3

Introduction

AllCaframostirrersarespecicallydesignedforprofessionaluseinthelaboratory

and for use in industry to stir numerous liquids with various properties and

applications.

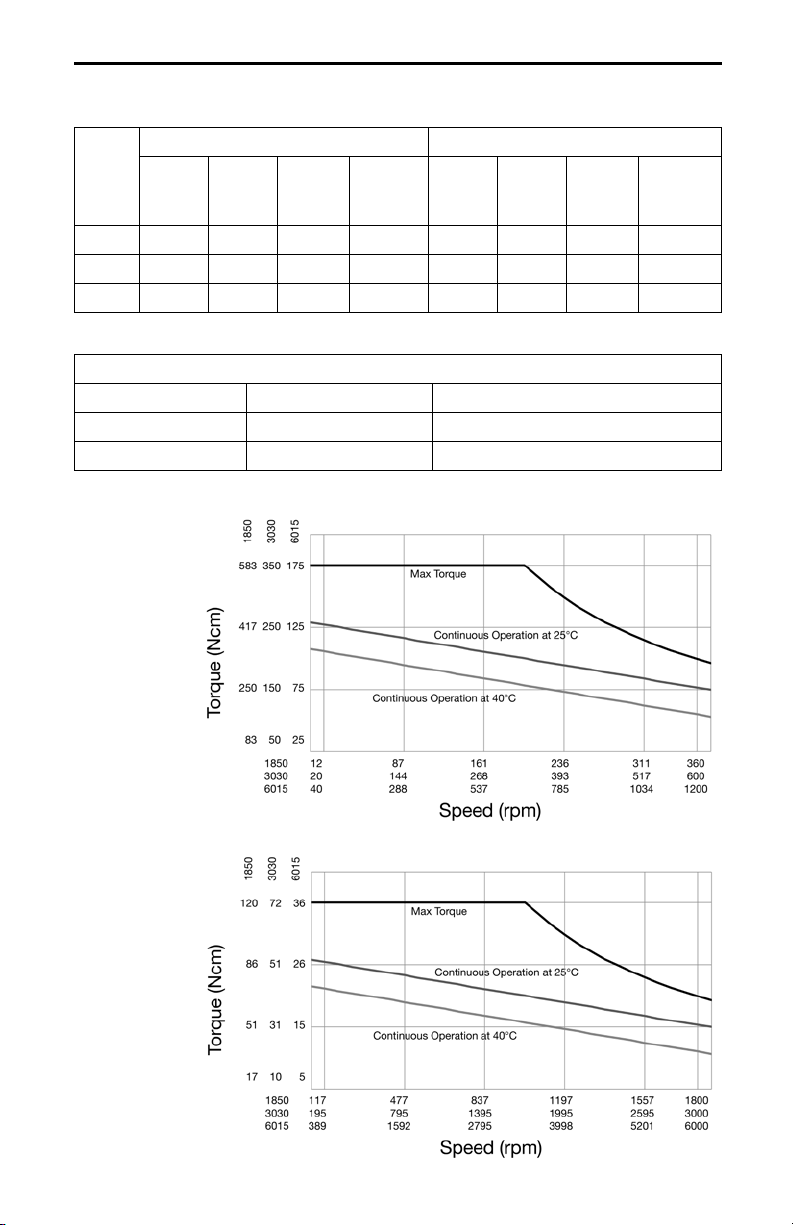

BDC1850 - Rotates at 12-1800 rpm with a maximum torque of 583 Ncm

BDC3030 - Rotates at 20-3000 rpm with a maximum torque of 350 Ncm

BDC6015 - Rotates at 40-6000 rpm with a maximum torque of 175 Ncm

ThestirrerusesahighefciencybrushlessDCmotor.Thespeediskeptconstant

with continuous feedback to the motor. All stirrers have integrated overload protec-

tion which ensures no damage can occur to the electronics, motor or transmission

when an overload situation occurs, such as too great a torque demand or stirrer

overheating.

