- 4 -

1. Safety & Warnings

1.3 Safety Instructions Governing Specific Operational Phases

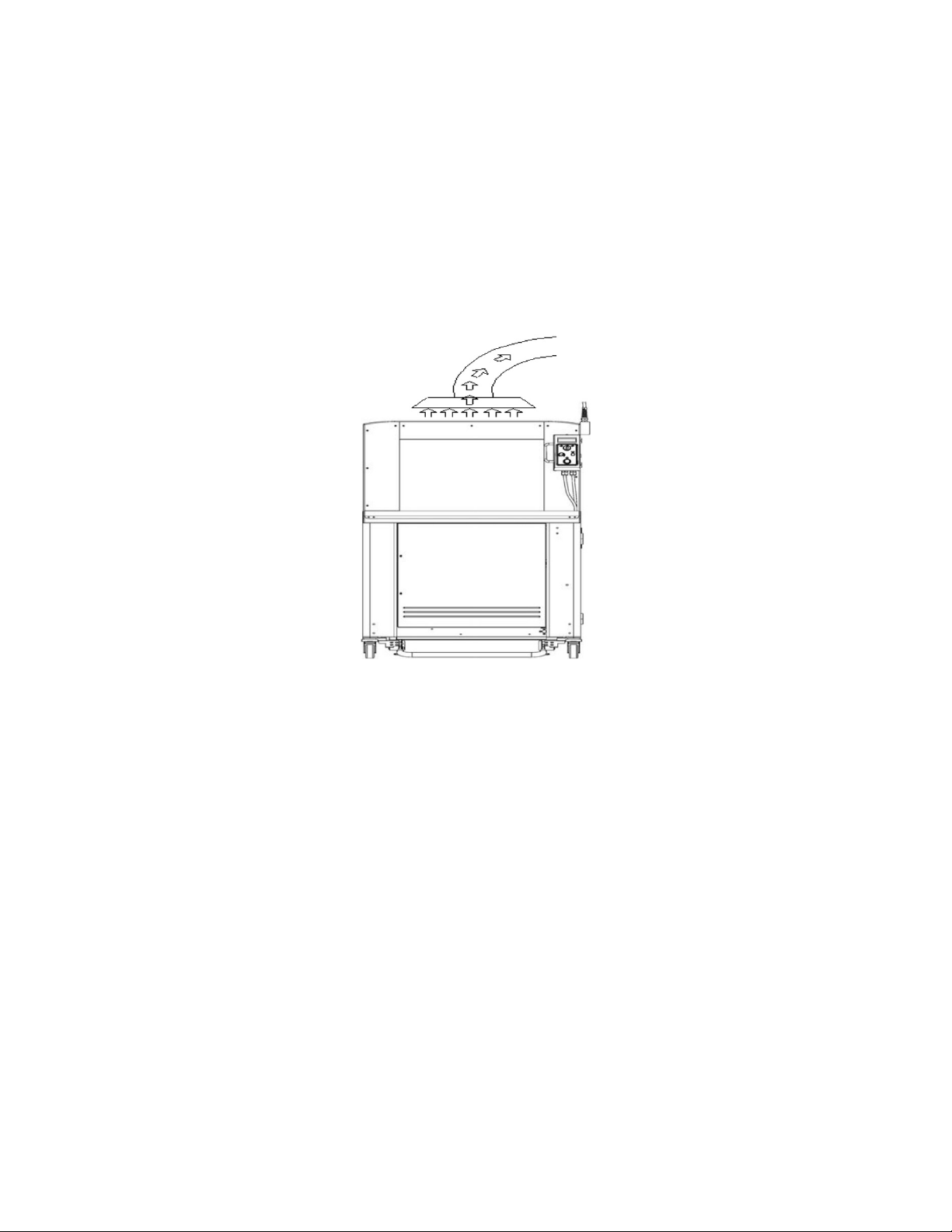

•Avoid unsafe operation of the equipment.

•The machine is only to be operated when it is in good running order. Only operate the

equipment in a safe manner; all protective and safety devices must be in place and fully

functional. This includes removable safety devices, emergency shut-off equipment, noise-

protection devices and exhaust fans.

•The machine is to be checked for damage and defects at least once each work shift. Any

changes, including the working behavior of the machine, are to be reported immediately.

•If necessary, the machine is to be stopped and locked-out immediately.

•In case of a malfunction, the strapping machine is to be immediately stopped and locked-out

until the fault has been eliminated.

•Before starting the strapping machine, make sure that the area is clear and safe.

•Do not place any tools or parts onto the machine.

•Operating personnel needs to be well trained before executing special operations and

maintenance work; this work needs to be done with the proper supervision.

•Always check and tighten connections after maintenance or repair.

•After completing maintenance or repair, all safety devices must be replaced and checked for

functionality before operating the equipment.

•To minimize the environmental impact, all consumables and replaced parts must be disposed of

safely.

•Before starting the machine, check that the accessories have been stowed away safely.

•Avoid operating the machine in a fashion that could upset its stability.

1.4 Electrical Dangers

•Immediately remove power to the machine in case of trouble in the electrical system.

•Replace a fuse with one with the same style and ratings; pay particular attention to matching

the specified current.

•Any electrical work performed on the equipment must be conducted by a skilled electrician or

under the supervision of a skilled electrician. All work must be observed good electrical

engineering practice and follow safety rules and local wiring standards.

•Inspect the electrical equipment of the machine at regular intervals. Tighten any loose

connections. Check wiring for scorch marks; replace scorched wiring and determine and correct

the reason for the overheating.

•When working on live equipment, ensure that a second person is available to cut power in case

of an emergency. When appropriate, secure the working area with safety tape and a warning

sign. Use insulated tools for electrical work.

•Before working on high-voltage assemblies, turn off the power supply. Carefully discharge the

supply cable and short-circuit any energy-storage components such as capacitors.

•If the equipment was moved, carefully refit and refasten all parts removed for transport before

reapplying power.

•Before moving the machine, remember to disconnect the power cable.