1 Safety measures

Page 2 / 10

EPA assembly line for DaeP

Assembly Station

VPP 21

Station x

Station 2

Station 3

Station 4

Station 5

Station 6

Station 7

Station 8

Station 9

Station 10

Station 11

Station 12

Station 13

Station 14

Station 15

Station 16

Station 17

Station 18

Station 19

Station 20

Station 21

Station 22

Station 23

Station 24

Station 25

Station 26

Station 27

Station 28

Station 29

Station 30

Station 31

Station 32

Station 33

Station 34

Station 35

Station 36

Station 37

Station 38

Station 39

Station 40

Station 50

Station 60

Station 70

Station 80

Station 90

Station 100

Station 110

Station 120

Station 130

Station 140

Station 150

Station 160

Station 170

Station 180

Station 190

Station 200

Station 210

Station 220

Station 230

Station 240

Station 250

Station 260

Station 270

M.3000314.190_0843.195.960 /

V0.0_0613_EN_PA--ATMO2

Robert Bosch GmbH

Intended use

Operation modes

Intended use

The station is exclusively designed to check the electronic control units

determined.

This is semi automatic machine with manual loading and unloading

operations.

After the screwing operation is completed, the WT is manually pushed out

of the station.

Any other or further use of the machine as for example the processing of

products not listed in the order confirmation as well as operating with

dangerous or hazardous substances is contrary to the regulations.For

damage resulting from use contrary to regulations the operator assumes

liability.

Notice!

Installation, startup and maintenance must be carried out as described in

this manual. This is also part of a Intended use of the machine according to

the regulations.

Non-permissible modes of operation

It is not allowed to operate the machine

dwith power sources, products, operating means, auxiliary means etc.

that are listed in a decree on hazardous substances or that have any

effect on the health of the operating personnel

dwith a machine/plant altered by the operator

dThe processing of types not listed under “Permissible modes of

operation” is not permitted. The manufacturer does not assume any

liability in this case.

dIf there is a modification to the machine that is not agreed with us,

the CE conformity declaration shall lose its validity. The

manufacturer then rejects any liability whatsoever!

DANGER!

It is forbidden to remove, bypass or disable safety devices when operating

the machine.

Only authorized personnel trained for this work is allowed to bridge the

safety doors with the safety switch for maintenance and adjustment

purposes.

