Boscarol OB500 FA User manual

ED01_REV01-2021 IFU OB500_ENG

1- 32

BOSCAROL MEDICAL SUCTION UNIT

OB500

FA / FM / LINER

OPERATING INSTRUCTIONS

OB500 type A FA

OB500 WE FM

OB500 ARI FA

OB500 IR LINER

ED01_REV01-2021 IFU OB500_ENG

2- 32

MANUFACTURED BY:

OSCAR BOSCAROL SRL

Via Enzo Ferrari 29

39100 Bolzano

ITALY

Tel. +39 0471 932893

Fax: +39 02 57760140

www.boscarol.it

Information on the manufacturer and the medical device:

•Oscar Boscarol applies a quality management system in accordance with international standards

ISO 13485 and ISO 9001.

•The OB500 medical device (in all its configurations) complies with MDD 93/42/EEC (and subsequent

amendments) and bears the CE marking (CE 0123 notify body TÜV SUD Italia).

•The medical device fulfils the essential requirements described in Annex I of MDD 93/42/EEC

Information on these operating instructions:

•This document contains important information for the safe, effective and compliant use of the

medical device.

•Use the information reported to train users and confirm their training

•This manual may not be altered (even in part). Only the manufacturer of the device may make

changes where necessary.

•These instructions should always accompany the device. We recommend using the electronic

version and making it available on operators' PDAs, tablets and mobile phones.

These operating instructions apply to the following devices:

OB500 FA

OB500 LINER

OB500 FM

REFERENCE CODES:

BSU402

BSU412

BSU414

BSU442

BSU462

BSU464

XAS0330

XAS0331

XAS0332

XAS0333

XAS0334

XAS0335

XAS0338

XAS0340

XAS0341

ED01_REV01-2021 IFU OB500_ENG

3- 32

INDEX

INDEX ......................................................................................................................................................................... 3

0. MEANING OF SYMBOLS AND PICTOGRAMS....................................................................................................... 4

0.1. Symbols used in these operating instructions to call the reader's attention.................................................... 4

0.2. Symbols used on the device and accessories.................................................................................................... 4

1. INTENDED USE................................................................................................................................................... 5

2. WARNINGS, PRECAUTIONS AND IMPORTANT INFORMATION........................................................................... 6

3. IMPORTANT INFORMATION TO KNOW BEFORE USE ......................................................................................... 7

4. CONTRAINDICATIONS (DO NOT USE FOR )......................................................................................................... 8

5. SIDE EFFECTS (POSSIBLE DURING SUCTION OPERATIONS) ................................................................................. 8

6. OB500 MEDICAL SUCTION UNIT ........................................................................................................................ 8

6.1. Description of OB500 suction unit .................................................................................................................... 9

6.2. Controls, operation and control panel............................................................................................................ 10

6.3. Motor block unit (suction pump) .................................................................................................................... 11

6.4. Electrical connections of the engine block unit (suction pump) ..................................................................... 11

6.5. Periodic test of OB500 suction unit (all variants)............................................................................................ 12

6.5.1. Daily periodic test of the OB500 suction unit(valid for all variants) ............................................................... 12

6.5.2. Periodic six-monthly/annual test of OB500 suction unit(valid for all variants) .............................................. 13

6.6. Safety information for the safety of users, patients and third parties............................................................ 14

7. SUCTION JARS FOR OB500 (all variants) ...........................................................................................................14

7.1. Autoclavable secretion collection jar OB-J FA................................................................................................. 15

7.2. Antibacterial filter ........................................................................................................................................... 15

7.3. OB-J FM: jar of secretions for SERRES® disposable bags................................................................................. 15

7.4. SERRES® jar for OB500 LINER ......................................................................................................................... 16

7.5. Secrets jar connection..................................................................................................................................... 16

7.6. Sterile disposable Yankauer catheter with suction control system ................................................................ 16

7.7. Silicone suction tube and sterile Fingertip (conical fitting)............................................................................. 16

7.8. Warnings concerning the re-use of single-use parts....................................................................................... 17

7.9. Support bracket for suction jar(wall mounting).............................................................................................. 17

8. REUSE, CLEANING AND DISINFECTION..............................................................................................................17

8.1. Re-use of OB-J FA suction jar .......................................................................................................................... 18

8.2. Cleaning, disinfection and/or sterilisation of OB-J FA suction jar and silicone tube....................................... 18

8.3. Jar assembly and connection of the silicone suction tube.............................................................................. 19

8.4. Replacing the antibacterial filter..................................................................................................................... 19

8.5. Cleaning the suction jar(OB-J or SERRES®) with SERRES® disposable bags..................................................... 20

8.6. Disinfection and/or sterilisation of the OB-J suction jarand silicone tube...................................................... 22

8.7. Assembling the suction jarwith the SERRES® disposable bag ......................................................................... 22

8.8. Disposal of contaminated single-use parts ..................................................................................................... 23

8.9. Cleaning and disinfection of the suction unit.................................................................................................. 23

8.10. Cleaning and disinfection plan ........................................................................................................................ 23

9. SUCTION UNIT POWER SUPPLY ........................................................................................................................24

10. SPECIAL CONDITIONS OF USE ...........................................................................................................................24

11. DEMOLITION OF SUCTION UNIT .......................................................................................................................24

12. ACCESSORIES, CONSUMABLES AND SPARE PARTS............................................................................................25

13. TECHNICAL SERVICE..........................................................................................................................................25

13.1.Troubleshooting .............................................................................................................................................. 26

14. TECHNICAL DATA AND CONFORMITY DATAFOR OB500 (ALL VARIANTS) ..........................................................26

15. INFORMATION ON EMC ELECTROMAGNETIC COMPATIBILITY ..........................................................................28

15.1. RISKS OF MUTUAL INTERFERENCE WITH OTHER DEVICES .............................................................................. 28

15.2. METHODS TO PREVENT ELECTROMAGNETIC INTERFERENCE ......................................................................... 28

15.3. GUIDELINES AND MANUFACTURER'S DECLARATIONS - ELECTROMAGNETIC EMISSIONS .............................. 28

15.4. GUIDELINES AND MANUFACTURER'S DECLARATIONS - ELECTROMAGNETIC IMMUNITY .............................. 28

16. DECLARATION OF CONFORMITY.......................................................................................................................30

17. WARRANTY ......................................................................................................................................................31

ED01_REV01-2021 IFU OB500_ENG

4- 32

0. MEANING OF SYMBOLS AND PICTOGRAMS

0.1. Symbols used in these operating instructions to call the reader's attention

Danger: Important safety information on the correct use of the suction unit to prevent injury to

the operator or patient and/or damage to the suction unit.

Warnings: information requiring special attention

Notes or information to prevent damage to the device or others. Activate the correct prevention

measures

1. List of actions to be performed: follow them step by step

These operating instructions

Electric and magnetic fields generated by radiographic or tomographic equipment, portable

radio equipment, RF radio and devices bearing this symbol may affect the operation of the

suction unit. In such cases the OB500 suction unit must not be used or must be kept at a suitable

distance from such equipment.

OB500 suction units contain electrical or electronic parts that have to be recycled according to

the WEEE Directive/19/EU - Waste Electrical and Electronic Equipment.

The suction unit complies with the European Directive 2011/65/EU (RoHS).

Required maintenance service (contact the manufacturer and/or its authorised service centres)

0.2. Symbols used on the device and accessories

Insulation class II (according to IEC 60601-1)

Patient Applied Part Grade BF (according to IEC 60601-1)

Use the suction unit only within the specified temperature range. Using the suction unit outside

this range may impair its operation, shorten battery life and cause the internal safety devices to

activate.

