INDEX

INDEX.......................................................................................................................................................................................................3

SYMBOLS .................................................................................................................................................................................................4

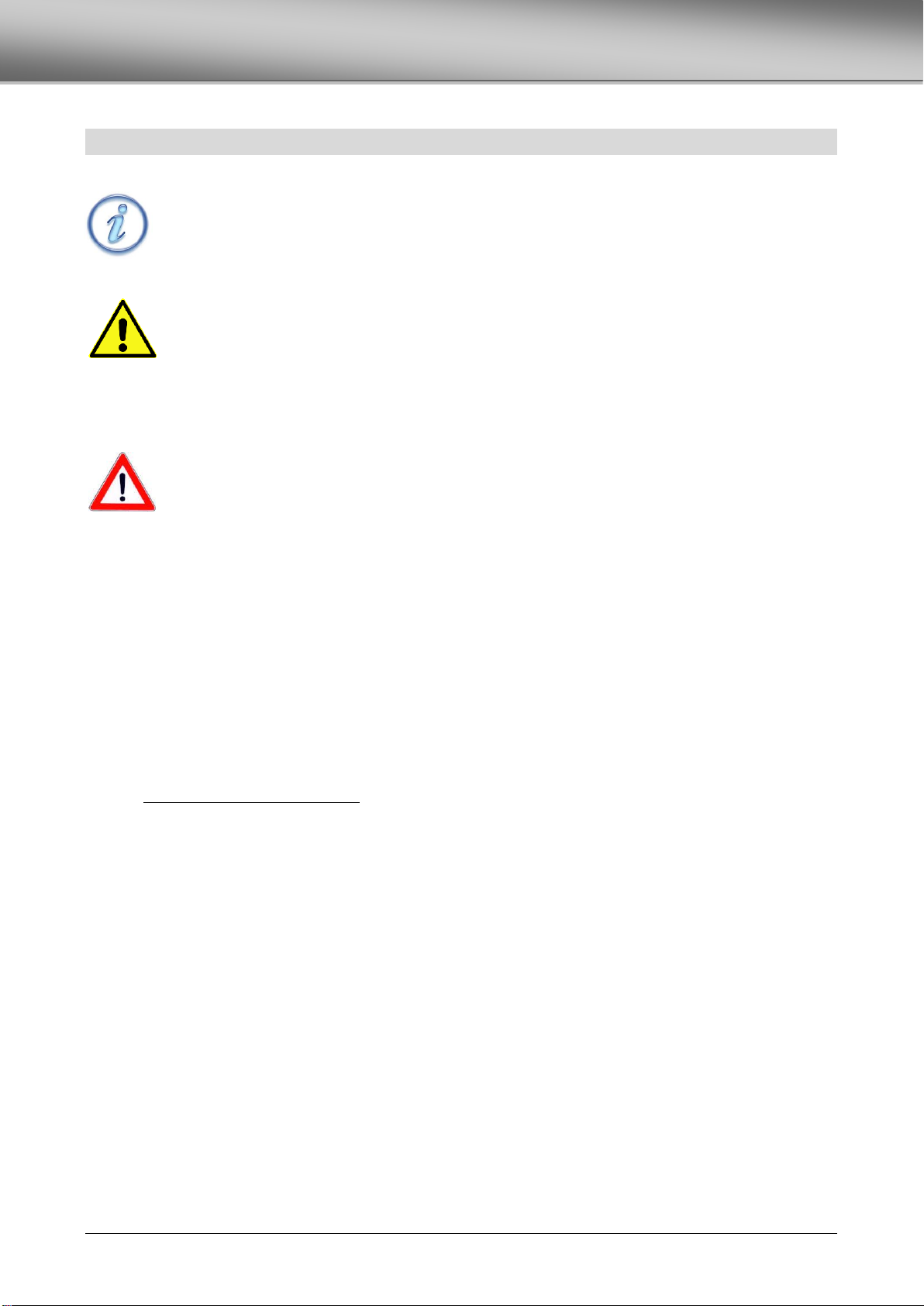

WARNINGS, PRECAUTIONS AND IMPORTANT INFORMATION................................................................................................................6

IMPORTANT INFORMATION....................................................................................................................................................................7

