CFB-CSL FLIP BOLT MORTICE LOCK - CONCEALED SHORT LEVER

The Next Generation in Locking

Distributed in Australia by

LOCK AND KEY a division on the

DAVCOR GROUP PTY LTD ABN 95 003 562 598

This product has been manufactured in China

to Lock and Key Company specifications

This product is guaranteed to be free from defects in materials and

workmanship for a period of one (1) year from the date of original

purchase. This warranty is for replacement of product only and Lock

and Key Company does not accept responsibility for any direct or

consequential damage caused by this product or its use. This warranty

does not cover damage that results from faulty installation or usage,

alteration or modification of the product or tarnishing of the finish

including colour change due to weather, salt or chemical. Should this

product not perform satisfactorily in its intended application, return it

to place of purchase for replacement.

LOCK & KEY Phone: 1300 652 692 Web: www.locknkey.com.au Web: www. daveweb.com.au

NOTE

Please dispose of plastic

bags and other packaging

in a thoughtful manner

WARNING

Please keep contents

away from small children.

Suffocation Hazard.

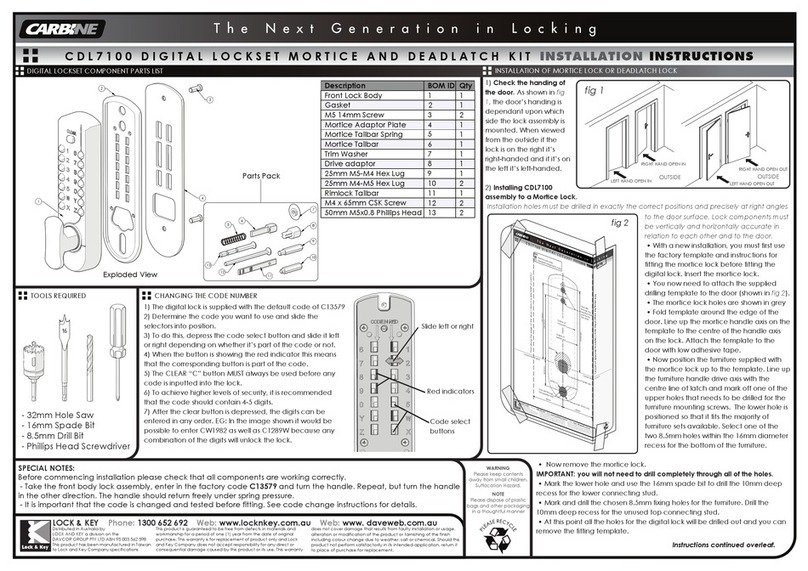

5C Rotate the short lever counter-clockwise

90° as shown on the diagram.

5D Whilst spring is as shown, replace short

lever back into door furniture and securely

re-fasten the central handle mounting screw.

5E Test the short lever rotation to ensure the

position is in right-hand configuration.

5F Rotate the short lever counter-clock-

wise 90° into the downward position as

shown on the diagram.

5A Remove central handle mounting

screw using supplied 3mm allen key.

5B Remove short lever together with

nylon bearing washer and hub.

Ensure parts are kept assembled together.

