2

1. GENERAL INFORMATION ............................................................................................................................ 2

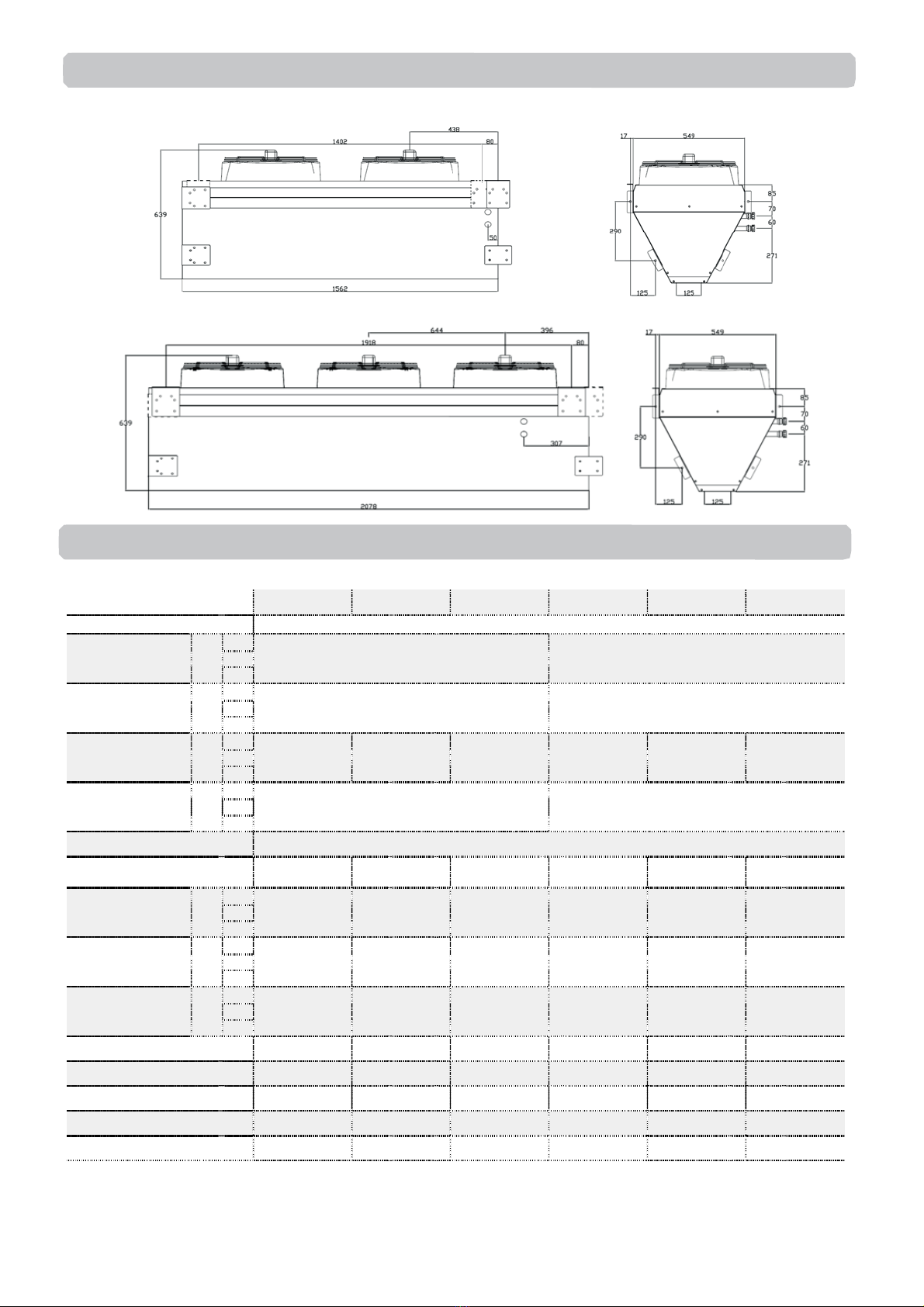

2. DIMENSIONS................................................................................................................................................... 3

3. TECHNICAL DATA......................................................................................................................................... 3

4. INSTALATION................................................................................................................................................. 4

4.1. INSTALATION SOLANO INDUSTRY-E.................................................................................................... 4

4.2. HARIZONTAL INSTALATION ................................................................................................................... 4