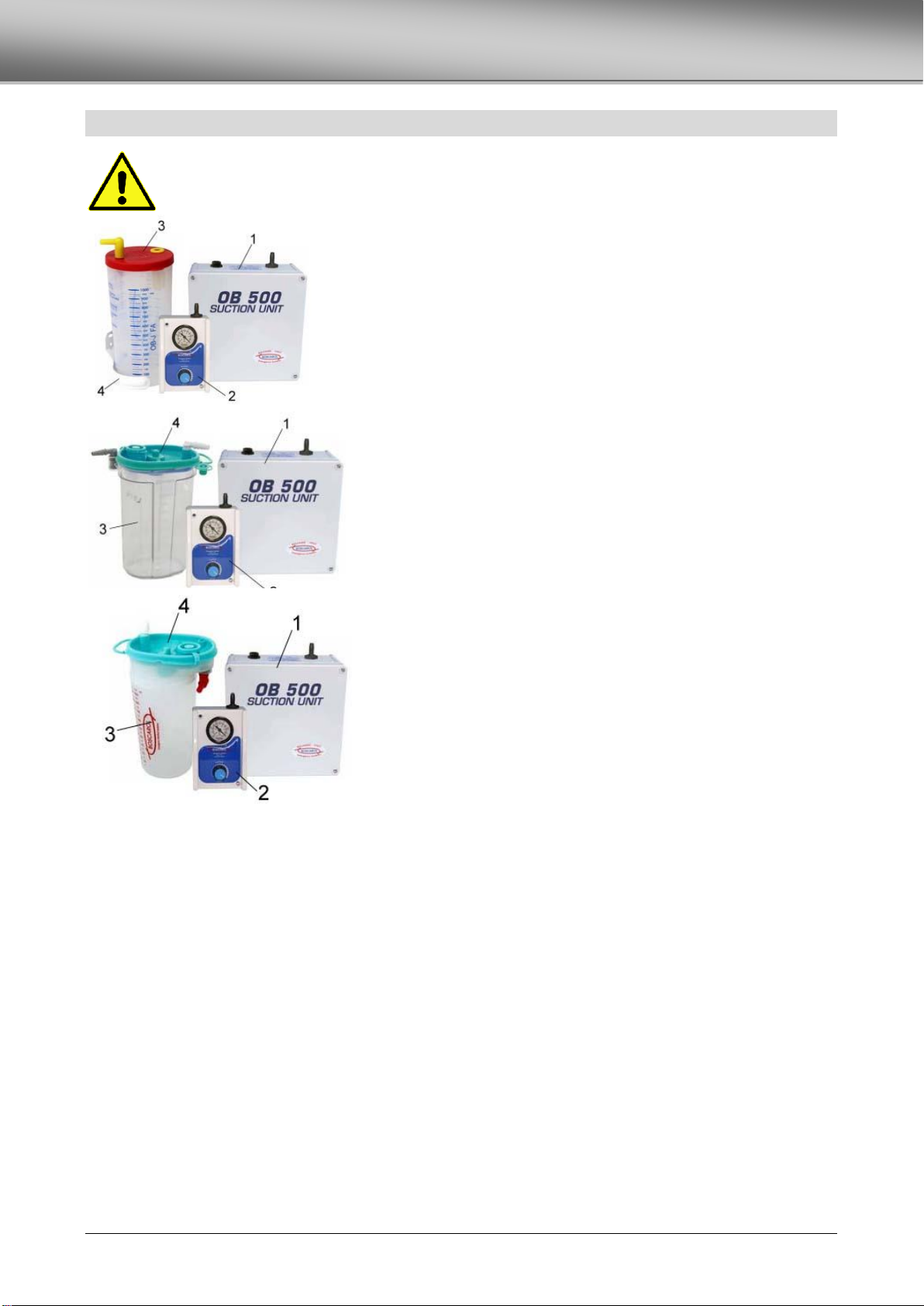

OB500 SUCTION UNIT..............................................................................................................................................................................8

DESCRIPTION AND INTENDED USE STATEMENT ................................................................................................................................8

CONTRA INDICATION FOR USE...........................................................................................................................................................8

CONTROLS, INDICATIONS AND CHECK PANEL....................................................................................................................................8

CONTROL MODULE ............................................................................................................................................................................9

SUCTION UNIT....................................................................................................................................................................................9

