7

HL2 Series

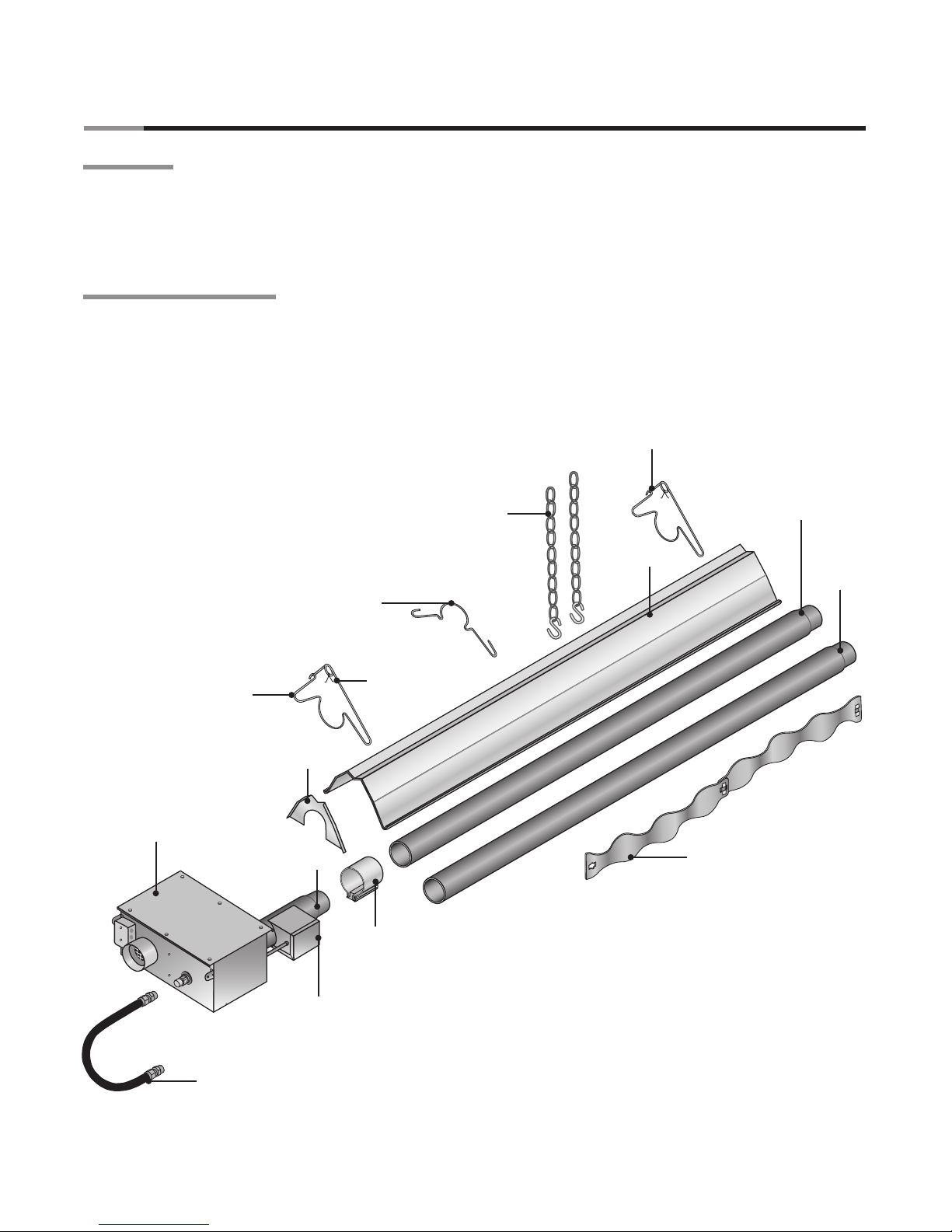

CLEARANCESTO COMBUSTIBLES IN. & CM / DÉGAGEMENTSAUXMATIÈRES COMBUSTIBLES PCE & CM

SAFETY INFORMATION / INFORMATIONS DE SÉCURITÉ

FAILURETO COMPLY WITH THE STATED

CLEARANCESTO COMBUSTIBLES

COULDRESULT IN PROPERTY DAMAGE,

PERSONALINJURY AND/OR DEATH.

LEDÉFAUT DE SE CONFORMER AUX DONNÉES DES

DÉGAGEMENTSAUX MATIÈRES INFLAMMABLES

PEUTRÉSULTER EN BLESSURES PERSONNELLES

ET/OUDOMMAGES SUR LA PROPRIÉTÉ.