Limits of use referring to atmospheric pressure

Limits of use in relation to humidity

Read these operating instructions carefully and completely

Accessories and/or consumables bearing this symbol are disposable. They cannot be reused and

must be discarded after use and replaced with new ones. The symbol is placed on consumables

Symbol indicating that the device is multiple-use but single-patient (in practice it can only be

used more than once on the same patient)

Indicates the need for the user to consult these operating instructions for information such as

warnings and precautions that cannot be displayed on the medical device in question

ED01_REV01-2021 IFU OB500_ENG

5- 32

CE mark in accordance with MDD 93/42/EEC for medical devices in class above I

Manufacturer

Production date

The OB500 suction unit contains electrical and/or electronic equipment that must be recycled

in accordance with European Directive 2012/19/EU - Waste Electrical and Electronic Equipment

(WEEE).

Authorised representative in the European Community if the producer is not resident in Europe

Expiry date

Order number (device code)

Please read the operating instructions in other languages available on the indicated website

Do not use the device in environments where MRI investigations are conducted

Production batch

Serial number

Indicates that the suction unit is a medical device

Connection/patient suction tube (cover for collection jar and Serres® disposable liner)

INPUT The external mains power supply indicates the accepted input voltage range

OUTPUT On the external mains power supply it indicates the output voltage value

Indoor use only

Continuous current

Alternating current

1. INTENDED USE

Device name Medical suction unit OB500 BOSCAROL

Primary use Suction unit designed to remove secretions, blood and other body fluids, solid pieces of

food or tissue in the medical field

Other uses The device can also be used as a pump to evacuate mattresses and vacuum splints (but

must be used with the filter and suction jar)

Medical purpose Upper and lower airway suction

Part of application in

the human body

Upper airways: nose, nasal cavity, throat, mouth

Lower airways: larynx, trachea, bronchi

ED01_REV01-2021 IFU OB500_ENG

6- 32

Type of patients Babies, children and adults of both sexes

Time of application on

the same patient

< 60 minutes - Temporary use

Information on use

The suction unit can be used on all types of patients following the correct medical

technique.

Lower respiratory tract release should be performed by medical professionals and/or

healthcare personnel (including paramedics and rescuers) trained and authorised for such

actions.

Upper respiratory tract release should be performed by medical professionals and/or

healthcare personnel (including paramedics and rescuers) trained and authorised for such

actions. In some countries, this information should be verified according to protocols

implemented by local emergency health services.

Device application

sites in accordance

with the standard

ISO 10079-1:2019

The OB500 suction unit can be used as a stationary device in medical emergency vehicles.

As it has no internal power source it cannot be used in the field or outdoors.

2. WARNINGS, PRECAUTIONS AND IMPORTANT INFORMATION

Read carefully

These operating instructions have been prepared using simple, easy-to-understand language. If

you have difficulty in interpreting what is written, contact the manufacturer for further

clarification.

Phone +39 0471 93 28 93 info@boscarol.it

•Read these instructions carefully before using the device. Careful and correct use will ensure smooth

operation and protect both patients and operators.

•The suction unit is designed exclusively to remove organic fluids (secretions) during medical procedures. For

this reason, it should only be used by trained personnel.

•Never use the suction unit in the presence of flammable and/or explosive liquids, gases and anaesthetic

mixtures as this may lead to explosions and/or fires.

•If aspiration is performed without the suction jar and/or without the antibacterial filter, or if it is suspected

that substances may have entered in the aspiration circuit (i.e. the OB500), contact the nearest service

centre or the manufacturer immediately to have the device checked.

•Do not spray substances onto the device. Before cleaning, make sure that the suction hole to the device is

closed (apply a piece of tape or connect the tube of the suction jar).

•The OB500 suction unit does not require any maintenance by the operator. The only authorised operations

are those listed in these operating instructions. For technical assistance, periodic inspection and repairs,

contact the authorised service centre or the manufacturer.

•The manufacturer provides authorised personnel, who have followed a specific technical training course,

with the documentation and tools required to carry out service operations (service manual).

•To ensure patient safety, the accuracy of the displayed values and correct functionality, use only original

spare parts. The operator assumes responsibility for any injury to the patient or damage to property if this

is not observed.

•The OB500 suction unit in all its variants does not perform diagnostic functions on the patient.

•An excessive increase in the internal temperature of the device can automatically interrupt the operation of

the device to prevent damage to the suction pump.

ED01_REV01-2021 IFU OB500_ENG

7- 32

LATEX

The OB500 device is designed and manufactured without the use of latex. However, it cannot be

ruled out that latex may have come into contact with it during the production chain.

DEVICE

CONTAMINATE

•Warning: Device contamination. If you use the suction unit according to these instructions,

with the original collection container and the bacterial filter, the circuit of the suction unit will

not be contaminated. However, if aspirated substances have entered the device, the suction

unit must be immediately removed from service. Sending a contaminated suction unit to the

manufacturer, installer or service centre is strictly prohibited. The risk of spreading pandemics

is high and must be avoided.

•Any device received in this condition will be rejected and the health authorities will be alerted

to the risk of possible contamination. In this case, the term contaminated indicates a suction

unit that has not been cleaned and disinfected from the secretions aspirated by the patient. If

aspirated substances have entered the suction unit, it must be demolished. For Boscarol, the

safety of its employees and the staff of the authorised service centre is of paramount

importance. If the suction units are contaminated, they may not be dismantled according to

the WEEE (Waste Electrical and Electronic Equipment) directive, leading to a possible risk of

infection (application of international worker protection law, where applicable).

•If you have any doubts, please contact Boscarol's technical service before sending a device in

for repair by sending an e-mail to info@boscarol.it or calling +39 0471 932893

REUSE OF

DISPOSABLE

PARTS

•Caution: Reuse of disposable parts may impair the functionality of the suction unit and be a

direct or indirect source of contamination of the operator and patient.

•Sterilisation and/or cleaning of disposable parts (anti-bacterial filters, suction tubes, Yankauer

suction catheters, etc.) can cause structural damage such that they lose their mechanical

integrity.

3. IMPORTANT INFORMATION TO KNOW BEFORE USE

The suction unit has been designed and tested according to the latest legal and regulatory standards. If the suction

unit is connected to a non-compliant electrical system and/or if the installation work is not carried out by specialised

personnel, both the suction unit and the electrical system may be damaged. Always consult a qualified technician

who is aware of all legal and regulatory aspects involved in the process.

If the user or patient becomes aware of a danger in use, a side effect, an accident caused

by the device or a critical issue (operational and design) not covered in these instructions

for use, he must immediately report this to the manufacturer at the following e-mail

address: raq@boscarol.it

PERIODIC SAFETY

INSPECTION

Preventive maintenance and periodic safety inspection:

The suction unit must be checked at least once a day (functional check). The operator must

check the date of purchase and manufacture and arrange for a safety inspection to be carried

out by the service centre or manufacturer 24 months after the date of manufacture (see date

of manufacture on the label).

Responsibility

operators/users

•The OB500 suction unit is designed for emergency medical service and must therefore

be ready for use at any time and in any situation.

•Immediately replace any components/parts that are damaged, altered or missing and/or

suspected of malfunctioning of the suction unit. Always replace such parts with original

spare parts.

•Dispose of packaging in accordance with local regulations and ensure that it is out of the

reach of children.

ED01_REV01-2021 IFU OB500_ENG

8- 32

Intervention

of the overflow

valve

WHAT TO DO IF THE OVERFLOW VALVE TRIPS?

