1 SAFETY INFORMATION

WARNING

This is not an explosion-proof heater. Where there is the possibility of exposure to flammable vapors, consult

the local fire marshal, the fire insurance carrier or other authorities for approval of the proposed installation.

This infra-red heater is designed for use in industrial and commercial buildings such as warehouses,

manufacturing plants, aircraft hangars, service garages, etc. and residential applications such as garages,

solariums, swimming pools, etc.

Brant Radiant Heaters Limited cannot anticipate every use which may be made of their heaters. Check with

your local gas supplier if you have questions about local regulations.

The following information should be reviewed before installing this heater:

* Check the CSA rating label on the heater to verify the minimum clearances to combustibles and the

proper gas to be used.

* The installation of this heater must conform with local building codes or, in the absence of local codes,

with the current CAN/CSA B149.1 and 2 Codes and with the Canadian Electrical Code C22.1-latest

edition.

* In public garages the heaters must be installed in accordance with the Canadian Electrical Code C22.1-

latest edition when an external electrical source is utilized.

* This is not an explosion-proof heater. Where there is the possibility of exposure to flammable

vapors, consult local fire marshall or other authorities for approval of the proposed installation.

* In aircraft hangars, the heater must be installed at least ten feet (3 m) above the upper surface of wings

or engine enclosures of the highest aircraft which may be stored in the hangar. In areas adjoining the

aircraft storage area, the heaters must not be installed less than eight feet (2.4 m) above the floor. Also, the

heaters must be located to prevent damage to the sections of the aircraft, cranes, scaffolds or other

movable objects.

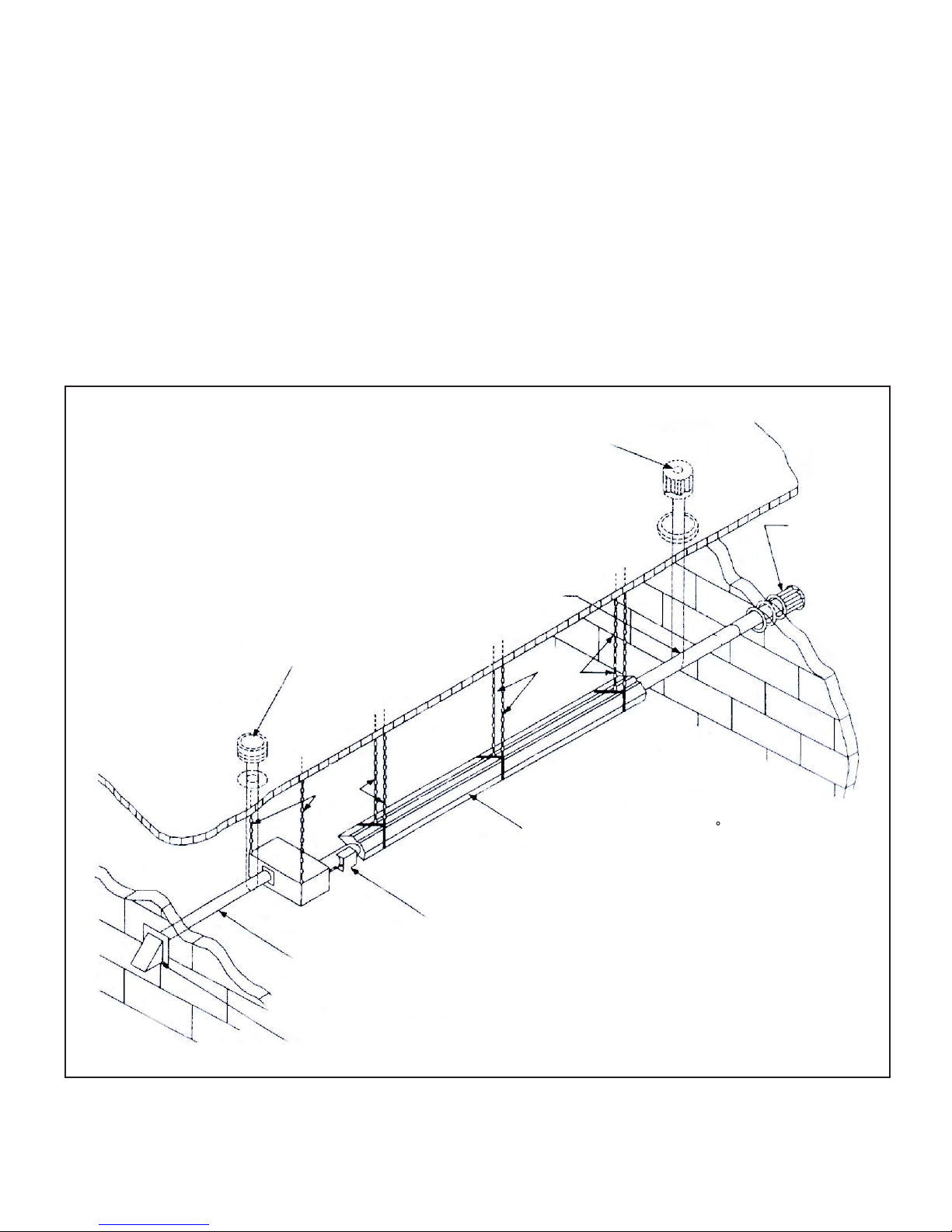

* Under no circumstances is either the gas supply line or the electrical supply line to the heater to provide

any assistance in the suspension of the heater.

* The weight of the heater must be entirely suspended from a permanent part of the building structure

having adequate load characteristics.

* Neither the gas supply line, electrical supply line nor sprinkler heads shall be located in or near the path

of the flue products from the heater.

* If wind conditions in the space are such that visible swaying of the heater is apparent, the control box

must be rigidly mounted.

* If chlorinated or fluorinated contaminants are present in the area where the heater is installed, then

noncontaminated air for combustion must be ducted to the heater. Sources of contaminants are

refrigerants, solvents, adhesives, paints, degreasers, paint removers, lubricants, pesticides, etc.

* If vaporized solvents are allowed to contact the heater’s HOT exchanger tube, noxious fumes may

result. Chemicals must be properly stored, per manufacturers instructions. Ventilation requirements, as

outlined by local codes, must be maintained.

* Signs should be posted in storage areas to specify maximum stacking height allowed in order to

maintain clearance to combustibles.

2

CAUTION