WARNING AVERTISSEMENT

CAUTION:KEEP COVER IN PLACE. REMOVE FOR SERVICE ONLY.

ATTENTION:GARDER LE COUVERCLE EN PLACE. N’ENLEVER QUE POUR L’ENTRETIEN

TOP

FRONT BEHIND

BELOW

45°MOUNTING ANGLE

SIDE

SIDE

TOP

BELOW

0°W/2 SIDE SHIELDS

TOP

SIDE

BELOW

0°W/1 SIDE SHIELD

TOCEILING

BR-VCF

12 IN.or 30.5 cm

CLEARANCE

TOWALLOR

COMBUSTIBLES

20ft or 6.1m

DOWNSTREAM

&BEYOND

FIRST20 ft

or6.1 m

BURNER

MIN.12IN.or 30.5 cm

ENDCLEARANCE

TOP

SIDE SIDE

0°MOUNTING ANGLE

SIDE

BELOW

47

47

47

47

47

47

47

47

60

60

60

60

66

66

66

66

76

76

76

76

30

81

81

81

81

92

92

92

92

94

94

94

94

44

6

10

6

6

6

10

6

6

6

10

6

6

6

10

6

6

6

10

6

6

6

6

10

6

6

6

10

6

6

6

10

6

6

6

9

8

8

9

9

8

8

9

9

8

8

9

14

8

8

16

20

8

8

20

7

24

8

8

23

34

8

8

30

41

8

8

30

11

9

39

29

9

9

39

29

9

9

39

29

9

14

39

29

16

20

58

42

20

7

24

58

42

23

34

63

50

30

41

63

54

30

11

DX,AG1, SE -

50,000N or P

W/1SIDE SHIELD

W/2SIDE SHIELDS

DX,AG1, SE -

60,000N or P

W/1SIDE SHIELD

W/2SIDE SHIELDS

DX,HL, SE, ST,AG1, AG2 -

75,000 N or P

W/1SIDE SHIELD

W/2SIDE SHIELDS

DX,HL, SE, ST,AG1, AG2 -

100,000N or P

W/1SIDE SHIELD

W/2SIDE SHIELDS

DX,HL, SE, ST,AG1, AG2 -

125,000N or P

W/1SIDE SHIELD

W/2SIDE SHIELD

20ft or 6.1 m

DOWNSTREAM

OFBURNER

DX,HL, SE, ST,AG1, AG2 -

150,000N or P

W/1SIDE SHIELD

W/2SIDE SHIELDS

DX,HL, SE, ST -

175,000N or P

W/1SIDE SHIELD

W/2SIDE SHIELDS

DX,HL, SE, ST -

200,000N or P

W/1SIDE SHIELD

W/2SIDE SHIELDS

20ft or 6.1 m

DOWNSTREAM

OFBURNER

0°

45°

0°

0°

0°

45°

0°

0°

0°

45°

0°

0°

0°

45°

0°

0°

0°

45°

0°

0°

0°

0°

45°

0°

0°

0°

45°

0°

0°

0°

45°

0°

0°

0°

22.9

20.3

20.3

22.9

22.9

20.3

20.3

22.9

22.9

20.3

20.3

22.9

35.6

20.3

20.3

40.6

50.8

20.3

20.3

50.8

17.8

61

20.3

20.3

58.4

86.4

20.3

20.3

76.2

104.1

20.3

20.3

76.2

27.9

22.9

99.1

73.7

22.9

22.9

99.1

73.7

22.9

22.9

99.1

73.7

22.9

35.6

99.1

73.7

40.6

50.8

147.3

106.7

50.8

17.8

61

147.3

106.7

58.4

86.4

160

127

76.2

104.1

160

137.2

76.2

27.9

15.2

25.4

15.2

15.2

15.2

25.4

15.2

15.2

15.2

25.4

15.2

15.2

15.2

25.4

15.2

15.2

15.2

25.4

15.2

15.2

15.2

15.2

25.4

15.2

15.2

15.2

25.4

15.2

15.2

15.2

25.4

15.2

15.2

15.2

119.4

119.4

119.4

119.4

119.4

119.4

119.4

119.4

152.4

152.4

152.4

152.4

167.6

167.6

167.6

167.6

193

193

193

193

76.2

205.7

205.7

205.7

205.7

233.7

233.7

233.7

233.7

238.8

238.8

238.8

238.8

111.8

ANGLEDE

MONTAGE

ARRIÈRE AVANT

DESSUS

DESSOUS

CÔTE

MODÈLES

MOUNTING

ANGLE

BEHIND INFRONT

TOP

BELOW

SIDE

MODELNO.

