5

INFORMATION

• Press "Help" to enter this

interface

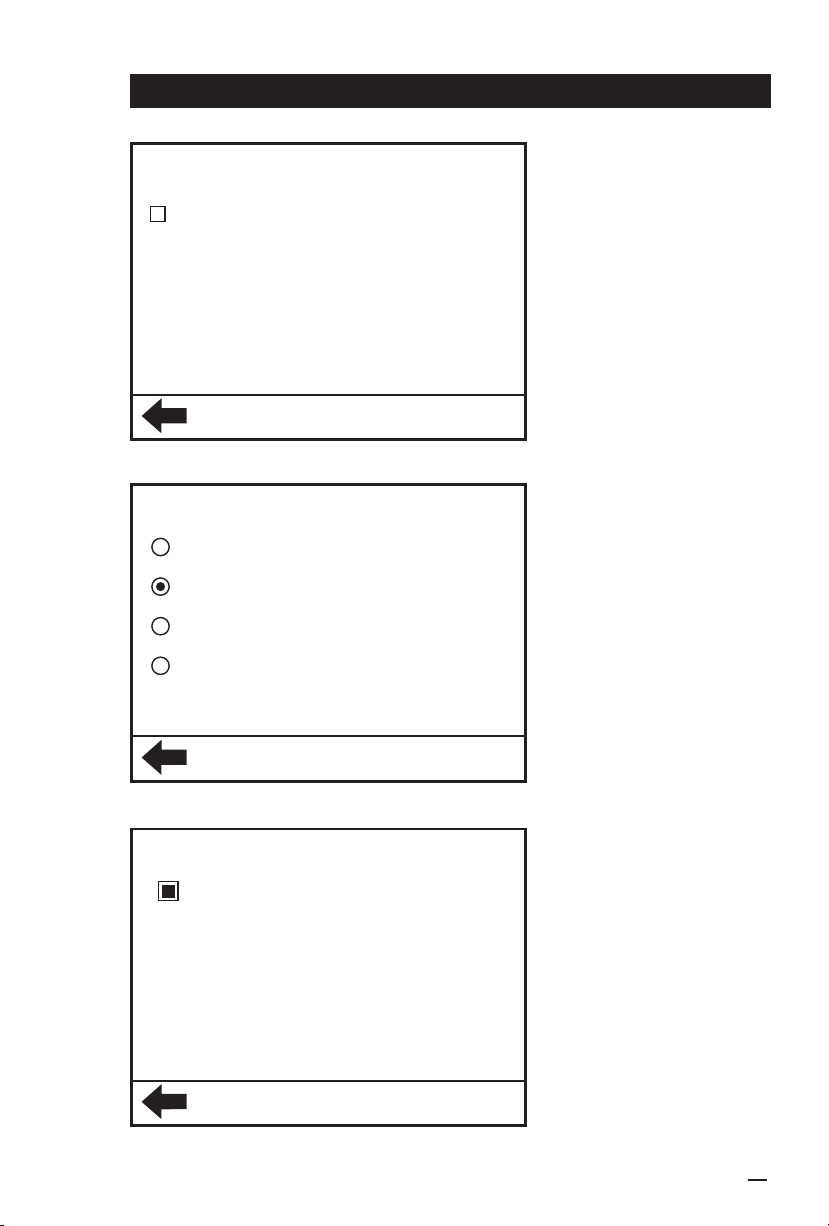

• "Brief Description" introduces

matters that need attention

during operation

• Press the left button to return,

press the right button for

troubleshooting query. See

page 12 for details

• Go to the page after "Brief

Description in the " Help"

interface

• Seek specific solution for

troubleshooting

• Press the left button to return,

press the right button for more

troubleshooting solutions(See

page 12 for details. For items

marked with *, please seek

immediate help from BROAD

or a BROAD authorized service

provider)

