Table of Contents

2

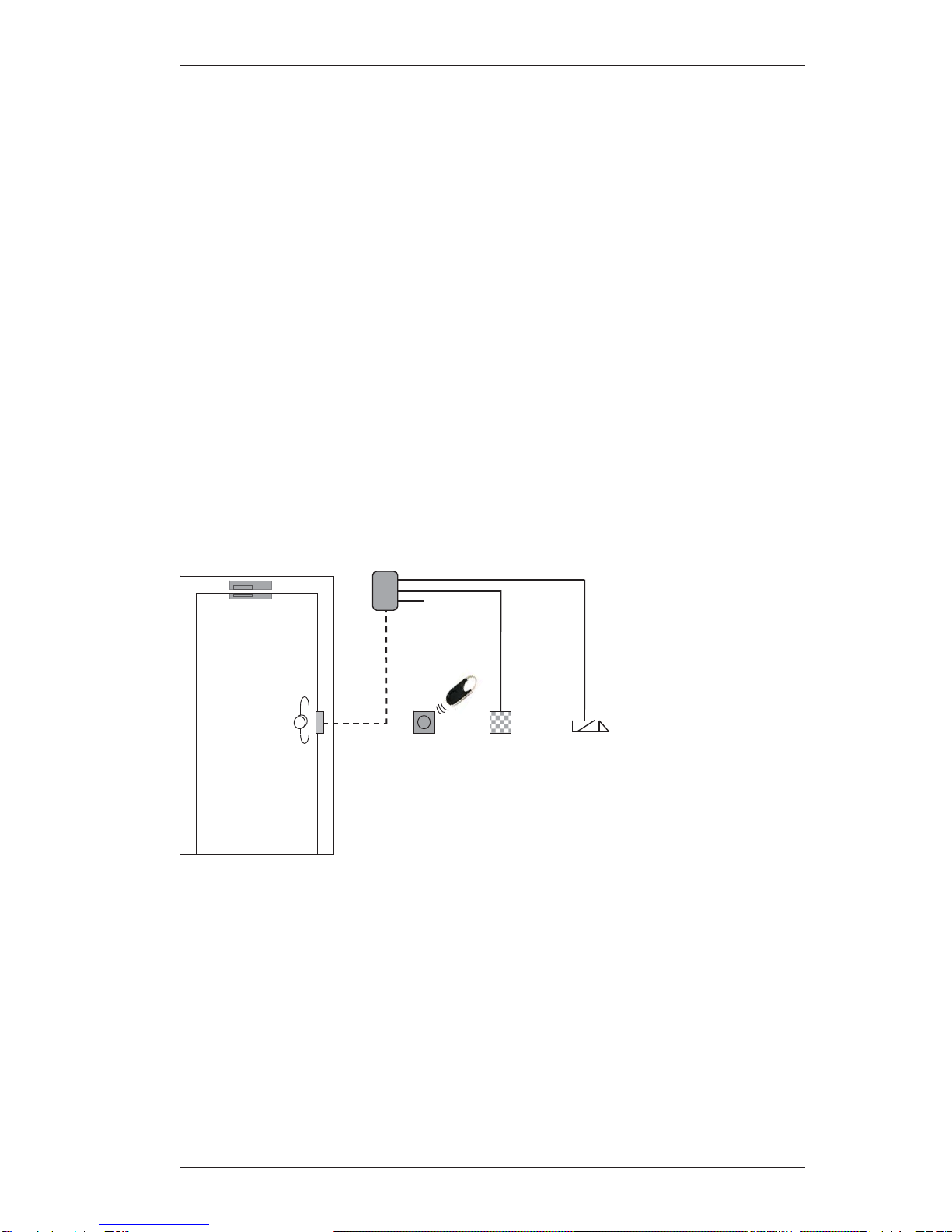

System Description

System Overview with Functional Variants................................................................................... 3

Description of the Connections on the Control Unit...................................................................... 6

Installation Instructions

Installing System Components...................................................................................................... 8

