BROUWER-16/24R

Self Propelled Sod Harvester

Foreword

IMPORTANT

The Owner and Operator, must assume responsibility for the safe operation of the machine, their own

safety, and the safety of others, by reading, understanding, and following all of the safety instructions

and operating procedures as outlined in the machines Operator’s Manual.

Failure of the Owner or Operator to adhere to the recommended safety instructions and operating

procedures, indemnifies Brouwer Turf Inc. against any claims that may arise, due to accidents resulting

in personal injury or property damage.

It is not possible to list all situations that may affect the safety of the machine or the operator, and therefore

Brouwer Turf Inc. cannot list all precautions, and identify all potential hazards, that may prevent accidents.

IF YOU DO NOT UNDERSTAND….ASK

BE A QUALIFIED OPERATOR BY ;

•Reading and obeying the instructions in this manual, and the safety decals on the machine.

•Receiving operational training on the sod harvester.

•Asking your supervisor or equipment dealer to explain anything you do not understand.

•Explaining the written instructions in the operator’s manual and safety decals to user/operators who

cannot read or understand them.

WARNING

Brouwer Sod Harvesters are designed for safe efficient operation and must not be used for any purpose other than

that for which they are designed.

Prior to being shipped from the manufacturer the machines are inspected to insure that all safety guards, shields

and warning/safety/operating decals are correctly positioned and secure

Before operating the machine the operator must check that all of the above items are correctly located.

The machine must not be used if any guards, shields or warning/operating decals are damaged or missing.

Brouwer Sod Harvesters are designed and built to give many years of outstanding performance.

The service and reliability you receive from this product will be affected by the proper maintenance and operation

of the machine.

Use only genuine factory placement parts. Parts not supplied by Brouwer may not meet the factory engineering

specifications or standards of manufacture and may void warranty. The use of non-approved parts may result in

component failure causing damage to the machine and possibly result in an accident to the operator or others.

IMPORTANT

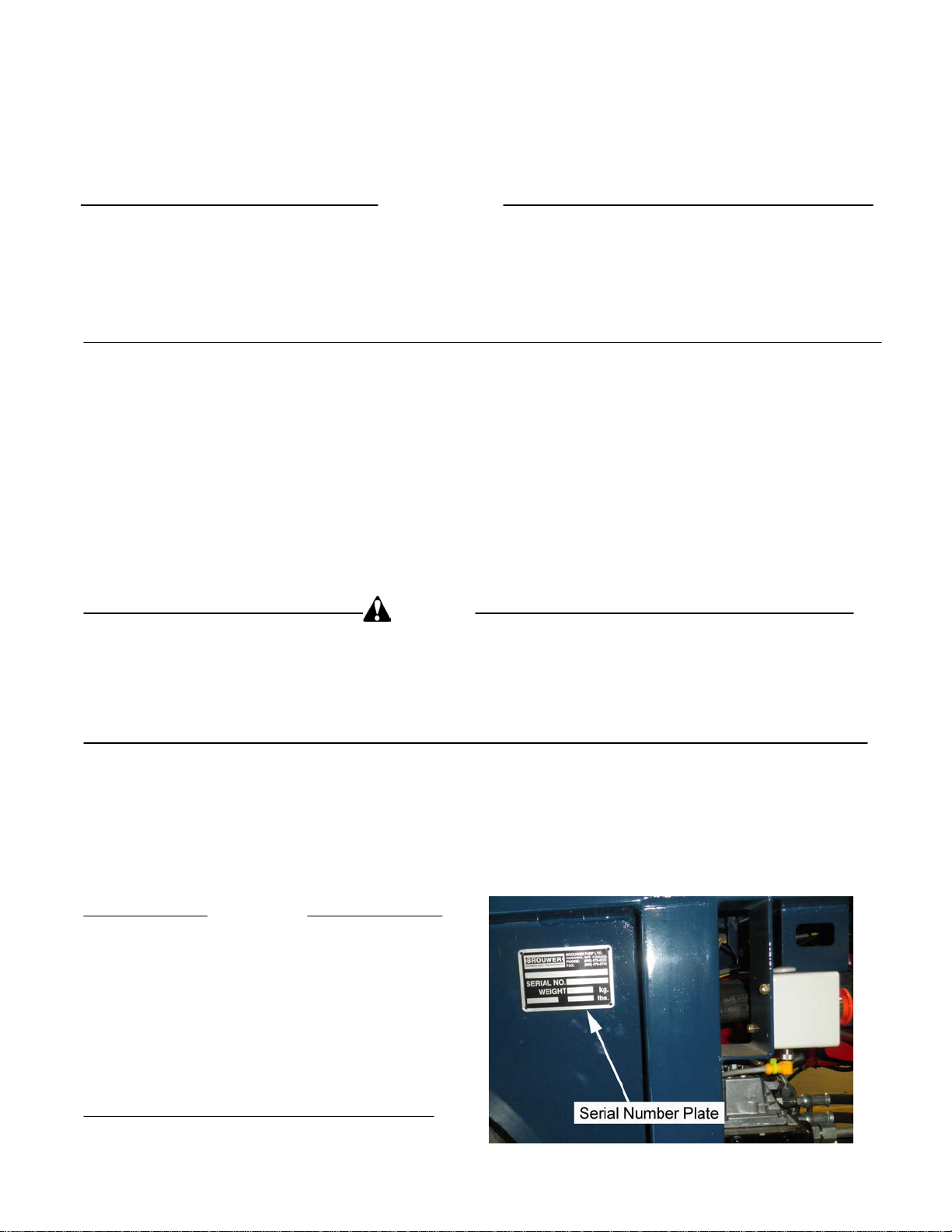

MODEL NUMBER

The Model Number appears on sales literature

technical manuals and price lists.

SERIAL NUMBER

The serial number applies only to the machine

to which it is allocated.

The serial number MUST be quoted when ordering

parts or calling for service or warranty

i