5. GENERAL CHARACTERISTICS

(continued)

Degree of pollution:

. 2

Rated impulse withstand voltage (Uimp):

. 4 kV

Influence of altitude:

. No influence up to 2 000 m

Assigned frequency:

. 50 / 60 Hz

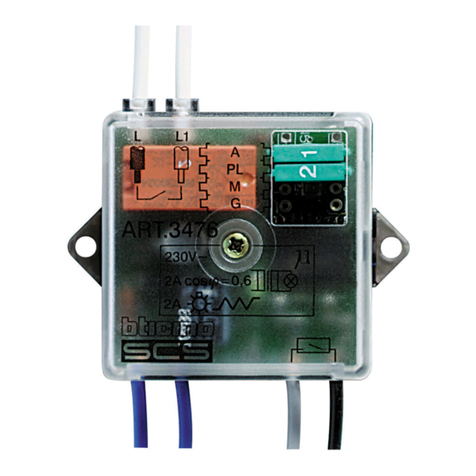

Rated operational Dry-Contact current:

. 2 A

Rated voltage of use (Ue):

. Ue = 100 to 240 V ~

Resistance to short-circuits:

. Presumed short circuit current 1500 A according to EN 60669-2-1

. Thermal stress: 15 000 A²s according to EN 60669-2-1

Recommendations:

. For the Dry-Contact protection against short circuits according to

the conditional current, it is recommended to use a circuit breaker

or fuse gG rated current 2 A.

Dry-Contact endurance:

-20 000 000 operations without load

-40 000 operations under resistive load

according to EN 60669-2-1

-10 000 operations under capacitive or both inductive and

capacitive according to EN 60669-2-1

Measuring coil characteristics:.

Max current 80A

Characteristics of the radio interface:

. Standard IEEE 802.15.4

. Frequencies 2,4 à 2,4835Ghz

. Transmitter output power <100mW

. Distance max between 2 radio devices: 50m in open field

Dielectric resistance:

. 2000V between terminals and rail.

. 750V between terminal 1 and 2 from Dry-Contact.

. 3750V between SELV and LV.

Protection degree:

. Protection index of terminals against direct contacts: IP2X

(IEC/EN 60529)

. Protection index of the front face against direct contacts:

IP3XD (IEC/EN 60529)

. Class II, front panel with faceplate.

. Class of protection against mechanical impacts IK04 (IEC/EN

62262)

Vibrations and shaking resistance:

. vibrations: 10 to 55 to 10Hz single amplitude 0.75mm

. Shaking: 1000m / s ² (6 ± 1ms)

. Classification UL 94 V0 (≥1.5mm)

5. GENERAL CHARACTERISTICS

(continued)

Plastic material:

. Self-extinguishing polycarbonate.

. Heat and fire resistant according to IEC/EN 60669-2-1, glow-wire

test at 960°C

Ambient operating temperature:

. Min. = - 5 °C Max. = + 45 °C.

Ambient storage temperature:

. Min. = - 40 °C Max. = + 70 °C.

Average weight:

. Dry-Contact: 93 g

Volume when packed:

. 0,23 dm3.

6. COMPLIANCE AND APPROVALS

Compliance to standards:

. IEC/EN60669-2-1 + EN60669-2-5

Environment respect –Compliance with European Union

Directives:

. Compliance with Directive 2002/95/EC of 27/01/03 known as

"RoHS" which provides for a restriction on the use of dangerous

substances such as lead, mercury, cadmium, hexavalent chromium

and polybrominated biphenyl (PBB) and polybrominated diphenyl

ether (PBDE) brominated flame retardants from 1st July 2006

. Compliance with the Directive 91/338/EEC of 18/06/91 and decree

94-647 of 27/07/04

. Compliant with regulation REACH

Conformity with electromagnetic interference (EMC):

. Compliant EN 301 489-1, IEC 60669-2-5, NF EN 60669-2-1

Immunity to shock waves

Radio transmission

Immunity to electrical transients in bursts.

Immunity to conducted disturbances induced by radio fields

Immunity to radiated fields

Electrostatic discharge immunity

Immunity to voltage dips and short break

. Compliance mission radiated according to NF EN55032.

Plastic materials:

. Halogen-free plastics.

. Marking of parts according to ISO 11469 and ISO 1043.

. ISO 7000: 2004, Graphical symbols to be used on equipment - Index

and synopsis

Packaging:

. Design and manufacture of packaging in accordance with Decree

98-638 of 20/07/98 and Directive 94/62 / EC.

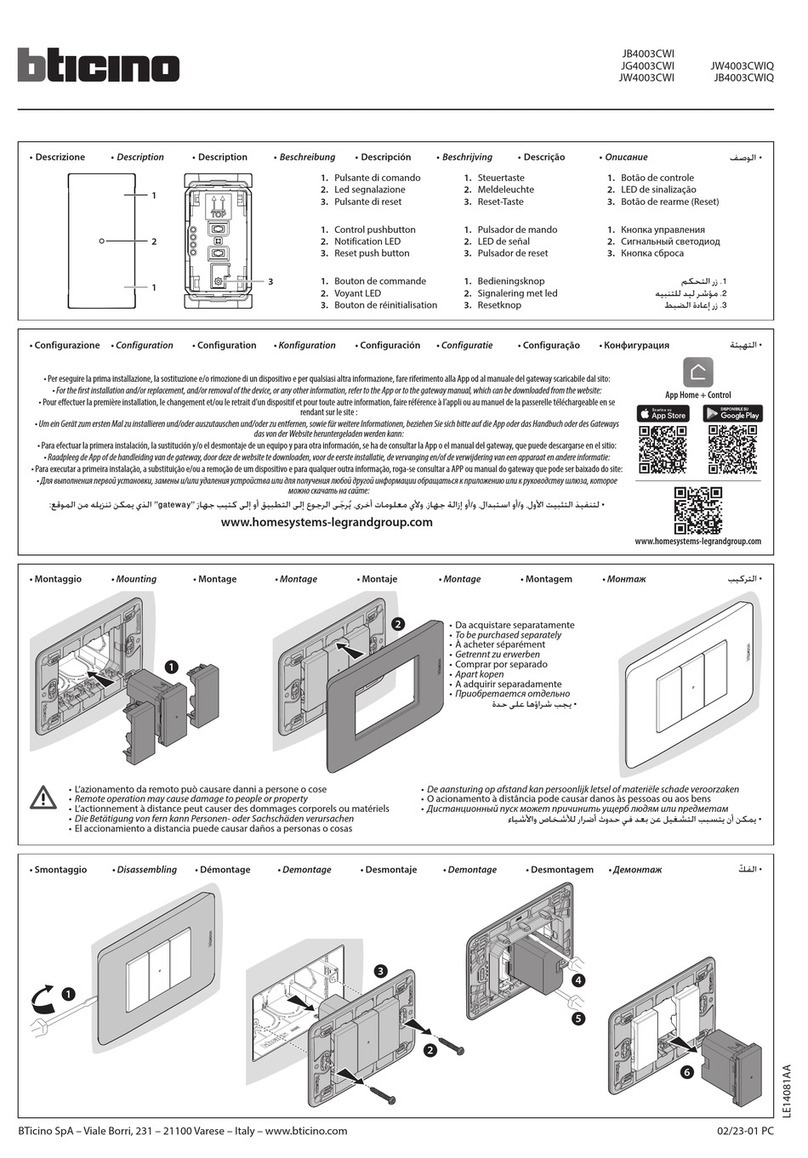

7. AUXILIARIES AND ACCESSORIES

Beforehand, requires the installation of a " connected starter pack "

or " a “gateway module".