BIKE SET-UP

FLOAT X

Setting Compression Damping on the Fox Float X

• Some Factory Series Float X features a blue low speed compression

adjustment knob, which can be used to fine tune the open mode of the

compression damping. This knob offers 10 additional fine tune adjustment

settings to the open mode.

• Turning the knob clockwise will increase low speed compression damping.

Turning the knob counter-clockwise will decrease low speed compression

damping. You can experiment with all of these options to find the setting that

provides the best compression support and plushest feel for your weight and

riding style.

• For a rider close to 100lbs, we recommend having the compression fully open, by

having the knob turned fully counter-clockwise. For riders 200lbs we like to start

at 3 clicks in from full closed as a good baseline setting. If the rider's weight is less

than 200lbs, open up compression damping 1 click counter-clockwise for every

10lbs. less. For every 10lbs over 200lbs we recommend increasing compression

damping by 1 click clockwise.

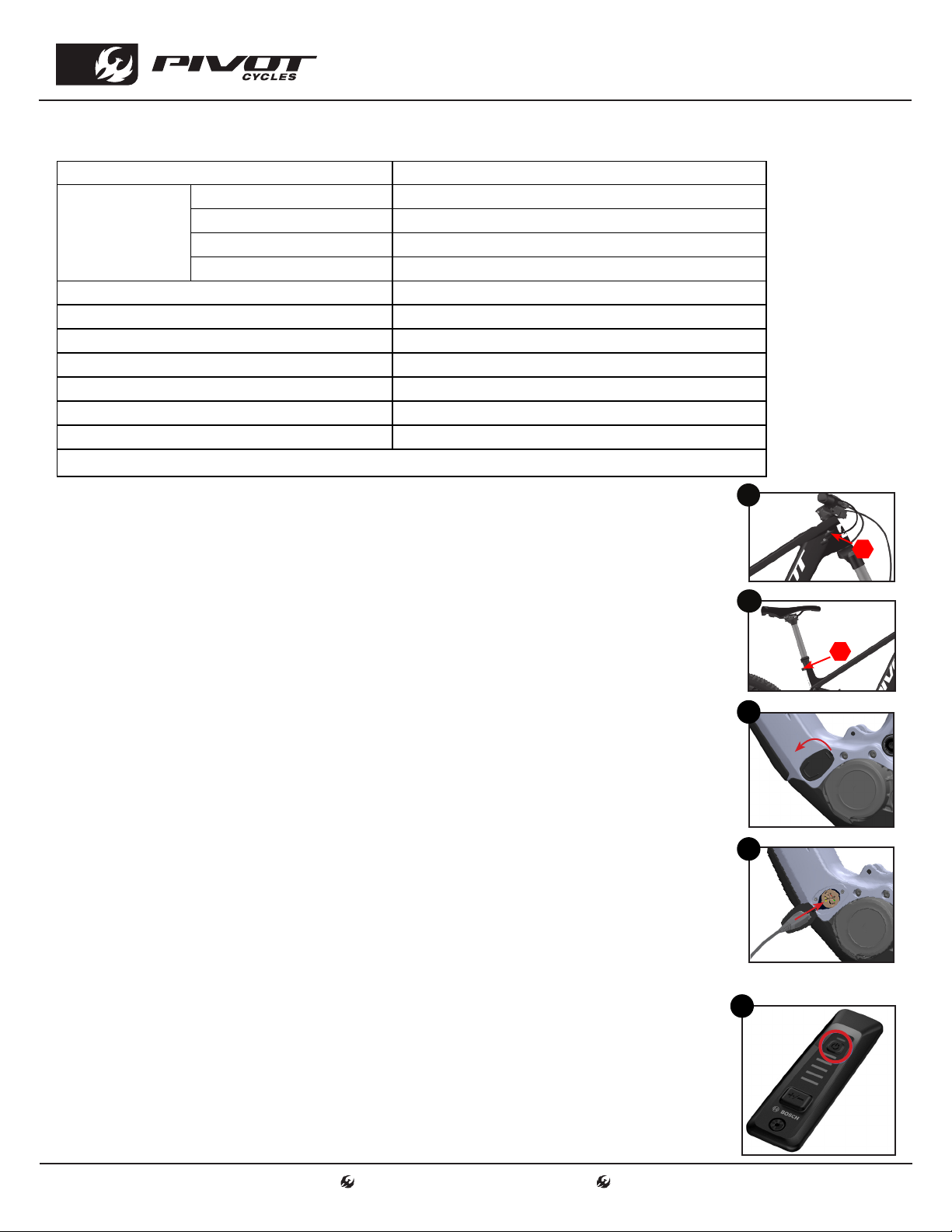

Using the Climb Switch on the Fox Float X

Some Float X shocks feature a two position lever allows for on-the-fly adjustment

between fully open and firm for climbing, As with other shocks, the firm setting is

best suited for long fire road climbs and smooth XC courses.

Setting Proper Sag

1. Always set sag with the blue climb switch lever to the

open position. (fig. 1)

2. If your shock has additional compression and rebound

adjustments ensure they are adjusted to be fully open,

compression to the softest setting, and rebound to its

fastest setting. Do this by rotating them fully counter-

clockwise.

