splash-and-splashcenter-manual-en Page 10 / 19

Etchants

Ferric-III-chloride is very easy to handle, has very good etching quality and broad band of applica-

tion. That is why it is the most popular etching agent for laboratory uses. Ferric-III-chloride has a

high etching speed and ensures perpendicular copper walls after etching. We strongly recommend

to use ferric-III-chloride with our machines.

Mix 800 g Granulate per litre water. This will be 1.4 l of ready solution. Ferric-III-chloride etches

warm and cold. The optimum temperature is approx. 45°C.

With our etching machine JET 34 a fresh solution of ferric-III-chloride etches 35 µm Cu in approx.

70 seconds. With increasing saturation etching time goes up to 3 Min for 35 µm Cu. Under-etching

increases only slightly.

Ferric-III-chloride can take up to 50 g Cu per Litre. In reality you will not reach that limit, because

etching time will take too long. Recognize the saturated solution from its milky look.

Experienced users add small portions of 15% Hydrochloride acid (HCl) to the used solution to pre -

vent copper mud and Ferric stain in the machine. We will supply further information on request.

The used etching agent has to be disposed according to your national legislation.

We do not recommend to neutralize the used etchant, because you have to precisely analyse the

copper concentration after neutralisation. In Germany copper concentration in waste water has to be

less than 0.5 mg Cu/l.

Your Disposal administration will advice you on how to dispose the used etchant. Additional informa -

tion you will find in the material safety data sheet (M D ).

By the way: the brown spots on clothing and items caused by Ferric-III Chloride are easily removed

by our stain remover RX3.

Other Etchants:

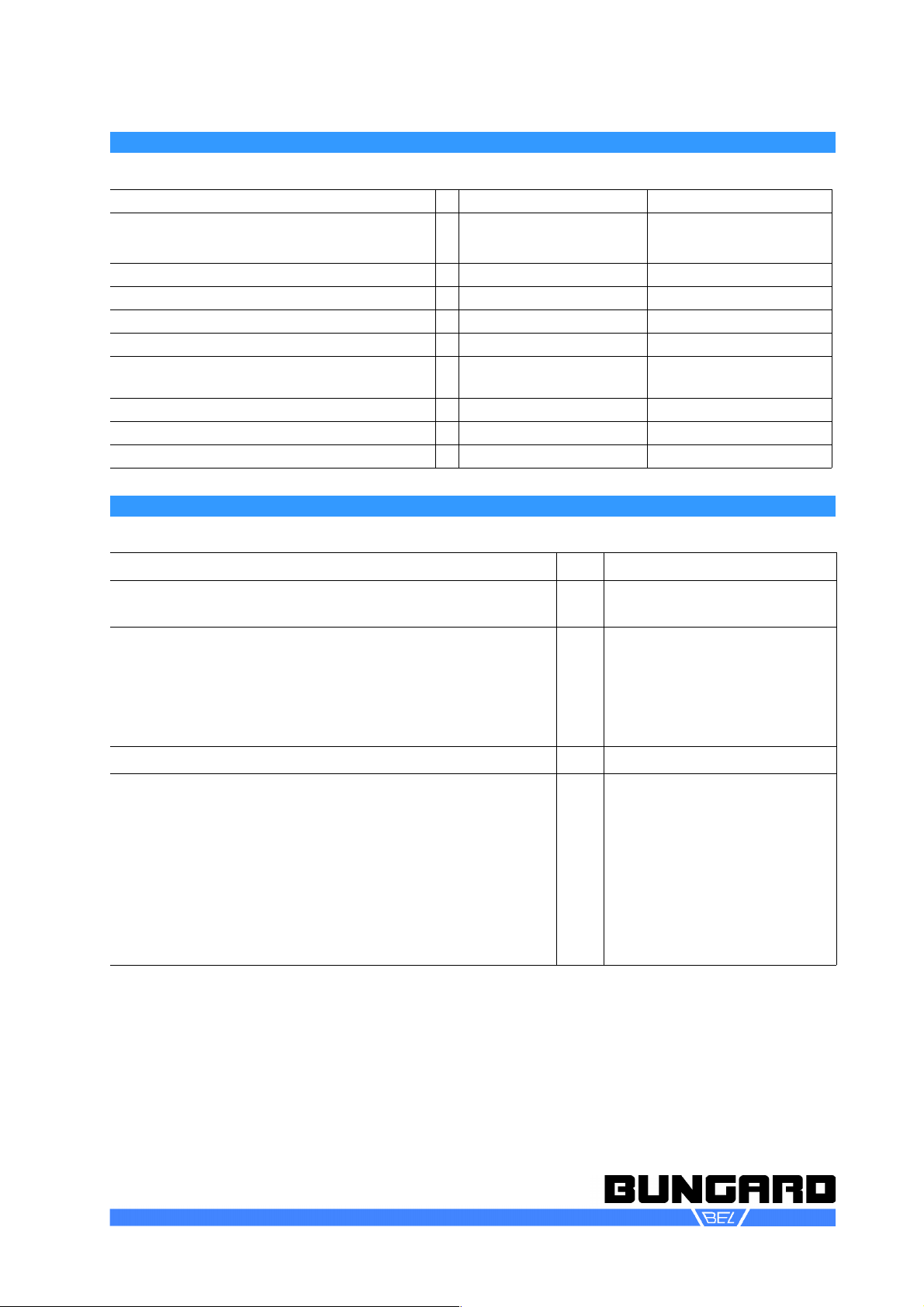

Etchants Pros Cons

Ferric-III-Chloride Cheap, high copper capacity (50g/l)

good etching rate (0,5µm/s), stable,

good sharpness, low underetching, not

considered as a dangerous good, stains

easily removable with RX3

sludge formation

Regeneration only difficult

ammonium persulfate „clean“, good etching rate (8-30µm/min)

and copper capacity (30-40 g/l)

Forms complex salts (including double salts of

copper sulphate and ammonium sulphate), dis-

posal 10 times as expensive as Fe3Cl, corrosive

fumes, Crystalline deposits at temperatures be-

low 30 ° C, which are sharp as glass and can

damage pumps and cut moveable machine

parts,

odium persulfate no sludge, suitable for metal, copper

can be deposited electrolytically

Low etch rate (0.1-0.2 micron/s), does not etch in

cold state, decomposes when heated (especially

in the vicinity of the heating rod), catalyst (mer-

cury) is toxic.

copper chloride Regenerable, good capacity (100g / l)

and etching rate (30μm/min)

Bath control is very complicated, fumes are

toxic/aggressive

ammonia suitable for metal resist, good copper

capacity (up to 200g / l)

bath control difficult, exothermic reactions, toxic

fumes, complex salts, crystallization risk