7

2010 T-104

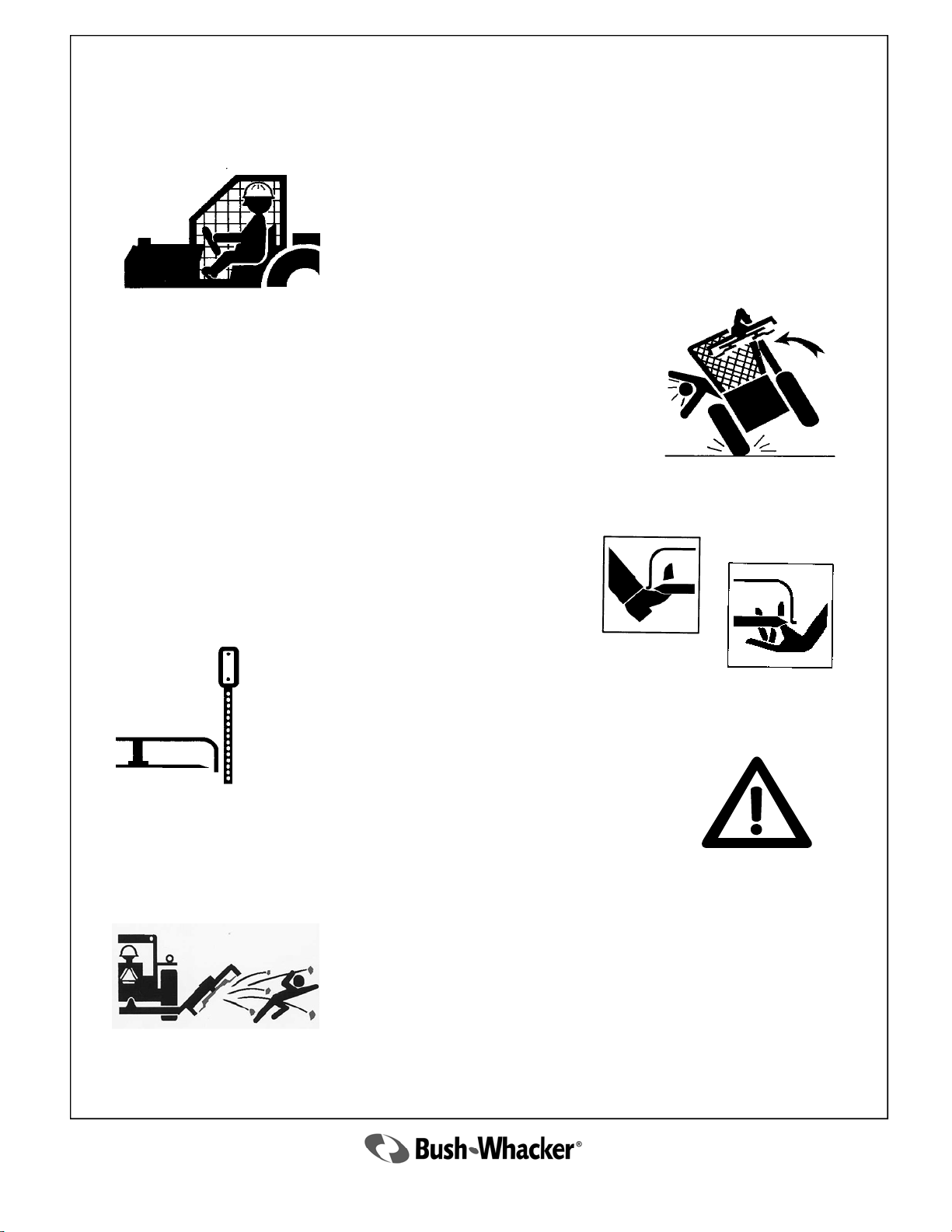

NEVER operate a rotary mower with a person or animal in the

area. The blades may throw objects for great distances and can

strike a person, passersby, or animal causing serious injury or

death.

Safety Warnings

Stop operation of the machine for a passerby or if someone appears to be approaching the area.

Objects can be thrown for hundreds of yards at great speed.

ALWAYS inspect the deflector shields and/or chain guards daily to ensure

that they are in proper working order and that no chains are missing. If the

deflector shields or chain guards are not operating correctly, chain links are

missing, or the complete deflector shields or chain guards assembly is

missing, do not operate the mower. NEVER OPERATE THE MOWER

WITHOUT CHAIN GUARDS OR DEFLECTORS IN PROPER

WORKING ORDER.

Operations

Rocks, gravel, wire, rope, bricks, or similar objects are potential hazards for

rotary mowers operation. These items can cause damage to the machine; but

more importantly, they can be ejected from underneath the mower at very high

speeds, resulting in property damage, injury or even death. Always inspect the

mowing area prior to the operation of any rotary mower. If any of these objects

or similar objects are found, remove them immediately before operation.

