Burkert 8750 User manual

Other Burkert Controllers manuals

Burkert

Burkert eCONTROL 8611 User manual

Burkert

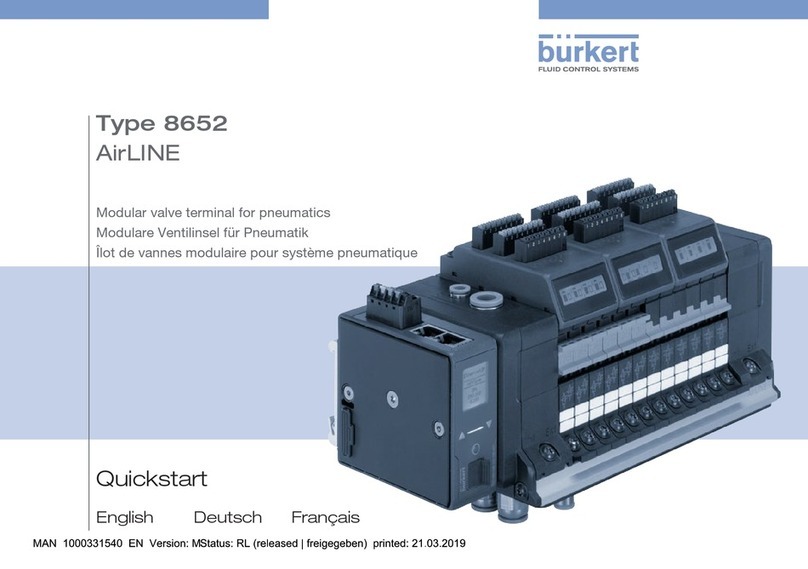

Burkert AirLINE 8652 User manual

Burkert

Burkert 8605 Series User manual

Burkert

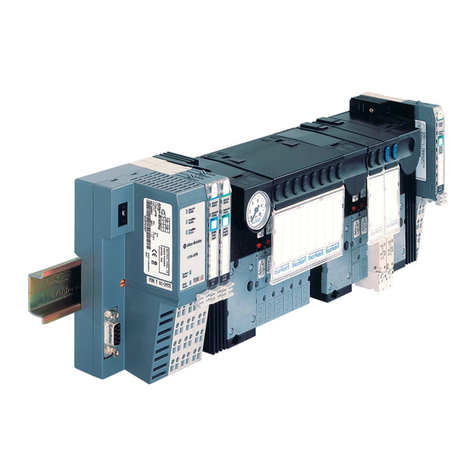

Burkert 8644 AirLINE User manual

Burkert

Burkert 8742 Operating manual

Burkert

Burkert 8691 REV.3 User manual

Burkert

Burkert 5470 User manual

Burkert

Burkert 1094 Series User manual

Burkert

Burkert 8025 Series User manual

Burkert

Burkert 0911 User manual

Burkert

Burkert 8681 User manual

Burkert

Burkert 8025 Series User manual

Burkert

Burkert 5413 User manual

Burkert

Burkert 6626 TwinPower User manual

Burkert

Burkert Positioner TopControl Basic 8694 User manual

Burkert

Burkert 8793 User manual

Burkert

Burkert 8756 BATCH User manual

Burkert

Burkert 3010 User manual

Burkert

Burkert 8691 User manual

Burkert

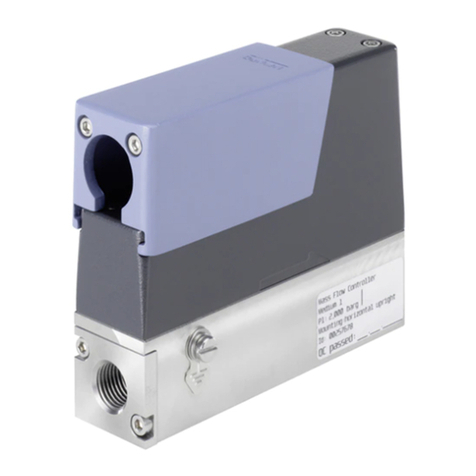

Burkert 8745 MFM Ethernet User manual

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions