+050004121 - rel. 1.0 - 19.10.2009

CAREL INDUSTRIES HQs

Via dell’Industria, 11 - 35020 Brugine - Padova (Italy)

T

el.

(+39)

0

4997

1

66

1

1

–

Fax

(+39)

049

97

1

6

6

00

–

http://www

.carel.com

–

e-mail:

[email protected]CAREL reserves the right to modify the features of its products without prior notice.

Disposal of the product

The appliance (or the product) must be disposed of separately in accordance with the local waste disposal

legislation in force.

WARNING: separate as much as possible the probe and digital input signal cables from the cables carrying

inductive loads and power cables to avoid possible electromagnetic disturbance. Never run power cables

(including the electrical panel wiring) and signal cables in the same conduits.

NO POWER

& SIGNAL

CABLES

TOGETHER

READ CAREFULLY IN THE TEXT!

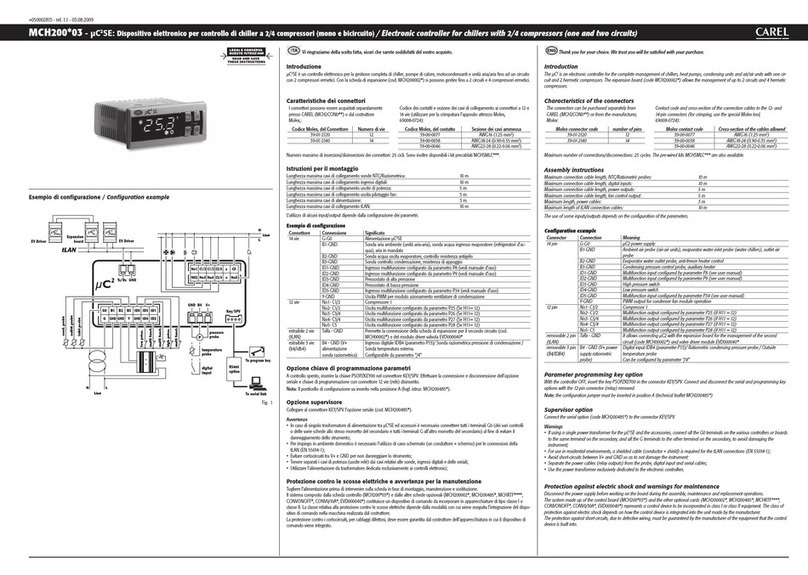

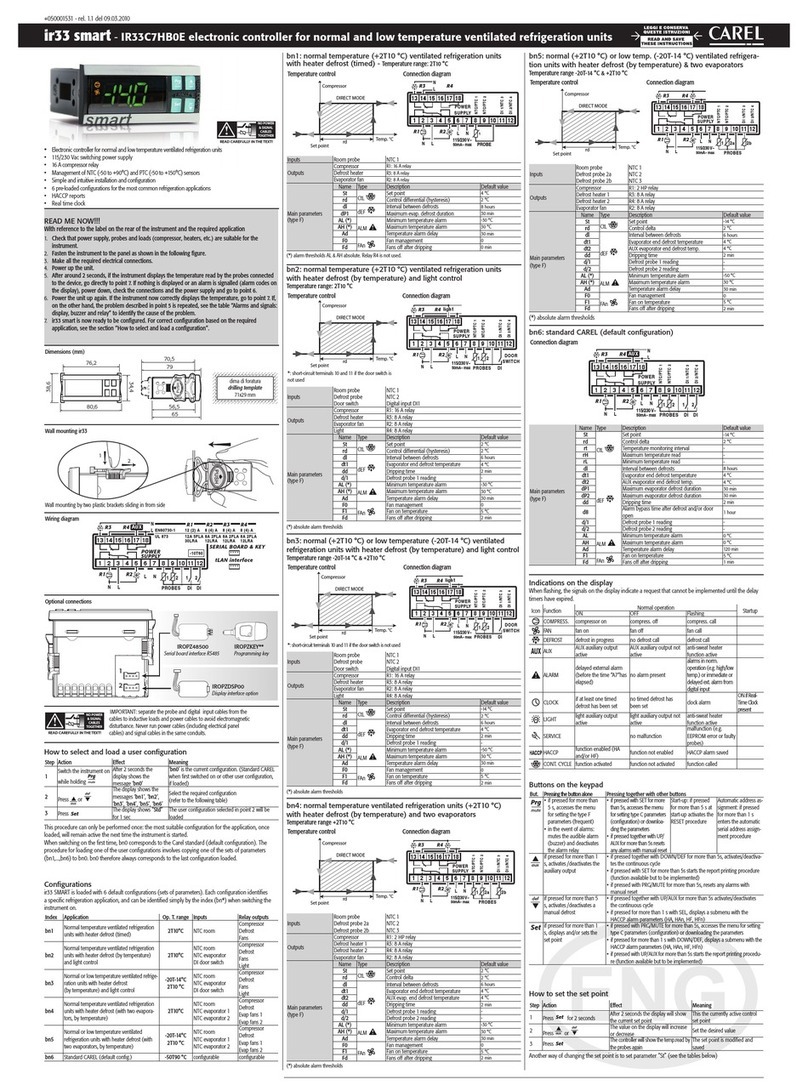

Table of parameters

Parameter Min. Max. Def. UOM

PS PASSWORD 09922-

/ PROBE PARAMETERS

/5 Select °C / °F ( 0 = °C; 1 = °F) 0 1 0 -

/6 Disable decimal point (1 = disabled) 0 1 0 -

/C1 Probe calibration (OFFSET) -50.0 50.0 0.0 °C/°F

r CONTROL PARAMETERS

St Setpoint (control temperature) -50.0 90.0 3.0 °C/°F

rd Control differential (hysteresis) 0.0 19.0 2.0 °C/°F

c COMPRESSOR PARAMETERS

c0 Comp. and fan start delay after start-up 0 100 0 min

c1 Min. time between successive comp. starts 0 100 1 min

c4 Compressor safety (duty setting) 0 100 15 min

d DEFROST PARAMETERS

d0 Type of defrost (0 and 1= defrost by temperature; 2, 3 and

4= defrost by time)

04 2-

dI Interval between defrosts 0 199 6 h/min

dP Max. or effective defrost duration 1 199 20 min/s

d4 Defrost when the instrument is switched on (1= activated) 0 1 0 -

