Welcome and Congratulations

Stronger. Faster. Beefier. The Shapeoko4XXL is a powerful CNC machine purpose-built for rigidity and

accuracy. An upgraded controller, inductive homing switches, and multiple built-in workholding options will

save you time and increase your productivity and workflow eciency.

In this guide we will walk you step-by-step through the assembly of your Shapeoko4. Precision-machined

parts, pre-assembled components, and self-contained packaging mean assembling your Shapeoko4 is

quick and easy. You’ll be up and machining in no time.

Shapeoko4XXL Assembly Video

Watch the Shapeoko4XXL Assembly Overview video at: youtu.be/wUxKKApCzfs.

Power Tools

The use of power tools is not recommended for assembly. Use hand tools only.

Finger-Tight Only

Several steps rely on non-tightened fasteners. Do not tighten fasteners beyond finger-tight until instructed

to do so.

Directional References

In this guide, any reference to direction or placement, such as front, back, left, right, inside, and outside, are

given from the perspective of one standing in front of and facing the machine. This is true, even when the

figure is shown from the rear of the machine.

Notes Used in This Guide

In this guide, you will find information that we’ve called out for you to pay particular attention to. We use

three types of call-outs: Warnings, Notes, and Pro Tips.

Stepper Motors

Your Shapeoko4 gantry is powered by NEMA 23 stepper motors. When the power is o, moving the motors

by hand will cause them to generate electricity.

WARNING: When moving the gantry by hand, go slowly. The power generated by the stepper motors will

feel like bumps. If the lights on the controller are lighting up, it’s very important to slow down because you

are pushing electricity back through the board. Too much back flow could damage the controller.

Firmware

The Shapeoko4 controller ships with GRBL 1.1 firmware, which must be used with Carbide Motion 5. This

document supersedes any information you may find regarding firmware and software on the Carbide 3D

website.

Glossary of Terms

See the Glossary of Terms at the end of this guide for common CNC terms and definitions.

Have Questions? Need Help?

We have a fully-staed support team waiting to help if you run into any trouble while assembling your

Shapeok

o4.

Just

send

us

an

email

at

[email protected] and

we’ll

get

back

to

you

right

away!

