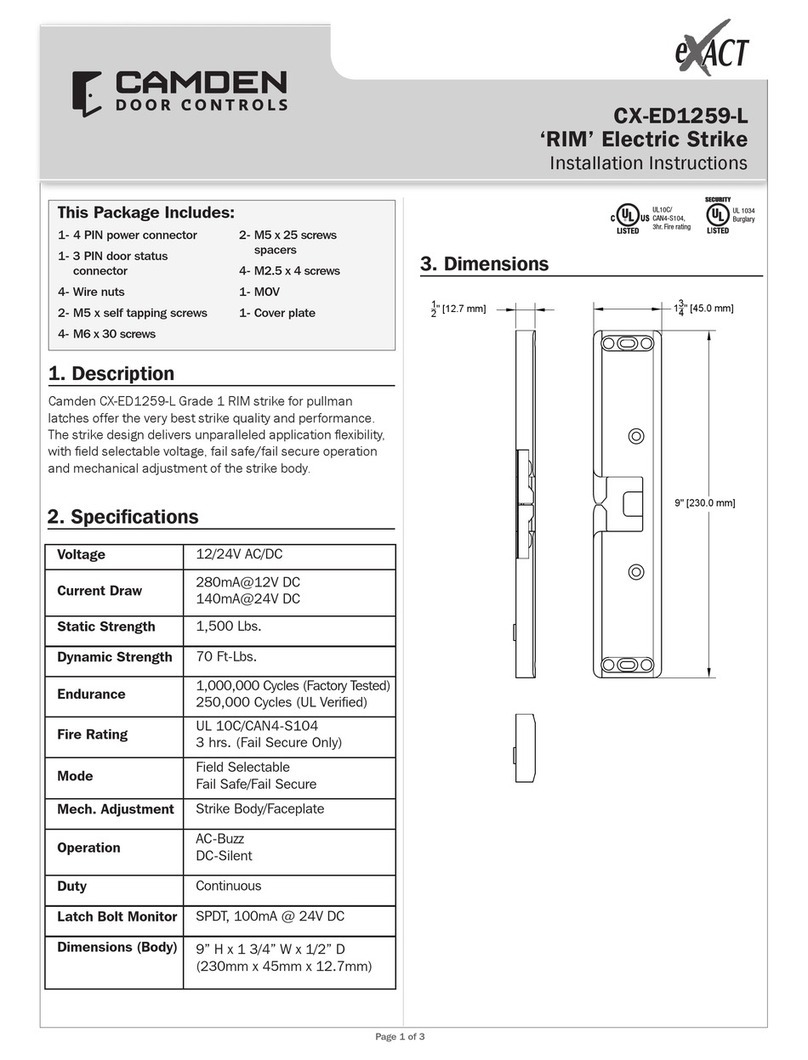

CX-ED1259L ‘RIM’ Electric Strike

INSTALLATION INSTRUCTIONS

Page 7 of 8

5. TROUBLESHOOTING

This guide has been produced to help installers understand

the most important physical considerations that need to be

addressed when installing the CX-ED1259L RIM strike.

Step 1 – Conrm Latch entry to rim strike

The position of the latch held by the RIM strike is of critical

importance to the operation of the strike. The most important

considerations, and potential causes of failure, are as follows:

• The centerline of the keeper

(jaws) of the RIM strike MUST

line up with the centerline

of the latch of the crash bar.

Mark the centerline of the latch

on the door frame, prior to

mounting the strike, to provide

a point of reference.

• The crash bar latch MUST NOT apply pressure on the

keeper (jaws) of the RIM strike. Pre-load pressure on the

jaws of the strike will prevent the strike from operating –

and is the most common reason for a strike failing.

Position the RIM strike so that the jaws of the strike are just

lightly resting against the latch of the exit device.

•The exit device latch MUST depress (activate) the latch

monitor ‘paddle’ of the RIM strike.

Even if the latch monitor is not

used, this placement insures

that the latch of the exit device is

fully held by the keeper (jaws)

of the strike.

(2) Spacer plates are provided

with the CX-ED1259L RIM

strike and are used as needed

for this.