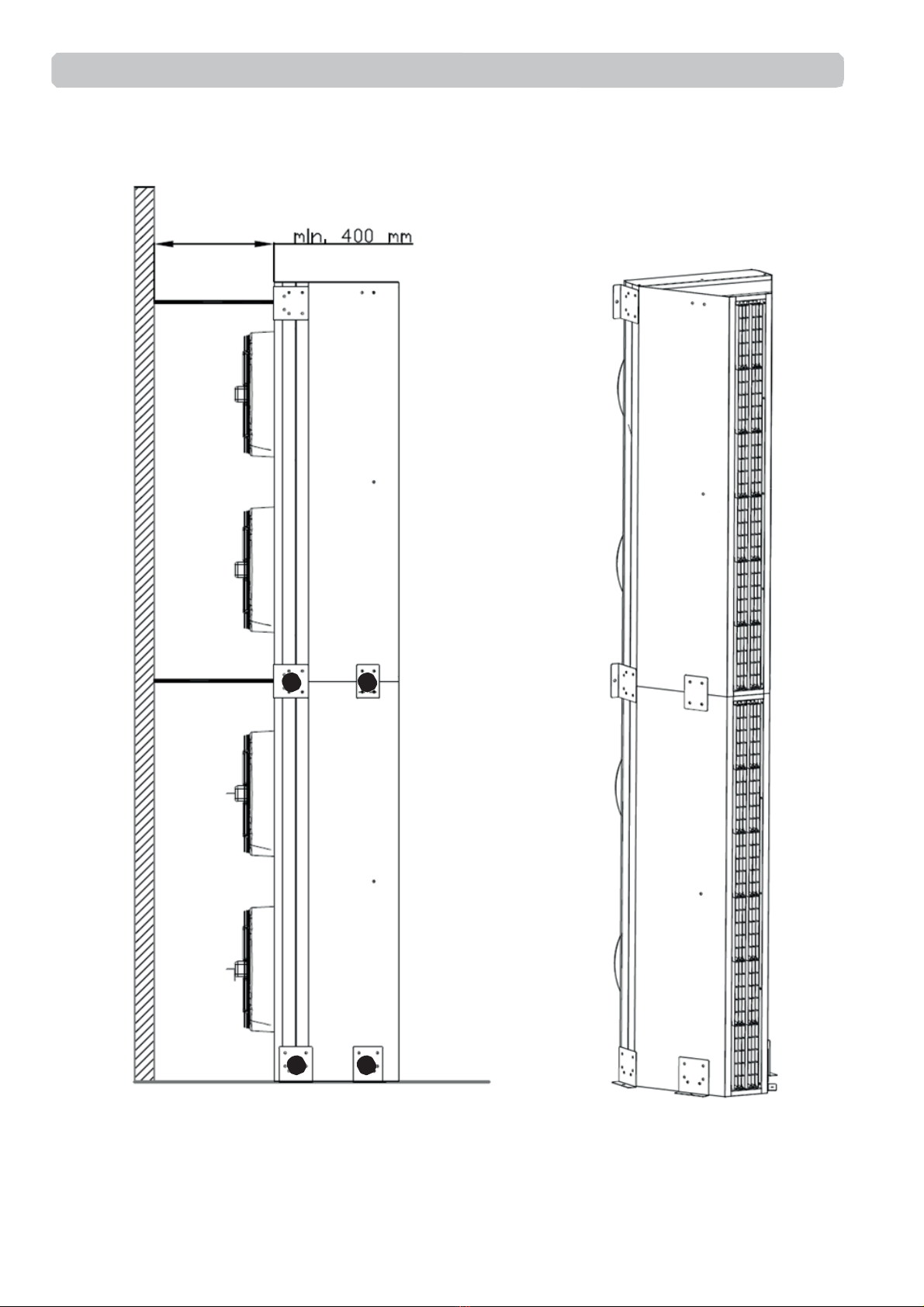

4.3. VERTICAL INSTALLATION....................................................................................................................... 5

5. CONTROL SYSTEMS .................................................................................................................................... .6

5.1. CONTROL ELEMENTS ............................................................................................................................... 6

