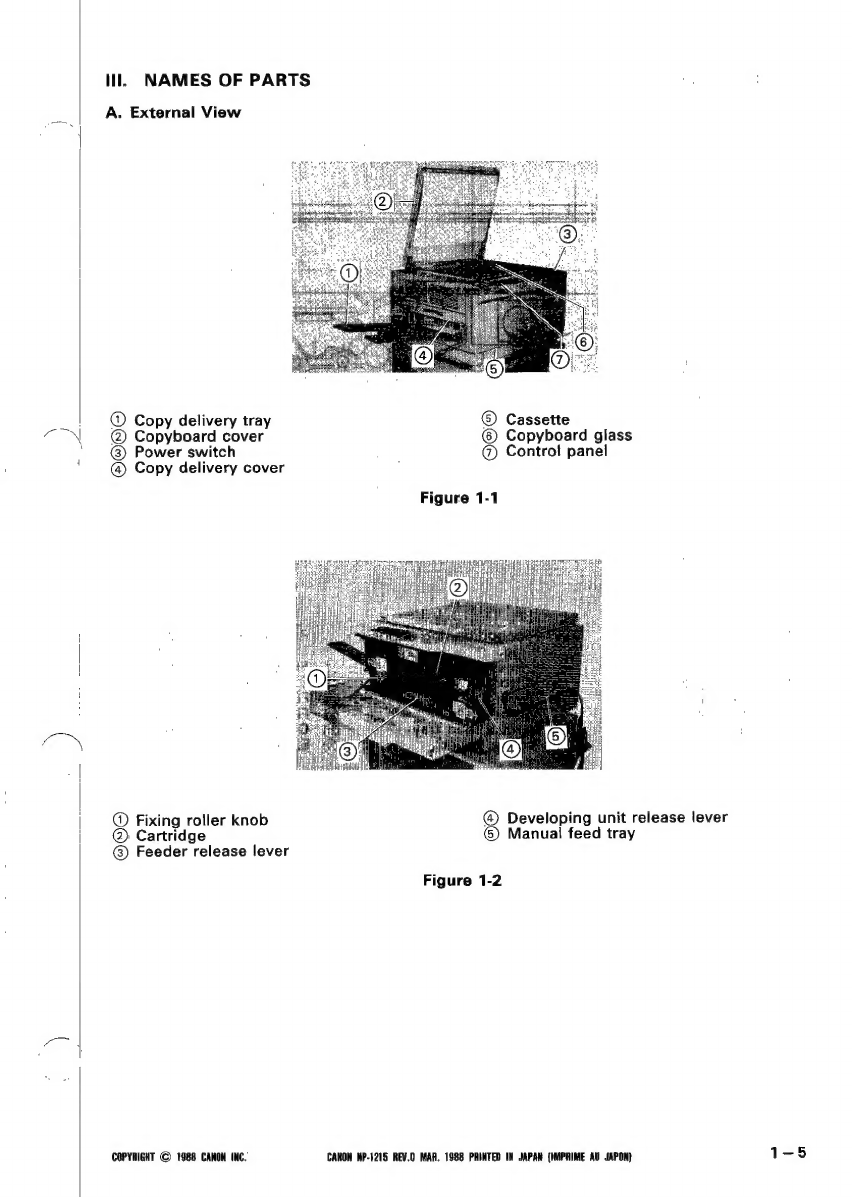

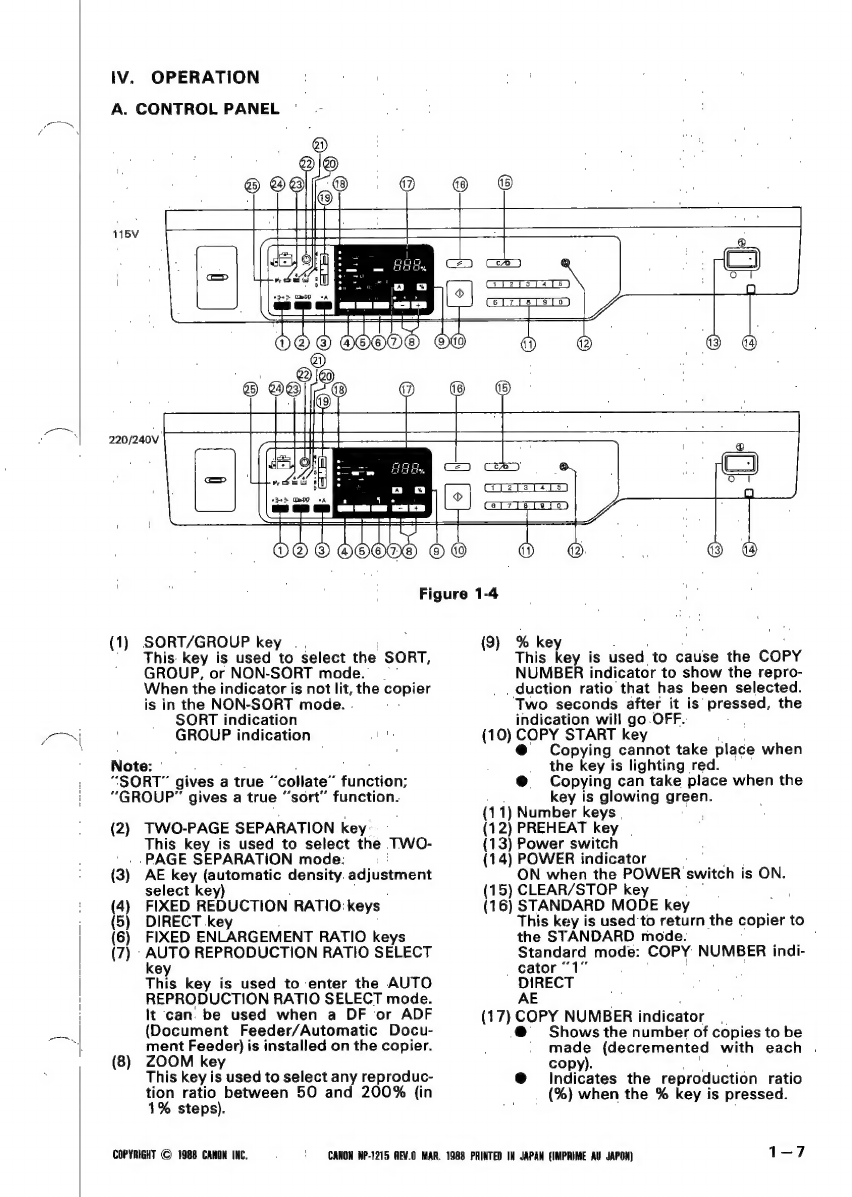

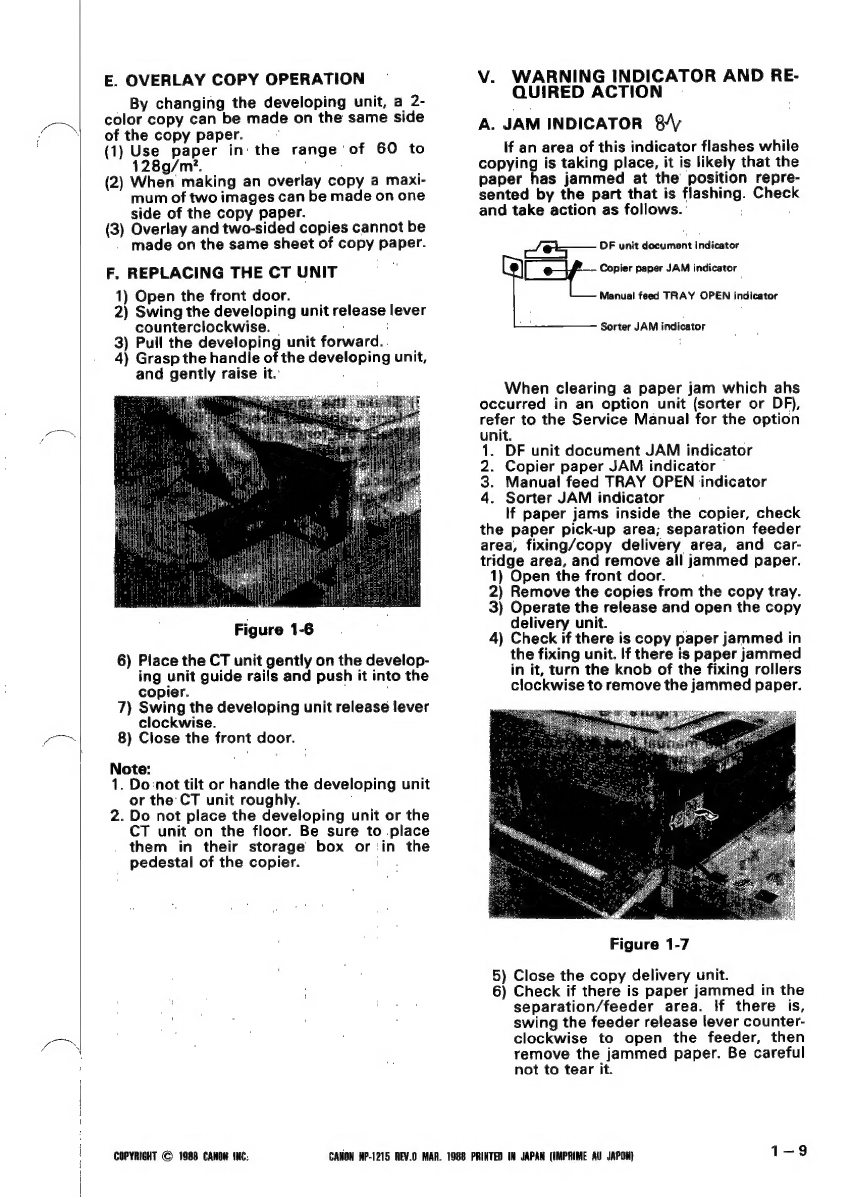

Canon NP-1215 User manual

Other Canon Printer manuals

Canon

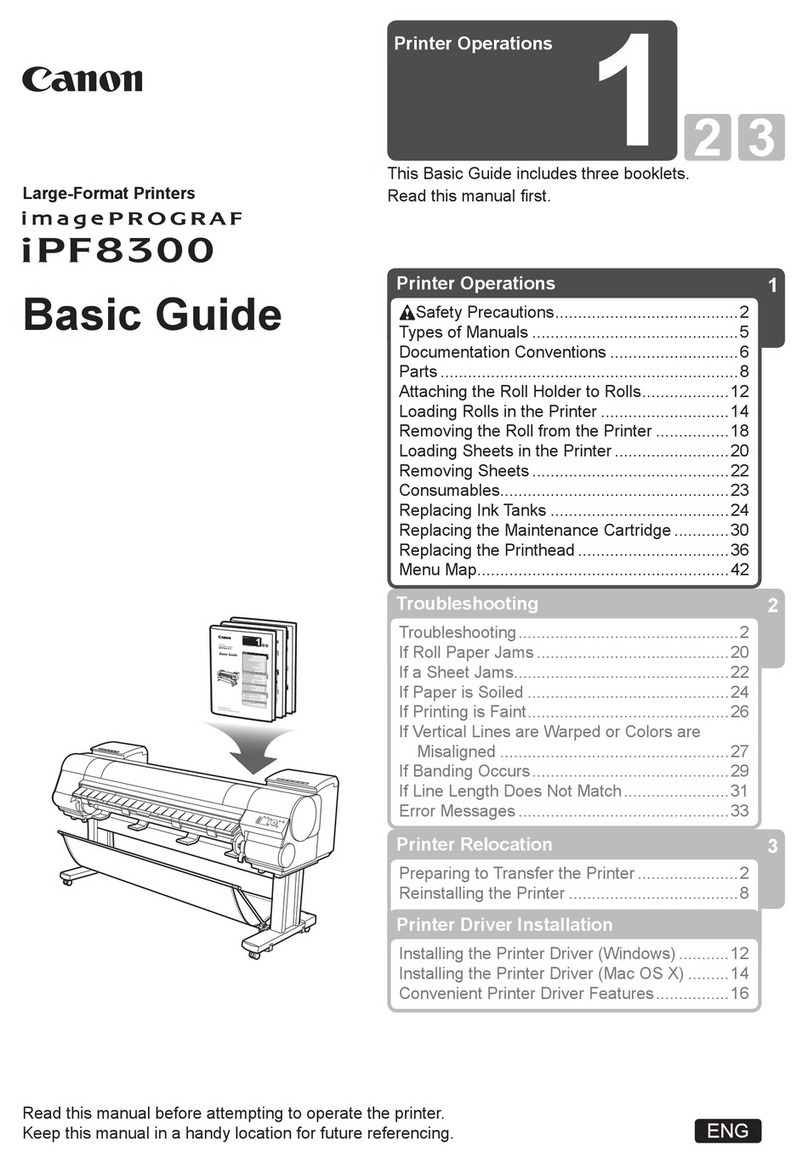

