6.

Calortrans / Wildre Innovaons B.V. Arkeneel 27 3905NS Veenendaal The Netherlands info@calortrans.com www.calortrans.com

IMPORTANT SAFETY INSTRUCTIONS!

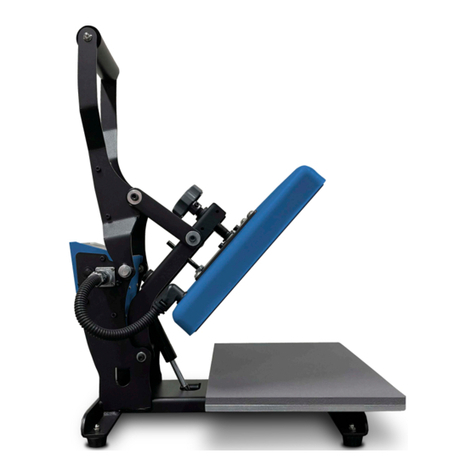

This manual was made to make the usage of the Calortrans transfer press as easy and safe

as possible. It is therefore recommended that you read this manual carefully and follow

the instrucons step by step.

Before use:

• Read the enre manual before using the press

• Upon delivery, check the press for transport damage. Then let the transfer press

acclimaze for 30 minutes at room temperature to prevent moisture problems or any

chance of a short circuit.

• Only use the transfer press when it is placed on a stable surface.

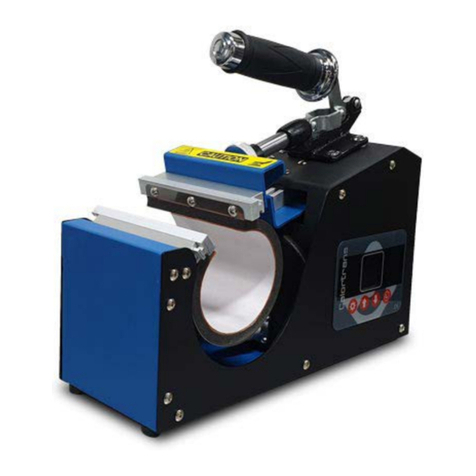

• Use the press only for texle transfers or products suitable for sublimaon

• The power cord must be connected directly to the power outlet without an extension

cord.

• The opmal recommended ambient temperature when using the transfer press is

between 15-50 ° C, with a relave humidity of up to 70%.

• Before connecng the machine, check that the voltage of the power cable is 230 volts

and the power is at least 10 amps.

• Do not use the machine if the power cord is damaged or defecve. In the event of

damage or malfuncon, do not open the press, but contact your dealer immediately.

If the press has been opened, the guarantee will expire.

• Do not use the transfer press in the presence of children or unauthorized persons,

due to the risk of catching burns. If the transfer press is nevertheless used in the

vicinity of children, a minimum distance of 1.5 meters must be maintained.

• Avoid contact of the transfer press with moisture, dirt, dust, mechanical vibraons, or

shocks.

• The manufacturer assumes no liability if property damage or personal

injury is caused by improper use of the transfer press

Safety