CHAPTER 3: CONTROL SCREEN

3.1. BUTTONS AND THEIR FUNCTIONS

ON/OFF: Switching the automatic door board supply.

TEST: Starts the Test Process when press-and-drop operation is performed. Pressing and holding

this button until “ADJ” icon appears on the screen starts the Auto-tunning Process.

UPWARD BUTTON: Used to switch between parameters. If the user entered to a parameter in

the menu, it increases the parameter value. If the commands are not existed, pressing and holding

this button gives “CLOSE” signal to the automatic door board as long as this button is held when

the display shows the main screen.

UPWARD BUTTON: Used to switch between parameters. If the user entered to a parameter in

the menu, it decreases the parameter value. If the commands are not existed, pressing and

holding this button gives “OPEN” signal to the automatic door board as long as this button is

held when the display shows the main screen.

ENTER: Pressing and holding this button until “PFd” icon appears on the screen starts the

“Entering to the Menu Process” when the display shows the main screen. Pressing and holding

this button until main screen appears on the screen performs the “Saving the Parameters Process”

when the display shows a parameter(For example; n00). When press-and-drop operation is

performed, it allows to enter the parameter is displayed on the screen and exit after the parameter

value is set.

3.2. LEDS AND THEIR FUNCTIONS

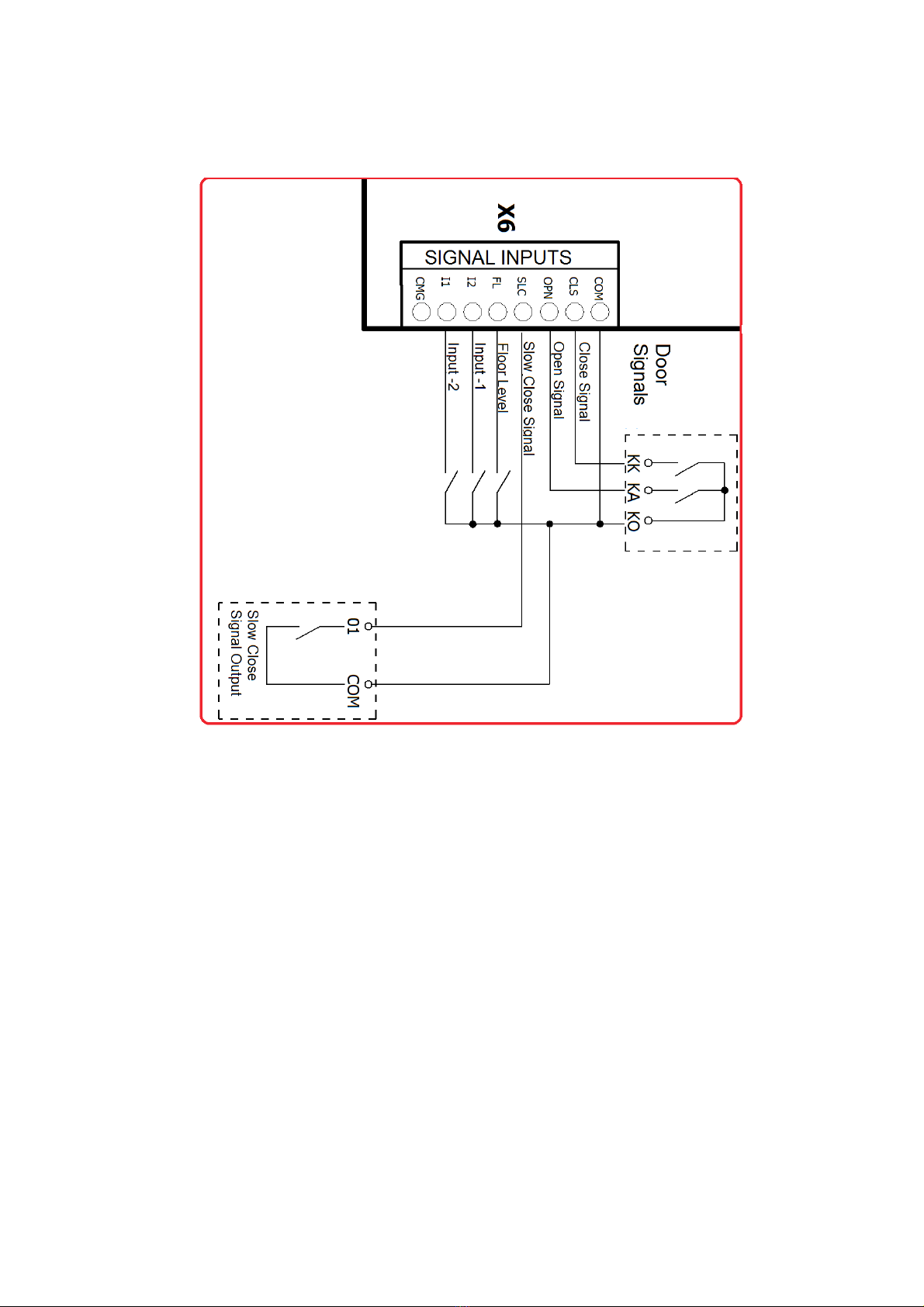

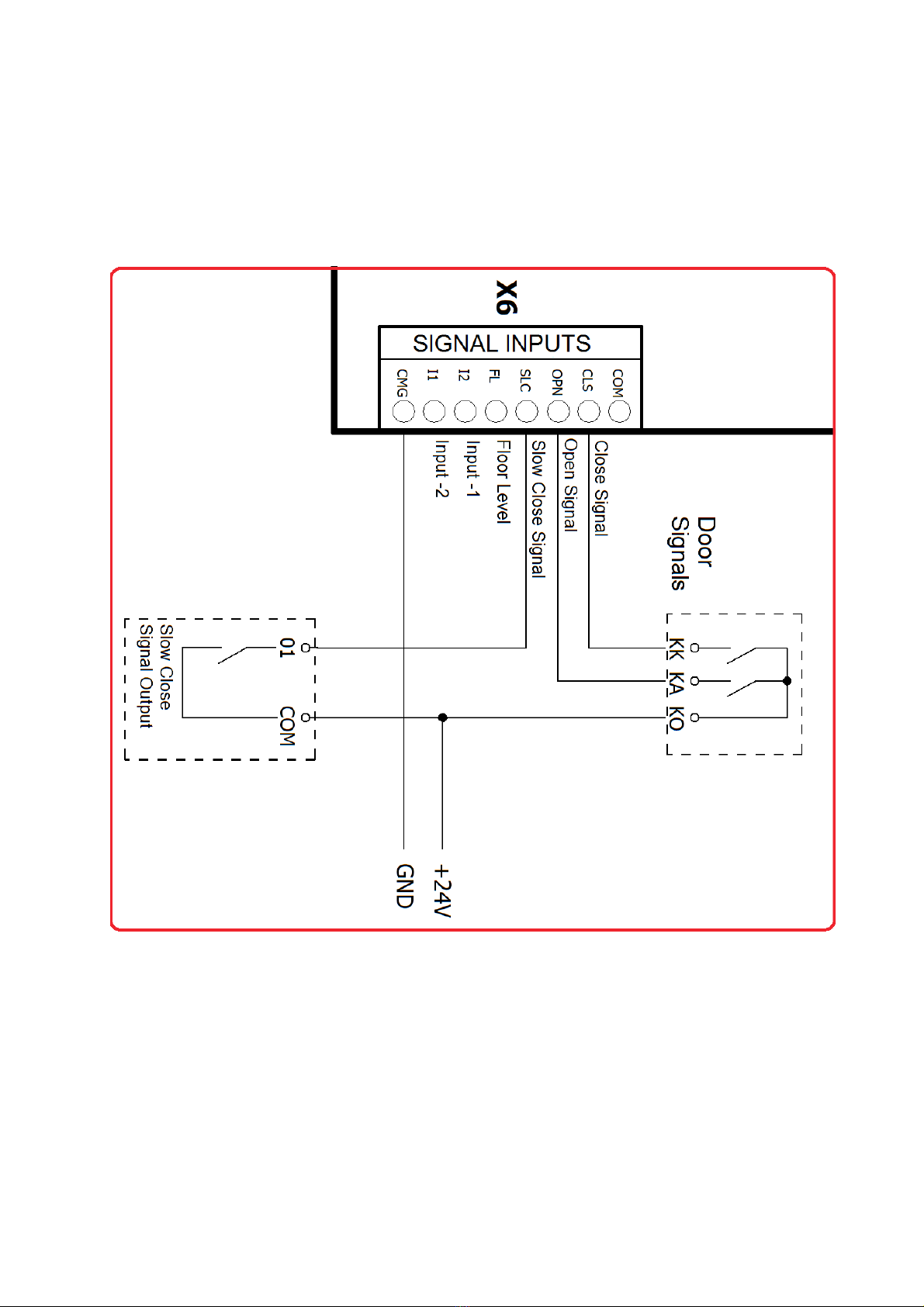

OPEN: This LED is lighting when OPEN signal is received.

CLOSE: This LED is lighting when CLOSE signal is recieved.

SLOW CLOSE: This LED is lighting when SLOW CLOSE signal is recieved.

FLOOR LEVEL: This LED is lighting when FLOOR LEVEL signal is recieved.

NORMAL: This LED is lighting when the system is in normal mode.

OPENED: This LED is lighting when the door is at opened limit.

CLOSED: This LED is lighting when the door is at closed limit.

OBSTRUCTION: This LED is lighting when the system detects an obstruction.

F/7.5.5.02.10 R:1 MBVF