

Boehringer Laboratories, LLC

800-642-4945

info@boehringerlabs.com

300 Thoms Dr

Phoenixville, PA 19460

www.boehringerlabs.com

Covered under one or more of the following Boehringer patents (Additional Patents Pending):

6,264,890 6,228,056 5,992,239 5,879,624 5,409,491 5,372,593

5,354,262 5,203,778

2011 Boehringer Laboratories, Inc.© Boehringer is a trademark of Boehringer Laboratories, Inc.

3930.003 Rev C P/N 34031 9 of 9

Released July 2014 User Manual VAVD Controller

Table of contents

Other Boehringer Laboratory Equipment manuals