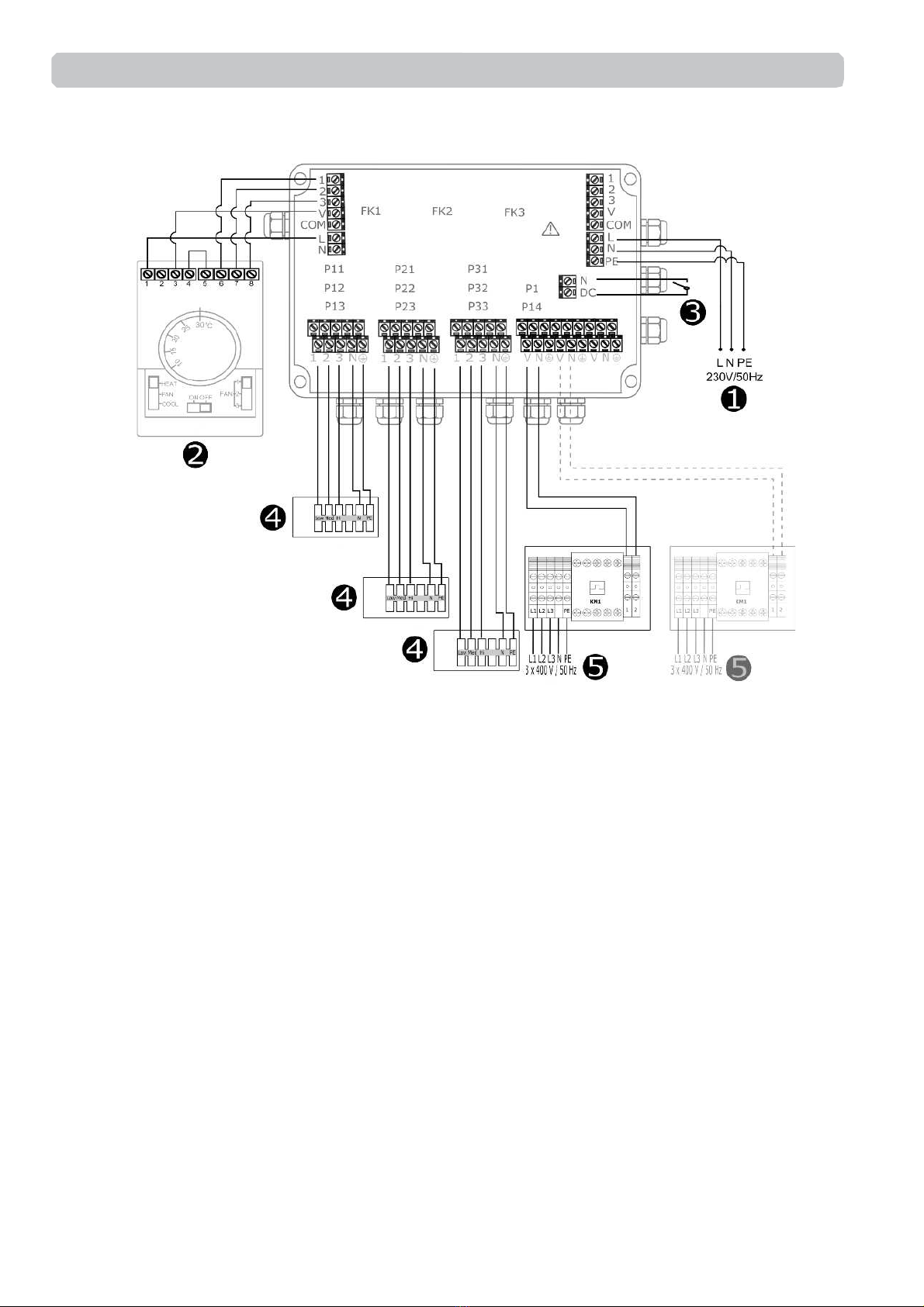

5.2. CONNECTING DIAGRAM .......................................................................................................................... 7

5.2.1 WIRING SCHEME SOLANO INDUSTRY W/N (S-C) .............................................................................. 7

5.2.2 WIRING SCHEME SOLANO INDUSTRY E (S-C) ................................................................................... 8

6. GUIDELINES FOR CONNECTION WITH POWER SUPPLY ...................................................................... 9

7. GUIDELINES FOR CONNECTION WITH PIPELINE................................................................................... 9

8. OPERATION .................................................................................................................................................... 9