UNITS DEGREES

IN.

PCE CM

IN.

PCE CM

IN.

PCE CM

IN.

PCE CM

MODEL /MODELE NO. INPUT BTU/H FOR USE WITH

NATURAL GAS

RADIATEUR A INFRAROUGE A FAIBLE INTENSITE

VOLTS A.C.

STARTING AMPS.

RUNNING AMPS.

120~60Hz

4.8

1.1

MANIFOLD PRESSURE

MIN. INLET PRESSURE

ORIFICE SIZE

3.5” WC

5.0” WC

#3 D.M.S

HEATER TYPE

VERSION

MIN. MOUNTING ANGLE:

COMBUSTION CHAMBER:

4” BC ALUMINUM

FOR INDOOR USE

BRANT RADIANT HEATERS LIMITED

34 SCOTT AVE., PARIS, ONTARIO

TEL: 1-519-442-7823 WWW.BRANTRADIANT.COM

ANSI Z83.20b - 2011 CSA 2.32b - 2011 Low - Intensity Infrared Htr.

ANS Z83.20b - 2011 CSA - 2011 Low - Intensity Infrared Htr.

SERIAL NO.

0870 XXXX XXXX 0001

RE-VERBER-RAY LOW INTENSITY INFRARED HEATER

FOR INDOOR INSTALLATION ONLY. NOT FOR USE IN RESIDENTIAL DWELLING.

INSTALLATION À L’EXTÉRIEUR SEULEMENT. NE PAS INSTALLER DANS UN LOGEMENT.

MAX. MOUNTING ANGLE:

0 DEGREES

45 DEGREES

FOR STAINLESS STEEL UPGRADES THE

COMBUSTION TUBE IS UPGRADED TO 409

STAINLESS STEEL.

C1

10/11

HL2-40-125N 125,000/95,000

SAMPLE

MODEL /MODELE NO. INPUT BTU/H FOR USE WITH

NATURAL GAS

RADIATEUR A INFRAROUGE A FAIBLE INTENSITE

VOLTS A.C.

STARTING AMPS.

RUNNING AMPS.

120~60Hz

4.8

1.1

MANIFOLD PRESSURE

MIN. INLET PRESSURE

ORIFICE SIZE

3.5” WC

5.0” WC

#3 D.M.S

HEATER TYPE

VERSION

MIN. MOUNTING ANGLE:

COMBUSTION CHAMBER:

4” BC ALUMINUM

FOR INDOOR USE

BRANT RADIANT HEATERS LIMITED

34 SCOTT AVE., PARIS, ONTARIO

TEL: 1-519-442-7823 WWW.BRANTRADIANT.COM

ANSI Z83.20b - 2011 CSA 2.32b - 2011 Low - Intensity Infrared Htr.

ANS Z83.20b - 2011 CSA - 2011 Low - Intensity Infrared Htr.

SERIAL NO.

0870 XXXX XXXX 0001

RE-VERBER-RAY LOW INTENSITY INFRARED HEATER

FOR INDOOR INSTALLATION ONLY. NOT FOR USE IN RESIDENTIAL DWELLING.

INSTALLATION À L’EXTÉRIEUR SEULEMENT. NE PAS INSTALLER DANS UN LOGEMENT.

MAX. MOUNTING ANGLE:

0 DEGREES

45 DEGREES

FOR STAINLESS STEEL UPGRADES THE

COMBUSTION TUBE IS UPGRADED TO 409

STAINLESS STEEL.

C1

10/11

HL2-40-125N 125,000/95,000

Air Metering Orifice

DO NOT REMOVE

TP-114

TP-3014 1 - 1/2"

Safety Labels and Their Locations

Back Panel

Top Panel

Bottom Panel

Rating

Plate

Clearance to Combustibles

Label.

F/N: LLLOGO1

Product safety signs or labels should be replaced by the product user when they no longer are legible.

Contact either your local distributor or the product manufacturer for obtaining replacement signs or labels.

