FOR TECHNICAL SUPPORT CALL 1800 658 111

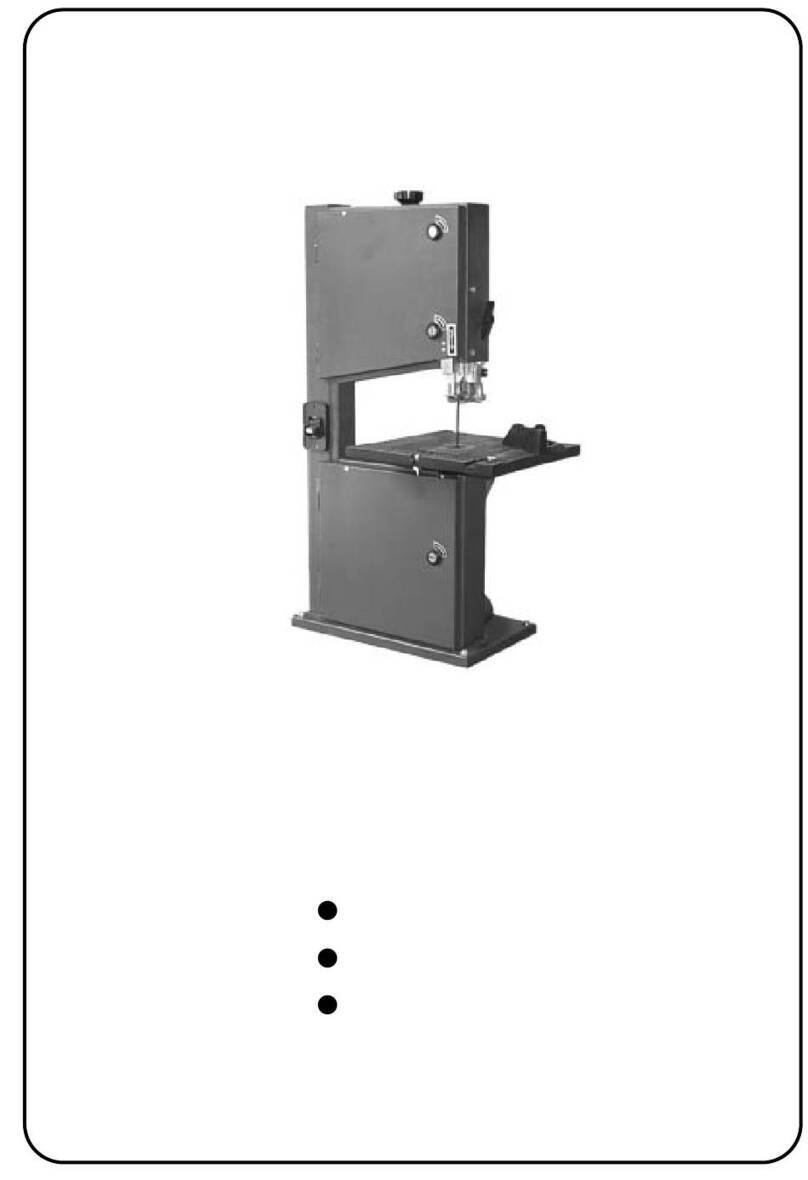

SS-400H

SPECIFIC SCROLL SAW SAFETY

NOTE: According to the applicable product

liability law the manufacturer of this device

is not liable for damages which arise on or in

connection with this device in case of:

• Improper handling

• Non-compliance with the instructions

for use

• Repairs by third party, non authorised

skilled workers

• Installation and replacement of non-

genuine spare parts

• Improper use

RECOMMENDATIONS:

• Read the entire text of the operating

instructions prior to the assembly and

operation of the device. These operating

instructions are intended to make it easier

for you to get familiar with your device

and utilise its intended possibilities of use.

• The operating instructions contain

important notes on how to work safely

with your machine and how to avoid

dangers, and increase the reliability and

working life of the machine.

• Retain and store these instructions near

the machine. The instructions must be

read and carefully observed by each

operator prior to starting the work. Only

persons who have been trained in the use

of the machine and have been informed

on the related dangers and risks are

allowed to use the machine.

• In addition to the safety notes contained

in the present operating instructions and

the special regulations of your country, the

generally recognised technical rules for

the operation of wood working machines

must be observed.

!

The device and packaging materials are

not toys! Children must not be allowed

to play with plastic bags, lm and small

parts! There is a risk of swallowing and

suocation!

INTENDED USE

• The machine must only be used

in technically perfect condition in

accordance with its designated use and

the instructions set out in the operating

manual, and only by safety-conscious

persons who are fully aware of the risks

involved in operating the machine. Any

functional disorders, especially those

aecting the safety of the machine, should

therefore be rectied immediately. The

safety, work and maintenance instructions

of the manufacturer as well as the

technical data given in the calibrations

and dimensions must be adhered to.

• Relevant accident prevention regulations

and other, generally recognized safety-

technical rules must also be adhered to.

• The machine may only be used,

maintained, and operated by persons

familiar with it and instructed in its

operation and procedures. Arbitrary

alterations to the machine release the

manufacturer from all responsibility for

any resulting damages.

• The machine may only be used with

original accessories and tools made

by or recommended by the manufacturer.

• Any other use exceeds authorisation.

The manufacturer is not responsible

for any damages resulting from

unauthorized use; risk is the sole

responsibility of the operator.

10