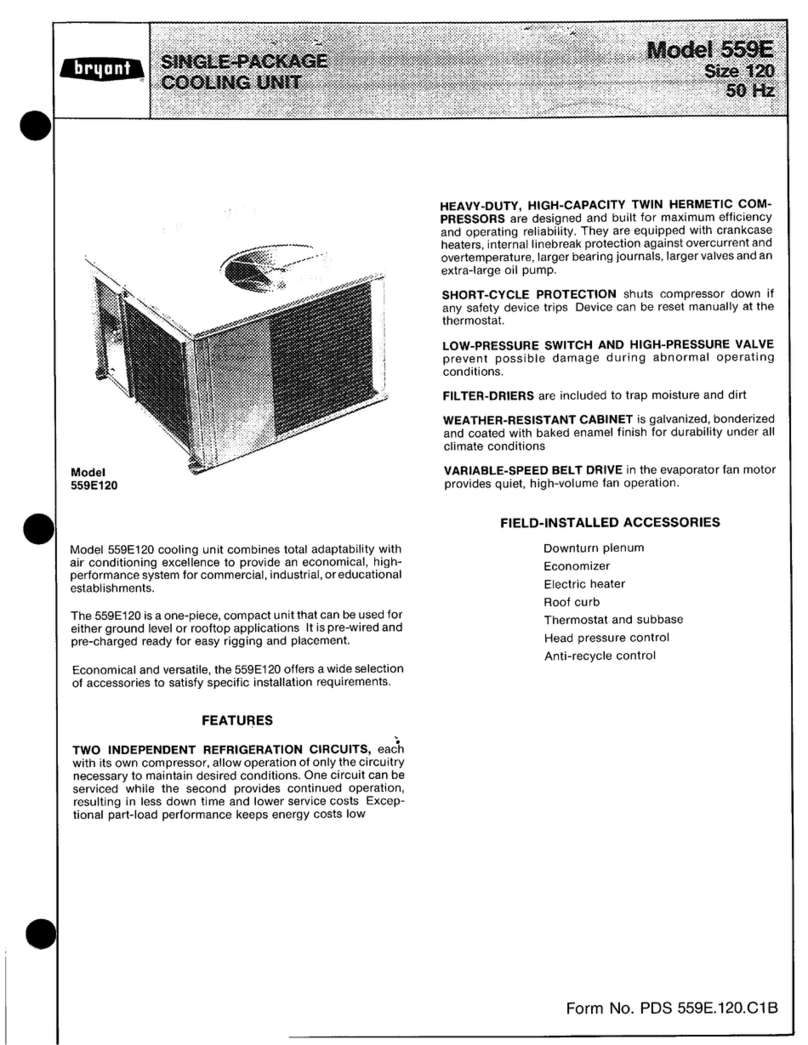

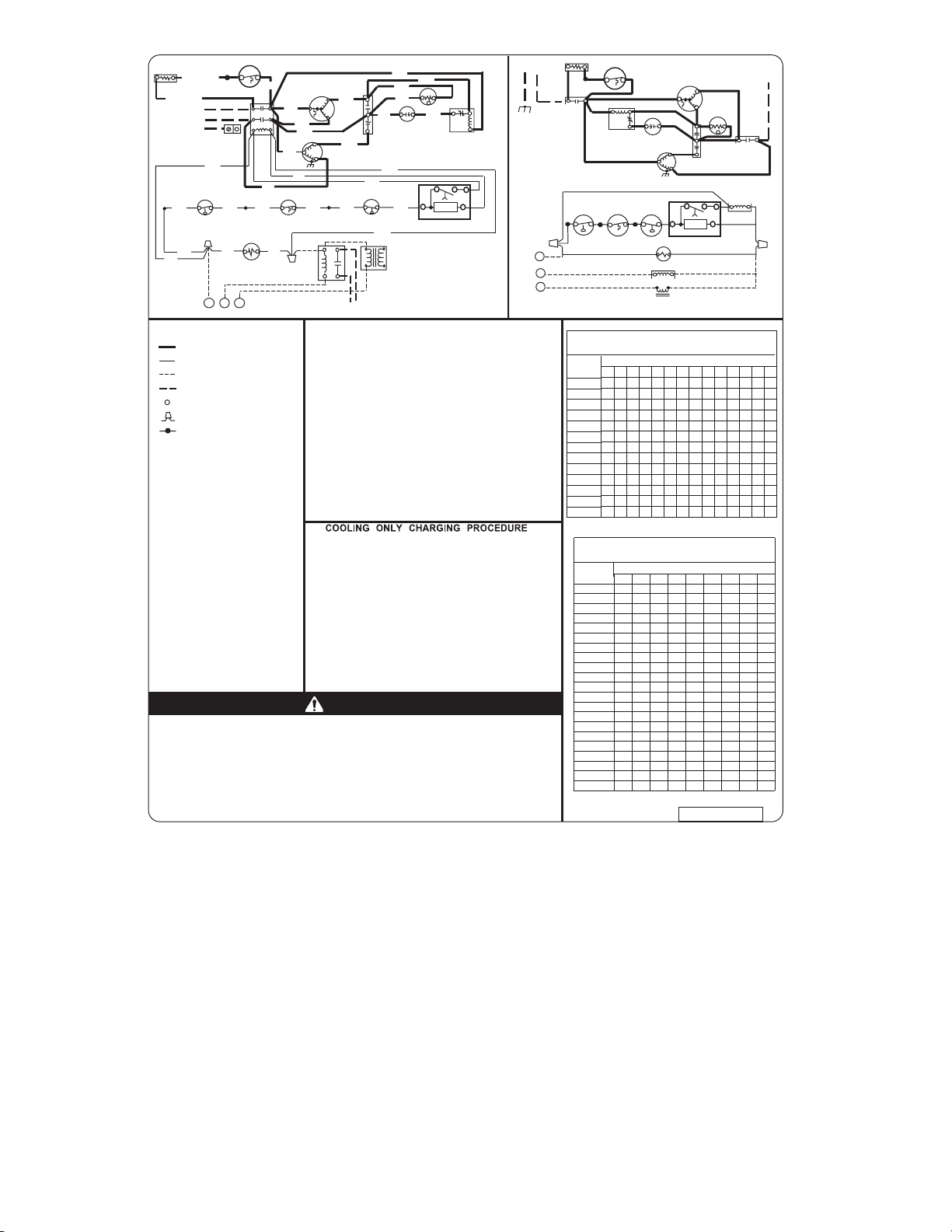

Fig. 2—563C and 563G 060 208/230v, 1 Phase, 60 Hertz A04022

*CH (NOTE #9)

RED or BLK

BLK

208/230 1Ø

POWER

SUPPLY

L1

L2

EQUIP

GND

CONT

11 21

13 23 YEL

OFM

YEL

COMP BLU

BRN

BRN

YEL

S

C

RYEL

YEL

BLU BLU

BRN

*SC

BLK

BLK

*ST

*SR

12

5

CAP

*LPS*DTS

*HPS

BLK BLK YEL

BLU

VIO

H

C

F

CONNECTION DIAGRAM

+t˚

BLU

BLK

BLU YEL

*CTD

BRN

(NOTE #14)

BLU

BLU BLK

*LLS

BLK

Y RG

INDOOR THERMOSTAT (NOTE #5) INDOOR BLOWER MOTOR

EXTERNAL POWER

SUPPLY 24V

(NOTES #3 & #6)

(NOTE #8)

SCHEMATIC DIAGRAM

(LADDER FORM)

11 21

CONT

L1

EQUIP

GND

*SR

*SC

52

1H

C

F

*ST

OFM

+t˚

CONT

23 13

CAP

S

CRCOMP

L2

*LPS

*DTS

*HPS

CONT

IFR

EXTERNAL POWER SUPPLY 24 V

*CTD

(NOTE #14)

Y

G

R

INDOOR THERMOSTAT

RC

*CH

1. Symbols are electrical representation only.

2. Compressor and fan motor furnished with inherent thermal protection.

3. To be wired in accordance with National Electric N.E.C. and local codes.

4. N.E.C. class 2, 24 V circuit, min. 40 VA required, 60 VA on units

installed with LLS.

5. Use copper conductors only.

6. Connection for typical cooling only thermostat, for other arrangements,

see installation instructions.

7. If indoor section has a transformer with a grounded secondary, connect

the grounded side to the BRN lead.

8. When start relay and start capacitor are installed, start thermistor is not

used.

9. CH not used on all units.

10.If any of the original wire, as supplied, must be replaced, use the same

or equivalent wire.

11.Check all electrical connections inside control box for tightness.

12.Do not attempt to operate unit until service valves have been opened.

13.Do not rapid cycle compressor. Compressor must be off 3 minutes to

allow pressures to equalize between high and low side before starting.