F/N: LLAC

Air Metering Orifice

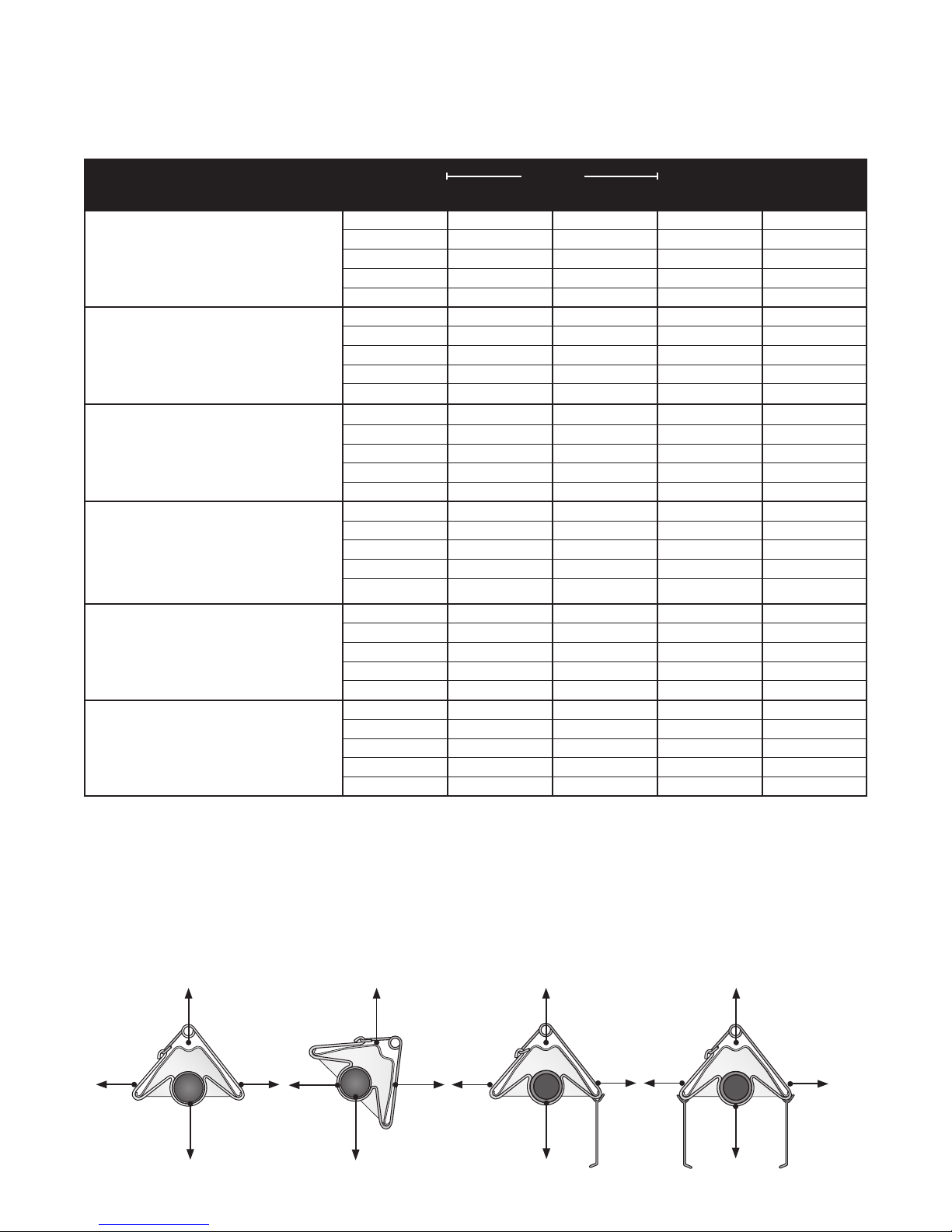

CLEARANCES TO COMBUSTIBLES IN. & CM / DÉGAGEMENTS AUX MATIÈRES COMBUSTIBLES PCE & CM

SAFETY INFORMATION / INFORMATIONS DE SÉCURITÉ

FAILURE TO COMPLY WITH THE STATED

CLEARANCES TO COMBUSTIBLES

COULD RESULT IN PROPERTY DAMAGE,

PERSONAL INJURY AND/OR DEATH.

LE DÉFAUT DE SE CONFORMER AUX DONNÉES DES

DÉGAGEMENTS AUX MATIÈRES INFLAMMABLES

PEUT RÉSULTER EN BLESSURES PERSONNELLES

ET/OU DOMMAGES SUR LA PROPRIÉTÉ.

WARNING AVERTISSEMENT

CAUTION: KEEP COVER IN PLACE. REMOVE FOR SERVICE ONLY.