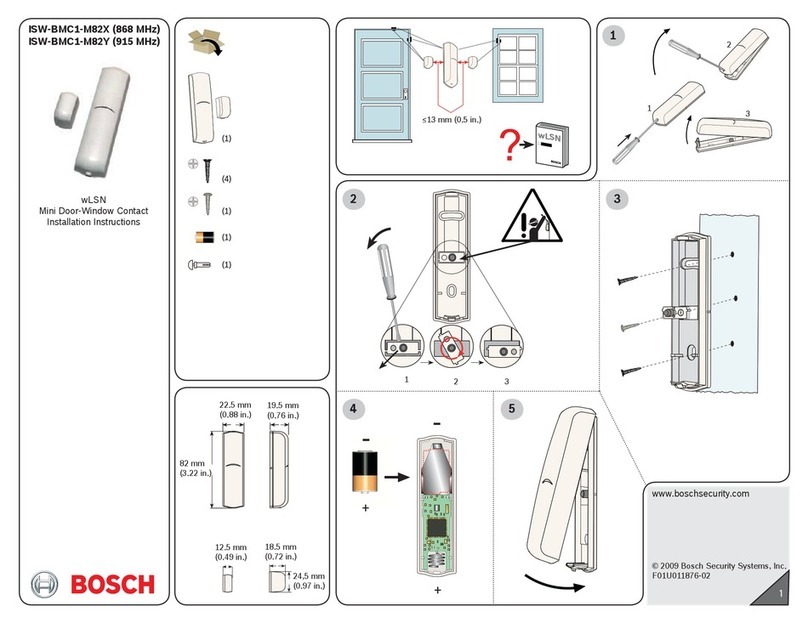

Installing the Magnetic Contact and Bolt Contact......................................................................... 9

Connection, Switch-Point Control, Address Switches ................................................................ 10

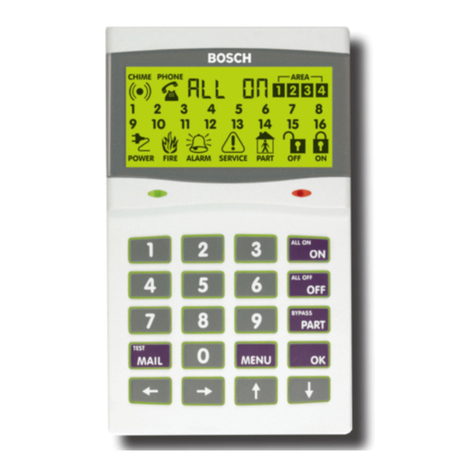

Connecting the Control Panel and Optional Components.......................................................... 11

Connecting for Operation Without an SPE Blocking Element .................................................... 12