The stirrers incorporate smart logic for automatic transmission control. This logic

determines the appropriate speed range at which the stirrer should operate. See

Torque Capabilities section. The automatic selection can be overridden by press-

ing the speed button.

The stirrer is designed for reliability and durability. There are no wear parts that

require user service during the normal life of the stirrer.

Safety Instructions

1. Before use, all operators must be familiar with the stirrer and should

read this entire manual as labeled on the back of the stirrer. If the

stirrer is used with accessories not provided or recommended by the

manufacturer,orusedinamannernotspeciedbythemanufacturer,

the protection provided by the equipment may be impaired.

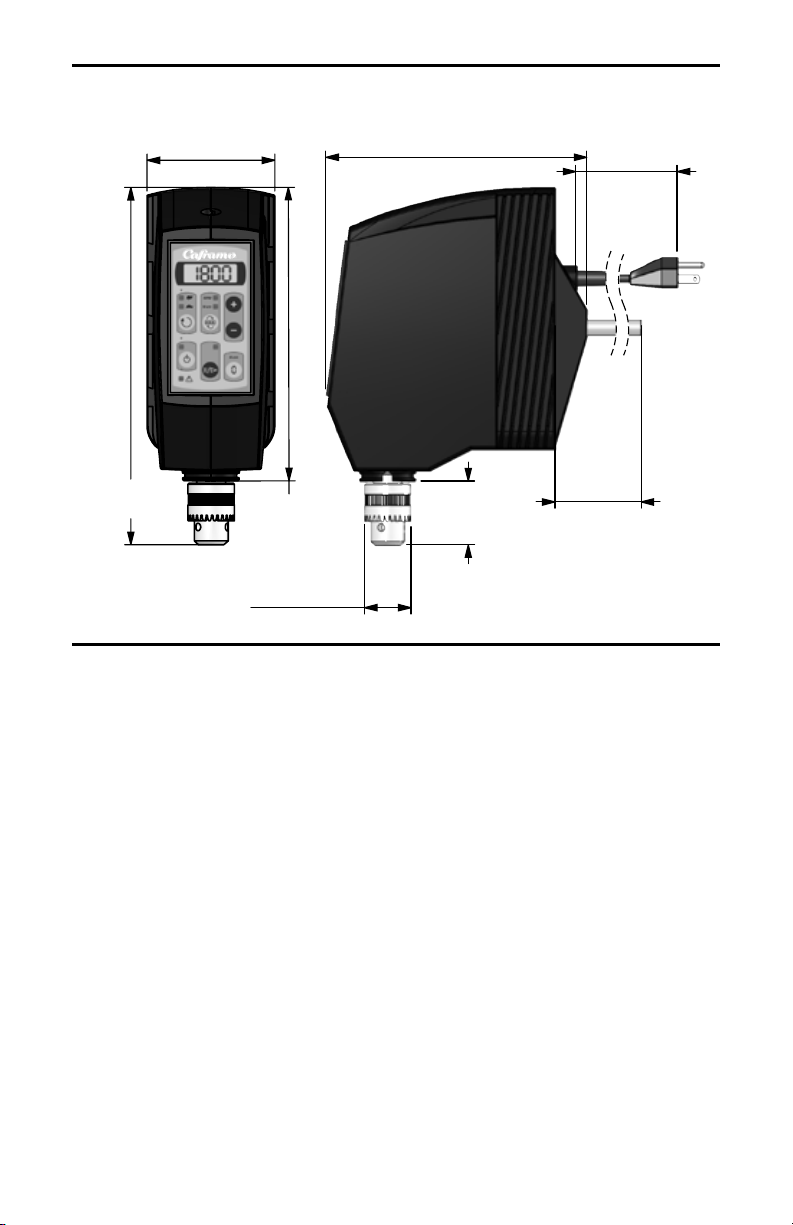

2. Thestirrermustbesecurelyxedtoastablesupport.MounttoaCaframo

Stand (Part Number A110) with a Caframo clamp (Part Number A120). If

other stands or clamps are used, the stirrer must be secure to prevent fall

if tipped up to ten degrees from the vertical.

