1

Table of contents

Section 1 Specifications ........................................................................................................................................ 3

Section 2 General Information .............................................................................................................................. 5

2.1 Safety information .............................................................................................................................................. 5

2.1.1 Use of hazard information ......................................................................................................................... 5

2.1.2 Precautionary labels ................................................................................................................................. 5

2.1.3 Chemical and Biological Safety ................................................................................................................ 5

2.2 Overview of product ........................................................................................................................................... 6

Section 3 Installation ............................................................................................................................................. 7

3.1 Unpack the instrument ....................................................................................................................................... 7

3.2 Environment considerations ............................................................................................................................... 7

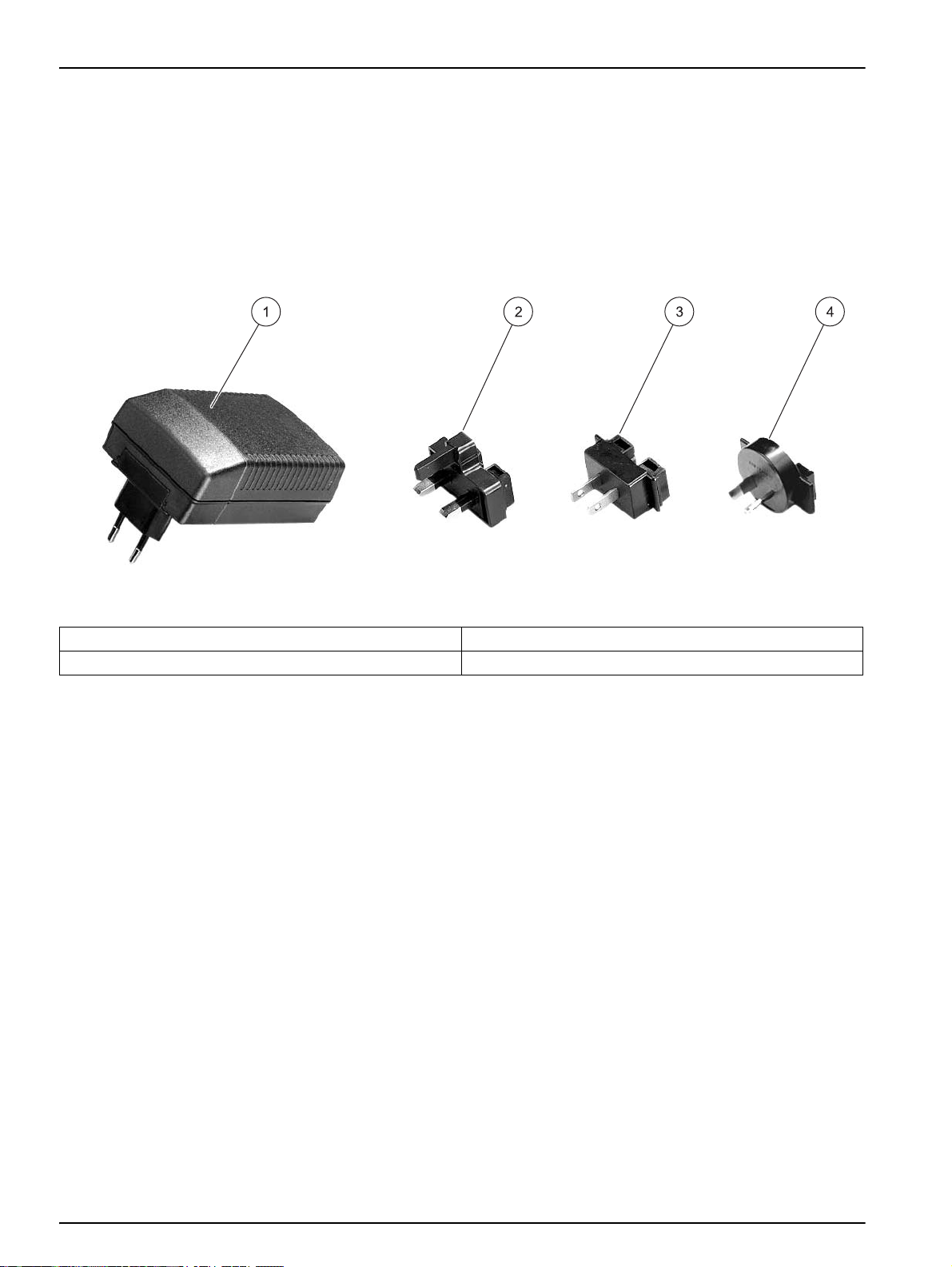

3.3 Power connections ............................................................................................................................................. 8

