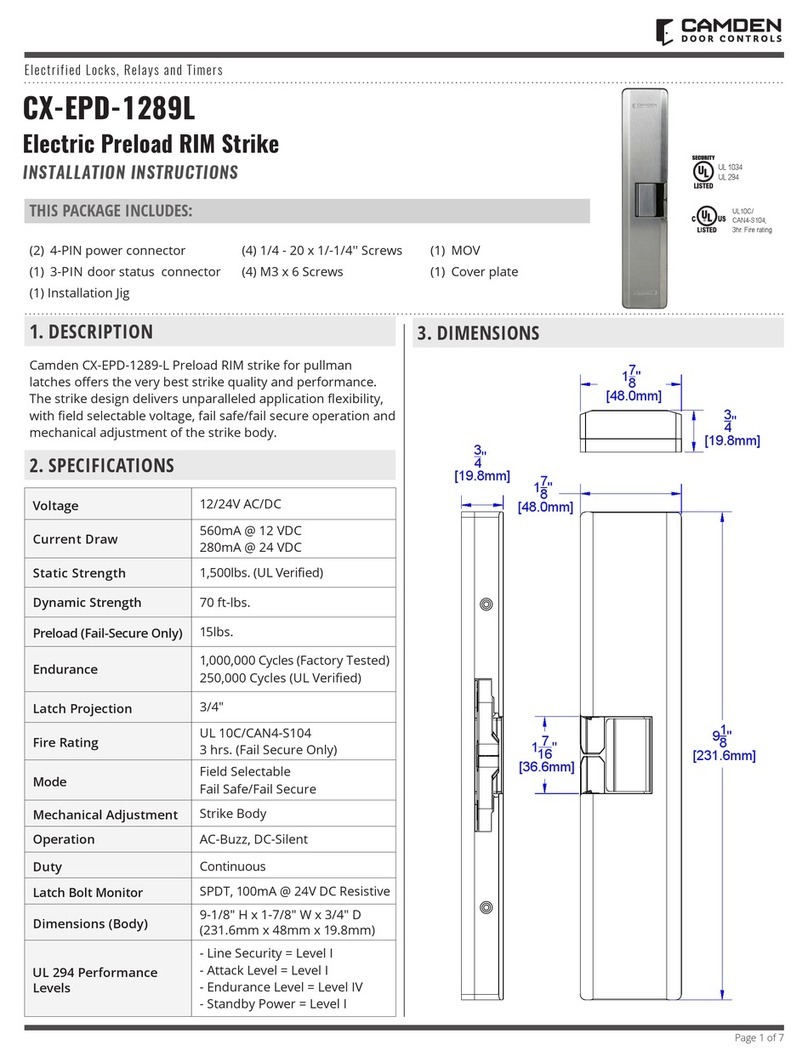

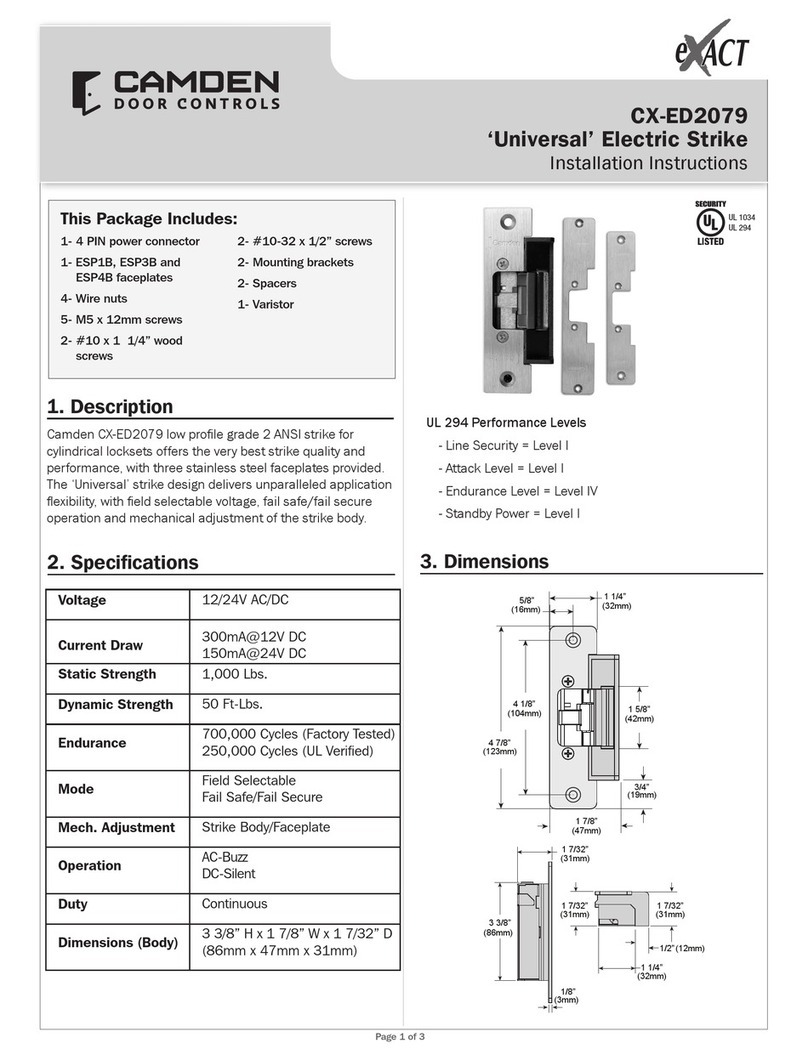

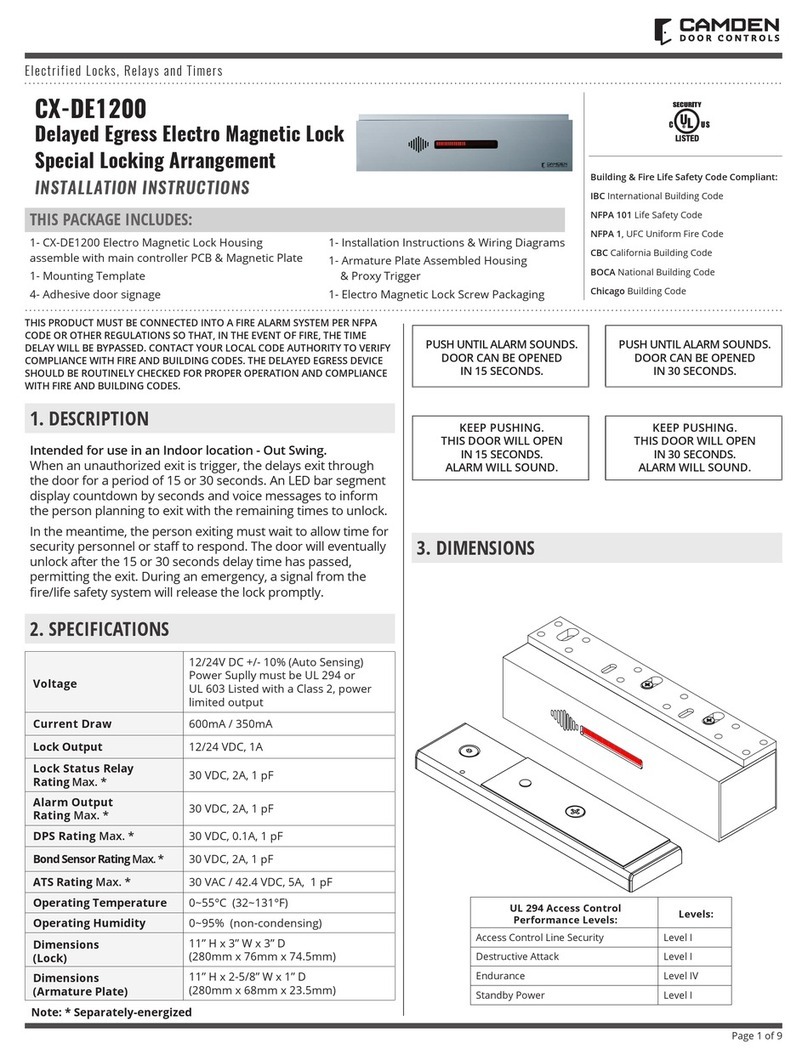

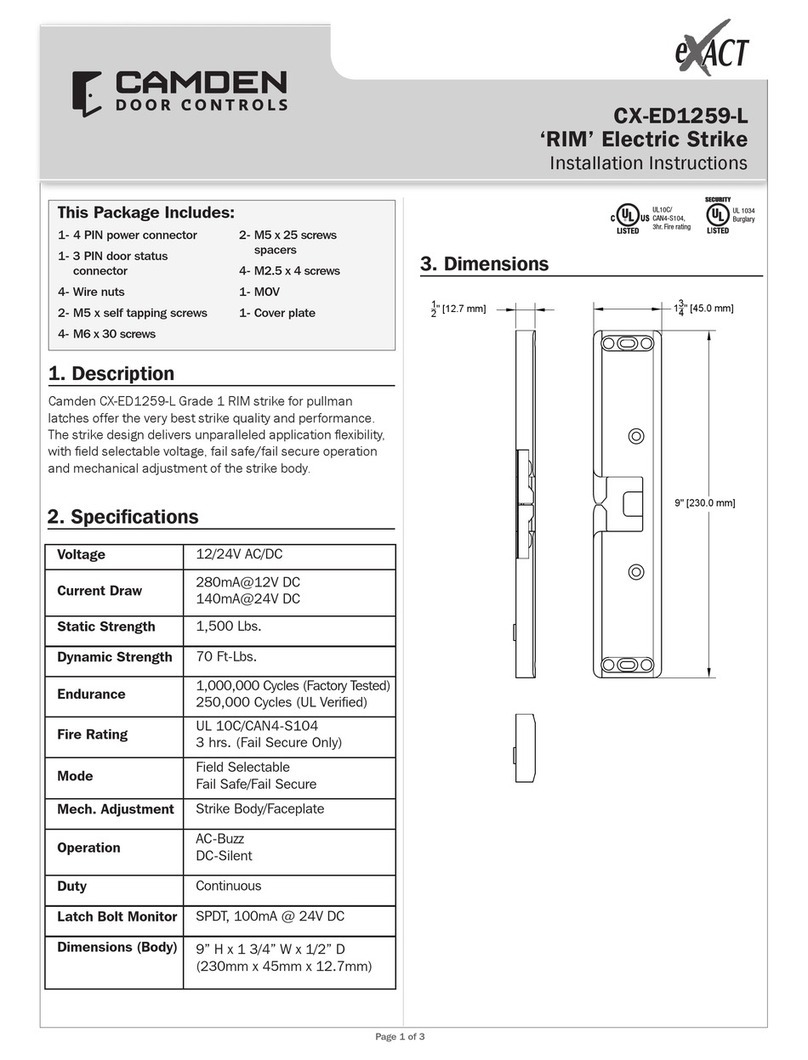

CX-EPD1289L Electric Preload RIM Strike

INSTALLATION INSTRUCTIONS

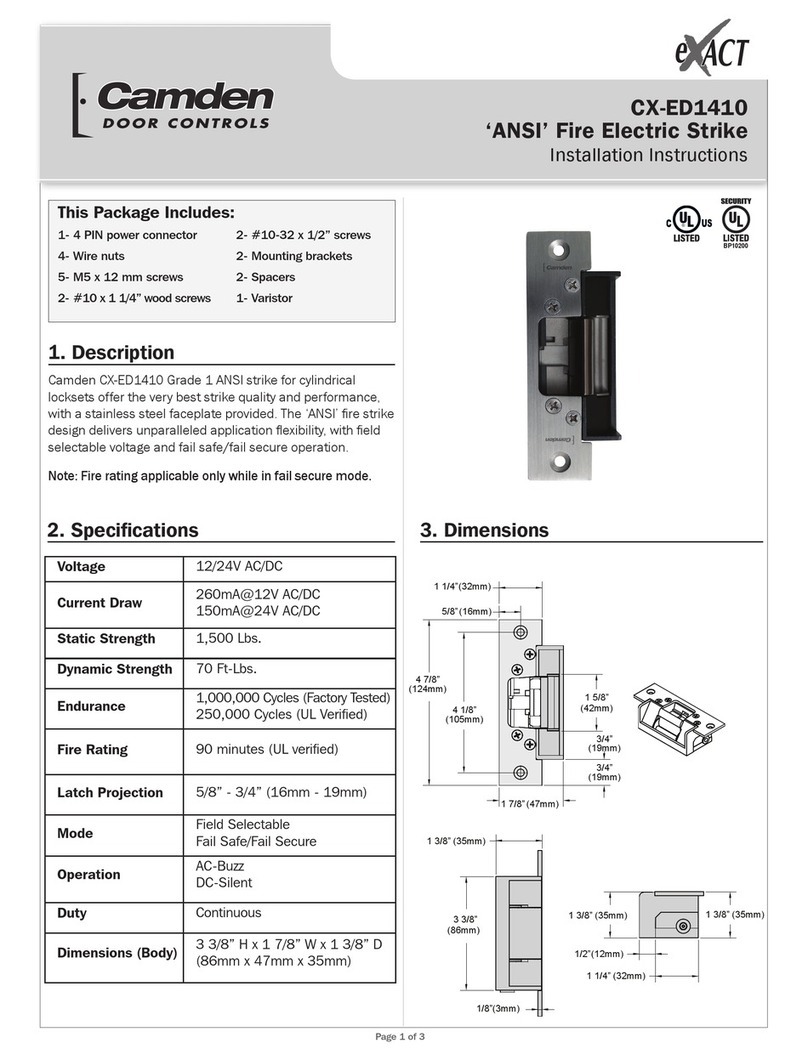

Page 3 of 7

2 1

2''

Ø5

8

''

Horizontal

Centerline

Jamb

Jamb

Connecting

Wire hole

1. Using center line, measure 4 3

16'' top and

bottom, and drill Ø5

8'' hole for connecting wires, as per drawing.

2. Close door (Ensure crash bar latch does not touch keeper

while closing the door) if necessary, adjust strike so that strike

and crash bar latch are well aligned,

4. While adjusting strike, allow a small gap between strike body

and crash bar (approx. 1

8''). Mark remaining screws position.

5. Open door and Remove strike. Drill threads at screws