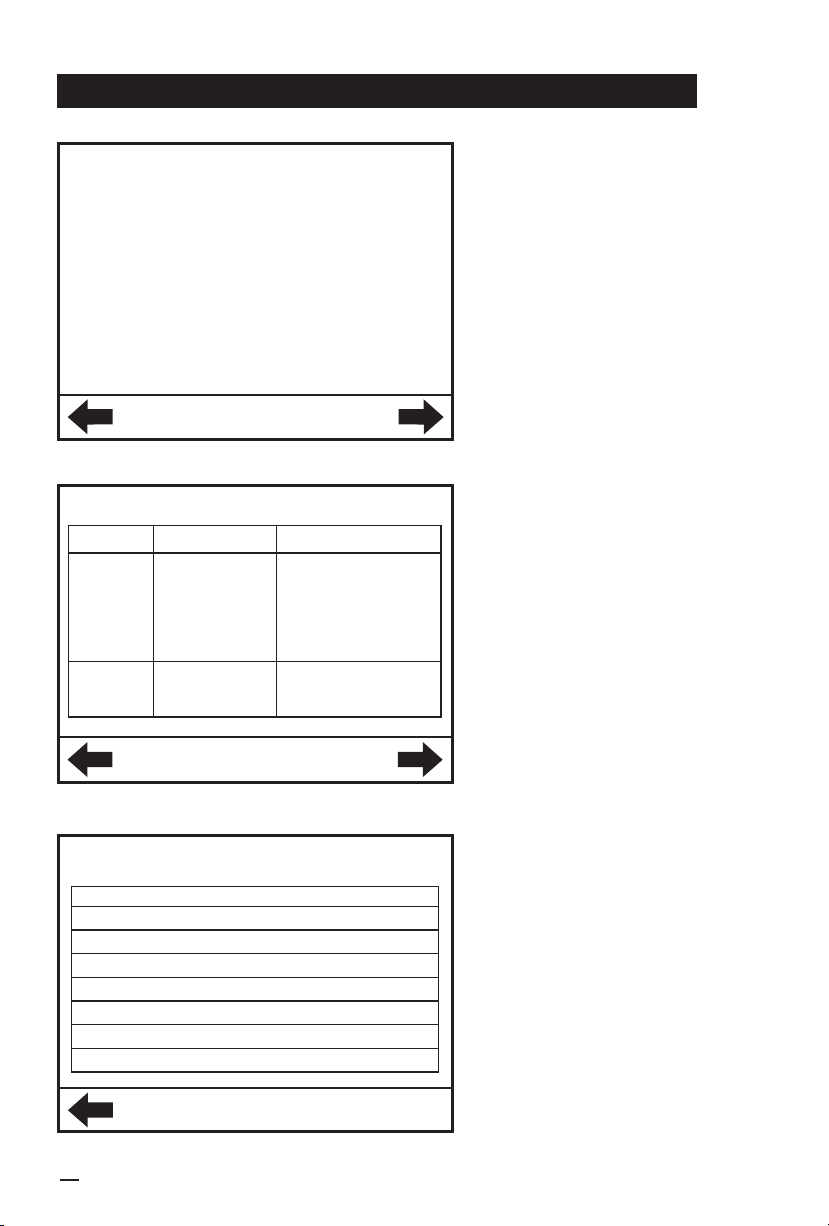

Troubleshooting

Phenomena

Big noise 1. Pan speed is

too high

2. Fan bearing or

rotor failuer

3. Wall or ground

is uneven

1. Lower fan frequency

2. Repair*

3. Fasten the bolts

or level the wall or

ground *

1.Close the door again

2.Replace it *

No blow

Causes Solutions

• If a fault occurs, the

"Fault" button on the main

interface will turn into a white

background automatically,

press "Reset" to clear the alert

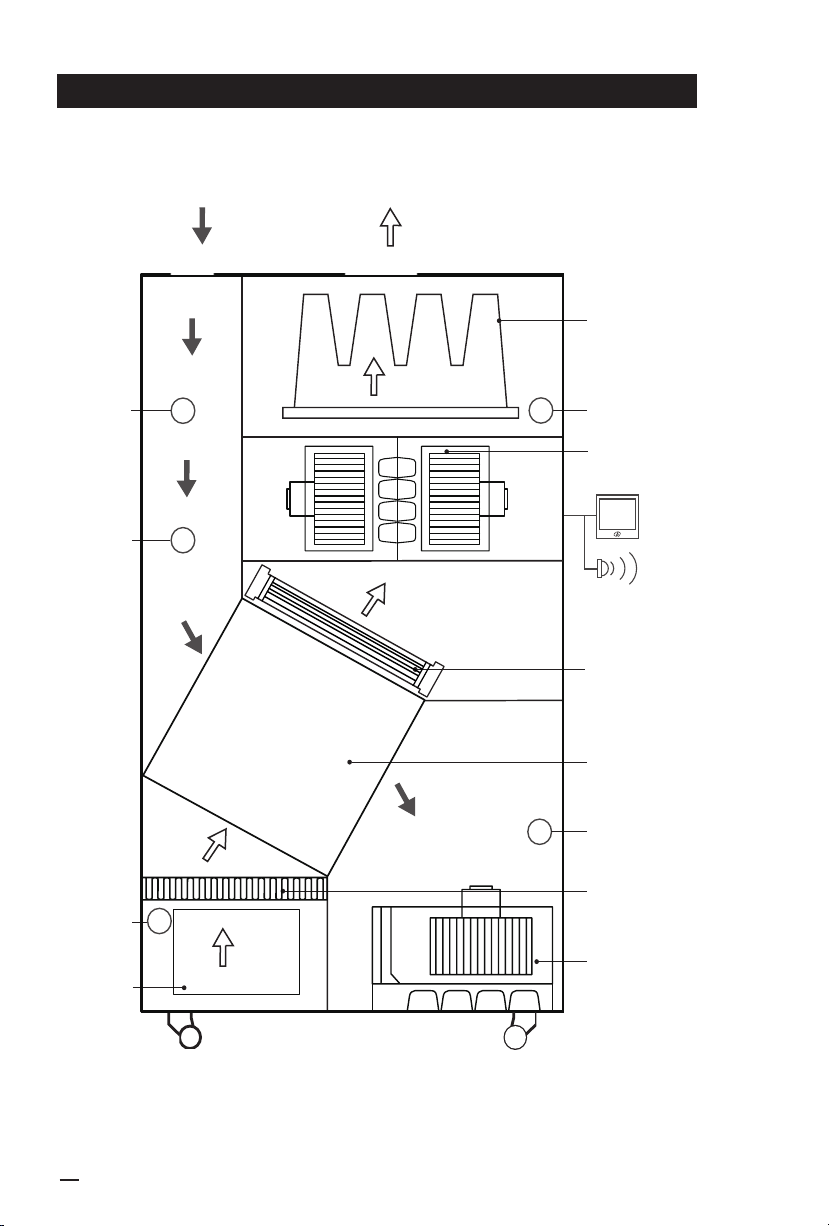

• If the CO2concentration

exceeds the upper limit, please

immediately increase the air

volume of the fresh air machine

• If the electrostatic cleaner

cleaning prompt appears,

clean or replace as soon as

possible

• For fresh air machine

component failure, please seek

immediate help from BROAD

or a BROAD authorized service

provider

Fault

Reset

1. The door is not

properly closed

2. Fan motor failure

Fresh air machine

Indoor air temperature probe fault

Brief description

1. The automatic freshness control refers to the control

of CO2concentration. When the CO2concentration

is too high, the air speed will increase automatically

to reduce the CO2concentration below the set

value. Vice Versa.

2. On the automatic freshness control mode, the fan

frequency rises and falls automatically to ensure the

freshness and comfort of the indoor environment,

while at the same time saving energy.