•Wear protective gloves, splash goggles and an FFP2 or FFP3 type mask.

•Switch off the suction unit and disconnect the silicone tube from the secretion container

to the device.

•Check whether the level of aspirated liquids has reached the maximum level in the

secretion container.

•Carefully remove the secretion container and store it in a safe place.

•Empt

y the secretion container safely by first removing the filter (which must be

discarded), then the lid. Empty the secretion container and carry out thorough cleaning

and disinfection (sterilisation if necessary).

•Clean and disinfect the device according to these operating instructions

4. CONTRAINDICATIONS (DO NOT USE FOR)

CONTRAINDICATIONS

•Low vacuum values, e.g. chest drainage or wound drainage in general

•Permanent endoscopic use

•Surgical rooms where potential equalisation is required (e.g. operating theatres for

heart surgery)

•Outside the medical field

•Extraction of flammable, corrosive or explosive substances

•Suction in explosive environments

5. SIDE EFFECTS (POSSIBLE DURING SUCTION OPERATIONS)

EFFECTS

COLLATERAL

•Bleeding in general in the nasal pharyngeal area. Also throat and tongue.

•Damage to the vocal cords

•Cardiovascular instability

•Side effects caused by vagus nerve stimulation

•Tachycardia caused by stress

•Choking, nausea, vomiting and coughing

•Respiratory tract infection (typical of hospitals)

•Convulsions by patients who tend to have cramps

SIDE EFFECTS

Attention: To minimise side effects, it is important to observe what is indicated in these

operating instructions

6. OB500 MEDICAL SUCTION UNIT

After receiving the device, make sure that all parts are present. All Boscarol suction units are assembled and ready for

use except for the antibacterial filter (in the version with reusable jar) which is not connected to the device (for transport

and storage reasons).

Package contents for FA version

1 OB500 suction unit complete with power cable

1 Vacuum control and regulation unit and connection to reusable jar

1 Reusable 1000 ml jar of Boscarol secretions complete with overflow valve in the lid

1 Antibacterial filter complete with silicone tube

1 Sterile Yankauer catheter (unassembled)

1 Ready-made power cable for SELV voltage (12÷15 Vdc)

1 Operating instructions in Italian or specific language depending on the destination and technical documentation

Package contents for LINER (SERRES®) version

1 OB500 suction unit complete with power cable

1 Vacuum control and regulating unit and jar connection with Serres® disposable bag

1 Serres® jar of secretions complete with Serres® disposable bag already inserted in the jar of secretions

1 Sterile Yankauer catheter (unassembled)

1 Ready-made power cable for SELV voltage (12÷15 Vdc)

ED01_REV01-2021 IFU OB500_ENG

9- 32

1 Operating instructions in Italian or specific language depending on the destination and technical documentation

Package contents for FM version with SERRES® disposable bag

1 OB500 suction unit complete with power cable

1 Vacuum control and regulating unit and jar connection with Serres® disposable bag

1 reusable 1000 ml jar of Boscarol complete with Serres® disposable bag already inserted in the jar of secretions

1 Sterile Yankauer catheter (unassembled)

1 Ready-made power cable for SELV voltage (12÷15 Vdc)

1 Operating instructions in Italian or specific language depending on the destination and technical documentation

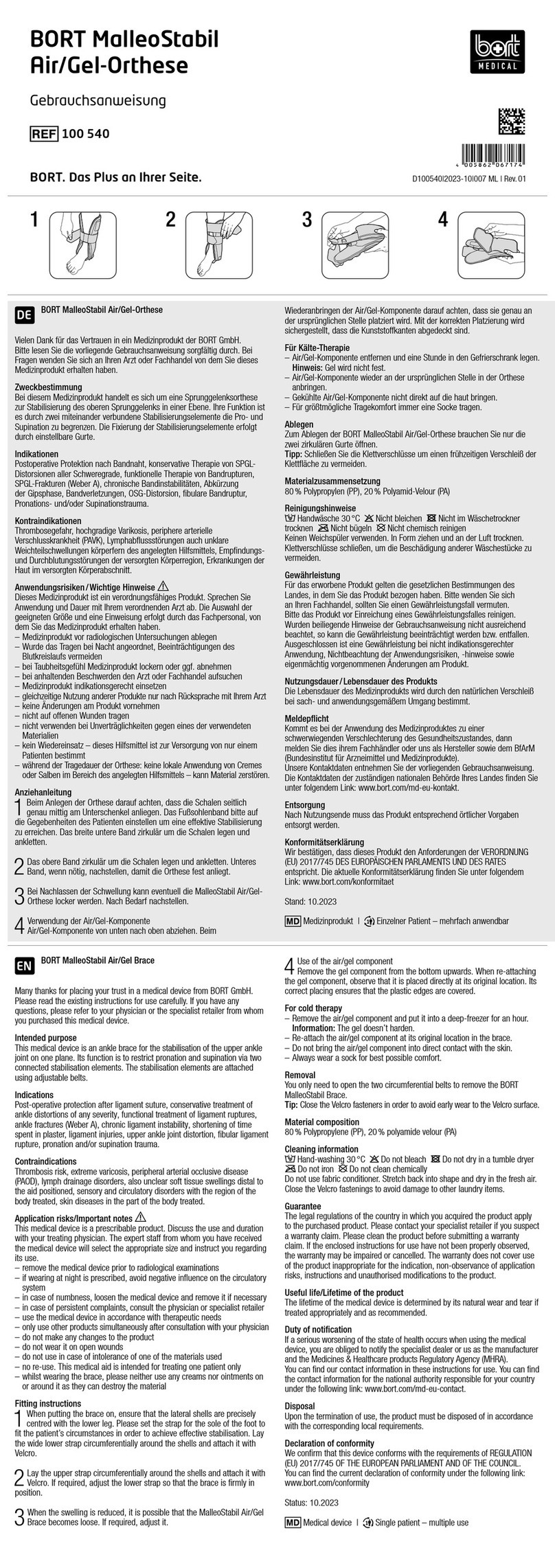

6.1. Description of OB500 suction unit

Model OB500 FA:

1. Suction unit

2. Vacuum regulation unit

3. Autoclavable jar OB-J FA

4. Jar holder

The versions alongside differ only in the

vacuum control module. The version with ABS

box is the only one that must be installed

above the ambulance wall. All other versions

are flush-mounted.

The vacuum control module consists of a

metal plate that can h

ave different

dimensions depending on the type of

ambulance.

In the version with the plastic module, all

connection pipes are visible. In the other

models they are concealed under the wall of

the vehicle.

All these versions are equipped with the

reusable (autoclavable) OB-J FA 1000 ml jar.

The jar is equipped with an overflow valve and

an antibacterial filter on the lid (not visible in

the picture opposite).

