Before System Installation

Chapter 1: Before System Installation

The EVO™Upgrade kit is compatible with existing Synchro™and AIM1Command systems.

Before assembly and installation, read the installation information carefully. Make sure that you

have all of the parts in the kits. Read all of the instructions in this document, the system operator

manual, and the machine manuals. The system operator manual includes information on operation,

adjustments, troubleshooting, and maintenance.

Attention: The correct function of the EVO™system cannot be guaranteed if the current

PWM system is not functioning correctly. Do the following procedures BEFORE installation to

verify the correct function of the existing system.

No warranty or returns of the system will be honored if the existing system is not verified to

function correctly before installation of the EVO™system.

For further assistance contact your CapstanAG representative.

Before installation of a new system, you must make sure that the existing AIM Command system is

operating correctly. Do these procedures:

• Clean the nozzle valves and inspect the plunger seals

• Do a Check of the Conventional Spray System

• Do a Check of the System Flow Control

• Do a Check of the System Pressure Control

Clean the Nozzle Valve(s)

Warning: Chemical residues may be present in the agricultural equipment. Always use the

proper personal equipment to avoid personal injury.

1. Release pressure from the system before servicing.

2. Clean the system before installation or service of the fittings, hoses, valves, or nozzles.

3. Remove the valve body.

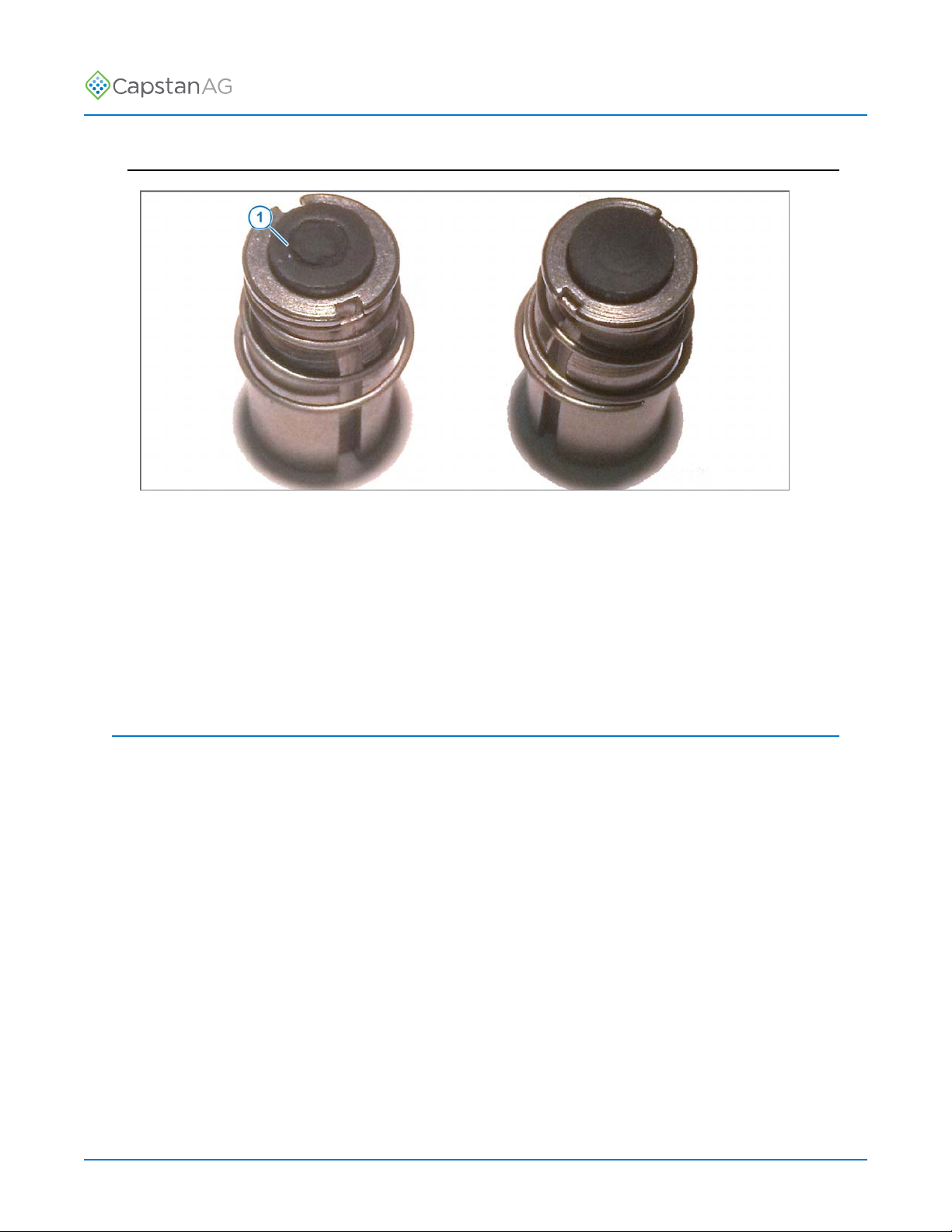

4. Remove the plunger.

5. Inspect the O-rings.

6. Wash the nozzle valve components to remove any debris.

7. Inspect the plunger for wear or damage.

8. If there is wear or damage to the plunger, replace the plunger.

9. Inspect the valve body.

Make sure that the orifice is not plugged with debris, worn, or damaged.

10.If there is wear or damage to the orifice, replace the valve body.

11.Wash the nozzle body components to remove any debris.

Important: Do not use brake cleaner. Brake cleaner can damage the seal.

Important: During installation, apply 40 lbf in of torque to the coil when it threads into the valve

body to properly seat the O-ring.

1AIM is a trademark of CNH Industrial LLC, and is not affiliated with Capstan Ag Systems, Inc.

©2019 Capstan Ag Systems, Inc. 3EVO Upgrade Kit