position.

INSTALLATION INSTRUCTIONS

6. Connect wires as per drawing.

7. Fix strike with remaining screws

(1/4-20 x 11

2(4pcs) at both ends / 10-32 x 1 and Remove latch

for (2pcs) in the middle

8. Door Status Sensor(Closed position)

White = NO

Orange = COM

Grey = NC

POWER:Red/Black,Blue/Green( 12VDC )

Red,Black/Blue,Green( 24VDC )

> Red / Green ( Short Black,Blue )

9. A varistor is provided to prevent strike from

spike.Connect varistor to between input wires.

10. How to modify fail-Secure to fail-safe or vice versa.

(1) Remove the cover plate. Remove the 6 screws at the Front of

the Electric strike as per the diagram below.

(2) Rotate status mechanism 180 degree to change operation

mode

Red

Green

Black

Blue

12V

24V

Black

Red

Blue

Green

(+12V)

(-)

Varistor

(+24V)

(-)

Varistor

Jamb

Jamb

Orange

White

Grey

Black Red

12V

24V

R

Horizontal

Centerline

Fail-Secure Type Fail-Safe Type

Rotate 180° to

Change

Operation Mode

Rotate 180° to

Change

Operation Mode

Remove 6 screws

To Change Mode

Of Operation

R+1''

Closed Door

Jamb

Top View

Latch Allow a small gap between

strike body and crash bar

(Approx. 1/8'')

Crash Bar

Remove Cover

Plate

Remove Cover

Plate

R +

3

4

''

M3 x 6

(4pcs)

Closed

Door

Door Jamb

Crash Bar

Ensure latch does not touch

strike keeper while closing door,

and while adjusting strike

1

OPERATION MODE CHANGE

2

4

576

Latch

Monitor

Blue Green

3

2 1

2''

Ø5

8

''

Horizontal

Centerline

Jamb

Jamb

Connecting

Wire hole

1. Using center line, measure 4 3

16'' top and

bottom, and drill Ø5

8'' hole for connecting wires, as per drawing.

2. Close door (Ensure crash bar latch does not touch keeper

while closing the door) if necessary, adjust strike so that strike

and crash bar latch are well aligned,

4. While adjusting strike, allow a small gap between strike body

and crash bar (approx. 1

8''). Mark remaining screws position.

5. Open door and Remove strike. Drill threads at screws

position.

INSTALLATION INSTRUCTIONS

6. Connect wires as per drawing.

7. Fix strike with remaining screws

(1/4-20 x 11

2(4pcs) at both ends / 10-32 x 1 and Remove latch

for (2pcs) in the middle

8. Door Status Sensor(Closed position)

White = NO

Orange = COM

Grey = NC

POWER:Red/Black,Blue/Green( 12VDC )

Red,Black/Blue,Green( 24VDC )

> Red / Green ( Short Black,Blue )

9. A varistor is provided to prevent strike from

spike.Connect varistor to between input wires.