d6 Disable temperature display during defrost (1= display disabled) 0 1 1 -

A ALARM PARAMETERS

A0 Alarm differential -20.0 20.0 -2.0 °C/°F

AL Low temperature alarm threshold/deviation -50.0 250.0 -5.0 °C/°F

AH High temperature alarm threshold/deviation -50.0 250.0 15.0 °C/°F

Ad Low and high temperature alarm delay 0 199 0 min

H OTHER SETTINGS

H2 Enable keypad

0= keypad disabled

1= keypad enabled

2= keypad enabled except for ON/OFF function

02 1-

EY Restore the Default settings 0 1 0 -

Table of alarms

Alarm code Description Parameters involved

E0 probe 1 error= control -

LO low temperature alarm [AL] [Ad]

HI high temperature alarm [AH] [Ad]

EE unit parameter error -

EF operating parameter error -

dF defrost running [d6=0]

Pd defrost awaiting execution -

How to restore the Default settings (refer to table of parame-

ters in this sheet)

1) Access parameter EY (entering password 22 and scroll parameter list).

2) Select the desired configuration:

• EY = 0 ¼No changes;

• EY = 1 ¼Restore of default settings (refer to Table of parameters in this sheet);

3) Exit the setting procedure (holding SET button for more than 3 s).

4) Power off the device and then power it on again while holding SET button.

5) The display shows “CE” to indicate that the configuration has been restored.

Switching the device ON/OFF

Press UP for more than 3 s. The control and defrost algorithms are now disabled and the

instrument displays the message “OFF” alternating with the temperature read by the set probe.

Manual defrost

Press DOWN for more than 3 s (the defrost starts only if the temperature conditions are valid).

Continuous cycle

Press UP and DOWN together for more than 3 s.