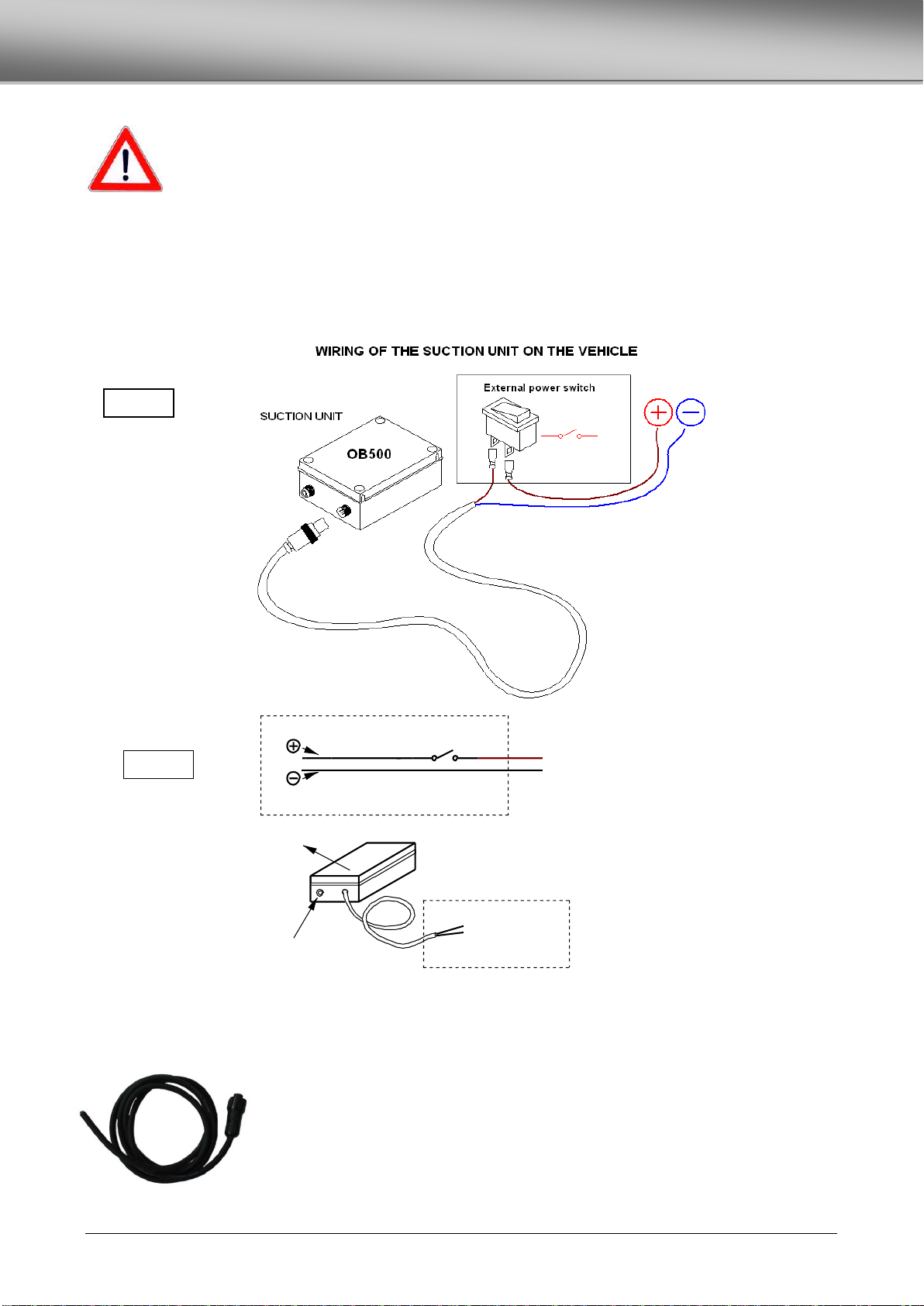

ELECTRICAL CONNECTIONS..............................................................................................................................................................10

TEST OF THE UNIT ............................................................................................................................................................................11

COLLECTION JAR...............................................................................................................................................................................11

