6

1 Description of the system

Measurement units of the micro-

gloss family can be used to

determine the gloss level of paint

coatings, plastics, ceramics and

metal surfaces.

Light is directed at the surface of

the sample at a defined angle and

the reflected light is measured

photoelectrically (reflectometer).

Depending on the typical gloss

level of the test object,

reflectometers that direct light onto

the surface at different angles

(geometry) can be used.

Measurement units are equipped

with standard geometries of 20°,

60° or 85°. All three of these

geometries are integrated into the

micro-TRI-gloss. Functions

described in this manual in terms of

geometry selection are only

available with the three angle

device.

In addition to measuring individual

gloss values, it is also possible to

record, save and statistically

evaluate series of measurements

consisting of up to 999 values.

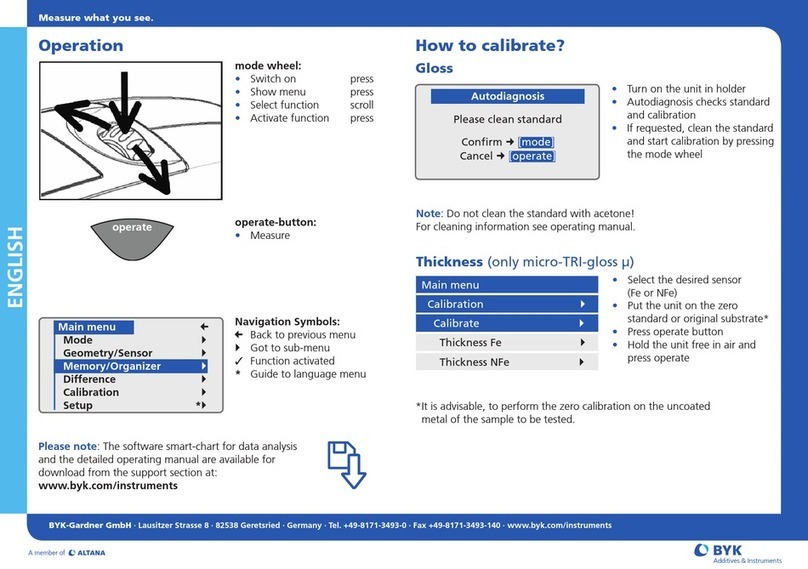

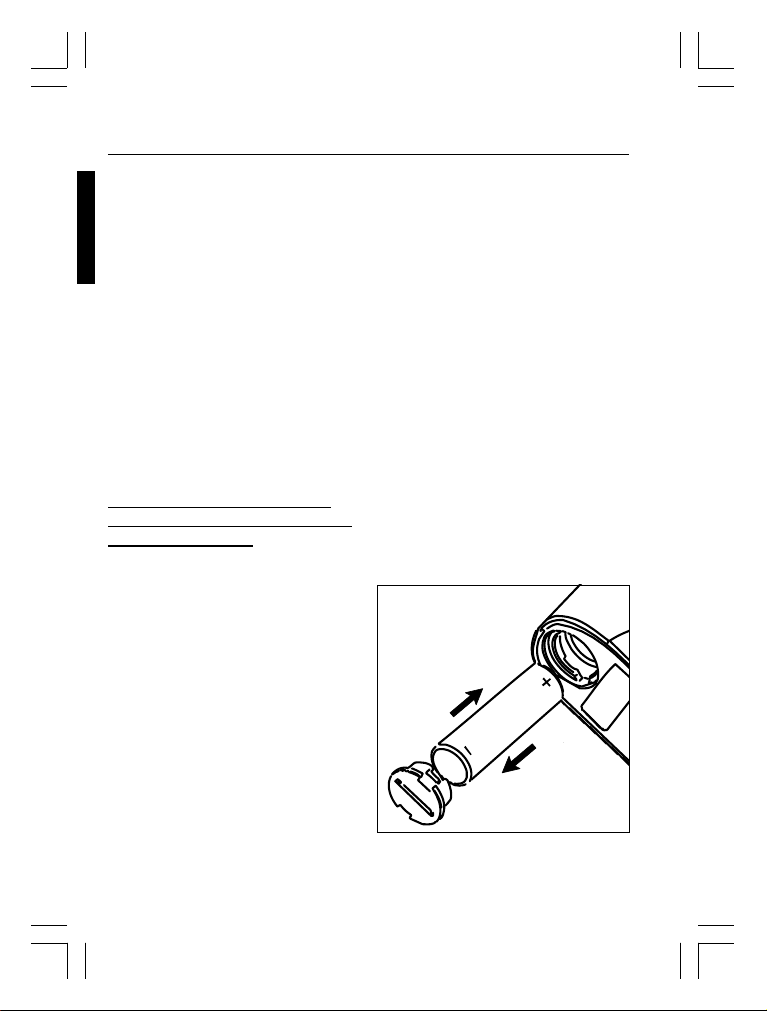

The operate button and scroll

wheel are used to control the

system. System operation is

supported by display messages

(autodiagnosis and error

messages). You can select

German, English, French, Spanish,

Italian or Japanese (Katakana) as

the display language.

The measurement unit conforms to

the standards DIN 67530, ISO

2813, ASTM D 523 and BS 3900

Part D 5.

In addition, it was tested by the

“Bundesanstalt für Material-

forschung und -prüfung (BAM)”

(German Federal Institute for Mate-

rials Research and Testing) and

found to be properly categorized

and to meet requirements as set by

DIN 67530.