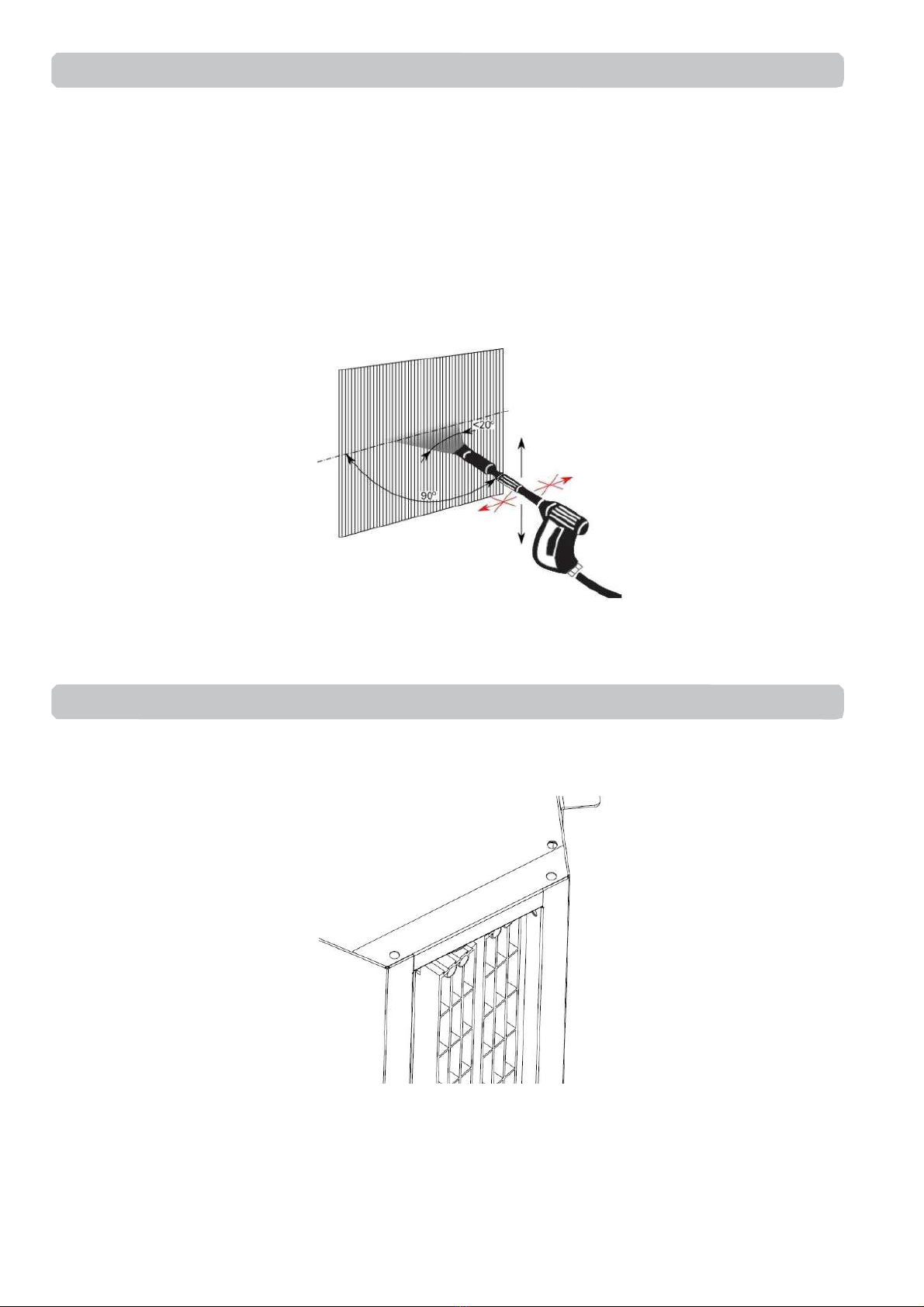

9. CLEANING AND CONSERVATION ........................................................................................................... 10

10. AIR BLADES REGULATION ..................................................................................................................... 10

11. HEATING CAPACITY ................................................................................................................................ 47