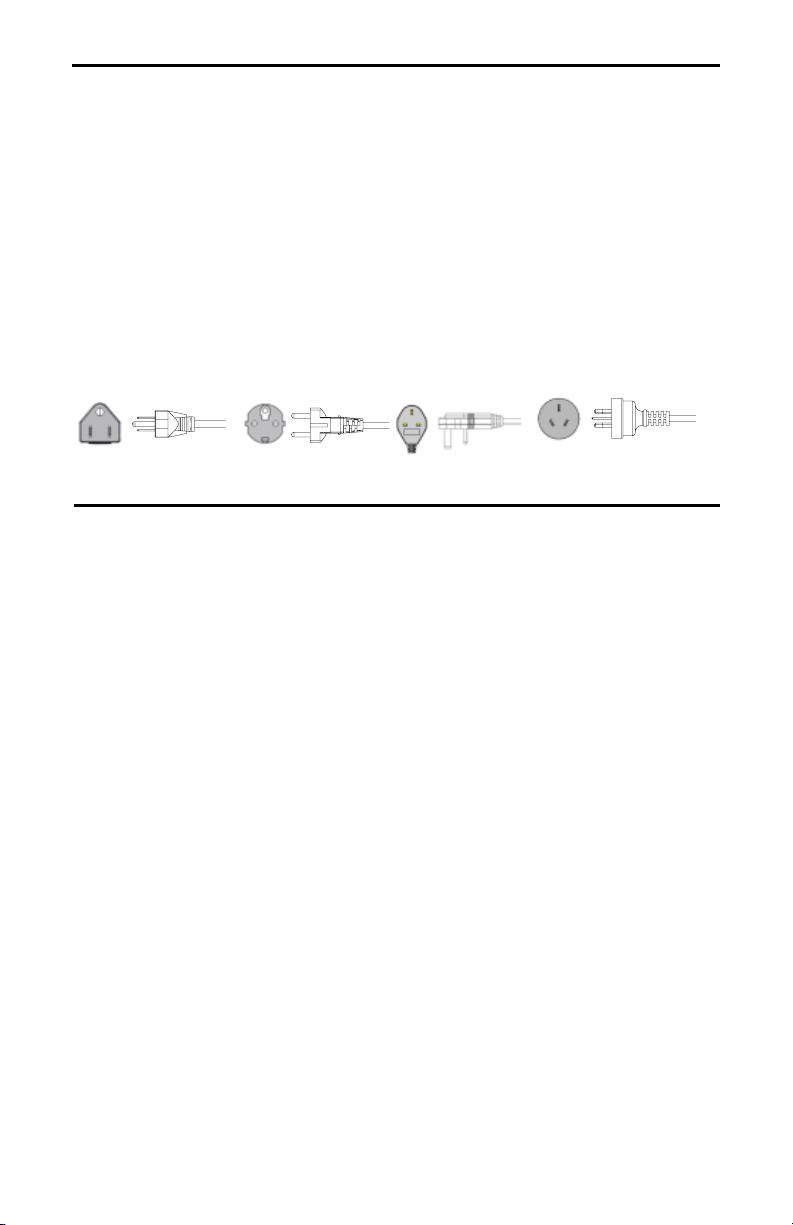

3. Thestirrermustbesuppliedwiththevoltagespeciedontheseriallabel.

4. CAUTION: This is not an explosion proof stirrer. Do not use with highly

ammableorexplosivematerials.Donotoperatethestirrerinexplosive

atmospheres, with hazardous substances or under water.

5. Spinning impellers can cause severe personal injuries. Operators must

use extreme care and good judgement when mixing at any speed. The

stirrers have higher torque capabilities than conventional stirrers.

Read operating instructions

carefully and in full.

Betriebsanleitung gründlich

und aufmerksam lesen.

Lire le mode d’emploi

attentivement et intégralement.

Lea las instrucciones de uso en

su totalidad y detalladamente.