Installation Instructions Overview

neonLEDs™NLED

CALIFORNIA ACCENT LIGHTING, INC.

2034 E. Lincoln Ave. #431, Anaheim, CA 92806

ph. 800.921.CALI (2254) or 714.535-7900 \ fx. 714.535.7902

© CALI. All rights reserved. CALI reserves the right to make changes or withdraw specications without prior notice.

2 of 10

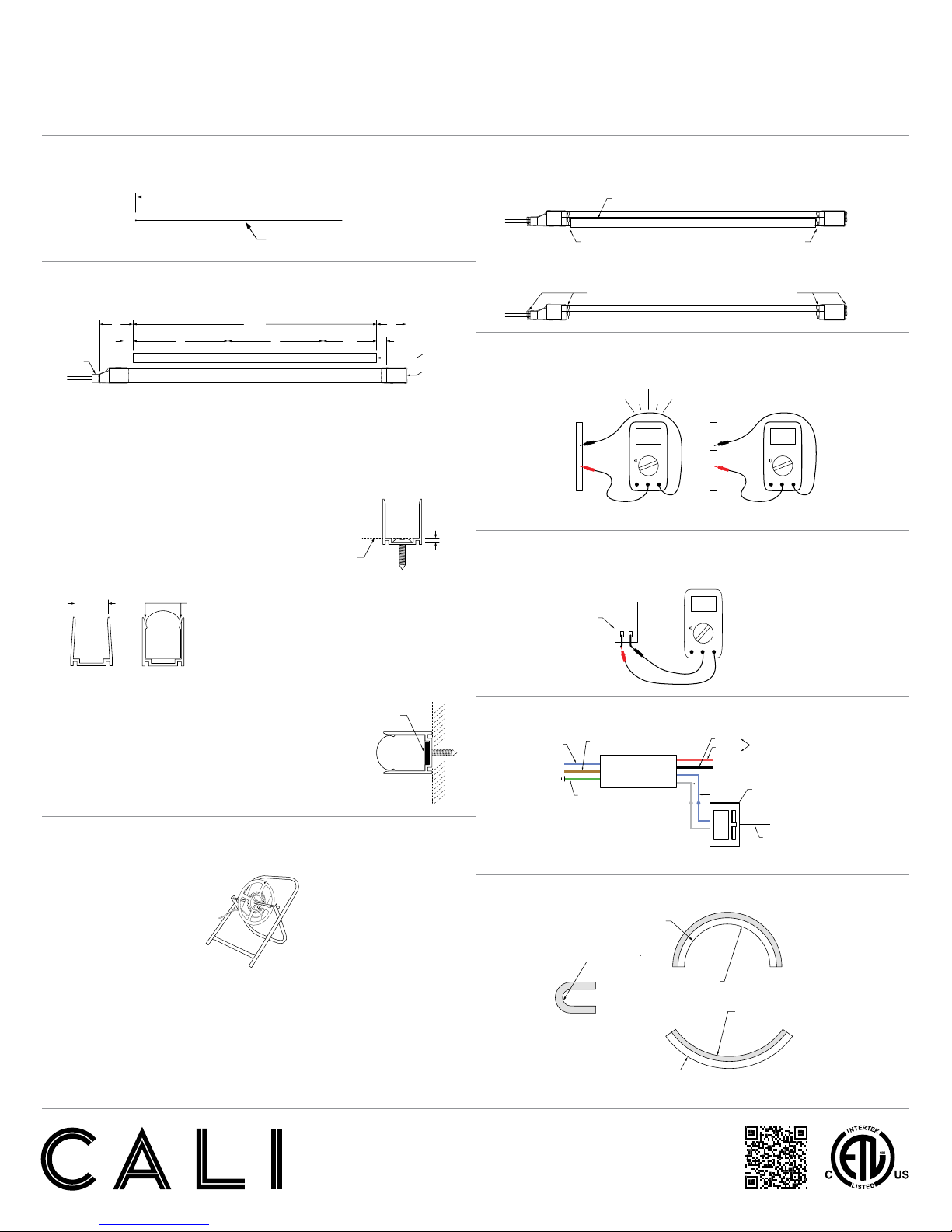

FEATURES

APPLICATIONS Decorative Lighting

VOLTAGE 24V or 120V

LAMP TYPE LEDs

DIMMING 120V: Not Dimmable

24V: 0-10V Dimming (TRA-E)

MAXIMUM RUN 32’ (24V), 150’ (120V)