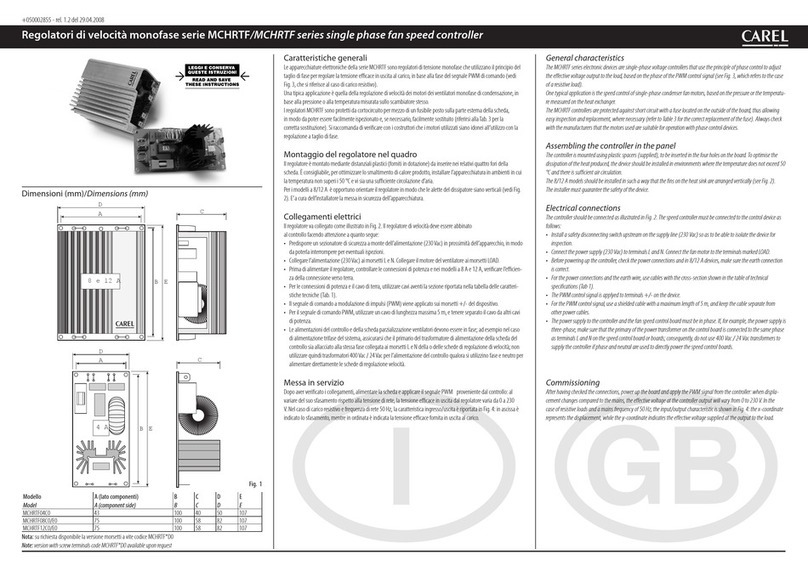

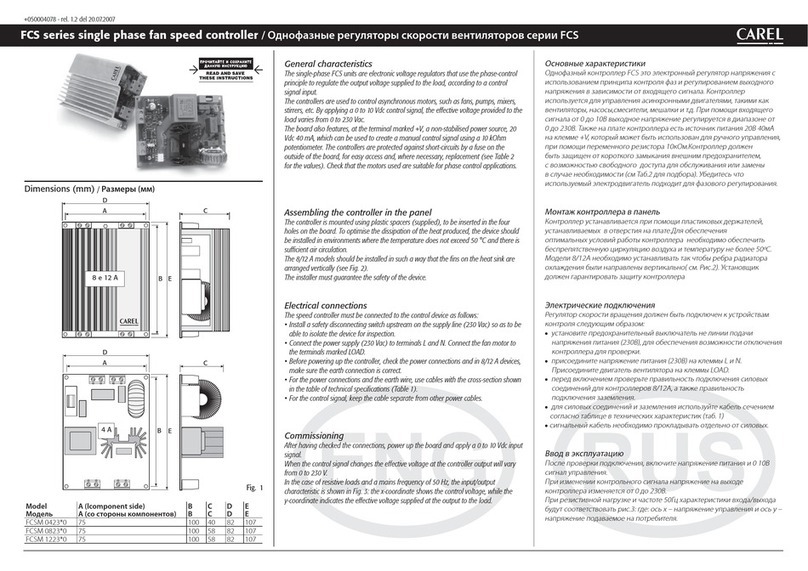

Technical specifications

power supply 230 V 1~, -10% +15% 50/60 Hz

rated power 3 W

input NTC probe

relay output 16 A relay UL: 12 A resistive 5 FLA, 30 LRA 240 Vac 30,000 cycles

EN60730-1: 12(2)A or 10(4)A (N.O. only) 250 Vac 100000 cycles;

type of probe Std CAREL NTC 10 KΩ at 25 °C

power supply/

relay output

connector

- screw terminals pitch 5mm for cables with cross-sect. from 0.5 mm2to 1.5 mm2;

12 A max;

probe connector screw terminals:

- 2-pin pitch 5mm for models with 1 probe (cable cross-section from 0.5 mm2to

1.5 mm2); 12 A max;

assembly using screws from the front or with brackets at the rear

display LED display, 2 digits plus sign, decimal point and compressor icon

keypad 3 buttons with membrane

operating conditions -10T50 °C - humidity <90% rH non-condensing

storage conditions -20T70 °C - humidity <90% rH non-condensing

range of measurement -50T90 °C (-58T194 °F) - resolution 0.1 °C/°F

front panel index of protection panel installation with IP65 type 1

case plastic terminal, 81x36x38 mm

classification according to protection

against electric shock

Class II

environmental pollution II

PTI of the insulating material 250 V

period of stress across the insulating

parts

long

category of resistance to heat and fire category D (UL94 - V0)

immunity against voltage surges category 1

type of action and disconnection micro-disconnection 1C

no. of relay automatic operating cycles EN60730-1: 100,000 cycles

UL: 30,000 cycles (250 Vac)

software class and structure Class A

cleaning the instrument Only use neutral detergents and water.

cable max. lenght serial: 1 km

probes: 30 m

relay: 10 m

Note: do not run the power cable less than 3 cm from the bottom part of the device or from the

probes; for the connections only use copper wires.

Safety standards

compliant with the relevant European standards. Installation precautions:

the connection cables must guarantee insulation up to 90 °C;•

for 12 Vac versions use Class II transformers. To ensure compliance with the immunity•

standards (surge), the transformer must be one of the models specified (see the CAREL price

list). For the 12 Vac/dc versions, as double insulation cannot be guaranteed between the

power supply and the relay outputs, only use safety low voltage loads (up to 42 V effective

rated value);

ensure a space of at least 10 mm between the case and the nearby conductive parts;•

digital and analogue input connections less than 30 m away; adopt suitable measures for•

separating the cables so as to ensure compliance with the immunity standards;

Secure the connection cables of the outputs so as to avoid contact with very low voltage parts.

IMPORTANT WARNINGS

The CAREL product is a state-of-the-art device, whose operation is specified in the technical documentation

supplied with the product or can be downloaded, even prior to purchase, from the website www.carel.com.

The customer (manufacturer, developer or installer of the final equipment) accepts all liability and risk relating

to the configuration of the product in order to reach the expected results in relation to the specific final instal-

lation and/or equipment. The failure to complete such phase, which is required/indicated in the user manual,

may cause the final product to malfunction; CAREL accepts no liability in such cases. The customer must use

the product only in the manner described in the documentation relating to the product. The liability of CAREL

in relation to its products is specified in the CAREL general contract conditions, available on the website www.

carel.com and/or by specific agreements with customers.