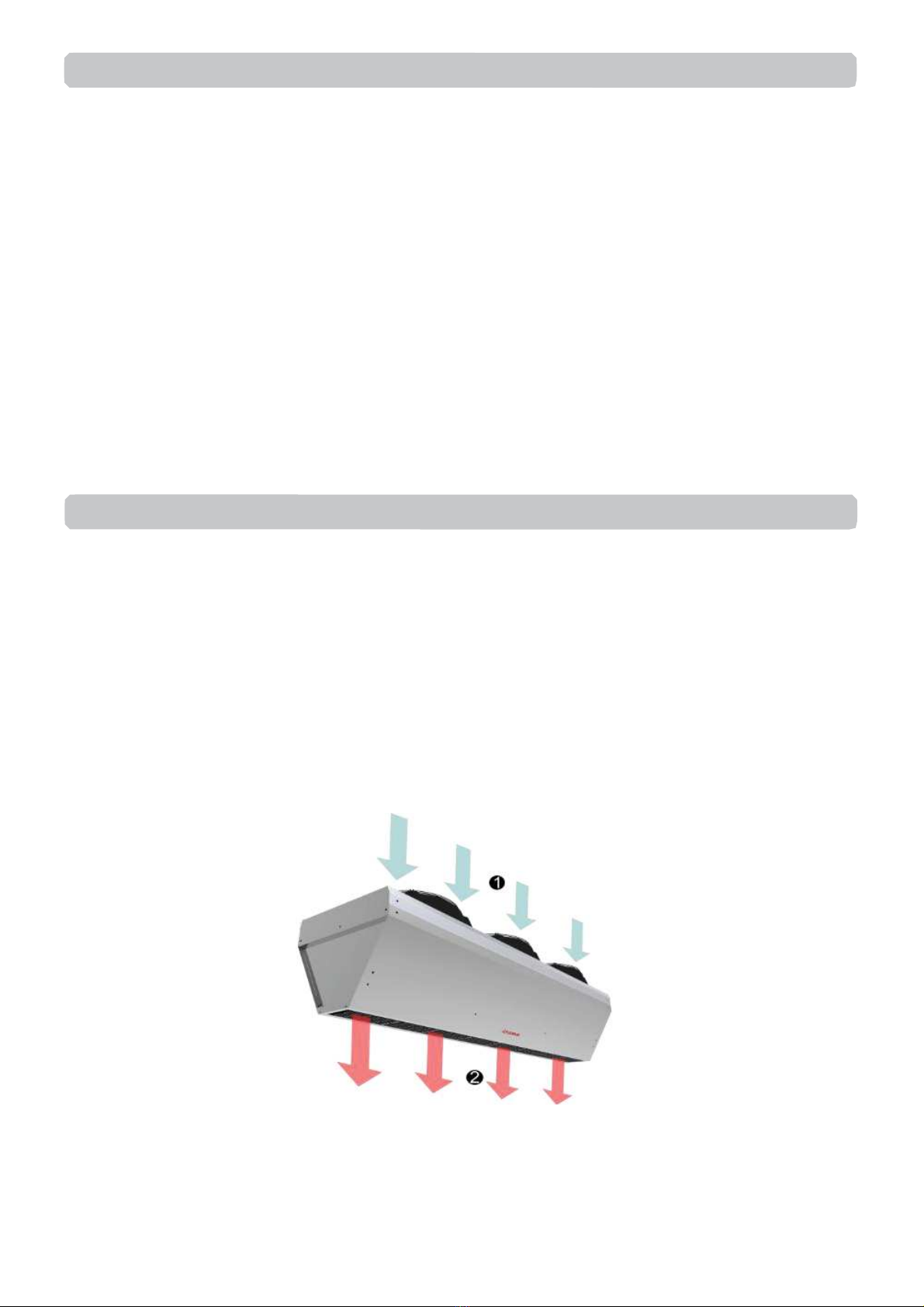

SOLANO INDUSTRY air curtain generating an air barrier which protects interior from external environment

(its temperature, solids and smog).

SOLANO INDUSTRY TYPES:

INDUSTRY-W-150 - curtain with water heat exchanger max. range 7 m*;

INDUSTRY-N-150 - curtain without heat exchanger (ambient); max. range 7,5 m*

INDUSTRY-E-150 - curtain with electric heat exchanger max. range 7 m*;

INDUSTRY-W-200 - curtain with water heat exchanger max. range 7 m*;

INDUSTRY-N-200 - curtain without heat exchanger (ambient); max. range 7,5 m*.

INDUSTRY-E-200 - curtain with electric heat exchanger max. range 7 m*;

* Vertical range of nonisothermal stream (at velocity boundary equal above 3,0 m/s),

Œair inlet; •air outlet;

1. GENERAL INFORMATION

TABLE OF CONTENTS