10. How to modify fail-Secure to fail-safe or vice versa.

(1) Remove the cover plate. Remove the 6 screws at the Front of

the Electric strike as per the diagram below.

(2) Rotate status mechanism 180 degree to change operation

mode

Red

Green

Black

Blue

12V

24V

Black

Red

Blue

Green

(+12V)

(-)

Varistor

(+24V)

(-)

Varistor

Jamb

Jamb

Orange

White

Grey

Black Red

12V

24V

R

Horizontal

Centerline

Fail-Secure Type Fail-Safe Type

Rotate 180° to

Change

Operation Mode

Rotate 180° to

Change

Operation Mode

Remove 6 screws

To Change Mode

Of Operation

R+1''

Closed Door

Jamb

Top View

Latch Allow a small gap between

strike body and crash bar

(Approx. 1/8'')

Crash Bar

Remove Cover

Plate

Remove Cover

Plate

R +

3

4

''

M3 x 6

(4pcs)

Closed

Door

Door Jamb

Crash Bar

Ensure latch does not touch

strike keeper while closing door,

and while adjusting strike

1

OPERATION MODE CHANGE

2

4

576

Latch

Monitor

Blue Green

3

1

Jamb

1. Remove the strike cover. Using center line, measure 4 3

16'' top

and bottom, drill Ø5

8'' hole for connecting wires, as per drawing.

2. Secure strike in place with the 1/4-20 x 1-1/4 ( 2 screws).

3. Close the door (Ensure crash bar latch does not touch keeper

while closing the door) if necessary, adjust strike so that strike

and crash bar latch are well aligned.

4. While adjusting strike, allow a small gap between strike body

and crash bar (approx. 1

8''). Remove the latch on strike and mark

the remaining 2 middle mounting screw positions on frame.

5. Open the door and remove the strike from the frame, drill and

thread the 2 middle mounting screw holes for the 1/4 - 20 x 1 -

1/4 screws.

6. Secure strike with all 1/4 - 20 x 1 - 1/4 screws and fix back the

latch on the strike. Use the M3 x 6 to secure the strike cover.

INSTALLATION INSTRUCTIONS

7. Door Status Sensor(Closed position)

White = NO

Orange = COM

Grey = NC

POWER:Red/Black,Blue/Green( 12VDC )

Red,Black/Blue,Green( 24VDC )

> Red / Green ( Short Black,Blue )

8. A varistor is provided to prevent strike from

spike.Connect varistor to between input wires.

9. How to modify fail-Secure to fail-safe or vice versa.

(1) Remove the cover plate. Remove the 6 screws at the Front of

the Electric strike as per the diagram below.

(2) Rotate status mechanism 180 degree to change operation

mode

Jamb

Jamb

R

HORIZONTAL

CENTERLINE

Fail-Secure type Fail-safe type

Rotate 180° To

Change

Operation Mode

Remove 6 screws

To Change Mode

Of Operation

Closed Door

Jamb

Top View

Latch Allow a small gap between

strike body and crash bar.

(Approx. 1

8'')

Crash Bar

Remove Cover

Plate

Remove Cover

Plate

Rotate 180° To

Change

Operation Mode

M3 x 6

(4pcs)

Closed Door

Door Jamb

Crash Bar

Ensure latch does not

touch strike keeper while

closing door, and while

adjusting strike.

OPERATION MODE CHANGE

Strike Latch

8

3

8''

4

3

16

''

4 3

16

''

1

5

8''

Ø5

8''

Horizontal

Centerline

Jamb

Connecting

Tighten Set

Screws onto

Fixing Bolts

Wire Hole

R+1''

R+

3

4''

