8

English

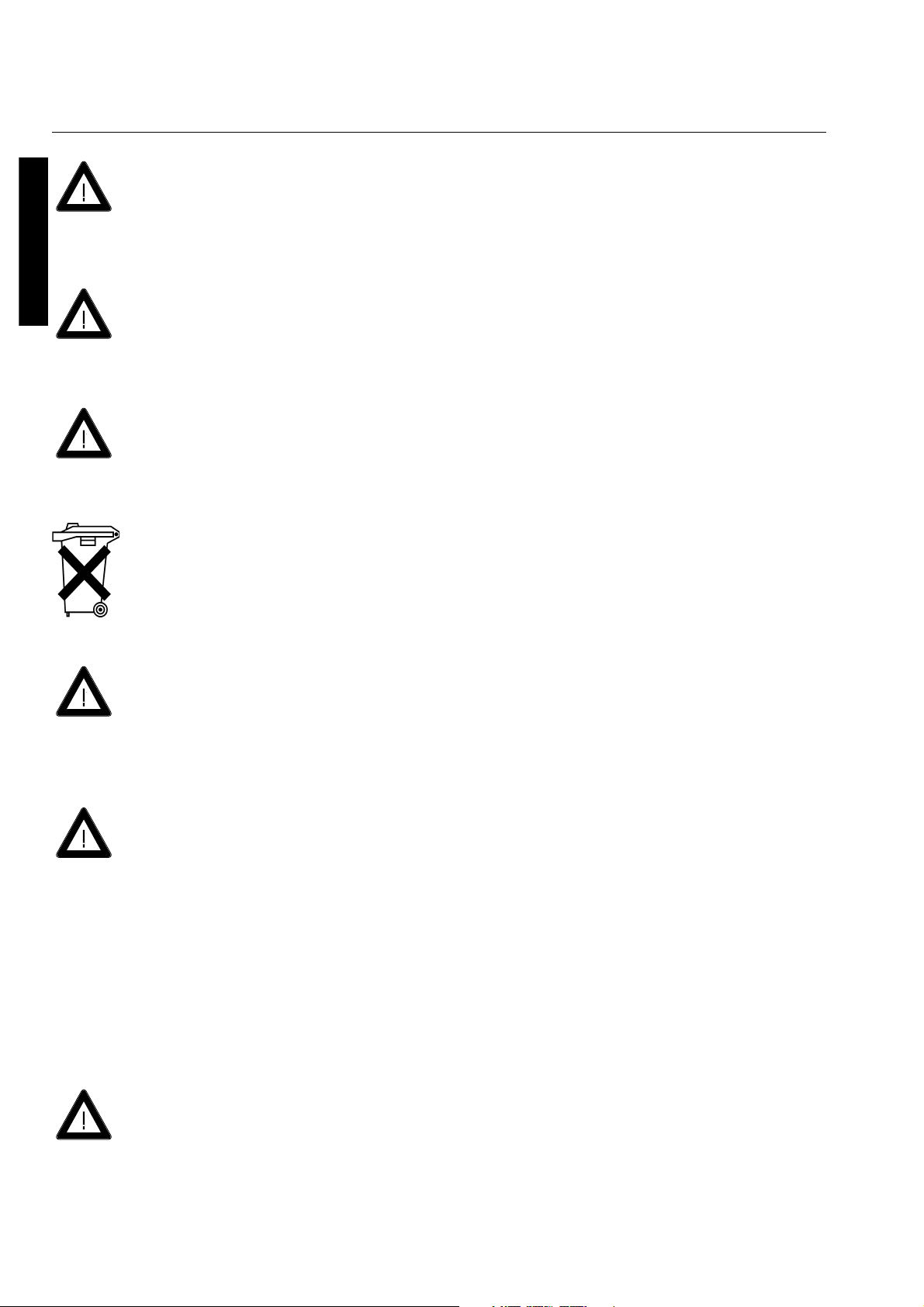

4 Installing the Batteries

Before putting the unit in

operation, read the operating

instructions and pay attention to

the safety instructions and

general instructions in Section 2.

Unpack the device and check

the delivery for completeness (for

scope of delivery, see Section

Delivery notes).

Power supply

battery - operated

The batteries must be placed in

the measuring unit for operation.

The device runs on four AA 1.5-V

alkaline batteries.

Use only alkaline batteries

(AA /LR6)!

Depending on the exact brand,

the capacity of each battery-set is

sufficient for about 3.000

measurements. When the battery

voltage falls below the required

minimum voltage in the course of

operation, the following message

appears on the display

Battery empty!

To ensure that the unit is always

ready for operation, it is

recommended to have spare

batteries handy, especially when

performing measurements in the

field.