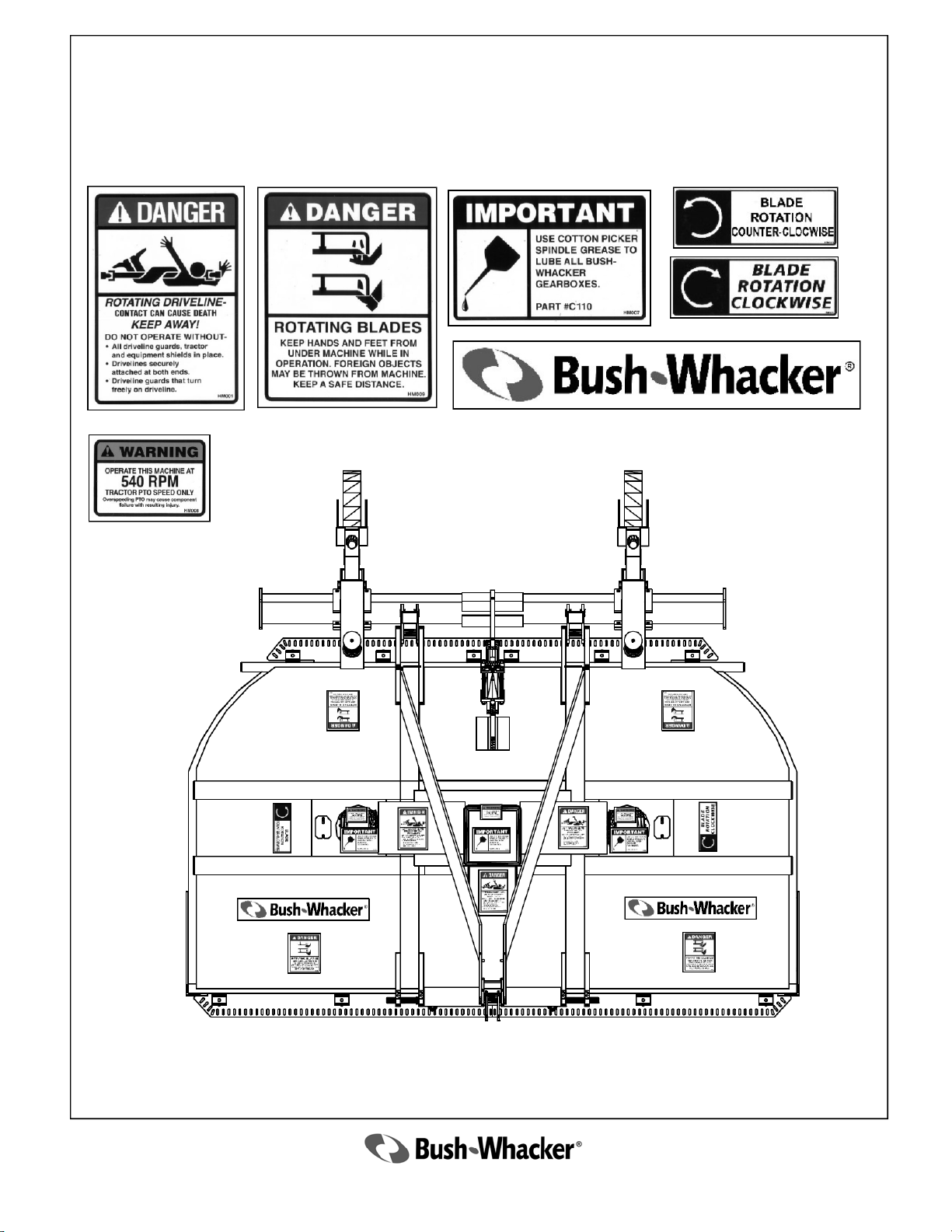

NEVER operate the mower without the driveline safety shields in place and in

proper working order. Operation without safety shields can lead to injury or

death.

EXTREMELY IMPORTANT—Make sure all gearbox shields are in place and tightened be-

fore operating the mower. If one works loose, stop mowing and tighten immediately. NEVER

OPERATE THE MOWER WITHOUT ALL GEARBOX SHIELDS PROPERLY IN-

STALLED. OPERATION WITHOUT SAFETY SHIELDS MAY CAUSE SERIOUS IN-

JURY OR DEATH.

This mower operates at a PTO speed of 540 RPM only. Check the tractor manufacture’s

instruction manual for the proper engine RPM to achieve the proper PTO speed. DO NOT

operate the mower at any higher RPM, doing so will cause damage to the mower as well

as create an extreme hazard to the operator, passersby, or animals. Also note that doing so

will void the warranty of the machine.