Table of Contents

1 Foreword....................................................................................... 4

2 Safety.............................................................................................4

2.1 Notes and symbols used.......................................................... 4

2.2 General safety...........................................................................5

2.3 Personnel qualifications............................................................ 5

2.4 Intended use............................................................................. 6

2.5 Reasonably foreseeable misuse...............................................6

2.6 Determining the lifetime and validating the entire system.........6

2.7 Example calculation.................................................................. 6

2.8 Equivalent T-network................................................................ 7

3 General description..................................................................... 8

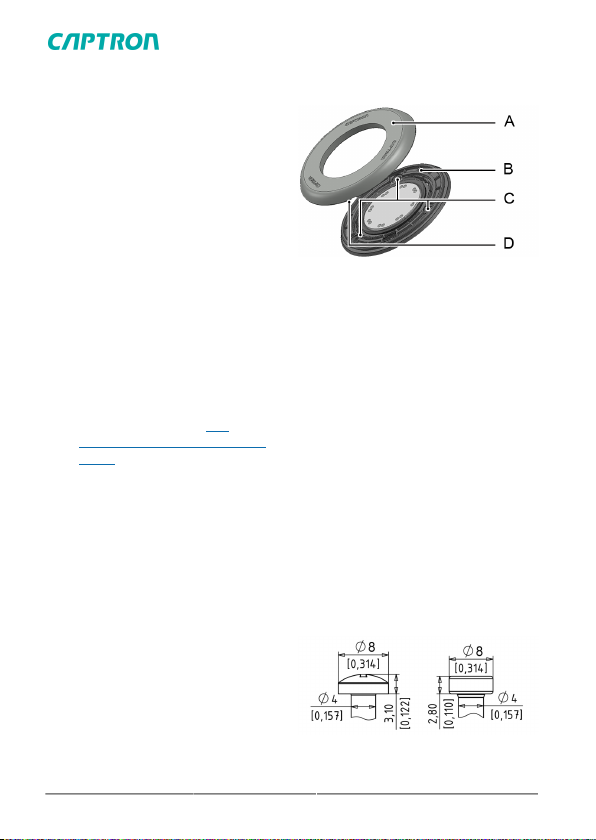

3.1 safeCAP SC4............................................................................ 8

3.2 Operating states........................................................................8

4 Storage.......................................................................................... 9

5 Assembly.......................................................................................9

5.1 Prepare SC4 for assembly......................................................10

5.2 Recommended screw types....................................................10

5.3 Maximum dimensions of the screws.......................................10

5.4 SC4 assembly without SCP4..................................................11

5.5 Connecting SC4 to the safety relay........................................12

5.5.1 MCR-225 connection plan................................................................... 12

5.5.2 Connecting SC4 to a spare safety relay..............................................12

5.6 Testing the safety function of the SC4....................................12

6 Maintenance................................................................................13

6.1 Maintenance operations..........................................................13

7 Disposal.......................................................................................14

8 Technical specifications............................................................ 14

8.1 Technical specifications, safety relay MCR-225......................15

2/19 1.3 safeCAP SC4

safeCAP SC4 with MCR-225