FINISH White

FEED Power Connector

MOUNTING U-Channel or Mounting Clip

LISTING Dry or Wet Location

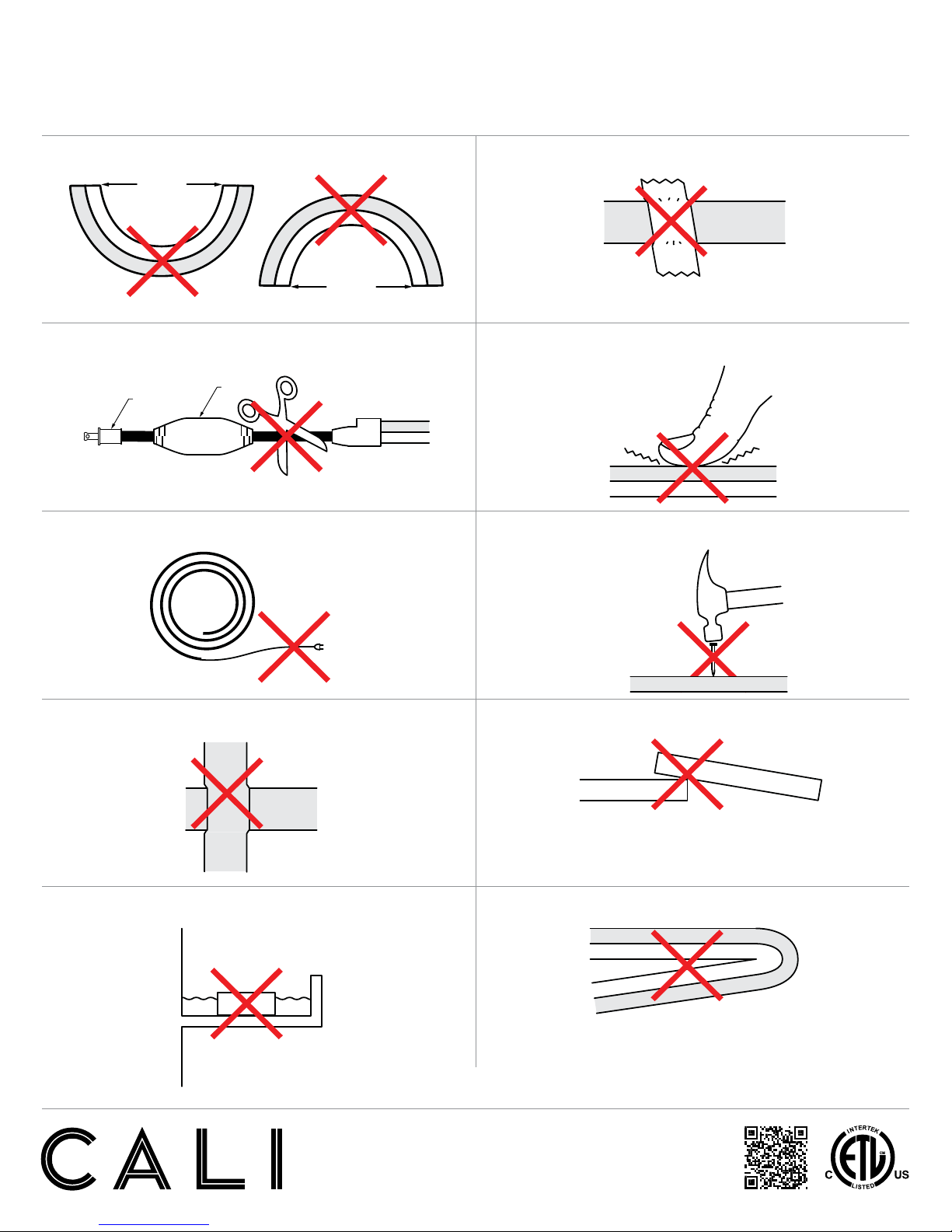

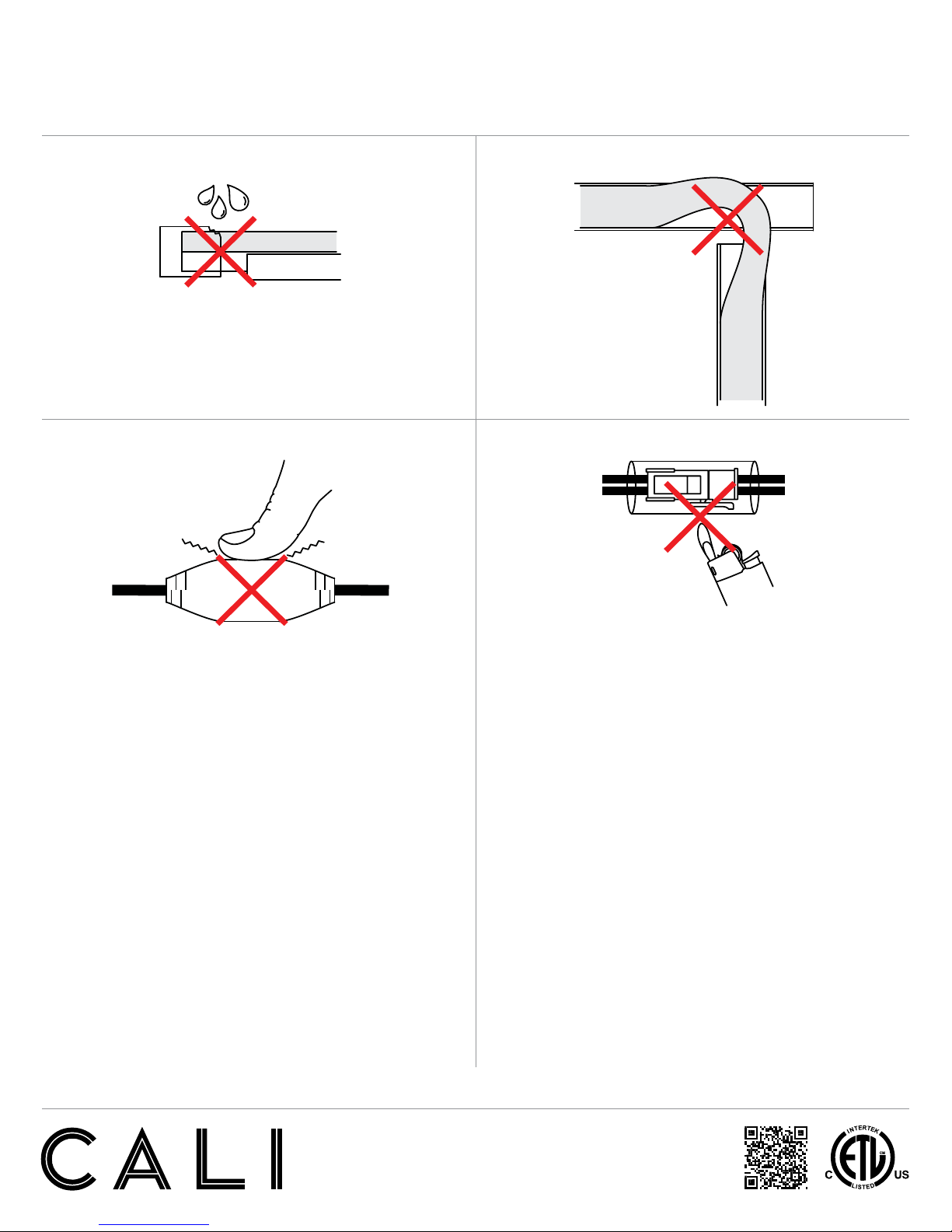

WARNING

When using NLED for any application, basic safety precautions should

always be followed to reduce the risk of fire, electric shock, and

personal injury. NLED must be installed in accordance with the NEC or

CEC as applicable.

• Do not exceed maximum length per circuit. Each maximum run requires

additional power feed from the transformer

• Do not cover NLED as the covering may cause it to overheat, melt,

or ignite.

• Do not install NLED in hazardous locations or closer than 6 inches

from any curtain or similar combustible material.

• Do not install NLED in places where it is subject to continuous

flexing.

• Do not install wet location model in areas where water will collect.

NLED 24V DIMMING PROTOCOL (0-10V)

NLED is available in 120 or 277 volts with a dimmable remote driver. The

remote driver is available with 0-10V dimming capabilities.

The following applies to 0-10V dimming interfaces. A 0-10v fluorescent

dimmer will not dim the LEDs.

Technical Requirements For Control Equipment (0-10V Protocol)

• The output current level of the dimmable driver is controlled by DC voltage

(0-10V) applied to the control terminals (blue and white). The light output of

LEDs is controlled by the amount of output current from the dimmable driver.

• The control device must be capable of sinking a DC current flow from the driver.

The maximum amount under any condition is 500 microamps (uA) per driver.

• The control terminals of the dimmable driver are isolated from the power lines

and are suitable for use as Class 2 wiring. Multiple drivers are desired for use

with same control device, the control terminals may be connected in parallel in a

bus configuration.

• Since the control bus is Class 2 wiring, all control devices that are connected

to the power line must have proper isolation between the power line and the

control terminals/bus.

• The control device, which intends to control more than one dimmable driver,

must be capable of sinking the total current supplied to control bus by the drivers.

• If the control terminals/bus is shorted in any case, the current on the control

terminals/bus will be 500 microamps (uA) per driver maximum.

• If the control terminals are opened, the voltage on the control terminals will them

be 10V ± 0.5 volt. As a result, dimmable driver supplies maximum output current

to LEDs under this condition.

• The driver is intended for use with control voltages between 0 and 10 VDC. The

control equipment must not impose a voltage greater than 11 V peak maximum

on the driver control terminals.

• Order transformer with TRA-E prefix.

(TRA-E) 0-10V Dimming