Operating Instructions Type 0211/0212

Design:

2-way solenoid valve, direct acting, normally closed (Circuit

function A) or normally open (Circuit function B).

Seal Materials and Fluids handled:

See Table.

Fluid and Ambient Temperature:

For Hazardous Locations Div. 1 (T4 rated)

Max. Ambient Temperature 104 °F (40 °C)

Max. Fluid Temperature 194 °F (90 °C)

The UL-listed valve for Hazardous Locations is suitable for

the fluids air, inert gas, water and gasoline.

For Hazardous Locations Div. 1 (T6 rated)

Max. Ambient Temperature 104 °F (40 °C)

Max. Fluid Temperature 140 °F (60 °C)

For Hazardous Locations Div. 2 and Ordinary Locations:

See Table.

Pressure Range:

Maximum inlet pressure see label on valve.

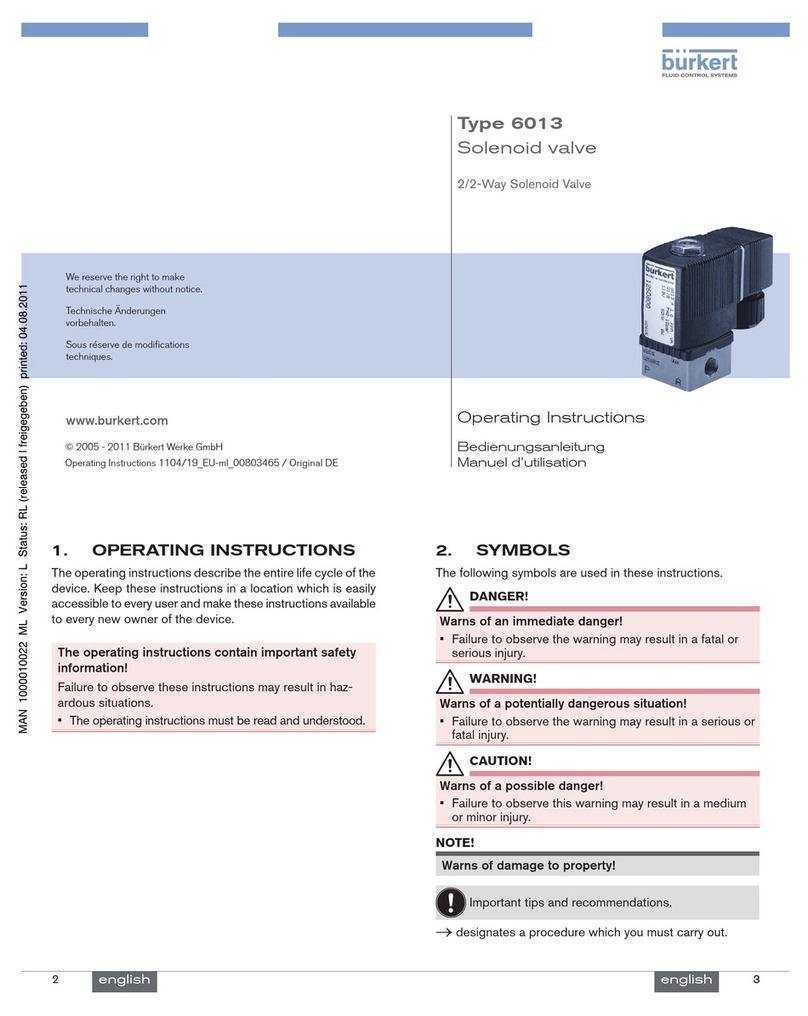

Installation:

Before installing valve ensure that piping etc. is free of foreign

matter (metal fillings, seal materials, welding scale etc.). In-

stallation as required but preferably with coil uppermost. Instal-

lation in this position tends to prevent foreign matter remaining

in core tube (increased life). Do not put any loads on coil unit.

Type 0211: PTFE tape is recommended for sealing ports.Arrow

on valve body indicates flow direction.Mounting is accomplished

by means of four M4 x 8 mm tapped holes located on the valve

underside.

Type 0212: Outlet port is coded on side of body. For common

pressure, align "A" marking on valve and manifold. To remove

valve from manifold loosen only the two unsealed screws.

Manifolds can be connected togehter with nipples.

Marking (example):

Circuit function

A = Normally Closed

B = Normally Open

Seal Material

EPDM = EPDM

NBR = NBR

FKM = FKM

EA = PTFE seat and EPDM O-ring

EF = PTFE seat and FKM O-ring

NN = Neoprene

Body Material

BR = Brass

SS = Stainless Steel

NI = Nickel Plated Brass

PL = Polyamide Plastic

Maximum Pressure

Voltage / Frequency / Power Consumption

Recorder No.

Approvals

The valve is either approved as

General Purpose valve for Hazardous Locations

Class I, Division 1, Group A, B, C, D

Class II, Division 1, Group E, F, G

Class III, Division 1 and 2

Operating Temperature T 4

or General Purpose valve for Hazardous Locations

Class I, Division 1, Group A, B, C, D

Class II, Division 1, Group E, F, G

Class III, Division 1 and 2

Operating Temperature T 6

or FM approved as

Nonincendive for Hazardous Locations

Class I, Division 2, Group A, B, C, D

Class II, Division 2, Group F, G

Class III, Division 1 and 2

Operating Temperature T 4

UL listed for Ordinary locations

CSA approved for Ordinary locations

See label on the valve.

Operating Instructions 0605/08_EU-EN_00893132

Seal Materials Seat / O-ring

Fluid Tempera-

tures [°F] Buna „N‰ Ethylene

Propylene FKM PTFE/

Ethylene

Propyl.

PTFE/

FKM Neoprene

Air Fluid T.

Ambient +14 to +194

+14 to +130 -40 to +266

+14 to +130 +14 to +266

+14 to +130 +14 to +266

+14 to +130 +14 to +266

+14 to +130

Water Fluid T.

Ambient +32 to +194

+32 to +130 +32 to +212

+32 to +130 +32 to +212

+32 to +130 +32 to +212

+32 to +130 +32 to +212

+32 to +130

Neutral Gas Fluid T.

Ambient +14 to +194

+14 to +130 -40 to +266

+14 to +130 +14 to +266

+14 to +130 +14 to +266

+14 to +130 +14 to +266

+14 to +130

Light oil Fluid T.

Ambient +14 to +194

+14 to +130 +14 to +266

+14 to +130 +14 to +266

+14 to +130

LP-gas Fluid T.

Ambient +14 to +140

+14 to +130 +14 to +140

+14 to +130 +14 to +140

+14 to +130

Refrigerants Fluid T.

Ambient +14 to +194

+14 to +130