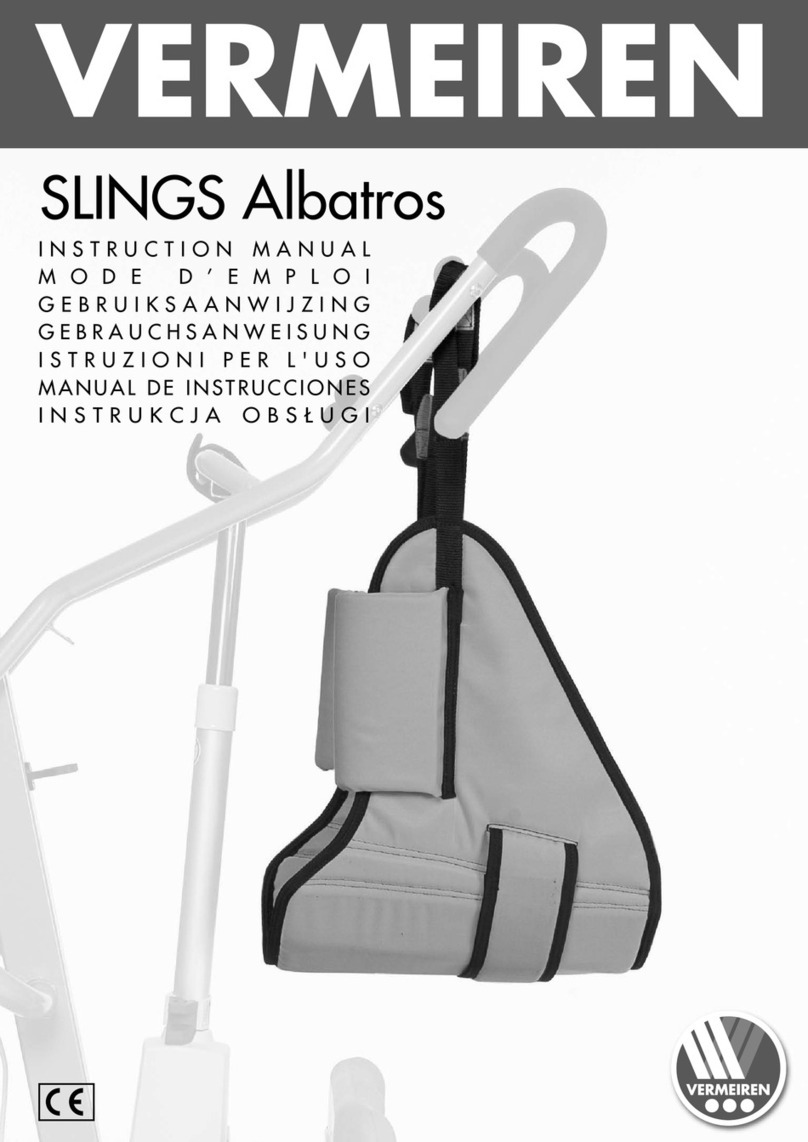

Model OB500 LINER:

1. Suction unit

2. Vacuum regulation unit

3. SERRES® jar

4. SERRES® disposable bag

The versions alongside differ only in the

vacuum control module. The version with ABS

box is the only one that must be installed

above the ambulance wall.

All other versions are flush-

mounted. The

vacuum control module consists of a metal

plate which can have different dimensions

depending on the type of ambulance.

In the version with the plastic module, all

connection pipes are visible. In the other

models they are concealed under the wall of

the vehicle.

All these versions use the reusable

(autoclavable) 1000 ml jar of the SERRES®

brand. They are equipped with a disposable

bag of the same brand. The antibacterial filter

is located in the lid of the disposable bag.

ED01_REV01-2021 IFU OB500_ENG

10- 32

Model OB500 FM:

1. Suction unit

2. Vacuum regulation unit

3. Jar OB-J

4. SERRES® disposable bag

The versions alongside differ only in the

vacuum control module. The version with ABS

box is the only one that must be installed

above the ambulance wall.

All other versions are flush-

mounted. The

vacuum control module consists of a metal

plate which can have different dimensions

depending on the type of ambulance.

In the version with the plastic module, all

connection pipes are visible. In the other

models they are concealed under the wall of

the vehicle.

All these versions are equipped with the

reusable 1000 ml OB-J jar and the SERRES®

disposable bag. The antibacterial filter is

located in the lid of the disposable bag.

PRELIMINARY

INSPECTION

Upon receipt of the device, inspect all parts contained in the packaging and verify their

integrity. Do not use the device if any parts are missing or damaged.

The OB500 suction unit is an active medical device that complies with all relevant standards.

It is used in rescue vehicles in general to clear the airways. Manufactured and marketed in kit form, its flexibility makes

it easy to install. The suction unit can be installed in inaccessible spaces (e.g. under a seat or cabinet), while the

adjustment block (together with the jar holder bracket) can be installed in the immediate vicinity of the patient

stretcher. The suction unit is electrically secured and must be connected to the vehicle's power supply circuit (12 VDC).

The device complies with the general standard ISO 10079-1 and is not transportable. OB500 is not equipped with an

internal battery.

The OB500 is available in a number of variants that allow it to be fitted separately in various types of ambulances, while

maintaining performance and compliance.

With the exception of consumables and spare parts, the OB500 has no accessories. Please consult the

manufacturer in case of further clarifications by sending an email to info@boscarol.it.

6.2. Controls, operation and control panel

All the controls for operating the device (except the operating switch, which is the responsibility of the installer) are

located on the front side of the control block. The device can be operated by means of an external switch provided in

the ambulance. The suction block has no controls or vacuum measuring instruments and is normally located in a remote

position from the control module and the jar.

The regulating block for external wall mounting is supplied ready to use and consists of a

plastic container (white ABS), a vacuum gauge and a vacuum regulator. The plastic material

is self-extinguishing and UL V0 grade.

The enclosure has two holes that allow it to be fixed to the wall with specific screws.

Vacuum adjustment is possible by means of a knob. By turning it clockwise, the maximum

vacuum value is reached (as indicated by the silk screen). The vacuum value achieved can

be measured using the analogue instrument and is expressed in millibar (mbar) and in kilo-

pascals (kPa).

In the adjacent drawing, the word "IN" indicates the connection to the pump-motor block,

which can be fixed in another position.

IN

ED01_REV01-2021 IFU OB500_ENG

11- 32

The flush-mounted version with metal plate has the

same controls: the vacuum gauge, the vacuum

regulator operated by the knob and the outlet to

the suction jar. The connection to the pump-motor

block is possible by connecting the hose on the rear

side (see figure opposite). This also applies to the

version with a rectangular cover.

Indicator lights on

the device

The device does not have indicator lights because the power switch is normally located in an

ambulance control unit or set of controls. Depending on the ambulance model and the type

of control, the indicator light may be directly installed in the switch or in the central display

showing the activation of the various devices.

Installing the module

Before attaching the module to the wall, check whether there are any electrical cables or

pneumatic tubes under the wall! After installing the control module, connect the pipe coming

from the suction unit to the top connector (version with external module) or rear connector

(in the case of a flush-mounted version).

6.3. Motor block unit (suction pump)

The suction unit consists of a shock-proof and fire-resistant ABS plastic housing (UL-V0 grade) and a suction pump. It is

equipped with a detachable power cable and a plastic connection for connecting the pneumatic tube to the control

module. The installation in the vehicle can be made on the floor or on the wall, by means of angle brackets fixed

appropriately (not included in the kit). Do not pierce the container of the suction unit, without first making sure not to

damage the internal parts. If necessary, unscrew the four screws that block the cover and identify the free spaces for

fixing. Do not use adhesives or mastics to fix the suction unit to the floor. Always check that the vent holes are not

obstructed. When removing the cover, make sure that the gasket is not damaged when closing it. Never install the unit

near sources of excessive heat, and/or near electric ventilation heaters. Do not install the unit in inaccessible parts of

the vehicle or where ventilation could be impaired. The unit should be easily removable for safety inspections and in

case of failure.

