Brouwland bvba • Korspelsesteenweg 86 • B-3581 Beverlo - Belgium

Tel. +32-(0)11-40.14.08 • Fax. +32-(0)11-34.73.59

Dear Customer,

You purchased a new product of our brand. We wish to thank

you for your trust in our company. We highly value the quality

and functionality of our products. Therefore we look forward to

receiving remarks or suggestions from you.

Use

The crusher for pomes is especially designed to cut the pomes

so small that they can be place immediately into a fruit press

guaranteeing the highest possible juice yield.

To guarantee an reliable use from the start we created these

instructions.

Your crusher for pomes will work perfectly and remain in good

condition when you closely follow the remarks below.

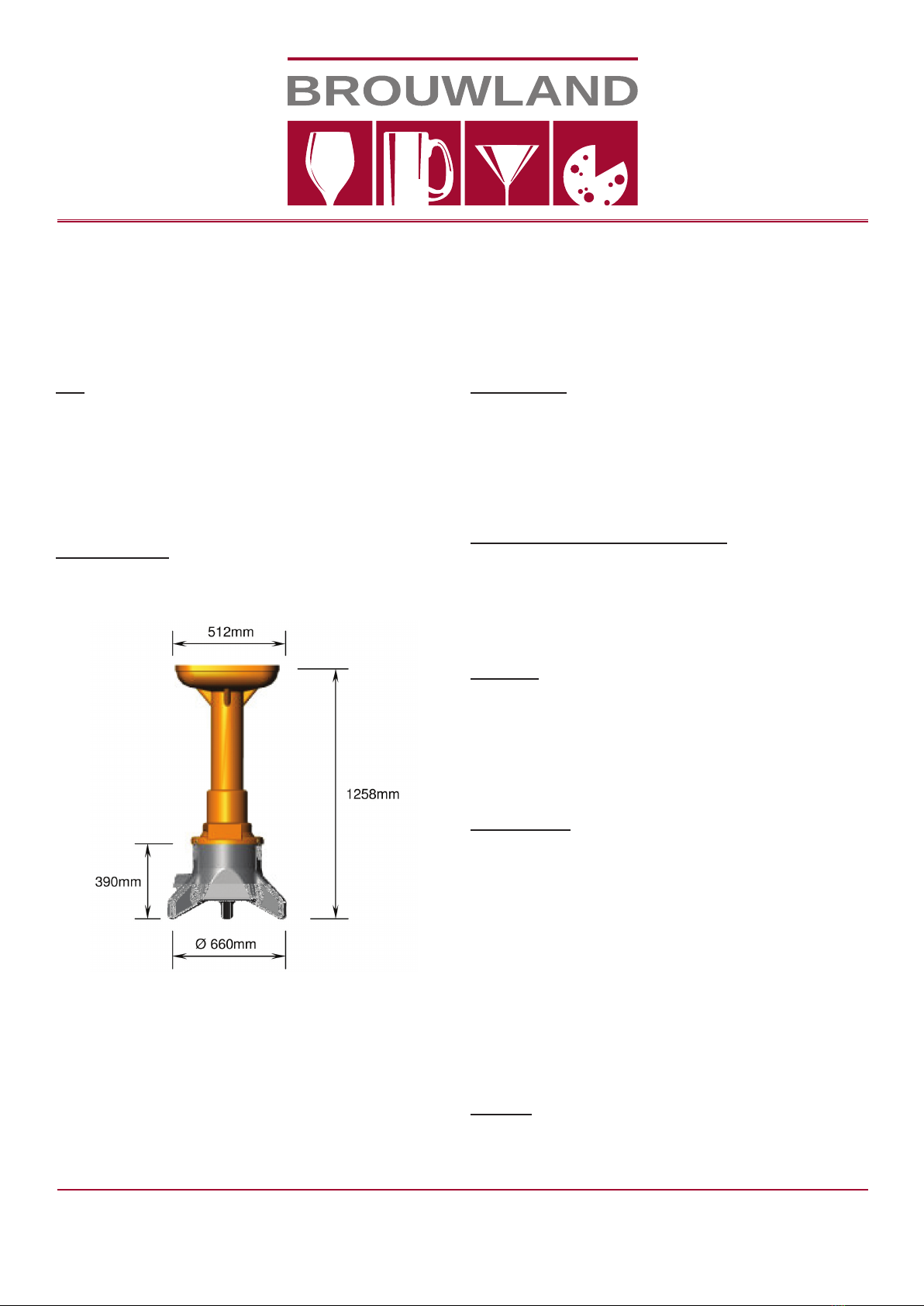

Technical data

Motor : 230 V / 50 Hz / 2,2 kW

Does not interfere with radio or

television reception

Constant sound pressure

< 70 dB(A)

Number of revolutions : 2.800 rpm

Feed hopper : stabile, stainless steel PE

construction with switch safety.

Blades : pre-crusher, knife blade and

reversible blade in stainless steel .

Connection : 230 V / 50 Hz, Schuko plug

Dimensions : diam. 660 x 1.258 mm

Weight : ca. 25 kg.

The crusher is ready for use. The crusher is designed and build

following the CE-rulings and can only be used for ne cutting

of pomes.

Please take the following safety instructions and instructions

for use into account for a functioning of the crusher without

complications.

Instructions

The crusher can be connected onto the light circuit with alter-

nating current. However only one Schuko plug is permitted.

For safety reasons it is equipped with a wire safety switch of

16 A. Should the crusher automatically shut down during ope-

ration an error occurred e.g. when fruit is stuck in the shred-

ding parts. After xing the error the crusher can be re-started.

Working with the pomes crusher

Plug in the crusher (230 V) and it switch on. When the motor

is running at full speed you can steadily add the fruit. Make

sure to add just the amount of fruit that the blades can ma-

nage, do not over feed. This way you get the best results (ca.

1000 kg/hour)

Cleaning

1. remove the plug from the socket.

2. remove the hopper by undoing the 3 snap fasteners.

3. clean the crusher and hopper with a soft water jet (no

high pressure). Never spray into the opening of the

casing.

4. put the machine back together.

Maintenance

The crusher hardly requires maintenance. The hopper, blades,

casing etc. are made of high quality stainless steel and there-

fore need no further care or treatment. Electricity is limited

to the wires onto the compact parts which are enclosed for

safety.

Only the blades are subjected to wear. When the fruit is no

longer cut properly it is due to the wearing of the blades. You

can easily obtain 2 sharp cutting edges again by rotating the

blades. Follow these instructions for rotating the blades :

1. remove the plug from the socket

2. remove the hopper

3. unscrew the blades with an appropriate screwdriver.

4. otate the blades

5. re-tighten the 4 screws of the blades.

6. Put the hopper back in place.

Storage

The crusher has to be stored in a dry place, not in a damp cel-

lar.