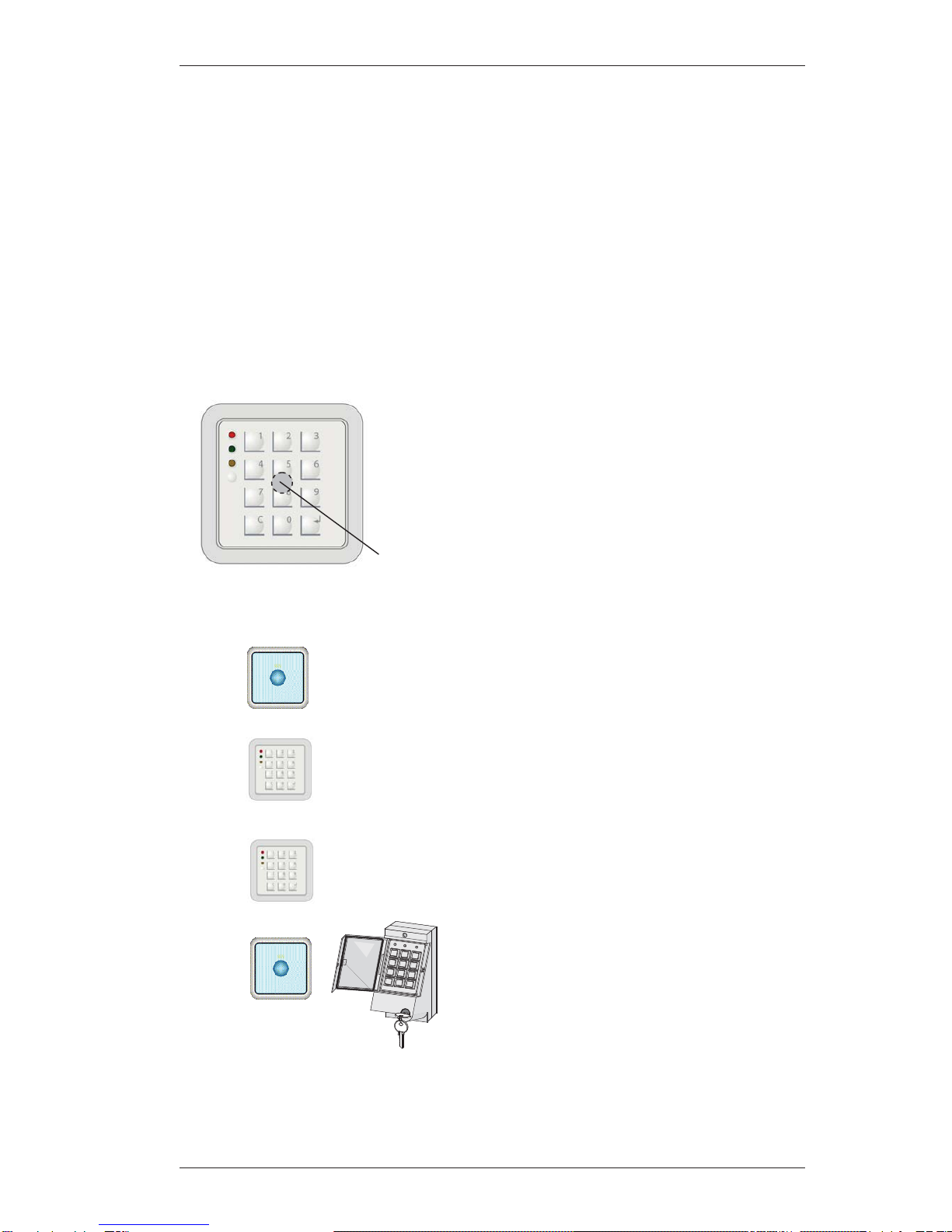

Connecting for Operation with SmartKey Code Keypad Only.................................................... 13

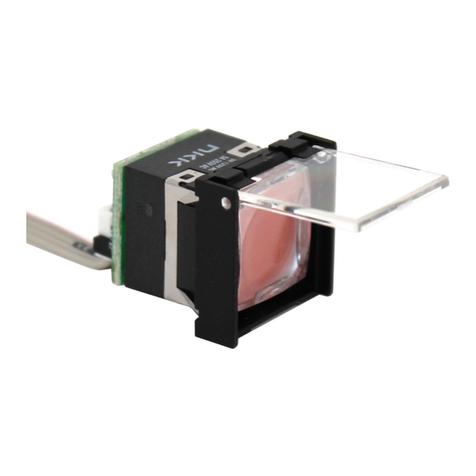

Connecting the SmartKey Code Keypad with Integrated Reader .............................................. 14

Connecting a Lockable Code Keypad......................................................................................... 15

Connecting a Door Opener Relay............................................................................................... 16

Connecting an E4.4 Blocking Element for Vault Doors .............................................................. 17

Connecting an E4.3 Blocking Element for Vault Doors .............................................................. 18

Function Test for SPE Blocking Element and Reader................................................................ 20

Reading In Keys and Programming the System......................................................................... 21

Starting up the SmartKey Code Keypad with Reader................................................................. 26

(or changing user codes)

Starting up the SmartKey Code Keypad Without Reader........................................................... 28

(or changing user codes)

Starting up a Lockable Code Keypad ......................................................................................... 30

(or changing user codes)

Concluding System Installation................................................................................................... 32

Operating the System

Viewing the System Status from the Reader.............................................................................. 33

Arming the System from the Reader or Code Keypad ............................................................... 34

Disarming the System from the Reader or Code Keypad........................................................... 35

Operation with SmartKey Code Keypad Only: Viewing the System Status................................ 36

Operation with SmartKey Code Keypad Only: Arming the System with the Code Keypad........ 36

Operation with SmartKey Code Keypad Only: Disarming the System with the Code Keypad... 37

Example of Operation with 4 SmartKeys/Code Keypads ........................................................... 38

Disarming for "Forced Unlocking and Alarm Display"................................................................. 38

Fault Elimination

Problems with Installation and Reading In Keys......................................................................... 39

Diagnostics Options on the Open Control Unit........................................................................... 39