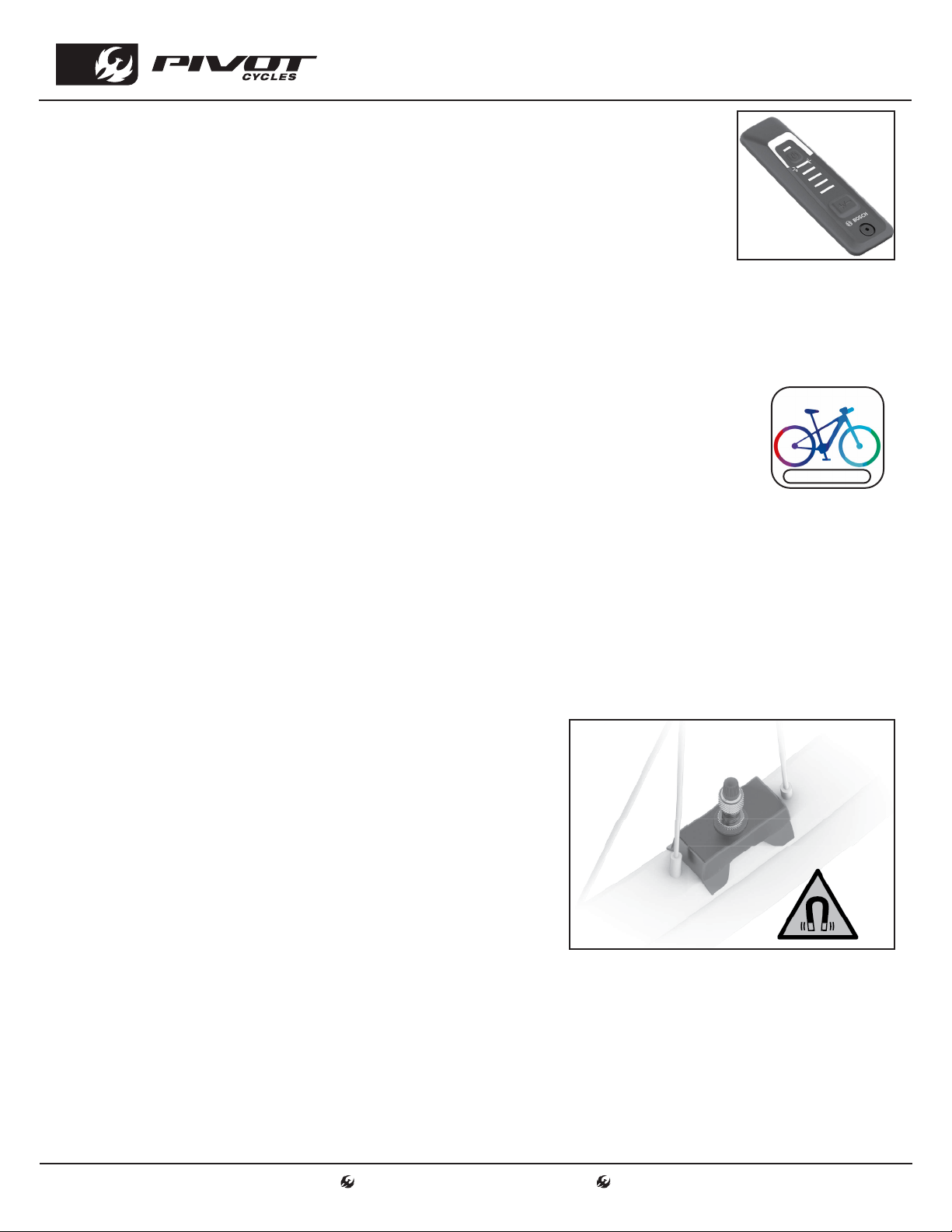

3. If it is not installed already, attach the sag indicator to

the bottom of the shock body using the provided zip-tie

and carefully cut the excess.(fig. 2)

4. Find a level surface and something to steady yourself

while mounted on the bike so you can be on the pedals

in a seated position. It may be easier to have a partner

hold your bike steady from the front, by holding the

handlebars while you are in your riding position.

5. While standing on the pedals, sit down hard into the

saddle to cycle the suspension well into the stroke.

This will ensure the bike comes to rest at the natural

sag setting with the rider in the saddle.

6. While in the saddle and not moving, slide the O-ring up

into position against the air can. (fig. 3)

7. Once the O-ring is set in place, slowly step off the bike

so as not to move the O-ring.

8. Make adjustments to the sag by removing or adding

air so that steps 4-7 result in the O-ring lining up with

the red line on the sag indicator. (fig. 4) When adjusting

air pressure in the shock, cycle the shock before re-

checking sag, so the large Evol negative air chamber equalizes pressure with the main chamber each time

air is added or removed. You can do this by pushing down on the saddle several times to compress the

shock past the sag point.

WARNING: Make sure the sag

indicator does not contact the

frame or linkage through the

suspension cycle. Otherwise,

the indicator may break while

riding.

CLIMB SWITCH OPEN

2 POSITION

LEVER

23

4

1

OPEN COMPRESSION

DAMPING

LOW SPEED

COMPRESSION KNOB