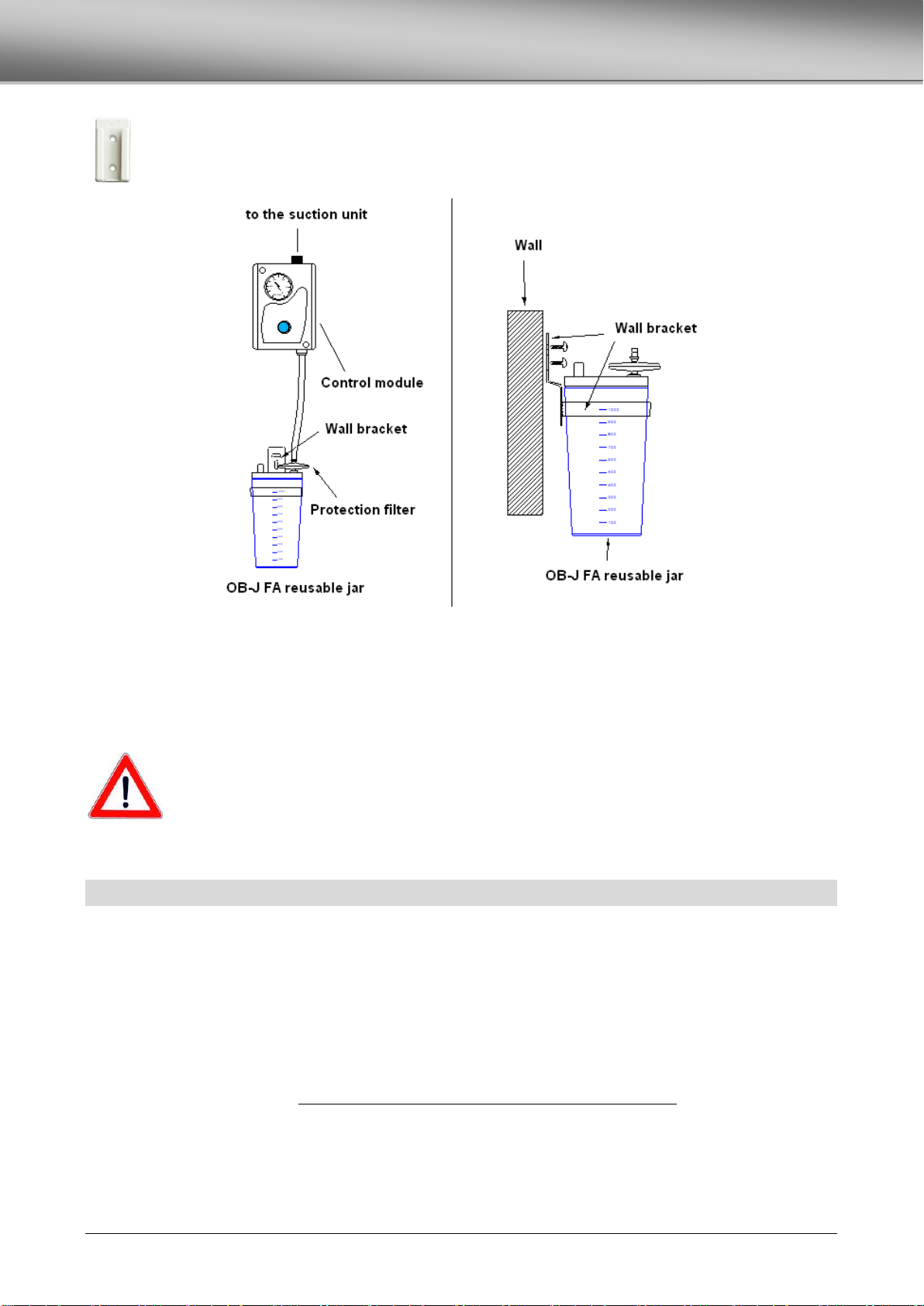

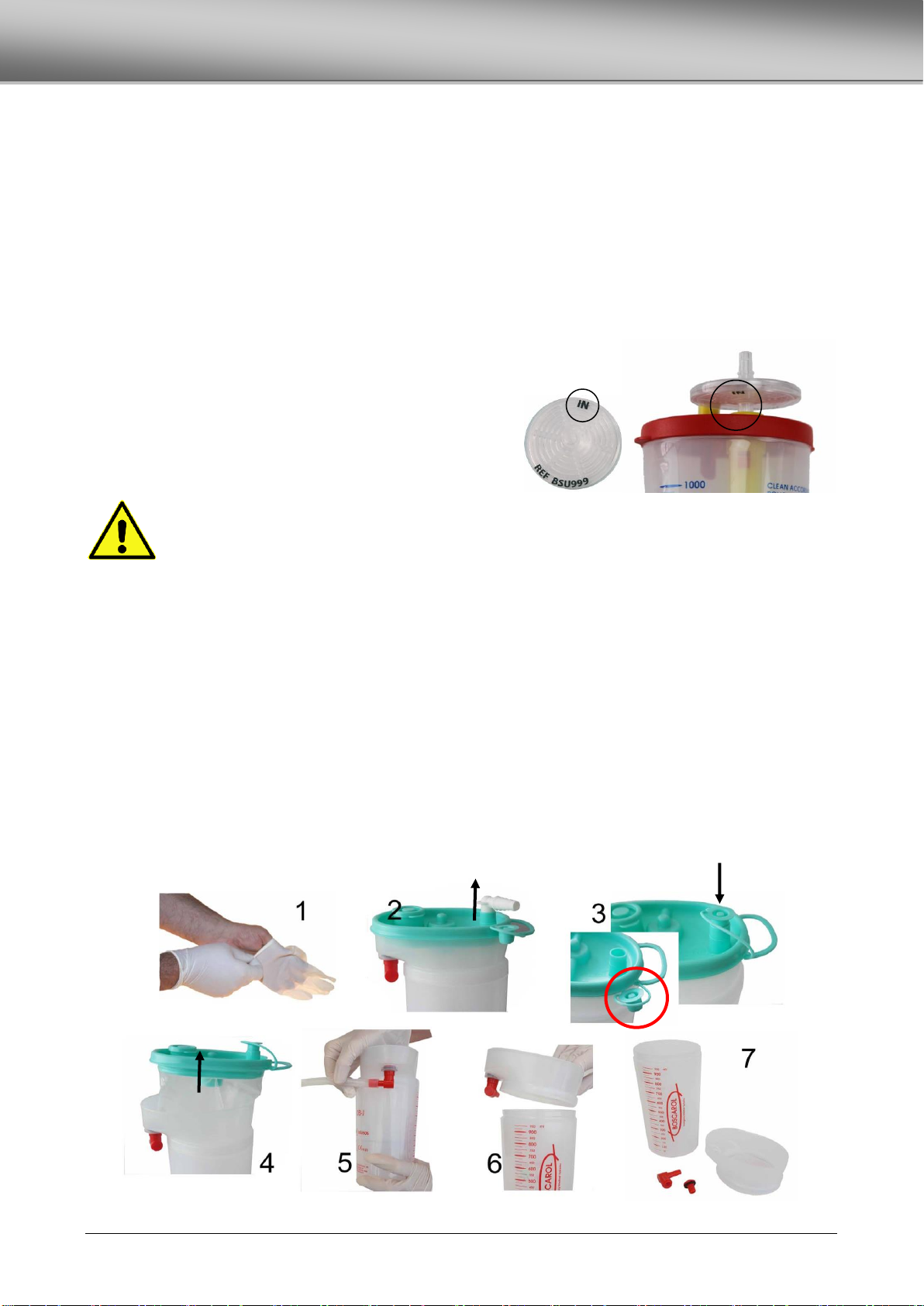

OB-J FA REUSABLE, AUTOCLAVABLE JAR..........................................................................................................................................11

PROTECTION FILTER .........................................................................................................................................................................11