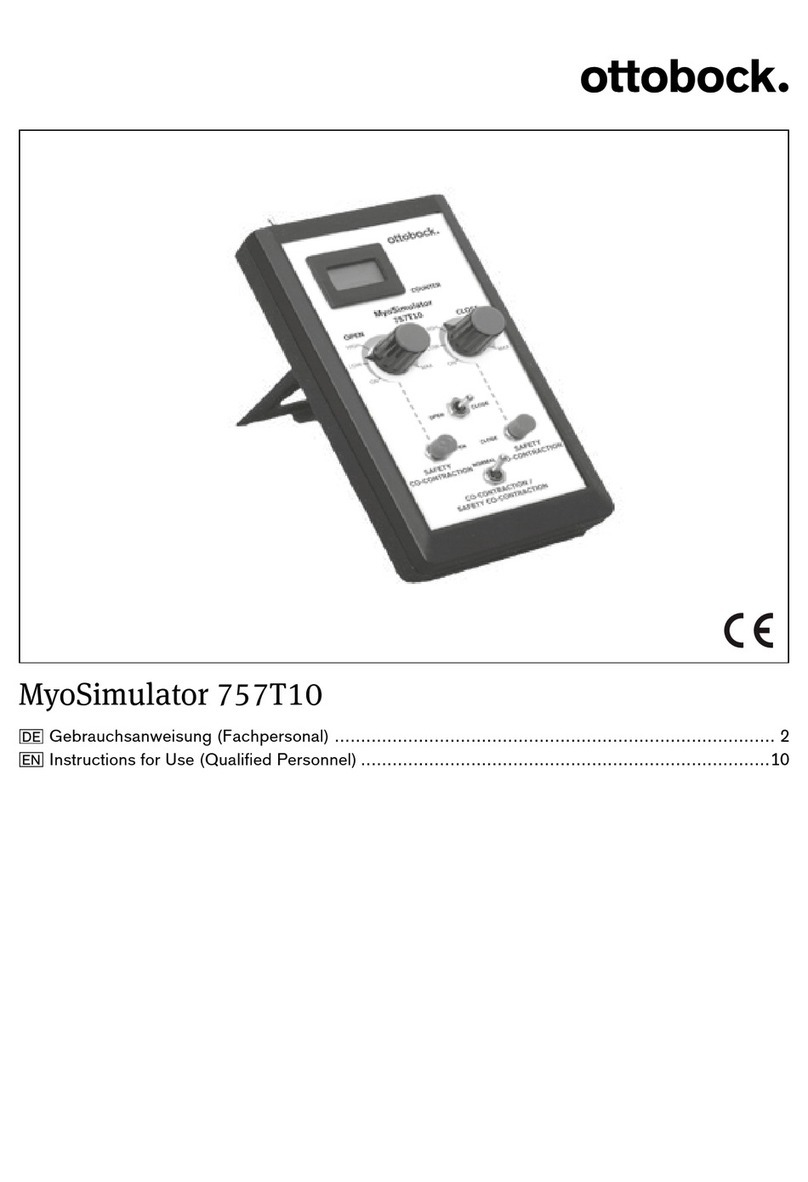

Installation of

the suction

pump

The picture opposite shows the

suction unit and the areas (green)

where metal brackets can be fixed

for installation in specific areas of

the rescue vehicle. Avoid the

connection area, as this can damage

the connectors and the electrical

connection.

Installation

easy

The suction unit is identical for all OB500 variants. Remember that since the unit must be

subjected to periodic inspections, it must be installed in such a way that it can be easily

inspected, checked and, if necessary, removed.

6.4. Electrical connections of the engine block unit (suction pump)

The suction unit is designed and built to be connected to the electrical system of the rescue vehicle. Normally such

vehicles have special connection and protection systems in accordance with the law. Remember to connect the device

to a suitable source of available current. Protection of the device by means of electrical safety devices is always

mandatory. A non-compliant cable section would produce a voltage drop that would not allow the suction unit to work

effectively and in compliance.

Towards the bottle of

Towards the pump-motor

ED01_REV01-2021 IFU OB500_ENG

12- 32

Refer to international and local standards for vehicle installations. The power supply connections for

the device are shown in the figure on the next page. The cross-section of the power source wires must

not be less than 1 mm² per wire. Do not connect the negative to the vehicle's housing, but to a

common point provided by the vehicle's electrical system.

Electrical

safety

Interpose a fuse on the positive side of the intake unit power cable. If

connected to a protected control unit, use at least one 15 A fuse to

prevent tripping during engine start-up.

Electrical

connections

Use the supplied cable for the electrical wiring of the suction unit. The

cable has two electrical wires which are coloured brown and blue. The

brown wire is connected to the 12 V positive (+).

6.5. Periodic test of OB500 suction unit (all variants)

In order to ensure proper functioning of the device, two types of periodic tests are foreseen:

the first should be on a daily basis to ensure the efficiency of the device, the absence of mechanical anomalies,

breakage of the external plastic casing and correct functioning

and the second half-yearly/annually to enable the full functionality of the device to be assessed and therefore

its compliance. These times should be reduced in case of heavy use, use in severe conditions and/or outside

the recommended limits.

The daily test allows you to check (quickly) whether the device is suitable for use in the field and includes functional

checks that can be completed in a maximum of 5 minutes.

6.5.1. Daily periodic test of the OB500 suction unit (valid for all variants)

DAILY TEST

•Stand in front of the suction control unit.

•Switch on the suction unit with the switch provided (depending on the type of installation on

the rescue vehicle). The suction unit should run smoothly and you should not hear any changes

in the speed of the external pump. You should not hear any unusual noise and/or abnormal

vibrations (however, this depends on where the suction unit is installed, which may dampen the

noise generated).

•Close the vacuum regulator completely (by turning it clockwise) and squeeze the silicone tubing

towards the suction jar (before the reusable OB-J jar filter) or before the connection to the jar

if SERRES® disposable bags are used. The noise generated by the pump should change and the

reading on the vacuum gauge should reach the maximum value (approximately 800 mbar, 80

kPa, 600 mmHg) in a few seconds.

•While holding the tube, turn the vacuum regulator anti-clockwise and check the reading on the

instrument to ensure that the suction falls to almost 0 (40-50 mbar due to the filter).

•Switch off the suction unit and check that all parts are intact (knob, pressure gauge, fittings,

etc.).

•Check that the filter is clean and not contaminated. If the filter is not white, it must be replaced.

A dirty filter prevents the suction unit from working properly and reduces its performance by

increasing the risk of contamination. Do not use the suction unit without a filter.

•Check that all disposable parts have been replaced and that the jar is clean.

At the end of the test operations compare them with the values in the table below:

ED01_REV01-2021 IFU OB500_ENG

13- 32

Test phase

Test result

Recommended action with negative outcome

Checking pump operation

Uniform engine noise, no rpm

drops, no abnormal vibration

Uneven noise indicates a fault in the pump operation. A drop in

speed indicates insufficient current to operate the motor

correctly.

Check for maximum

suction by occluding the

tubing from the filter or

disposable bag to the

device with your fingers

The maximum vacuum value

readable on the vacuum gauge

should be around 800 mbar (±10

%).

If this value is not reached, close the vacuum regulator

completely by turning the knob clockwise. Check that the

occlusion exerted on the tube is complete. If this is not the case,

do not use the device and contact the authorised service centre.

Setting the maximum

vacuum value

Value between approximately 0

and maximum by turning the knob

If the vacuum value cannot be adjusted, contact the authorised

service centre. Remove the device from use

If one or more tests fail, even after carrying out the recommended actions, request the intervention of

an authorised technician or contact the manufacturer for a full field check.

6.5.2. Periodic six-monthly/annual test of OB500 suction unit (valid for all variants)

This test is used to check whether the device conforms to the original manufacturing characteristics and is therefore

suitable for use in the field. The checks and controls should be carried out by persons and/or companies specialised in

this type of operation on medical devices and must have been instructed/authorised by the manufacturer. Following

the inspection, an electrical safety test in accordance with IEC 60601-1 should be performed and a test summary

document made available to the user.