3.4 Connection ......................................................................................................................................................... 9

3.5 Cell compartments and cell adapter ................................................................................................................ 10

3.5.1 Cell compartments and adapter .............................................................................................................. 10

3.5.2 Installation of the cell adapter ................................................................................................................. 11

Section 4 Start Up ................................................................................................................................................ 13

4.1 Power the instrument on and off ...................................................................................................................... 13

4.2 Language selection .......................................................................................................................................... 13

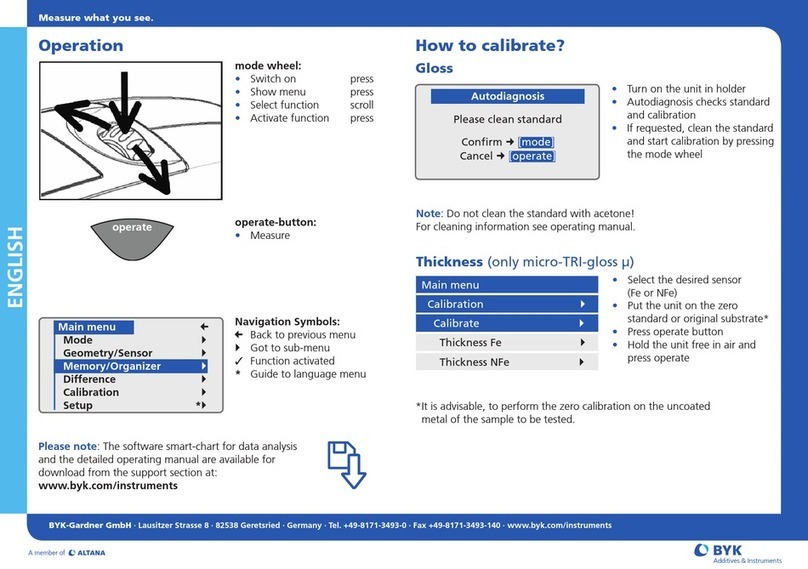

4.3 Self-Check ....................................................................................................................................................... 13

4.4 Characteristics in continuous operation ........................................................................................................... 14

Section 5 Standard Operations ........................................................................................................................... 15

5.1 Overview .......................................................................................................................................................... 15

5.1.1 Tips for the use of the touch screen ........................................................................................................ 15

5.1.2 Use of the alphanumeric keypad ............................................................................................................ 15

5.1.3 Main Menu .............................................................................................................................................. 16

5.2 Instrument Setup mode .................................................................................................................................... 16

5.2.1 Operator ID ............................................................................................................................................. 16

5.2.2 Sample ID ............................................................................................................................................... 17

5.2.3 Date and time .......................................................................................................................................... 18

5.2.4 Display and sound preferences .............................................................................................................. 19

5.2.5 Power Management ................................................................................................................................ 19

5.2.6 PC and printer ......................................................................................................................................... 20

5.2.6.1 Printer setup ............................................................................................................................... 21

5.2.6.2 PC setup ..................................................................................................................................... 23

5.2.6.3 Print data .................................................................................................................................... 23

5.2.7 Password ................................................................................................................................................ 24

5.2.7.1 Deactivate a password ............................................................................................................... 25

5.3 Store, recall, send and delete data .................................................................................................................. 26

5.3.1 Auto/manual data storage ....................................................................................................................... 26

5.3.2 Recall stored data from the data log ....................................................................................................... 26

5.3.3 Send data from the data log .................................................................................................................... 27

5.3.4 Delete stored data from the data log ....................................................................................................... 28

5.4 Sampling and sample preparation ................................................................................................................... 29