Canon imagePROGRAF iPF8300 User guide

Canon

Canon Satera LBP-3910 User manual

Canon

Canon PIXMA E3300 Series Setup guide

Canon

Canon BJC-S6300 User manual

Canon

Canon PIXMA MP460 User manual

Canon

Canon SELPHY CP790 User manual

Canon

Canon CP-220 Installation and operation manual

Canon

Canon imageRUNNER 105 Installation and maintenance instructions

Canon

Canon iP6700D - PIXMA Color Inkjet Printer Manual

Canon

Canon imageCLASS MF543dw User manual

Canon

Canon image Prograf iPF680 Series User manual

Canon

Canon TS700 Series User manual

Canon

Canon imagePROGRAF iPF8400 User manual

Canon

Canon G540 Setup guide

Canon

Canon Selphy CP600 User manual

Canon

Canon imagePROGRAF TX-4000 User manual

Canon

Canon image Prograf iPF780 Series User manual

Canon

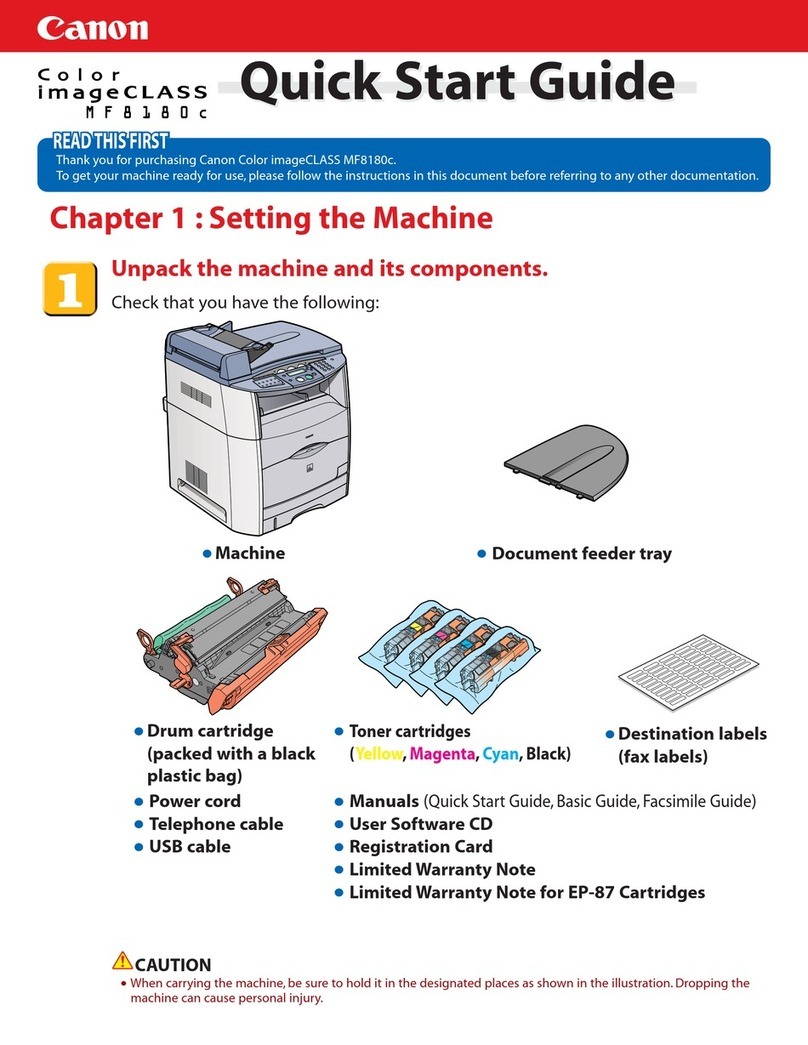

Canon Color imageCLASS 8180c User manual

Canon

Canon PIXMA TS5340 User manual

Canon

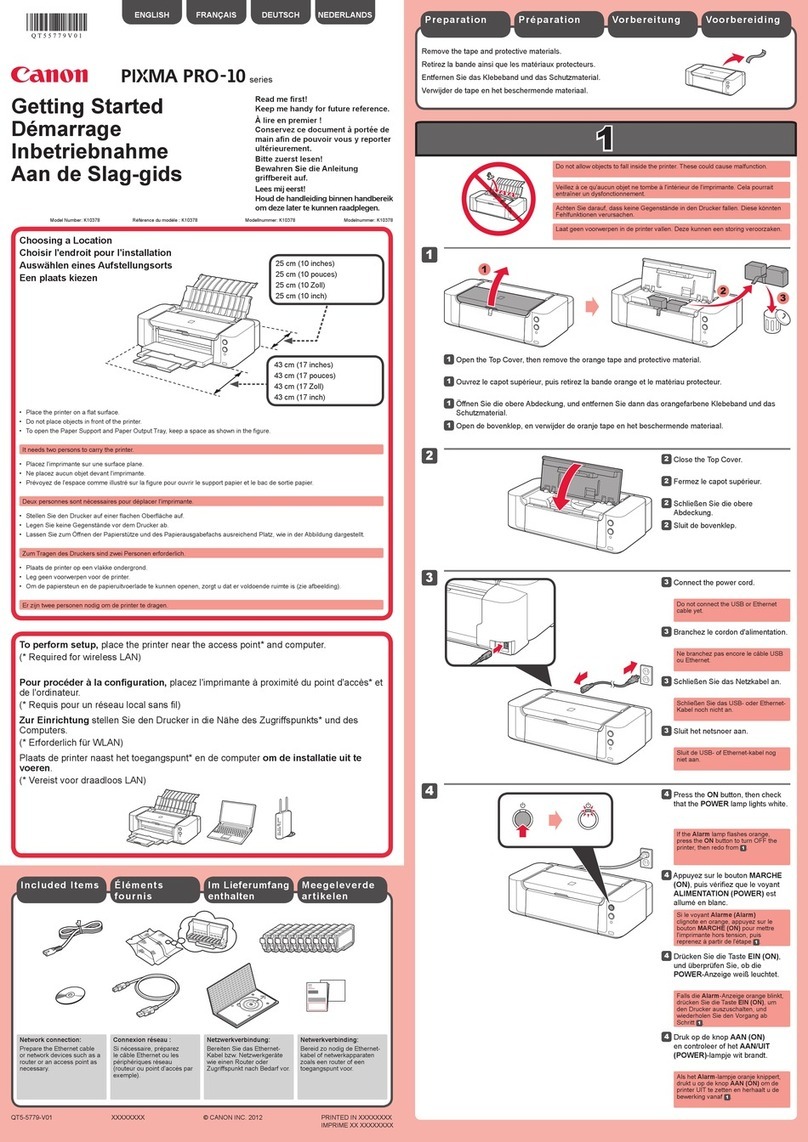

Canon PIXMA PRO-10 User manual