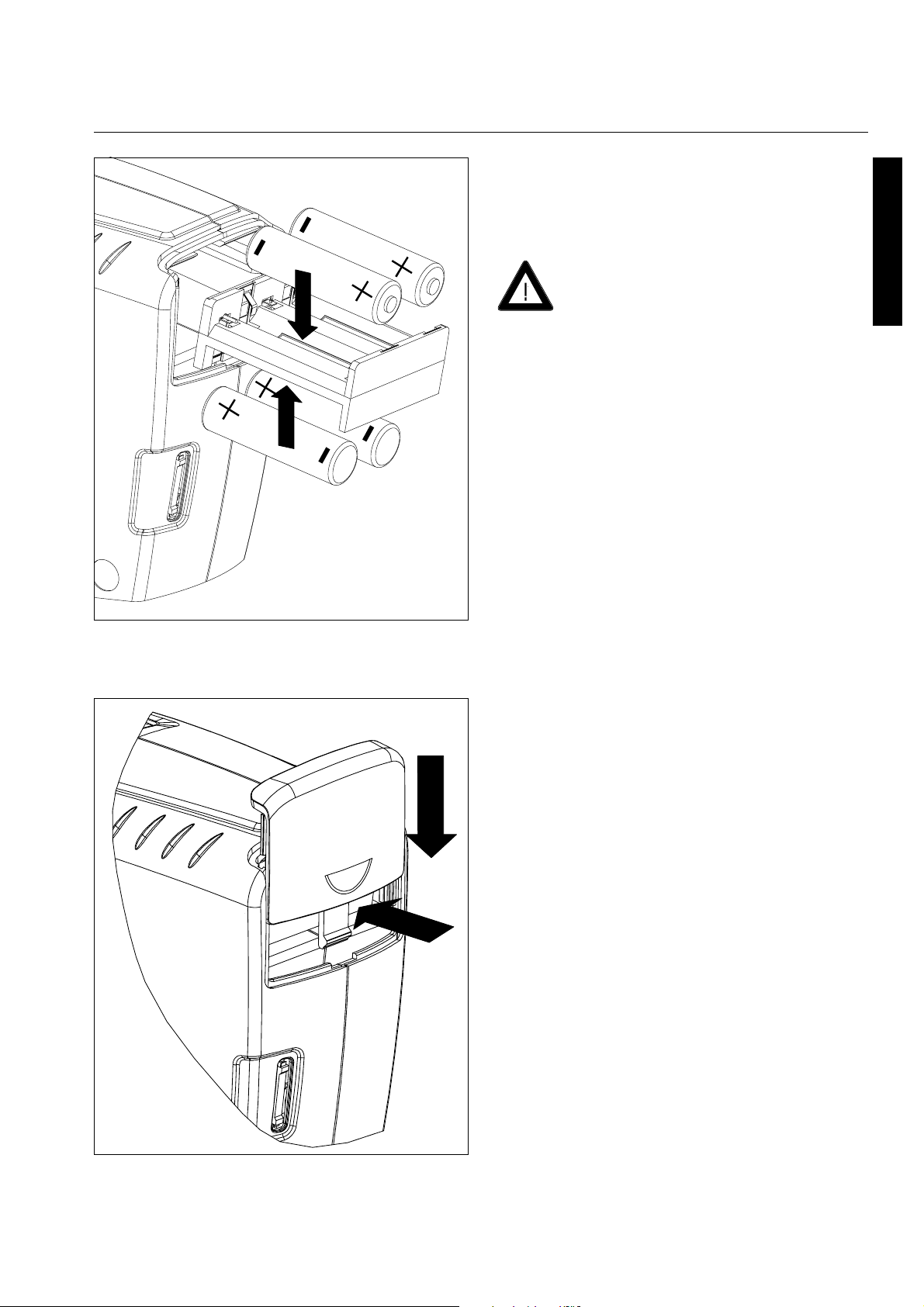

Changing the battery

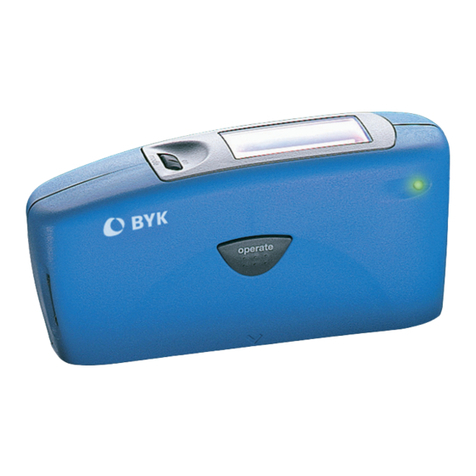

To insert or change the batteries,

open the lid of the battery

compartment (1) and take out the

battery box as shown below (2).

1

2