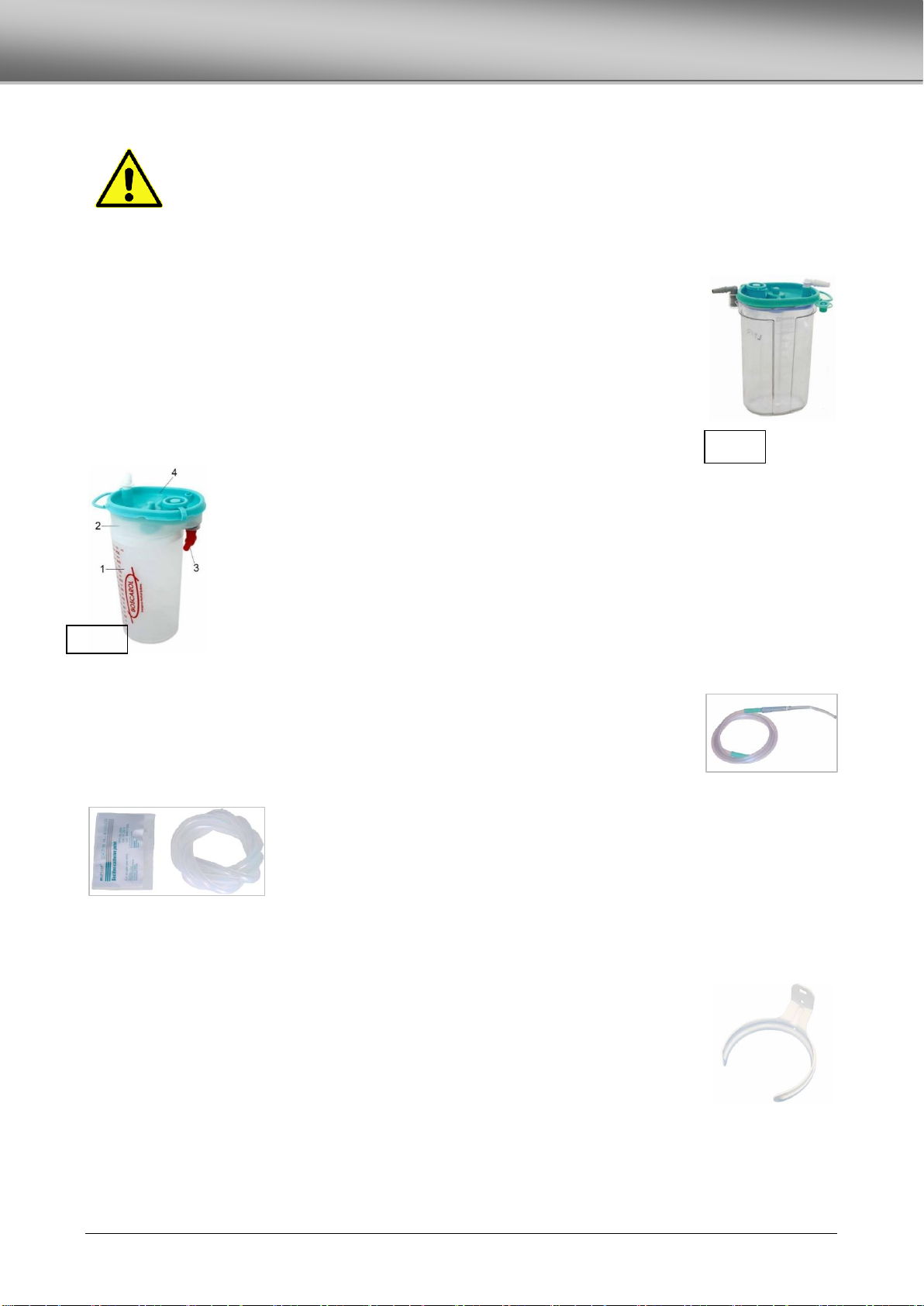

REUSABLE JAR WITH DISPOSABLE LINER SERRES® ...........................................................................................................................12

OB-J COLLECTION JAR.......................................................................................................................................................................12

JANKAUER SUCTION TUBE AND FINGER-TYP END-PIECE .................................................................................................................12

WALL BRACKET FOR THE JAR............................................................................................................................................................12

POWER SUPPLY ................................................................................................................................................................................13

MAINTENANCE AND REUSE...................................................................................................................................................................13

AFTER EACH REUSE ..........................................................................................................................................................................13

CLEANING INSTRUCTION..................................................................................................................................................................14

REUSABLE COLLECTION JAR OB-J FA ................................................................................................................................................14