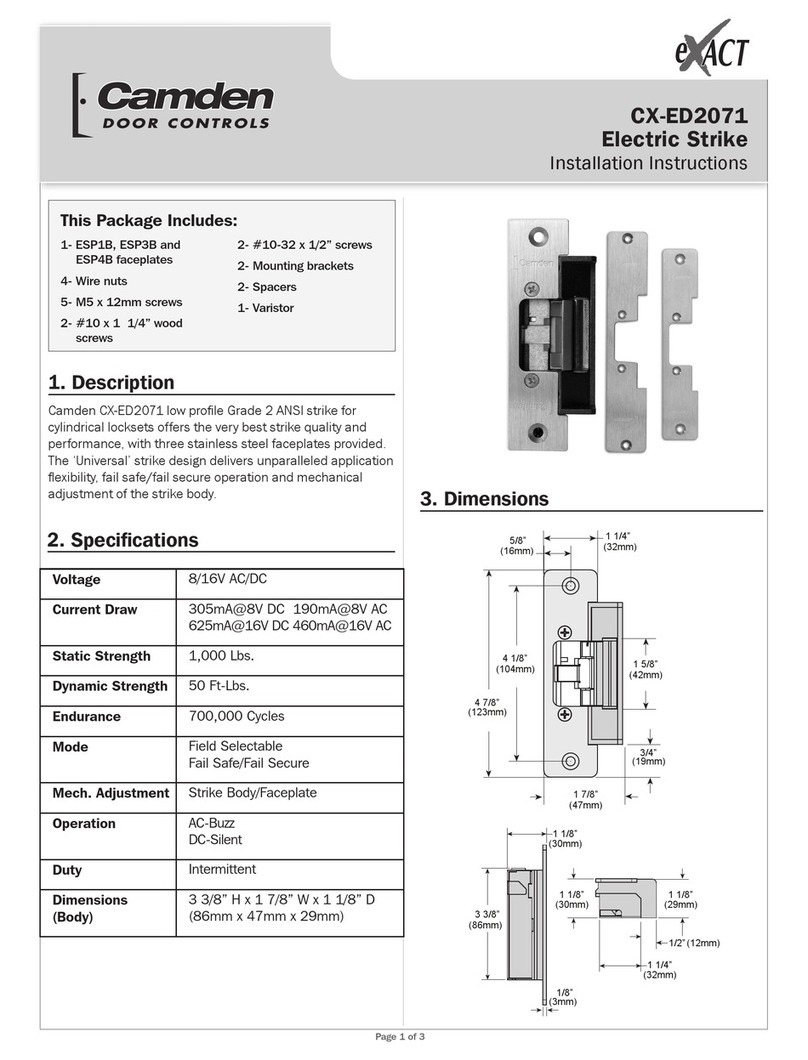

Step 2 – Conrm Door Alignment

Virtually all of Camden’s electric strike models, including the

CX-ED1259L RIM strike, oer horizontal adjustment, to

compensate for doors that are misaligned with the door

frame– but there is a limit to the strike adjustment.

• Check that the door is not binding on the frame. An

electric strike cannot compensate for this. If present, the

door hinges will need to be adjusted.

• Check the gap between the

door and the stop of the

frame (where the top and at

the bottom of the door. A ¼”

dierence in gap is very common

and can be compensated for

by the strike – IF INSTALLED

CORRECTLY.

If the door stop gap at the top and bottom of the door is

dierent, the electric strike cannot be installed plumb

(‘straight’ up and down). The horizontal orientation of the

RIM strike will need to be adjusted to match the angle of the

misaligned door. To do this:

• Mount the RIM strike in position

on the frame, using only the

(2) center (elongated) screw

holes, top and bottom.

• Rotate the strike until both jaws

of the strike very lightly touch the

crash bar latch, with equal gap,

on both jaws.

• Tighten the center screws and open/close door to conrm

that the latch does not bind on the jaws of the strike.

• After this is done, you can then ax the 6 screws that

permanently mount the strike on the frame.

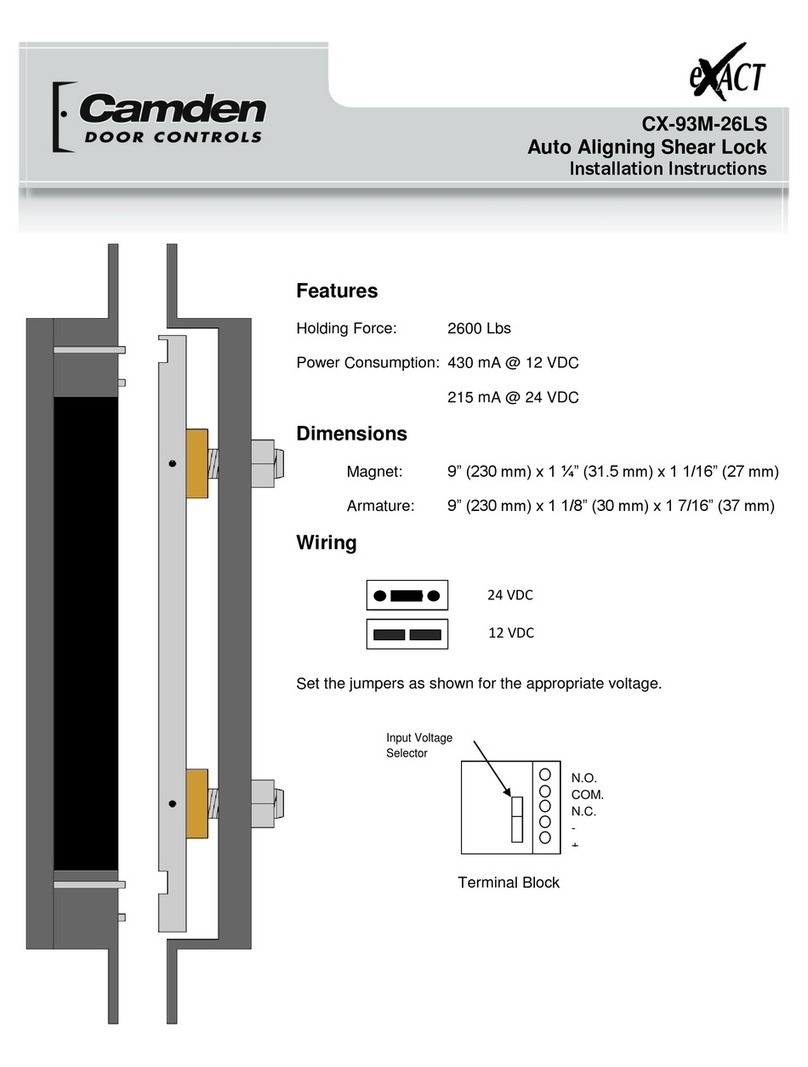

Other Considerations

Although the considerations above will address the majority of

installation steps needed for a successful installation, there are

a few additional items that you will need to check for:

•Consideration for deadlocking

latch (as shown here) If the

exit device has a deadlocking

latch, the CX-ED1259L RIM strike

must be mounted so that the

deadlocking latch does not enter

the latch cavity of the RIM strike.

Position the strike so that the

deadlocking latch rests against

the face of the strike.