%NGLISH

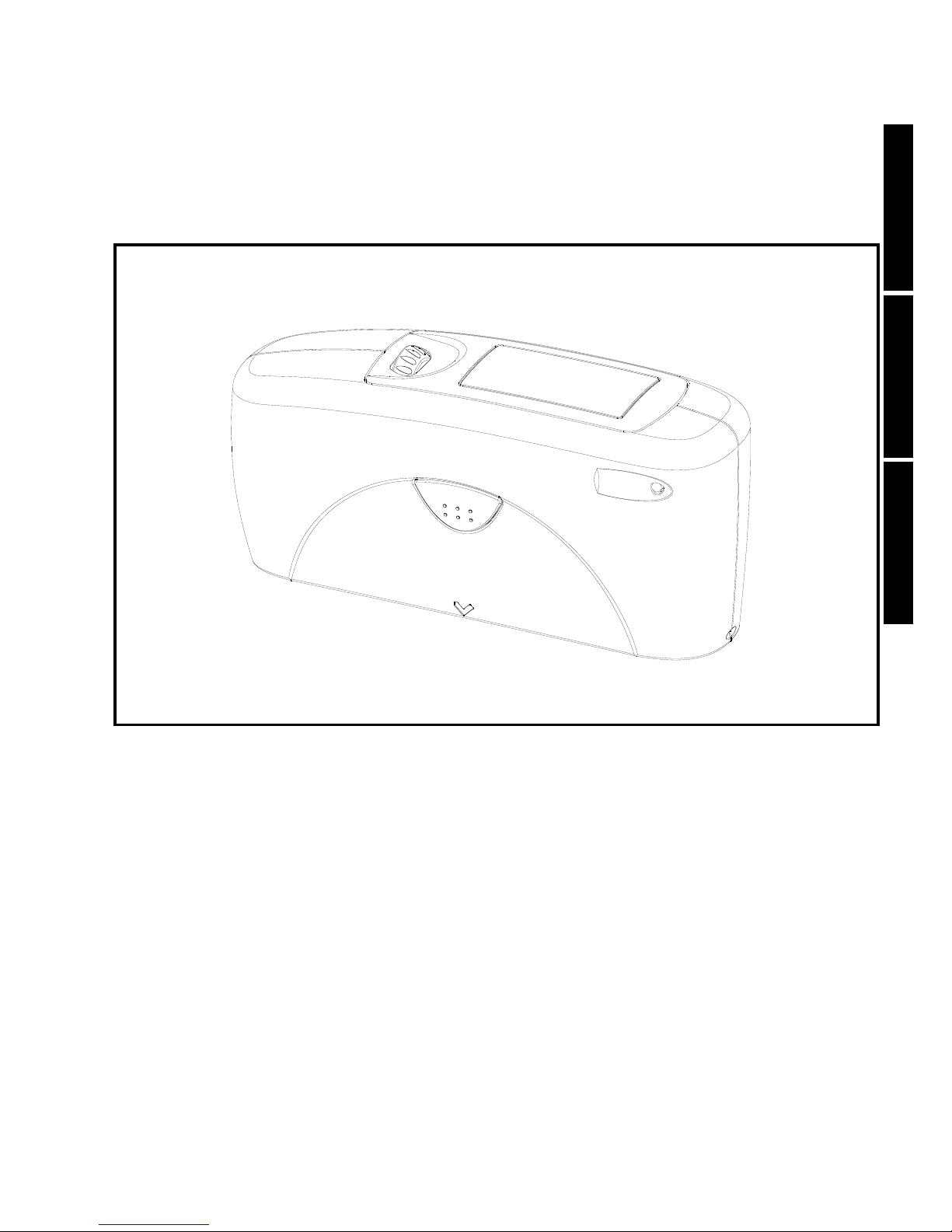

¬ $ESCRIPTION¬OF¬THE¬SYSTEM

4HE¬MEASUREMENT¬UNITS¬CAN¬BE¬

USED¬TO¬DETERMINE¬THE¬GLOSS¬LEVEL¬

AND¬lLM¬THICKNESS¬OF¬PAINT¬AND¬

COATINGS¬ON¬MAGNETIC¬&E¬AND¬

NONMAGNETIC¬SUBSTRATES¬.&E

,IGHT¬IS¬DIRECTED¬AT¬THE¬SURFACE¬OF¬

THE¬SAMPLE¬AT¬A¬DElNED¬ANGLE¬AND¬

THE¬REmECTED¬LIGHT¬IS¬MEASURED¬

PHOTOELECTRICALLY¬REmECTOMETER¬

$EPENDING¬ON¬THE¬TYPICAL¬GLOSS¬

LEVEL¬OF¬THE¬TEST¬OBJECT¬DIFFERENT¬

ANGLES¬GEOMETRY¬ARE¬TO¬BE¬USED¬

4HE¬MEASUREMENT¬UNIT¬IS¬¬

EQUIPPED¬WITH¬STANDARD¬¬

GEOMETRIES¬OF¬ª¬ª¬AND¬ª