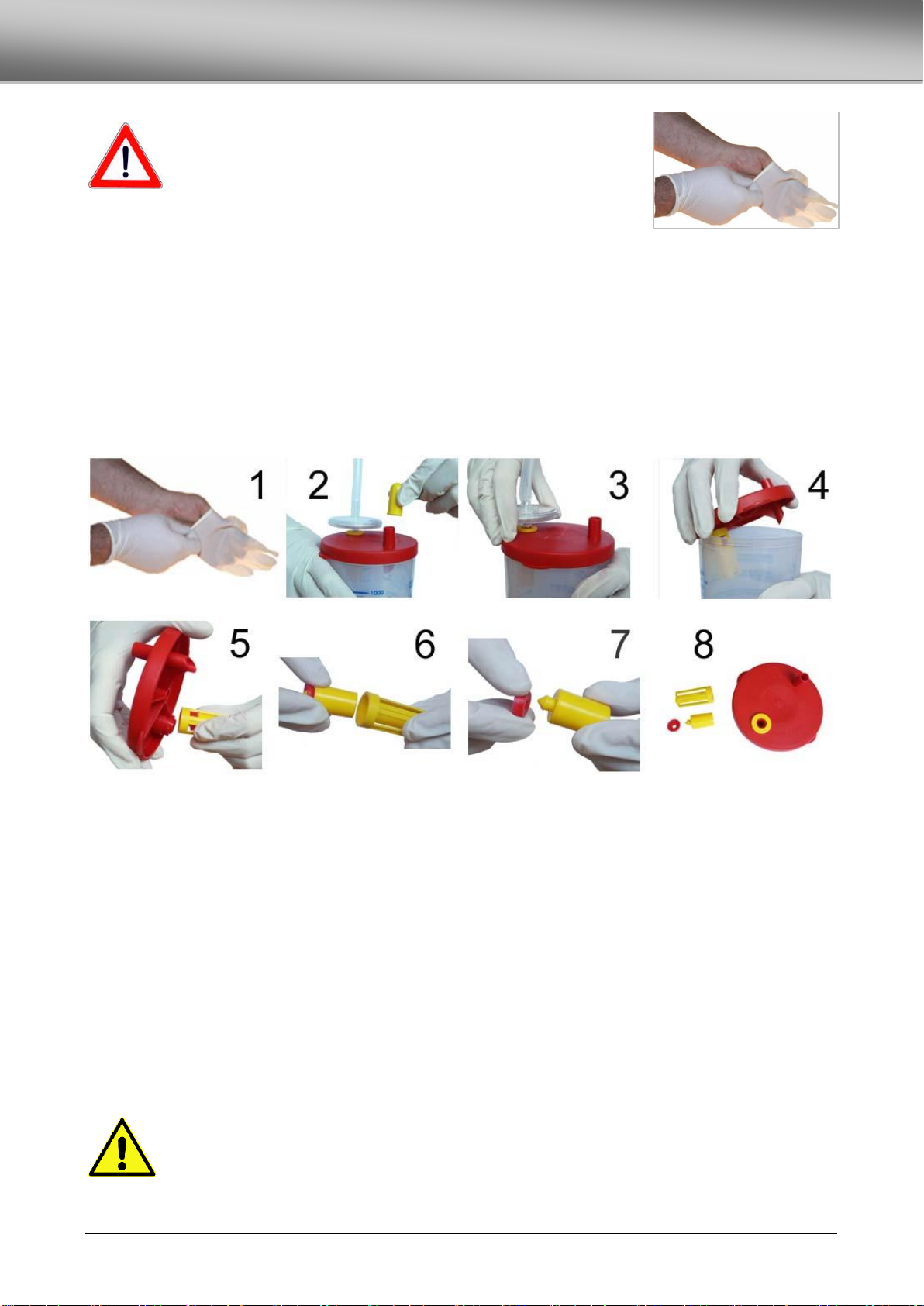

DECONTAMINATION OF THE COLLECTION JAR ................................................................................................................................14

REPLACING THE PROTECTION FILTER...............................................................................................................................................15

REUSABLE COLLECTION JAR OB-J .....................................................................................................................................................15