Operating Problems During Normal Operation........................................................................... 40

Replacing the Bolt in the SPE Blocking Element........................................................................ 42

Notes for Maintenance and Service

General........................................................................................................................................ 43

Inspection and Maintenance....................................................................................................... 43

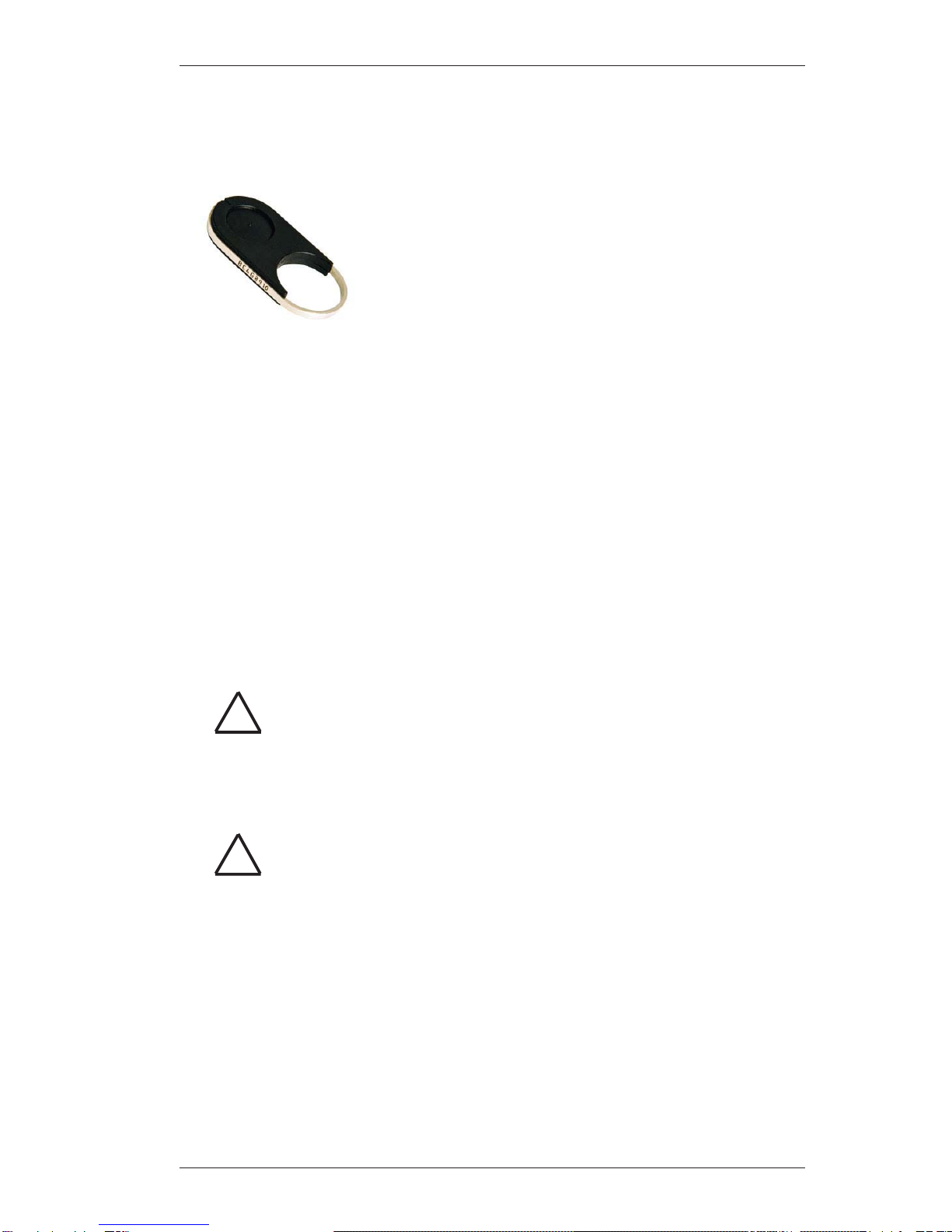

Loss of Keys................................................................................................................................ 44

Ordering Additional Keys ............................................................................................................ 44

Loss of the Security Card............................................................................................................ 45

Restoring the Default Settings .................................................................................................... 45

Technical Data........................................................................................................................... 46