14.Wire not present if HPS, LPS, DTS or CTD are used.

15.Use conductors suitable for at least 75˚C (167˚F).

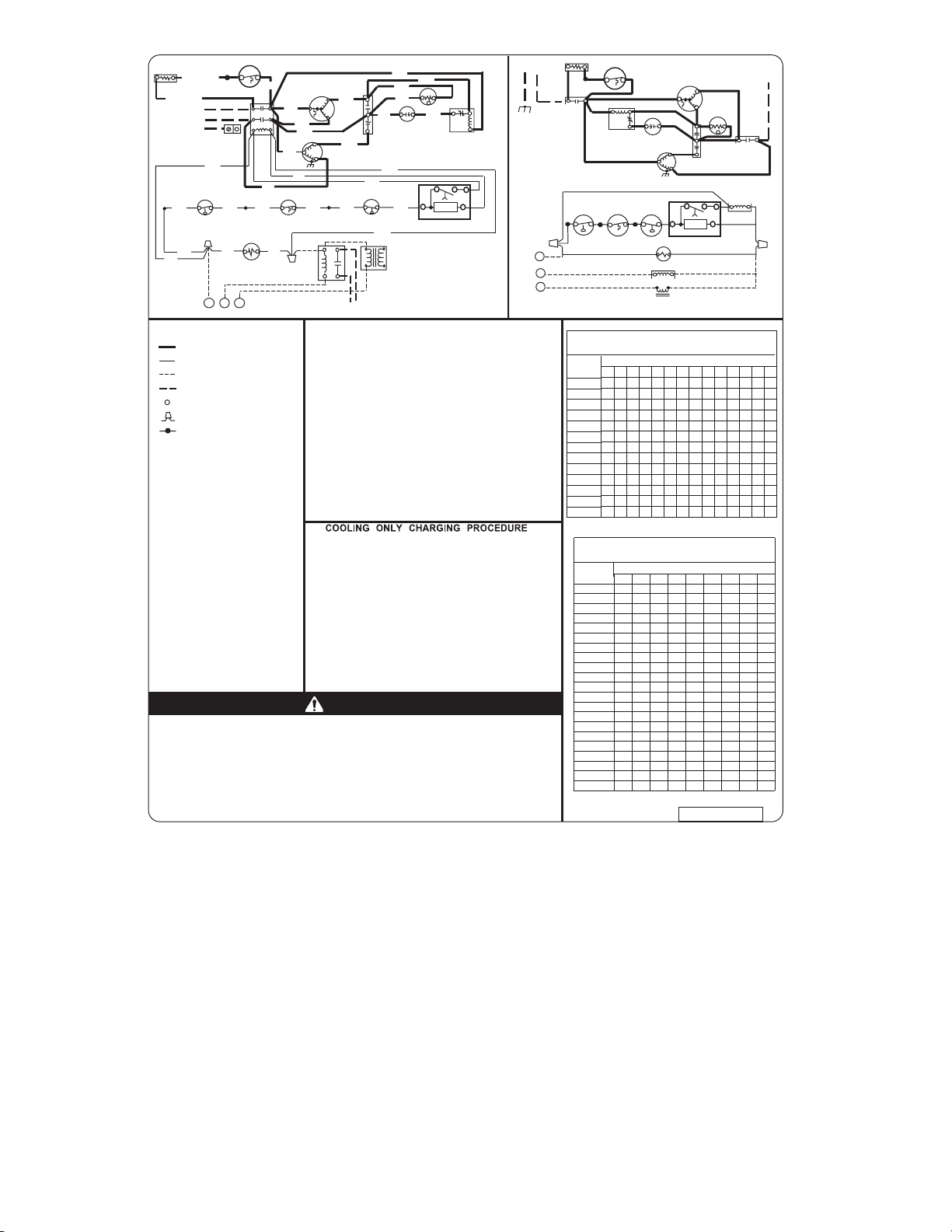

EVAPORATOR ENTERING AIR ˚F WB.