SIX-

MONTHLY

OR

ANNUAL

TEST

•Replace the SERRES® disposable bag or antibacterial filter before performing these operations.

•Check the connection of the electrical cables to the motor block.

•Check the operation of the internal pump by operating the vacuum. The maximum vacuum value

must be between a minimum of 730 mbar and 880 mbar. Use a precision vacuum gauge to

measure this value (tolerance ±2.5 % or less). There should be no operational anomalies such as

unusual noise, rpm fluctuations, excessive gauge hand movement, and operation of the vacuum

regulator knob should be linear and unobstructed.

•Check the vacuum regulator which should operate from minimum to maximum. Turn the knob

clockwise and anticlockwise. When the regulator is fully open, it is normal to measure a small

vacuum value (introduced by the antibacterial filter).

•Check the control and suction unit for structural damage (ask the installer for the location of access

to this unit or consult the technical documentation of the vehicle). All plastic containers must be

intact and not deformed.

•Check that all labels and screen prints are present and legible.

•Never open the suction unit for any reason. For technical assistance, contact only one of the

authorised service centres listed available by the manufacturer.

•Check the function of the vacuum gauge. When the vacuum unit is switched off, the needle should

be at "0".

•Check that the suction jar is intact and that there are no cracks or breaks that could impair suction.

Penetration of liquids or solids may damage the unit and make it unsafe for operators and patients

(running mechanical parts).

•Check that the jar holder is fixed to the wall and in a vertical position. If the jar is tilted more than

20° from the vertical, the overflow valve may be triggered.

•Before declaring the suction unit compliant with the manufacturer's data plate, carry out an

electrical safety test according to IEC60601-1 with a specific safety analyser

. Contact the

manufacturer or the authorised service centre for information on how to carry out this test.

ED01_REV01-2021 IFU OB500_ENG

14- 32

DEVICE

COMPLIANCE

Only use consumable or spare parts supplied by the manufacturer. Do not use similar or

apparently identical components. The conformity of the component can only be confirmed by the

manufacturer.

Keep a document confirming that all checks have been carried out and, if possible, a photographic

report on the condition of the device before and after the check. Always also keep a copy of the

safety report carried out with the appropriate calibrated instrument.

If you have any doubts or concerns regarding the conduct of the tests, please always contact the manufacturer of the

device or its authorised service centre. If you fail even a single test, please contact a service centre or the manufacturer.

Do not use the device if you have not passed all tests.

For further information please call +39 0471 932893 or send an e-mail to info@boscarol.it.

6.6. Safety information for the safety of users, patients and third parties

To avoid unwanted effects and risks, always follow the information below:

•Do not take unnecessary risks: always replace defective parts to ensure that the device is always efficient in case

of use and emergency.

•We recommend another suction unit in case this one does not work or is defective (e.g. manual suction unit).

•Always bear in mind what is stated in the initial warnings regarding the risks arising from the effects of magnetic

fields (EMC).

•Always select the appropriate level of vacuum according to the patient and medical guidelines.

•Do not alter or modify the medical device. Serious consequences for the patient and the user may occur.

•OB500 (all variants) is not a sterile device and cannot be sterilised with the exception of the suction jar and silicone

tubing.

•Keep children away from hoses and connecting cables. Also keep them away from small parts.

Risk of infection

•Improper use of the device can lead to transmission of infections, even fatal ones.

•Always wear disposable gloves, especially if there is a risk of coming into contact with aspirated secretions.

•Never use components marked disposable more than once. Disposable parts or medical devices are marked

as in the figure opposite (number 2 crossed out).

•Never use the device without the bacterial filter.

•Always use only original accessories and original spare parts.

Attention

Assembly, repairs and modifications to the device are prohibited and may only be carried out by the

manufacturer or authorised personnel.

7. SUCTION JARS FOR OB500 (all variants)

The device is marketed with two different types of jars with a capacity of 1000 ml:

•Suction unit with autoclavable suction jar (OB500 FA).

•Suction unit with suction jar equipped with disposable bag (OB500 FM and OB500 LINER)

ED01_REV01-2021 IFU OB500_ENG

15- 32

7.1. Autoclavable secretion collection jar OB-J FA

The jar is made of transparent plastic (medical-grade polypropylene). It includes

the jar (1), the snap-on lid (2), the anti-reflux valve (3) and the 90° plastic

connection (4). The jar lid allows direct insertion of the antibacterial filter (from

the outside). The autoclavable jar can be sterilised conventionally in a steam

autoclave at a maximum temperature of 121° C and a pressure of 2 bar (200 kPa).

The jar must be replaced if it is deformed, broken or cracked. The suction jar must

be used vertically to prevent the anti-reflux valve from tripping. If the anti-reflux

valve is triggered, switch off the device and disconnect the tube connected to the

suction unit, remove the antibacterial filter to rebalance the pressure inside the

jar.

Service life OB-J FA

The jar of secretions must be replaced after 30 sterilisation cycles or 5 years from the

date of manufacture.

7.2. Antibacterial filter

The protective filter protects the suction circuit from any contaminants sucked

in during use. The filter is manufactured from hydrophobic PTFE material which

prevents fluids from entering the pneumatic circuit. Working in conjunction with

the overflow valve on the jar, the filter isolates the pneumatic suction pump

from gases and fluids. The filter is disposable and must be replaced after each

use

. In the event of contamination, discolouration and increased suction

resistance, it must always be replaced. The filter is not produced by the Boscarol

company.

Antibacterial

filter

If the device is used on patients where the infection status is unknown, always replace the filter

after use on the same patient. This will prevent even serious contamination of the environment

in which the device is placed and therefore of operators and patients. If, on the other hand, it is

known and/or there is no risk of indirect contamination, it is advisable to replace the filter after

each work shift or in any case when the suction level decreases or the filter changes colour.

Risk of infection

•

Never use the device without the antibacterial filter. Please always keep at least three spare

filters in case of emergency.

•Always wear gloves and personal protective equipment when changing the antibacterial filter

and emptying the suction jars.

•Before each use, check that the filter is dry and clean (it must not be any colour other than

white). Replace the wet or contaminated filter with a new one.

•Never reuse the antibacterial filter (disposable).

7.3. OB-J FM: jar of secretions for SERRES® disposable bags

The OB-J suction jar for SERRES® disposable bags is made of transparent plastic

(medical grade polypropylene). It comprises a container (1), a SERRES® disposable bag

adapter (2), a red 90 degree connector (3) and a SERRES® disposable bag (4). The

antibacterial filter is integrated in the lid of the disposable bag and prevents aspirated

fluids from entering the suction unit. The suction jar can be sterilised in a conventional

steam autoclave at a maximum temperature of 121° C and a pressure of 2 bar (200

kPa). The disposable bag must be replaced after use on the same patient or if it is full.

When used in a domestic environment, the jar of secretions can be cleaned using a

special detergent to ensure disinfection of medical devices. Contact Boscarol for

information on disinfectants.

ED01_REV01-2021 IFU OB500_ENG

16- 32

7.4. SERRES® jar for OB500 LINER

The SERRES® suction jar is suitable for disposable bags from the same manufacturer (as

for the OB-

J FM version) and is made of transparent plastic (polycarbonate). It

comprises a container (1), a grey movable connector for connection to the suction

control module (2) and a SERRES

® disposable bag (3) complete with disposable

connector (white in the picture). The antibacterial filter is integrated in the green lid of

the disposable bag and prevents aspirated fluids from entering the suction unit. The jar

of secretions (not the dispo

sable bag) can be sterilised in a conventional steam

autoclave at a maximum temperature of 121° C and a pressure of 2 bar (200 kPa). The

disposable bag must be replaced after use on the same patient or if it is full.

