FOR TECHNICAL SUPPORT CALL 1800 658 111

10

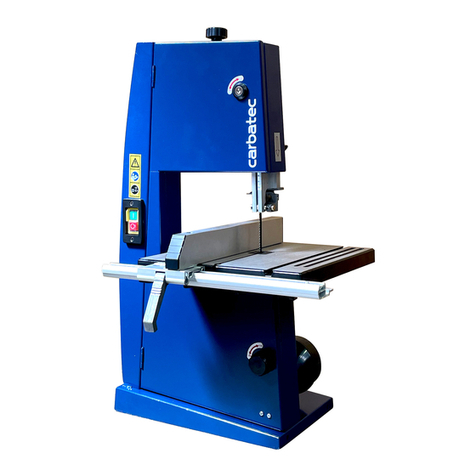

BS-345C

BANDSAW SAFETY

INTENDED USE

• The machine must only be used in

technically perfect condition in accordance

with its designated use and the instructions

set out in the operating manual, and

only by safety-conscious persons who

are fully aware of the risks involved in

operating the machine. Any functional

disorders, especially those aecting the

safety of the machine, should therefore

be rectied immediately. The safety, work

and maintenance instructions of the

manufacturer as well as the technical data

given in the calibrations and dimensions

must be adhered to.

• Relevant accident prevention regulations

and other, generally recognised safety-

technical rules must also be adhered to.

• The machine may only be used, maintained,

and operated by persons familiar with it and

instructed in its operation and procedures.

Arbitrary alterations to the machine release

the manufacturer from all responsibility for

any resulting damages.

• The machine may only be used with original

accessories and tools made

by or recommended by the manufacturer

• Any other use exceeds authorisation.

The manufacturer is not responsible

for any damages resulting from unauthorized

use; risk is the sole responsibility of the

operator.

SAFETY FOR BANDSAWS

• This bandsaw is intended for use in dry

conditions, and for indoor use only.

• Do not cut pieces of material too small

to hold by hand outside the blade guard.

• Avoid awkward hand positions where

a sudden slip could cause a hand to move

into the blade.

• Always use the blade guard to avoid

possible injury due to blade breakage.

• Never leave the work area with the power

connected, or before the machine has come

to a complete stop.

• Do not perform layout, assembly or set

up work on the table while the cutting tool is

in operation.

• Never turn your bandsaw on before clearing

the table of all objects: (tools, scraps of

wood, etc) except for the workpiece and

related feed or support devices for the

operation planned.

REMAINING HAZARDS

The machine has been built using modern

technology in accordance with recognised safety

rules. Some remaining hazards, however, may

still exist.

• Long hair and loose clothing can be

hazardous. Wear personal protective gear

such as a hair net and tight tting

work clothes.

• Saw dust and wood chips can be hazardous.

Always wear AS/NZS approved personal

protective gear such as safety goggles, dust

mask and hearing protection.

• The use of incorrect or damaged mains

cables can lead to injuries caused

by electricity.

• Even when all safety measures are taken,

some remaining hazards which are not yet

evident may still be present.

• Remaining hazards can be minimised

by following the instructions in Safety

Precautions, Proper Use and

in the entire operating manual.

• Do not force the machine unnecessarily:

excessive cutting pressure may lead to rapid

deterioration of the blade and a decrease in

performance in terms of nish and

cutting precision.