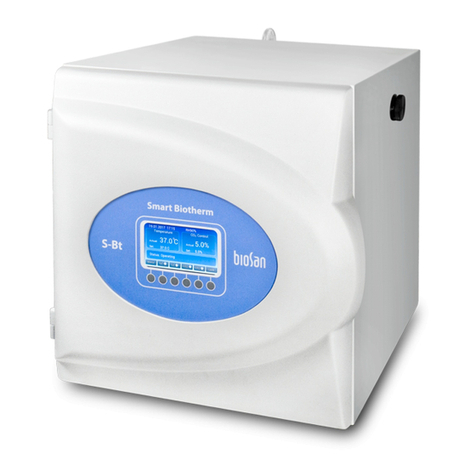

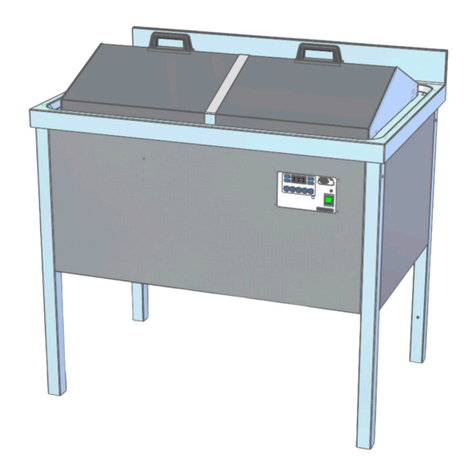

Biosan S-Bt User manual

Other Biosan Laboratory Equipment manuals

Biosan

Biosan Automatic Luminescence Analyser ALA1/4 User manual

Biosan

Biosan Vortex MSV-3500 User manual

Biosan

Biosan MMS-3000 User manual

Biosan

Biosan Assistboy User manual

Biosan

Biosan Bio RS-24 User manual

Biosan

Biosan Inteliwasher 3D-IW8 User manual

Biosan

Biosan LMC-4200R User manual

Biosan

Biosan RCP-24 User manual

Biosan

Biosan FTA-1 User manual

Biosan

Biosan S-Bt Smart BioTherm User manual

Biosan

Biosan RTS-1C User manual

Biosan

Biosan Multi Bio 3D User manual

Biosan

Biosan DEN-1 User manual

Biosan

Biosan DEN-1B User manual

Biosan

Biosan MMS-3000 User manual

Biosan

Biosan CH-100 User manual

Biosan

Biosan OD Plate User manual

Biosan

Biosan Sunflower Mini-Shaker 3D User manual

Biosan

Biosan UVT-B-AR User manual

Biosan

Biosan Bio RS-24 User manual

Popular Laboratory Equipment manuals by other brands

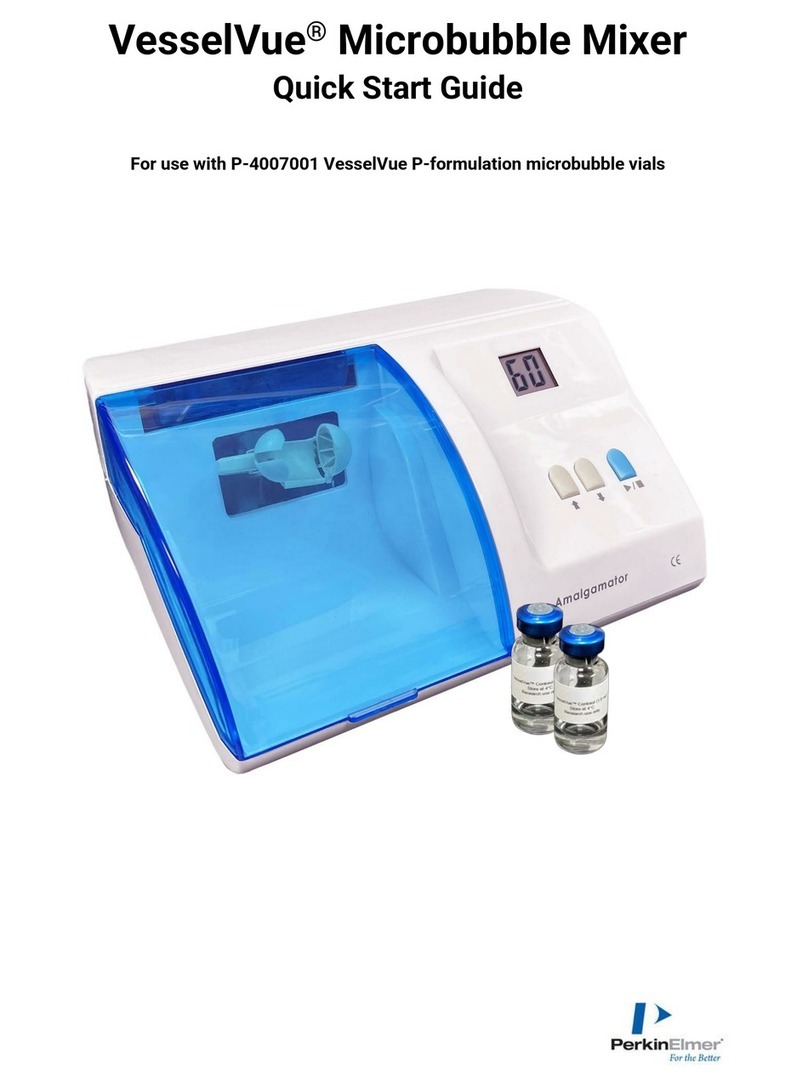

PerkinElmer

PerkinElmer VesselVue quick start guide

PerkinElmer

PerkinElmer Lambda 365 Peltier Temp Ctrl Unit Multi installation instructions

Multi Channel Systems

Multi Channel Systems MEA Series manual

Phase Technologies

Phase Technologies 70Xi Quick installation guide

PerkinElmer

PerkinElmer Frontier FT-IR user guide

Star Lab

Star Lab Ergo One user manual

German pool

German pool OSS-400 user manual

J.P. SELECTA

J.P. SELECTA PRECISBIG 6001240 quick start guide

Roche

Roche MagNA Pure Compact Instrument Operator's manual

Nippon Genetics

Nippon Genetics FastGene FAS Digi Installation instruction

Selecta

Selecta CENCOM 2 instruction manual

FLUXANA

FLUXANA VITRIOX GAS Series user manual