3

Instruction Manual Brew Monk Titan - EN

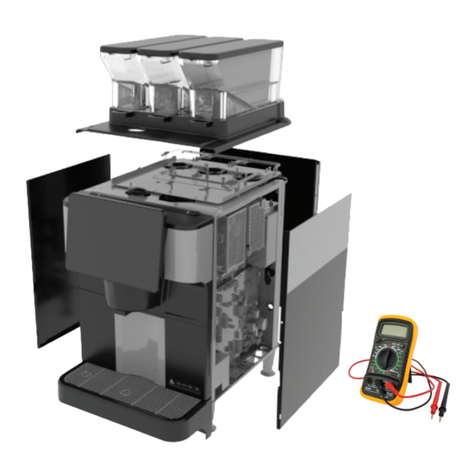

Brewing kettle 70 litres SST malt pipe:

Transparent tube with litre graduation - 70 litres: malt quantity 18 kg

Removable SST ball valve ½” + nozzle Main power and pump switch

Programmable controller with tilted digital display Removable handle for lifting malt pipe

RVS lid Curved pipe

Telescopic SST overow pipe SST bazooka lter

Adjustable SST malt screens Accessories

1. Safety Instructions

• Read all the instructions carefully and keep this manual for future reference.

• Do not use the device if the cord or plug is damaged; it should be replaced before use.

• The machine is intended for use only with 220-240 V and 50/60 Hz. Do not use an adaptor as

the wattage power of this device is high.

• Avoid overloading the electric supply.

• If the device requires extra power, do not use multi-outlets of under 13 A, and do not connect

any other device to this outlet.

• Check the product’s rating label and make sure its voltage is t for your outlet voltage before use.

• The device must only be used as intended. It must be operated safely and correctly under fault-

free conditions. Ensure to check the proper conditions prior to each use.

• The appliance is only to be installed in locations where it is supervised.

2. Brewing Preparation

• The device must be positioned on a stable, secure and horizontal support structure prior to use.

• A full vessel contains boiling hot liquids and can weigh up to 70 kg (70 litres Brew Monk). A

horizontal positioning is a prerequisite for transfer pumping during the brewing process. Avoid

an unsteady surface.

• The device may not be moved during the brewing process. The handles are only meant for

transporting the device in an empty state.

• It is imperative to keep children and animals away from the device while it is in operation.

Remember boiling water is very dangerous.

• Always clean all the parts of your brewing equipment, hygiene is imperative to get good

brewing results.

• Before use, it is advisable to heat a quantity of hot water in the boiler to clean the brewing

equipment by using a proper cleaning agent (Chemipro Wash).

2.1 Circulation Pipe Assembly and Pump Information

• We advise not to run the pump without water. The boiler must be lled with water before

switching on the pump.

• We recommend using the pump during mashing process.

• Before switching on the pump, make sure to install the curved pipe (11). Assemble the

curved pipe (11) by placing it on top of the circulation pipe (2). Check that the seal ring

is installed and lock the curved pipe (11) in place by pressing down the two handles.

If you want to use the glass lid (5) during mashing, you will have to place the lid (5) before

assembling the curved pipe (11). The curved pipe (11) should rst be inserted through

the hole in the lid (5).

• Adjust the ow rate using the blue valve on the circulation pipe for correct circulation speed.

If the pump speed is too fast, the grain basket (8) will overow down the central pipe, and the

bottom of the boiler may run dry and cause ingredients to burn and overheat the element.