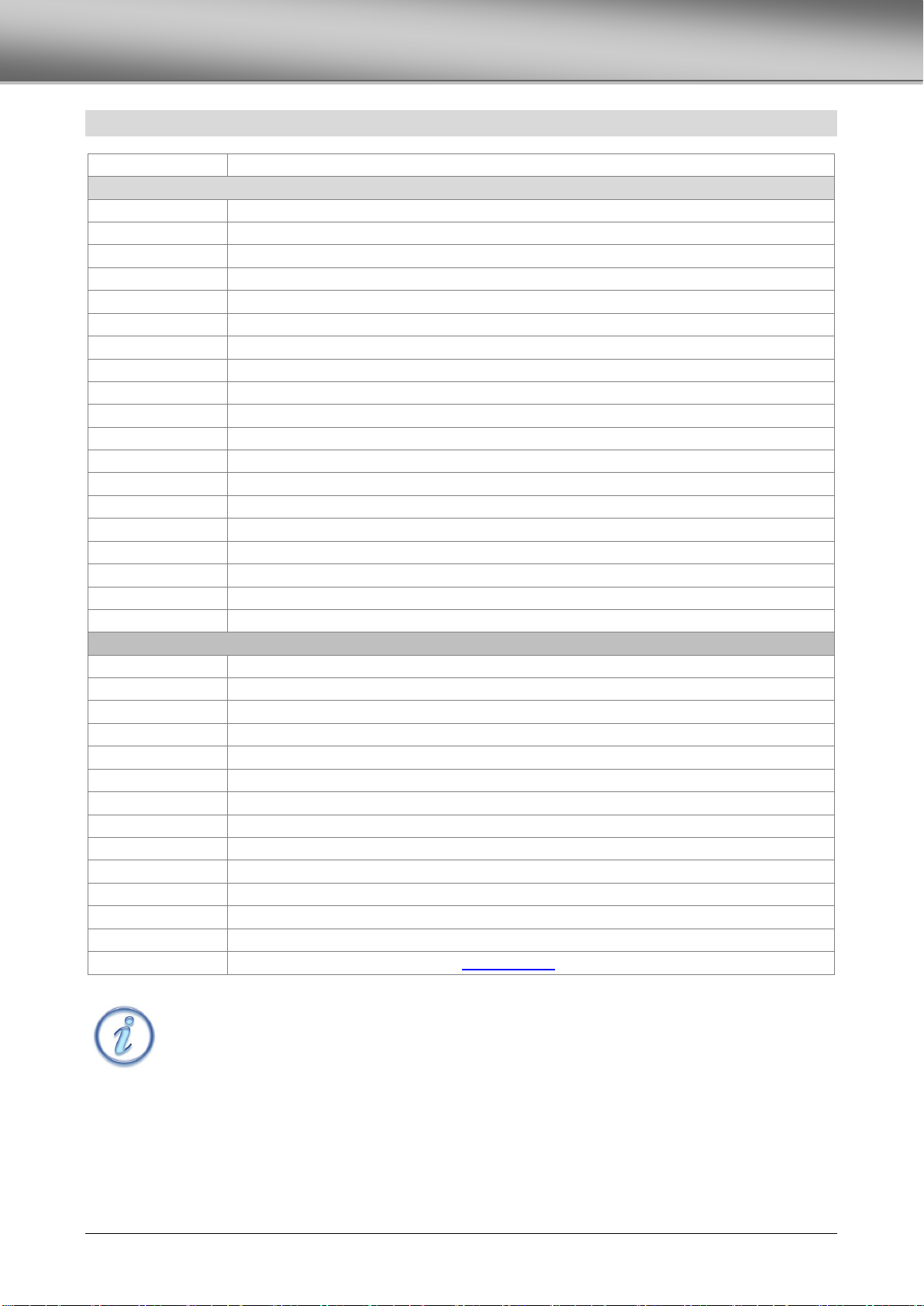

REUSABLE COLLECTION JAR SERRES®...............................................................................................................................................16

REASSEMBLY OF THE JAR .................................................................................................................................................................16

DISPOSAL OF CONTAMINATED PARTS..............................................................................................................................................17

CLEANING THE SUCTION UNIT .........................................................................................................................................................17

SAFETY..............................................................................................................................................................................................17

DISPOSING OF THE SUCTION UNIT...................................................................................................................................................17

ACCESSORIES AND SPARE PARTS...........................................................................................................................................................18

SERVICE..................................................................................................................................................................................................19

FAULT FINDING......................................................................................................................................................................................19

TECHNICAL DATA AND CONFORMITY TO INTERNATIONAL LAW...........................................................................................................19

THE RISKS OF RECIPROCAL INTERFERENCE WITH OTHER DEVICES........................................................................................................21

RISK OF ELECTROMAGNETIC INTERFERENCE AND POSSIBLE REMEDIES ...............................................................................................21

GUARANTEE...........................................................................................................................................................................................24

DECLARATION OF CONFORMITY............................................................................................................................................................25