TEMP ˚F

OUTDOOR

50

TABLE I-SUPERHEAT CHARGING TABLE

(SUPERHEAT ˚F AT LOW-SIDE SERVICE PORT)

52 54 56 58 60 62 64 66 68 70 72 74 76

55 9 12141720232629323537404245

60 7 10121518212427303335384043

65 -- 6 101316192124273033363841

70 -- -- 7 1013161921242730333639

75 -- -- -- 6 9 12 15 18 21 24 28 31 34 37

80 -- -- -- -- 5 8 12 15 18 21 25 28 31 35

85 -- -- -- -- -- -- 8 11 15 19 22 30 3326

90 -- -- -- -- -- --

--------------

-- -- -- -- -- -- --

--

--

--

--

--

----

--

----

--

----

--

------

--

-- --

--

5 9 13 16 20 24 27 31

95 6 101418222529

100 8 1215202327

5 9 13 17 22 26

6 11152025

8 141823

--

--

-- --

-- -- --

105

110

115

324474-101 REV. C

1. Operate unit a minimum of 10 minutes before checking charge.

2. Measure suction pressure by attaching a gage to suction valve service port.

3. Measure suction temperature by attaching an accurate thermistor type or electronic

thermometer to the suction line at service valve.

4. Measure outdoor air dry-bulb temperature with a thermometer.

5. Measure indoor air (entering indoor coil) wet-bulb temperature with a sling

psychrometer.

6. Refer to table I. Find outdoor temperature and evaporator entering air wet-bulb

temperature, at this intersection note the superheat.

7. Refer to table II. Find superheat temperature located in step 6 and suction

pressure, at this intersection note suction line temperature.

8. If unit has a higher suction line temperature than charted temperature, add

refrigerant until charted temperature is reached.

9. If unit has a lower suction line temperature than charted temperature, remove and

recover refrigerant until charted temperature is reached.

10. If outdoor air temperature or pressure at suction valve changes, charge to new

suction line temperature indicated on chart.

11. This procedure is valid when indoor air flow is within ±21% of its rated CFM.

1. Compressor damage may occur if system is over charged.

2. This unit is factory charged with R-22 in accordance with the amount shown on the rating plate. The

charge is adequate for most systems using matched coils and tubing not over 15 feet long. The

best performance will be achieved when the unit operates with a suction gas superheat at the

compressor inlet of 5 ˚F at normal rating conditions of the air conditioning and refrigeration institute

(ARI). This chart may be used to approximate the charge if ARI rating conditions cannot be obtained.

ARI rating conditions are equivalent to DOE test "A" conditions. See product data literature for required

indoor air flow rates and for use of line lengths over 15 Ft.

3. Relieve pressure and recover all refrigerant before system repair or final unit disposal. Use all service

ports and open all flow-control devices, including solenoid valves.

91898785838179777540

89878583817977757338

87858381797775737136

85838179777573716934

83817977757371696732

81797775737169676530

79777573716967656328

77757371696765636126

75737169676563615924

73716967656361595722

71696765636159575520

69676563615957555318

67656361595755535116

65636159575553514914

63615957555351494712

61595755535149474510

5957555351494745438

5755535149474543416

5553514947454341394

5351494745434139372

5149474543413937350

85.782.479.276.073.070.067.164.2

SUCTION PRESSURE AT SERVICE PORT PSIG.

TEMP. ˚F

61.5

SUPERHEAT

(MEASURED AT LOW-SIDE SERVICE PORT)

TABLE II-REQUIRED SUCTION TUBE TEMPERATURE ˚F

LOGIC

T1 T3

T2

IFR

C

R

*LLS

LOGIC

T1 T3

T2

*CHS

RED or BLK

*CHS

FACTORY POWER WIRING

FACTORY CONTROL WIRING

FIELD CONTROL WIRING

FIELD POWER WIRING

COMPONENT CONNECTION

FIELD SPLICE

JUNCTION

CONT CONTACTOR

CAP CAPACITOR (DUAL RUN)

*CH CRANKCASE HEATER

*CHS CRANKCASE HEATER SWITCH

COMP COMPRESSOR

*CTD COMPRESSOR TIME DELAY

*DTS DISCHARGE TEMP. SWITCH

*HPS HIGH PRESSURE SWITCH

IFR INDOOR FAN RELAY

*LLS LIQ. LINE SOLENOID VALVE

*LPS LOW PRESSURE SWITCH

OFM OUTDOOR FAN MOTOR

*SC START CAPACITOR

*SR START RELAY

*ST START THERMISTOR

* MAY BE FACTORY OR FIELD

INSTALLED.

NOTES:

-LEGEND-

CAU

TIO

N

BLK

© 2004 Bryant Heating & Cooling Systems 7310 W. Morris St. Indianapolis, IN 46231 —2— Printed in U.S.A. 563c182 Catalog No. 5356-305