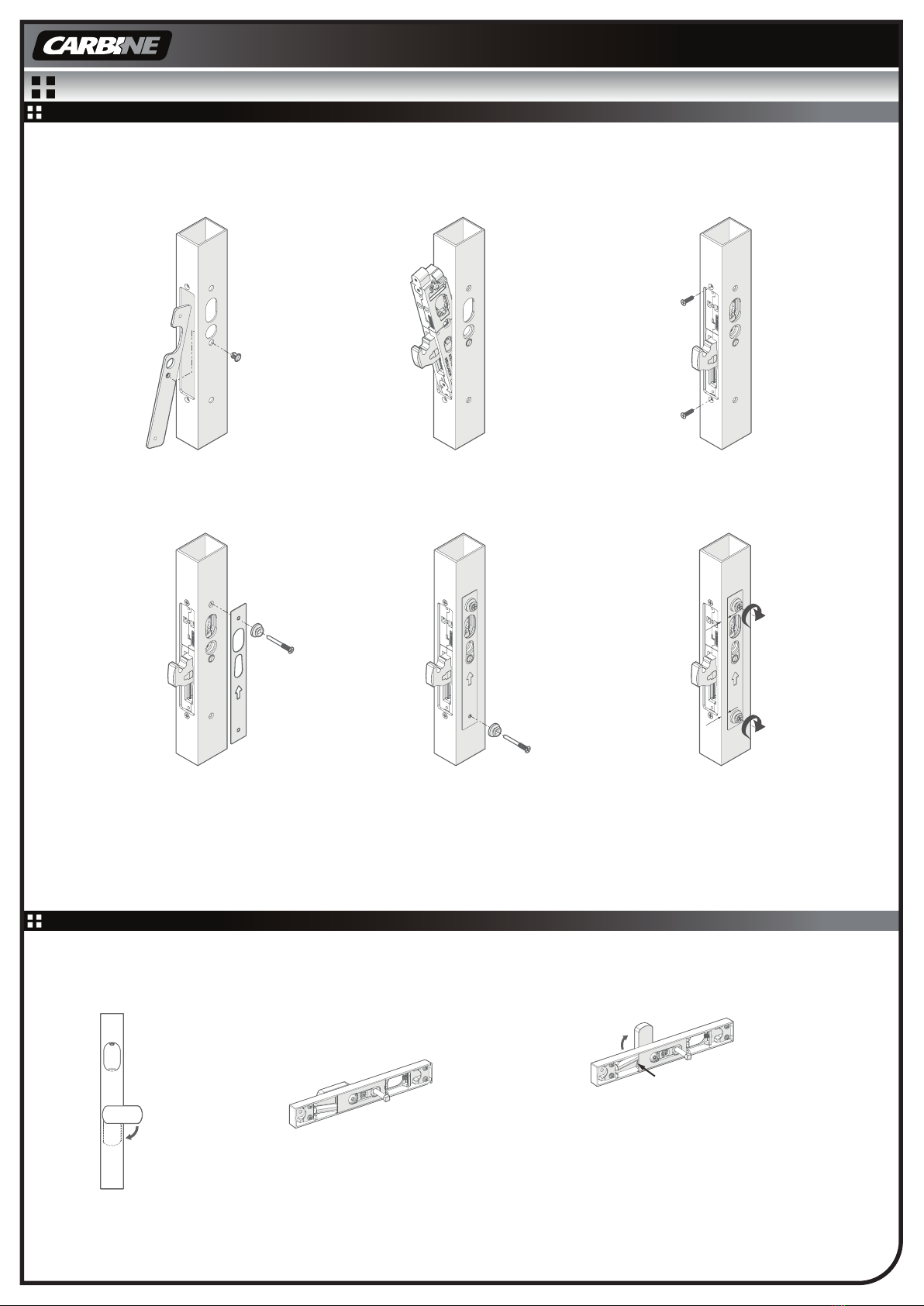

6. INSTALLATION OF CONCEALED SHORT LEVER

6D Insert oval key cylinder

with CSL cam and secure

with retainer pin.

Check retainer pin is flush

with lock body.

Insert oval key

cylinder and

retainer pin

if required.

6E Insert oval key cylinder

and secure retainer pin if

required.**

Attach cover plate to lock

and secure with

2x M4x6mm CSK Screws.

**With rabbit ear / R cam fitted on

the oval cylinder.

6F Installation is now complete.

6B Whilst keeping the

furniture flush with the slide

plate, insert the supplied

2.5mm T-handle allen key

into the grub screw inside

the top of the cylinder hole.

Rotate the grub screw

clockwise until tight, sliding

the faceplate downwards

into its fitted position.

Remove allen key

afterwards.

Test lever operation.

Spring Position

Spring Position Spring Position

Lever Down

Right-hand

Configuration

6A Ensure short lever

is in the horizontal

position and the lock

bolt is extended.

Position the faceplate to

the door and insert the

spindle into the lock

drive and the faceplate

over the mounting

bosses.

Ensure lock bolt is extended

Mounting Boss

Mounting Boss

6C Attach CSL cam to oval

key cylinder.

Special Notes:

For lock installation instructions, please refer to installation instructions provided with CFB-D / CFB-HB.

For installation together with CLS-FAB - Flip Bolt Latching Strike, please refer to the installation instructions provided with CLS-FAB.

For installation together with CFB-OCEP - Oval Cylinder Rectangular Escutcheon, please refer to the installation instructions provided with CFB-OCEP.

5. CHANGE OF HANDING TO RIGHT-HAND CONFIGURATION