1/4-20 x 1-1/4

screws x 4pcs

Orange

White

Grey

Black Red

12V

24V

Blue Green

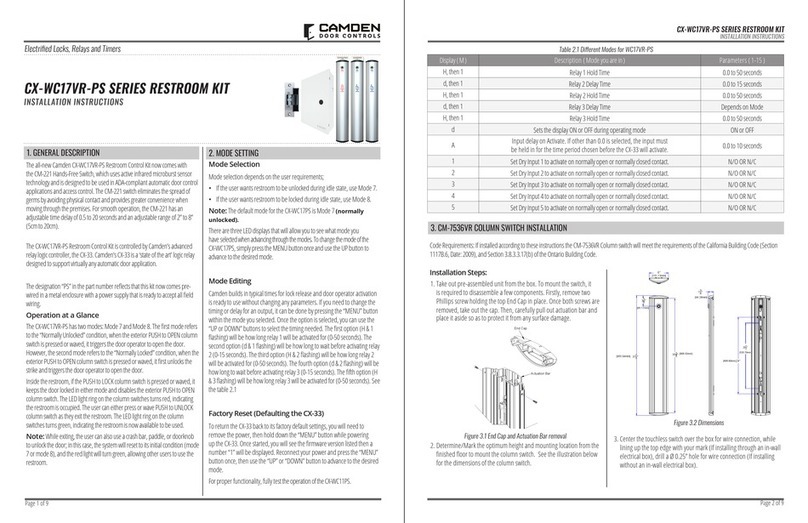

1. Mark the location and drill the 5/8" diameter hole for the

electrical cable as per template or dimensions shown below.

2. Secure strike in place with the 1/4-20 x 1-1/4 (2 screws).

3. Close the door (ensure crash bar latch does not touch keeper

while closing the door). If necessary, adjust strike so that strike

and crash bar latch are well aligned.

4. While adjusting strike, allow a small gap between strike

body and crash bar (approximately 1/8"). Remove the latch

on strike and mark the remaining 2 middle mounting screw

positions on frame.

5. Open the door and remove the strike from the frame, drill

and thread the 2 middle mounting screw holes for the 1/4 - 20

x 1-1/4 screws.

6. Secure strike with all 1/4 - 20 x 1-1/4 screws and x back the

latch on the strike. Use the M3 x 6 screws to secure the strike

cover.

Step 2: Aligning the Strike

23

2 1

2''

Ø5

8

''

Horizontal

Centerline

Jamb

Jamb

Connecting

Wire hole

1. Using center line, measure 4 3

16'' top and

bottom, and drill Ø5

8'' hole for connecting wires, as per drawing.

2. Close door (Ensure crash bar latch does not touch keeper

while closing the door) if necessary, adjust strike so that strike

and crash bar latch are well aligned,

4. While adjusting strike, allow a small gap between strike body

and crash bar (approx. 1

8''). Mark remaining screws position.

5. Open door and Remove strike. Drill threads at screws

position.

INSTALLATION INSTRUCTIONS

6. Connect wires as per drawing.

7. Fix strike with remaining screws

(1/4-20 x 11

2(4pcs) at both ends / 10-32 x 1 and Remove latch

for (2pcs) in the middle

8. Door Status Sensor(Closed position)

White = NO

Orange = COM

Grey = NC

POWER:Red/Black,Blue/Green( 12VDC )

Red,Black/Blue,Green( 24VDC )

> Red / Green ( Short Black,Blue )

9. A varistor is provided to prevent strike from

spike.Connect varistor to between input wires.

10. How to modify fail-Secure to fail-safe or vice versa.

(1) Remove the cover plate. Remove the 6 screws at the Front of

the Electric strike as per the diagram below.

(2) Rotate status mechanism 180 degree to change operation

mode

Red

Green

Black

Blue

12V

24V

Black

Red

Blue

Green

(+12V)

(-)

Varistor

(+24V)

(-)

Varistor

Jamb

Jamb

Orange

White

Grey

Black Red

12V

24V

R

Horizontal

Centerline

Fail-Secure Type Fail-Safe Type

Rotate 180° to

Change

Operation Mode

Rotate 180° to

Change

Operation Mode

Remove 6 screws

To Change Mode

Of Operation

R+1''

Closed Door

Jamb

Top View

Latch Allow a small gap between

strike body and crash bar

(Approx. 1/8'')

Crash Bar

Remove Cover

Plate

Remove Cover

Plate

R +

3

4

''

M3 x 6

(4pcs)

Closed

Door

Door Jamb

Crash Bar

Ensure latch does not touch

strike keeper while closing door,

and while adjusting strike

1

OPERATION MODE CHANGE

2

4

576

Latch

Monitor

Blue Green

3

4 5