Risk of infection

•Please always keep at least three ® SERRES bags in reserve.

•Always wear gloves and personal protective equipment when

changing the SERRES® bag and for disposal.

•Before each use, check that the SERRES® container has not already

been used.

•Always replace the contaminated disposable bag with a new one.

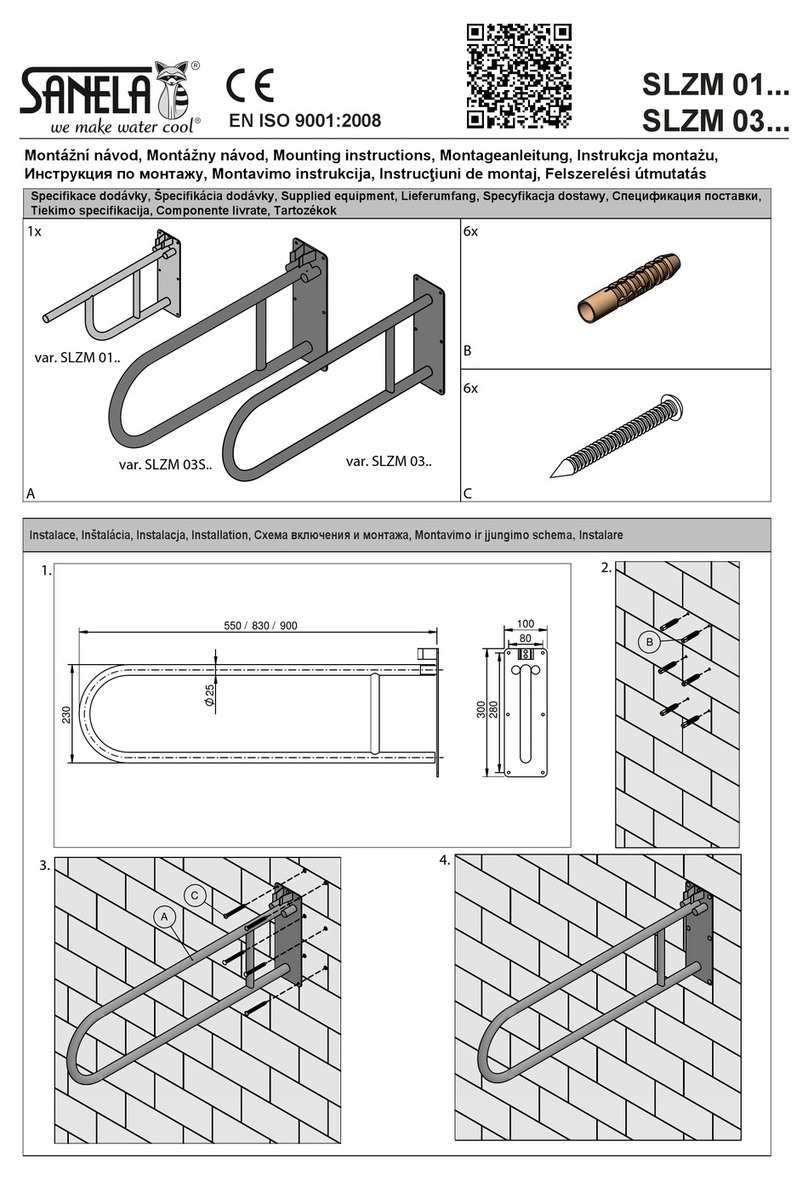

7.5. Secrets jar connection

The suction jar must be connected to the control unit module

(which can be recessed or fixed externally to the wall).

Depending on the version of the control module (external or flush-

mounted), the suction jar must be connected to the control unit via

the silicone tube from the jar. In the adjacent photos you can see

the OB-J FA suction jar connected to the external wall-mounted

module (photo A) and the pipe connection point in the built-in

version (photo B).

A

B

7.6. Sterile disposable Yankauer catheter with suction control system

OB500 is sold complete with a sterile Yankauer type suction catheter and two tubes for

connection from the jar to the regulating unit and from the regulating unit to the suction

unit respectively. The suction probe and catheter are disposable and must be changed after

each use. To facilitate correct operation, the tip of the rigid suction probe is angled so that

it can reach all parts of the mouth and upper airway. The rigid suction tip is spherical and

equipped with lateral holes to avoid damage to tissue during suction.

Yankauer

The Yankauer suction catheter is a sterile, single-use medical device. Never reuse this

device. It must be disposed of after use on the patient.

Caution! Never use sterile medical devices beyond their expiry date or if the packaging is

damaged.

Always connect the Yankauer catheter to the "PATIENT" side on the lid of the reusable jar (FA) or

SERRES® disposable bag via the white conical fitting.

7.7. Silicone suction tube and sterile Fingertip (conical fitting)

On request, the device can be equipped with a silicone patient tube (length: 130 cm) and

a sterile conical Fingertip fitting that allows the use of standard sterile catheters of an

appropriate size. The tube is reusable.

From the suction

jar

2

3

1

ED01_REV01-2021 IFU OB500_ENG

17- 32

The sterile Fingertip connection allows fingertip control of the suction value by

closing and opening the specific hole. The disposable devices supplied with the

suction unit

are identified with labels that provide all the necessary

information for correct use.

The Fingertip (also called catheter connector) allows you to

attach standard sterile catheters (see figure opposite).

7.8. Warnings concerning the re-use of single-use parts

Disposable

medical devices

Risk of infection

Caution: The suction unit is supplied with a number of sterile disposable accessories to facilitate

patient aspiration. These devices may not be used on more than one patient. Disposable medical

devices are made of materials to withstand limited use and must not be reused. The operator

must dispose of them properly and restore the medical device to make it efficient for the next

use. Reuse of single-use devices can be dangerous for both patient and operator and

may result in loss of performance and irreparable damage to the device.

SERRES® disposable

bag

The SERRES® disposable bag cannot and should not be emptied. The top cap is designed to allow

the extraction of secretion samples for laboratory analysis. Whenever the filter comes into

contact with fluids or liquids (of any kind), it is blocked and the bag must be replaced!

7.9. Support bracket for suction jar (wall mounting)

The OB500 FA and FM devices include a special metal bracket, which is required for wall

mounting of the suction jar. The bracket must be installed in such a way that the jar is kept

in a vertical position (maximum inclination ±20°).

The bracket is made of painted metal and has two holes for vertical and horizontal

adjustment. The ideal position, both for use and for cleaning and sterilisation, is under the

adjustment module. The

silicone tube, supplied with the device, can be shortened

appropriately, depending on the distance of the bracket from the module itself.

The OB500 Liner suction unit

includes a special original bracket produced by the

manufacturer SERRES® to fix the suction jar on the wall. The bracket must be installed in

such a way that the jar is kept in a vertical position (maximum inclination ±20°).

8. REUSE, CLEANING AND DISINFECTION

After each use, disconnect all disposable parts and dispose of them. Check the integrity of the jar, the connection tube

and check the state of cleanliness and contamination of the control unit. Clean and disinfect the suction unit as described

below. Replace all disposable parts and restore the functionality of the device. After conducting the reuse operations,

carry out the daily test as described in chapter § 6.5 Periodic test of the OB500 suction unit (all variants) for the daily

test. The decontamination process is always a process to be followed meticulously, which implies specific training,

especially in medical emergencies where the medical condition of the patient and the degree of contamination are

mostly unknown. For this reason, the operator must always wear personal protective equipment (PPE) to protect

themselves and others. If PPE is not available, please contact your safety representative.