ATTENTION: GARDER LE COUVERCLE EN PLACE. N’ENLEVER QUE POUR L’ENTRETIEN

TOP

FRONT BEHIND

BELOW

45° MOUNTING ANGLE

SIDE

SIDE

TOP

BELOW

0° W/2 SIDE SHIELDS

TOP

SIDE

BELOW

0° W/1 SIDE SHIELD

TO CEILING

BR-VCF

12 IN.or 30.5 cm

CLEARANCE

TO WALL OR

COMBUSTIBLES

20 ft or 6.1 m

DOWNSTREAM

& BEYOND

FIRST 20 ft

or 6.1 m

BURNER

MIN. 12 IN.or30.5 cm

END CLEARANCE

TOP

SIDE SIDE

0° MOUNTING ANGLE

SIDE

BELOW

47

47

47

47

47

47

47

47

60

60

60

60

66

66

66

66

76

76

76

76

30

81

81

81

81

92

92

92

92

94

94

94

94

44

6

10

6

6

6

10

6

6

6

10

6

6

6

10

6

6

6

10

6

6

6

6

10

6

6

6

10

6

6

6

10

6

6

6

9

8

8

9

9

8

8

9

9

8

8

9

14

8

8

16

20

8

8

20

7

24

8

8

23

34

8

8

30

41

8

8

30

11

9

39

29

9

9

39

29

9

9

39

29

9

14

39

29

16

20

58

42

20

7

24

58

42

23

34

63

50

30

41

63

54

30

11

DX, AG1, SE -

50,000 N or P

W/1 SIDE SHIELD

W/2 SIDE SHIELDS

DX, AG1, SE -

60,000 N or P

W/1 SIDE SHIELD

W/2 SIDE SHIELDS

DX, HL, SE, ST,AG1, AG2 -

75,000 N or P

W/1 SIDE SHIELD

W/2 SIDE SHIELDS

DX, HL, SE, ST,AG1, AG2 -

100,000 N or P

W/1 SIDE SHIELD

W/2 SIDE SHIELDS

DX, HL, SE, ST,AG1, AG2 -

125,000 N or P

W/1 SIDE SHIELD

W/2 SIDE SHIELD

20 ft or 6.1 m

DOWNSTREAM

OF BURNER

DX, HL, SE, ST,AG1, AG2 -

150,000 N or P

W/1 SIDE SHIELD

W/2 SIDE SHIELDS

DX, HL, SE, ST -

175,000 N or P

W/1 SIDE SHIELD

W/2 SIDE SHIELDS

DX, HL, SE, ST -

200,000 N or P

W/1 SIDE SHIELD

W/2 SIDE SHIELDS

20 ft or 6.1 m

DOWNSTREAM

OF BURNER

0°

45°

0°

0°

0°

45°

0°

0°

0°

45°

0°

0°

0°

45°

0°

0°

0°

45°

0°

0°

0°

0°

45°

0°

0°

0°

45°

0°

0°

0°

45°

0°

0°

0°

22.9

20.3

20.3

22.9

22.9

20.3

20.3

22.9

22.9

20.3

20.3

22.9

35.6

20.3

20.3

40.6

50.8

20.3

20.3

50.8

17.8

61

20.3

20.3

58.4

86.4

20.3

20.3

76.2

104.1

20.3

20.3

76.2

27.9

22.9

99.1

73.7

22.9

22.9

99.1

73.7

22.9

22.9

99.1

73.7

22.9

35.6

99.1

73.7

40.6

50.8

147.3

106.7

50.8

17.8

61

147.3

106.7

58.4

86.4

160

127

76.2

104.1

160

137.2

76.2

27.9

15.2

25.4

15.2

15.2

15.2

25.4

15.2

15.2

15.2

25.4

15.2

15.2

15.2

25.4

15.2

15.2

15.2

25.4

15.2

15.2

15.2

15.2

25.4

15.2

15.2

15.2

25.4

15.2

15.2

15.2

25.4

15.2

15.2

15.2

119.4

119.4

119.4

119.4

119.4

119.4

119.4

119.4

152.4

152.4

152.4

152.4

167.6

167.6

167.6

167.6

193

193

193

193

76.2

205.7

205.7

205.7

205.7

233.7

233.7

233.7

233.7

238.8

238.8

238.8

238.8

111.8

ANGLE DE

MONTAGE

ARRIÈRE AVANT

DESSUS

DESSOUS

CÔTE

MODÈLES

MOUNTING

ANGLE

BEHIND IN FRONT

TOP

BELOW

SIDE

MODEL NO.

UNITS DEGREES

IN.

PCE CM

IN.

PCE CM

IN.

PCE CM

IN.

PCE CM

2.0 Safety • Safety Labels and Locations