)N¬ADDITION¬TO¬MEASURING¬INDIVIDUAL¬¬

GLOSS¬VALUES¬IT¬IS¬ALSO¬POSSIBLE¬TO¬¬

RECORD¬SAVE¬AND¬STATISTICALLY¬¬

EVALUATE¬SERIES¬OF¬MEASUREMENTS¬

CONSISTING¬OF¬UP¬TO¬¬VALUES¬

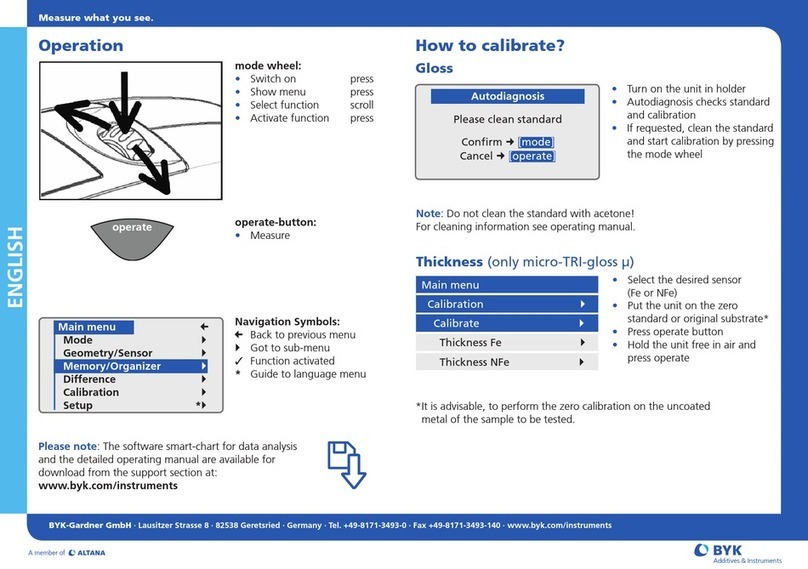

4HE¬OPERATE¬BUTTON¬AND¬SCROLL¬

WHEEL¬ARE¬USED¬TO¬CONTROL¬THE¬¬

SYSTEM¬3YSTEM¬OPERATION¬IS¬¬

SUPPORTED¬BY¬DISPLAY¬MESSAGES¬

AUTODIAGNOSIS¬AND¬ERROR¬¬

MESSAGES¬9OU¬CAN¬SELECT¬¬

'ERMAN¬%NGLISH¬&RENCH¬3PANISH¬

)TALIAN¬OR¬*APANESE¬+ATAKANA¬AS¬

THE¬DISPLAY¬LANGUAGE¬

4HE¬MEASUREMENT¬UNIT¬CONFORMS¬¬

TO¬THE¬STANDARDS¬$).¬¬¬

)3/¬¬!34-¬$¬¬AND¬¬

"3¬¬0ART¬$¬¬