Risk of infection

Always wear gloves and personal protective equipment when

changing the antibacterial filter and emptying the suction jars.

DANGER

Organic secretions collected in the suction jar can cause serious infections to the operator. For

this reason, always use PPE and disinfectants as recommended by the industry and competent

authorities.

ED01_REV01-2021 IFU OB500_ENG

18- 32

8.1. Re-use of OB-J FA suction jar

The steps required to separate the jar of secretions from the suction unit, disassemble it and assemble it after cleaning

and disinfection are described below. Before starting, wear protective gloves, also covering your forearms, mouth and

protecting your eyes.

Remove the antibacterial filter from the cover by turning it on its seat and

discard it.

Remove the lid from the jar by pressing lightly on the jar and levering the lid

flap. Empty the contents of the jar.

Remove the overflow valve from the lid.

Separate all the parts.

Parts that make up the lid:

•Polypropylene cage yellow

•Polypropylene float, yellow

•Red silicone gasket

•Red polypropylene lid

DANGER

Risk of infection due to leakage of potentially contaminated substances during emptying of

secretions. Possible transmission of life threatening infections. Always use suitable PPE and

disinfectants as stipulated by hospital regulations and the relevant authorities.

Beware of certain disinfectants that may stain the jar of secretions and its parts even without

damaging it.

8.2. Cleaning, disinfection and/or sterilisation of OB-J FA suction jar and silicone tube

The suction jar and the silicone tube can be cleaned with specific non-abrasive substances for cleaning medical devices.

Alcohol-based cleaning agents can be used if diluted appropriately (follow the instructions for use on the label of the

disinfectants). Avoid using coloured disinfectants as they may stain the plastic of the jar and the silicone tube, reducing

its transparency. After disposing of the disposable antibacterial filter and Yankauer suction catheter, complete with

tubing, place the reusable parts in warm water (temperature not exceeding 60°C to avoid scalding) containing a diluted

disinfectant for medical devices. Rinse thoroughly and, if necessary, use a non-abrasive brush to remove any deposits.

After washing, dry all parts. Refer to the cleaning and disinfection plan on the following pages. In the event of serious

contamination, always refer to the instructions of medical personnel and the competent authorities. If necessary,

sterilize "REUSABLE PARTS" (see above) with steam autoclaves at a maximum temperature of 121°C for a maximum of

15-20 minutes (typical cycle). Do not use autoclaves with pressures above 2 bar (200 kPa). The jar should be placed

vertically upside down. At the end of the cycle, allow the parts to cool to room temperature and check that they are

undamaged and not deformed.

ED01_REV01-2021 IFU OB500_ENG

19- 32

CYCLE OF

DISINFECTION

WARNINGS

•Do not spray liquids onto the device. Clean the device with the suction inlet closed. Place a

piece of tape or leave the suction jar connected to the unit.

•Do not use aldehyde and/or amine-based disinfectants to prevent discolouration.

•Use only disinfectants for cleaning medical devices. Before applying them to the surface of

the device and the suction jar, check at an angle for damage.

•Consult specialised personnel in hospitals and clinics. Check for specific disinfection and

cleaning plans and/or protocols for the area concerned.

STERILISATION

CYCLE

WARNINGS

•Never sterilise devices or parts that have not been previously cleaned.

•Do not place any weight on the parts or devices during the sterilisation cycle.

•Observe the maximum limits for temperature, pressure and sterilisation time (temperature:

121° C, pressure: 200 kPa, maximum time 15-20 minutes).

•Cleaning and/or sterilisation should only be carried out by qualified personnel.

•Replace the jar of secretion if it is cracked, fissured or even partially broken.

•After reassembling the jar, always check that the lid is fitted correctly to avoid loss of vacuum

and spillage of liquids or aspirated fluids.

•

Always follow the instructions provided by the autoclave manufacturer.

8.3. Jar assembly and connection of the silicone suction tube

Place all jar components on a flat, stable surface. During assembly and disassembly, always check all parts for damage

or deformation. The overfill valve has a float that slides on a plastic cage. Ensure that it moves inside unhindered (by

sliding it) and that the red silicone gasket is intact. Assemble the jar by proceeding in the opposite direction to that seen

above.

AFTER CLEANING

Warning

•Check, after each cleaning, whether the device and its parts are functional.

•If in doubt, send the device to the manufacturer or an authorised centre for review and

inspection.

•After the assembly process always carry out a function check as described in chapter § 6.5

Periodic test of the OB500 suction unit (all variants) of these operating instructions.

•Prepare the device for the next use.

8.4. Replacing the antibacterial filter

Carefully disconnect the silicone tube from the contaminated

filter. To easily remove the filter from the lid, proceed by screwing

and/or unscrewing it from its housing. This facilitates removal

from the lid and prevents it from breaking inside! Dispose of the

filter in accordance with local regulations for the disposal of

hospital waste.

Depending on our stock availability, we can supply two different

types of anti-bacterial filter: one has the inscription "IN" on the

side which must be connected to the vacuum socket on the lid.

The second one has a side with the inscription "PATIENT". Connect

this side to the "VACUUM" socket on the lid.

Failure to observe this detail may result in filter failure and

contamination of the suction unit's suction circuit.

ANTIBACTERIAL

FILTER

Attention

The filter must be inserted with the side marked "IN" or "PATIENT" facing the jar lid. Using the

suction unit with the filter inserted incorrectly may lead to contamination of the suction circuit.

Writing IN

PATIENT"

ED01_REV01-2021 IFU OB500_ENG

20- 32

8.5. Cleaning the suction jar (OB-J or SERRES®) with SERRES® disposable bags

The OB-J Liner or SERRES® version of the suction jar is equipped with a specific SERRES® brand disposable bag, which is

certified for this type of use. Unlike the OB-J FA version, the antibacterial filter is located inside the bag and is

automatically replaced after each bag change.

A number of safety precautions should be taken before removing the

disposable bag. Remove the Yankauer disposable catheter complete

with rigid probe. Always remember the risks of infection and

contamination

If the device is equipped with silicone tubing,

Fingertip conical fitting and suction catheter

proceed as follows:

•

Remove the disposable catheter

together with the conical connection

(see adjacent photo).

•Disconnect the silicone tubing from the

white plastic fitting on the SERRES® bag.

Discard the bag but keep th

e silicone

tubing as it can be reused, disinfected

and/or sterilised.

Remove the white 90-degree connector located on the

SERRES bag (if not already done) and close the inlet hole

(PATIENT) with the cap (see black arrow in the picture

opposite).

Remove the disposable bag (previously closed) from the jar and

dispose of it in accordance with official instructions for disposal of

contaminated waste.

Use your hand to operate the 90° connector on the jar and remove

the silicone tube (do not remove it!).

Silicone tube

Sterile

disposable

Sterile disposable

fingertip

REUSABLE

REUSABLE

This manual suits for next models

17

Table of contents

Other Boscarol Medical Equipment manuals

Boscarol

Boscarol OB 500 Series User manual

Boscarol

Boscarol IMM121640 User manual

Boscarol

Boscarol PAL32000 User manual

Boscarol

Boscarol OB 2012 FA User manual

Boscarol

Boscarol OB WB User manual

Boscarol

Boscarol OB OXIKIT PLUS User manual

Boscarol

Boscarol OB1000 Series User manual

Boscarol

Boscarol OB 2012 FA User manual

Boscarol

Boscarol OB 1000 User manual

Boscarol

Boscarol OB1000 FA User manual