ATTENTION!

READ BEFORE ATTACHING THE AIR HOSE

HVLP AIR SUPPLY REQUIREMENTS

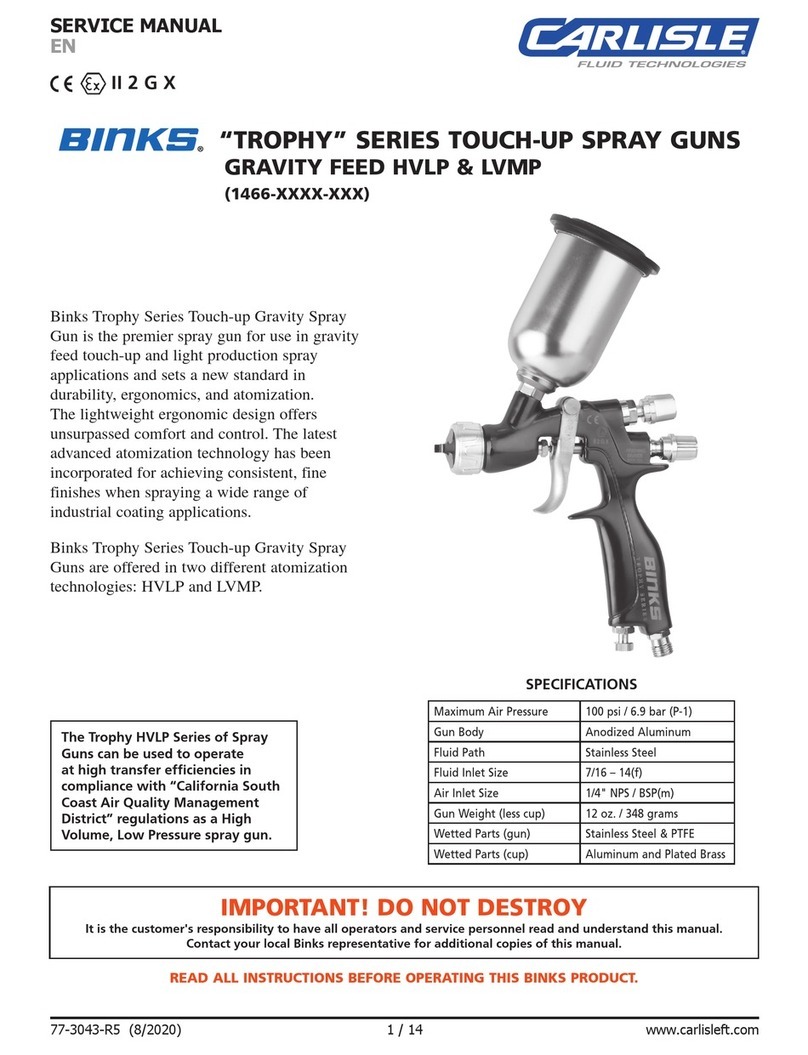

FULL SIZE GUN: 30 PSI inlet pressure provides 10 PSI at the air cap. Consumes 13 CFM.

TOUCHUP GUN: 30 PSI inlet pressure provides 10 PSI at the air cap. Consumes 8 CFM.

NOTE: USE 5/16" OR LARGER I.D. AIR HOSES

4. If desired, attach air adjust-

ing valve with gauge and/

or quick disconnect to air

inlet, then attach hose.

5. Spray test and adjust air

pressure, fan size, and

fluid flow as required.

Recommended spray

distance is 6-8 inches.