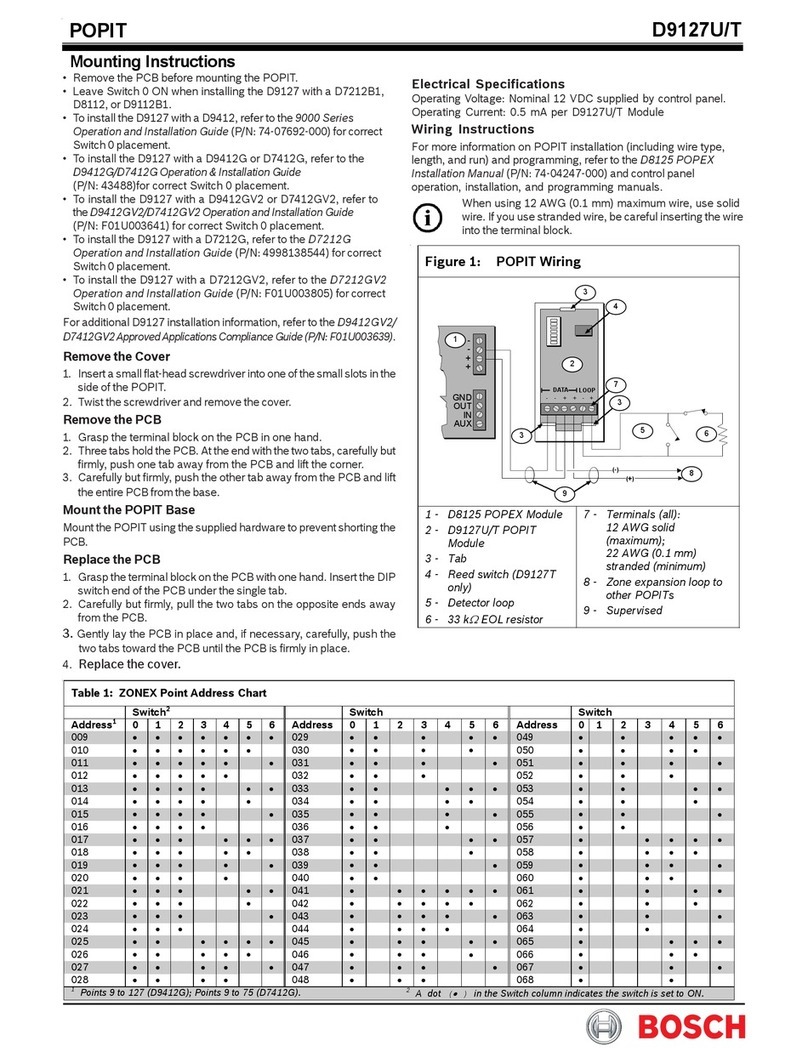

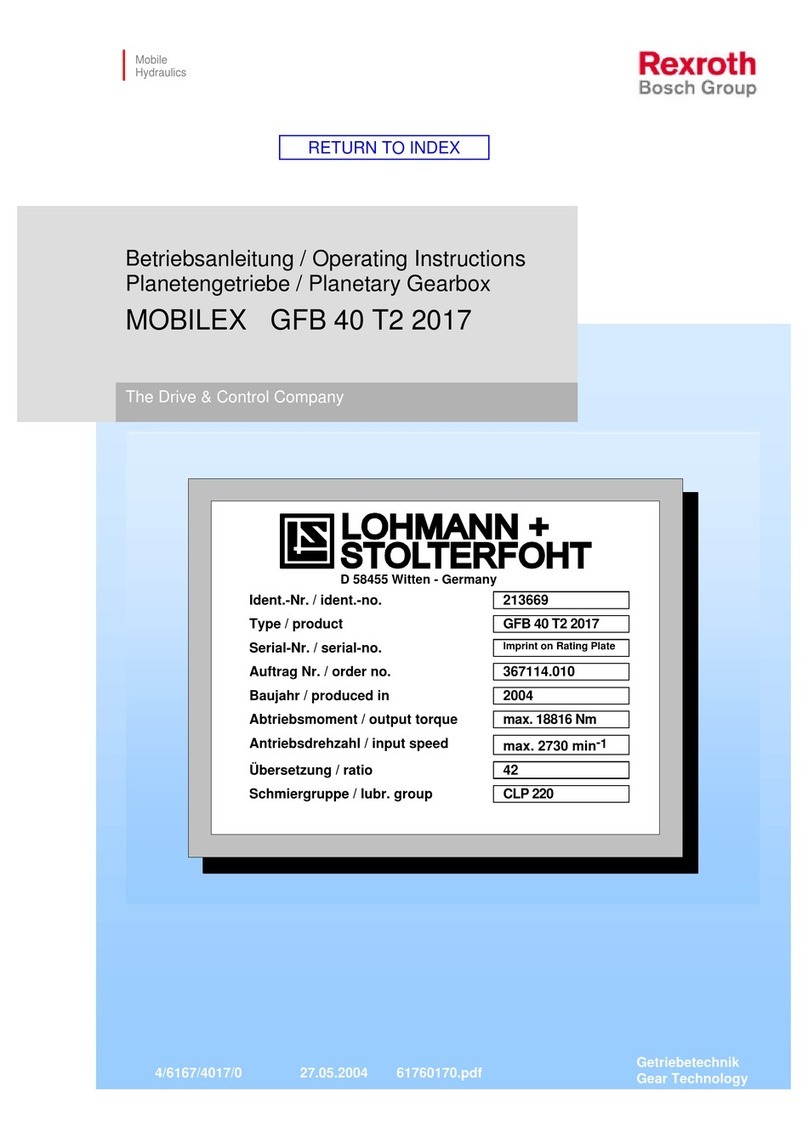

In the case of bought--in parts and outside makes that are installed in

the line, the respective manufacturers’ notices and operating

instructions must be observed!