WELCOME AND CONGRATULATIONS ......................1

IMPORTANT SAFETY INSTRUCTIONS ......................2

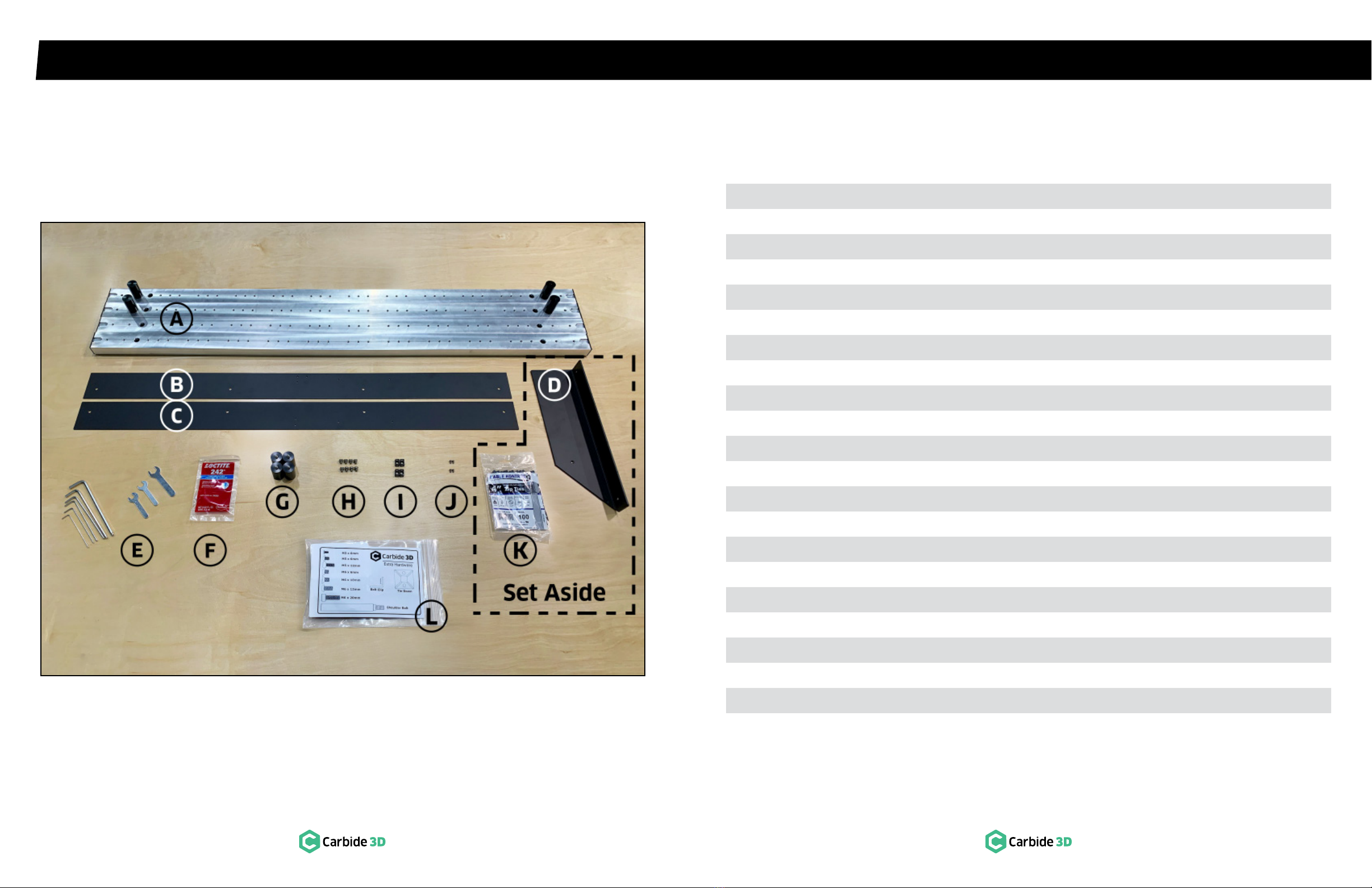

INVENTORY.............................................3

STEP 1 – BASEFRAME ....................................4

1.1 Review Box 1 Components ...................................5

1.2 Position Crossmembers and Drag Chain Support Panels.........6

1.3 Assemble Baseframe .......................................7

1.4 Install Cable Tie Mounts .....................................7

STEP 2 – Y‑RAILS ........................................8

2.1 Review Box 2 Components ..................................9

2.2 Install Y-Left Rail ..........................................10

2.3 Install Y-Right Rail ......................................... 11

STEP 3 – GANTRY ......................................12

3.1 Review Box 3 Components .................................13

3.2 Eccentric Nuts And V-wheels Explained......................14

3.3 Open V-wheels ...........................................15

3.4 Install X-Axis Gantry .......................................16

STEP 4 – ENDPLATES ...................................18

4.1 Review Box 4 Components .................................19

4.2 Install Front-Right Endplate................................20

4.3 Install Back-Right Endplate ..................................22

4.4 Install Y-Left Endplates.................................... 23

4.5 Square Machine ......................................... 24

4.6 Install Side Skirts.........................................25

STEP 5 – X/ZASSEMBLY ............................... 26

5.1 Review Box 5 Components ................................ 27

5.2 Open Eccentric Nuts ..................................... 28

5.3 Pre-Assemble V-wheels................................... 28

5.4 Install X/ZCarrier Plate ................................... 29

5.5 Attach Belt Clip to Belt.................................... 30

5.6 Install X-Motor and Belt ....................................31

5.7 Install Data Drag Chain Head Bracket ...........................34

5.8 Install Router Drag Chain Head Bracket .........................35

5.9 Install X/ZAssembly...................................... 36

5.10 Install X-Axis Drag Chain Support Panel .................... 36

5.11 Install Y-Axis Belts........................................ 38

5.12 Install Y-Left Belt ........................................ 38

5.13 Install Y-Right Belt ........................................41

STEP 6 – DRAG CHAIN ................................. 42

6.1 Review Box 6 Components ................................ 43

6.2 Install X-Axis Drag Chain .................................. 44

6.3 Secure X-Axis Drag Chain Head and Tail .................... 45

6.4 Attach Transition Bracket to Y-Axis Drag Chain Head ......... 46

6.5 Install X/Y Transition Bracket and Y-Axis Drag Chain .......... 46

6.6 Secure Y-Axis Drag Chain Tail ..............................47

6.7 Attach Cable Tie Down ....................................47

STEP 7 – ROUTER ..................................... 48

7.1 Review Box 7 Components................................. 49

7.2 Install Router Mount ......................................50

7.3 Install Router.............................................50

7.4 Prepare Drag Chains .....................................52

7.5 Insert Power Cable ....................................... 53

7.6 Attach Transition Bracket to Y-Axis Drag Chain Head..........54

7.7 Install X-Axis Drag Chain ..................................55

7.8 Secure X-Axis Drag Chain Head and Tail ....................55

7.9 Install X/Y Transition Bracket and Y-Axis Drag Chain .......... 56

7.10 Secure Y-Axis Drag Chain Tail ............................. 57

7.11 Attach Cable Tie Down to Drag Chain Support Panel ......... 57

STEP 8 – HYBRID TABLE ............................... 58

8.1 Review Box 8 Components ................................ 59

8.2 Install Hybrid Extrusions ..................................60

8.3 Install MDF Strips .........................................61

STEP 9 – CONTROLLER ................................ 62

9.1 Review Box 9 Components ................................ 63

9.2 Install Controller Mount ................................... 64

9.3 Install Controller ......................................... 65

9.4 Attach Grounding Wire ...................................65

9.5 Connect Controller Cables ................................66

9.6 Connect Cables ......................................... 68

9.7 Tidy Cables.............................................. 69

9.8 Connect Power and USB.................................. 70

9.9 Install an End Mill ........................................ 70

STEP 10 – SET UP MACHINE‑CONTROL SOFTWARE ........72

10.1 Download CAD/CAM and Machine-Control Software ......... 72

10.2 Connect to Machine .................................... 72

10.3 Update Machine Settings .................................72

10.4 Check Proximity Switches .................................73

10.5 Home the Machine .......................................73

10.6 Set Up BitSetter Accessory (Optional).......................74

10.7 Set Post Processor in Carbide Create (Optional) ..............74

EXTRAS ...............................................76

Beginner Tutorials ............................................ 76

Projects and Inspiration on YouTube and CutRocket............... 76

Join Our Community .......................................... 76

Software User Guides and Tutorials..............................77

Machining Guides .............................................77

Material Guide Videos .........................................77

Workholding and Dust Collection Videos .........................77

Glossary of Terms ............................................ 78

Machine-Use Log............................................. 79

Table of Contents