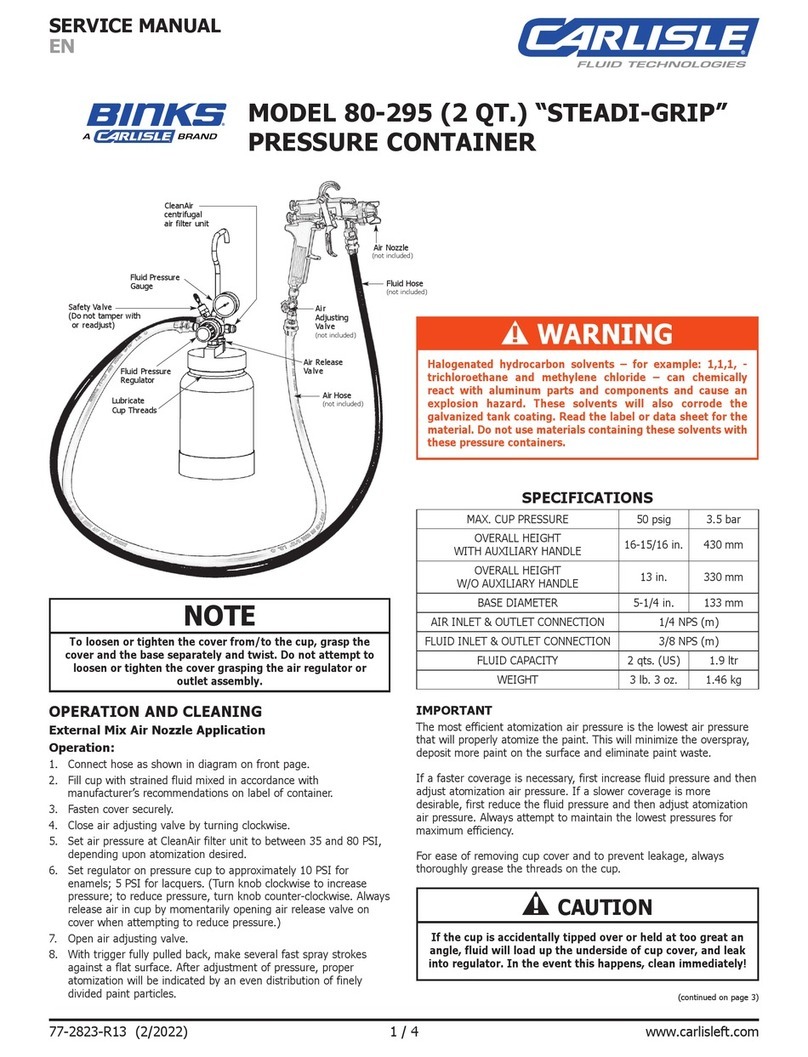

SET-UP AND ADJUSTMENT INSTRUCTIONS

1. Attach cup to gun and

flush solvent through gun

to remove oils.

2. Tighten packing nut—see

instructions.

3. Fullyopenfanandfluid

needle controls (turn

counter-clockwise).

Before using this spray gun,

the packing nut should be

adjusted as follows:

1. Tighten packing nut until

fluid needle starts to bind

in the packing.

2. Loosen packing nut just

enough so the fluid needle

moves freely.

PACKING ADJUSTMENT INSTRUCTIONS

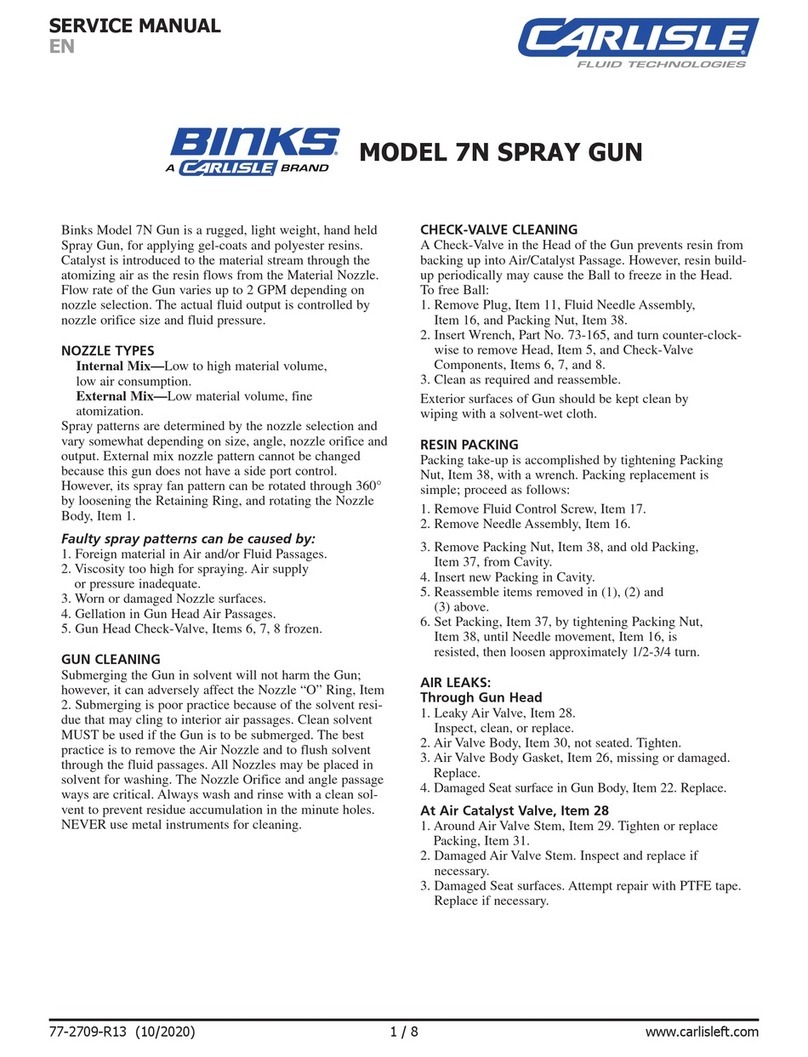

AIR CAP

PACKING

NUT

FLUID NEEDLE

FAN CONTROL

FLUID NEEDLE CONTROL

The packing nut is intentionally left loose so the PTFE packing

does not take a "set" before the spray gun is used. This allows

full utilization of the packing.

A failure resulting in injury or damage may be caused by pressure

beyond top of scale, excessive vibration or pressure pulsation,

excessive instrument temperature, corrosion of the pressure con-

taining parts or other misuse of the air adjusting valve with gauge.

A

C

B

D

Spray a test area. Turn the fluid needle

adjusting knob counterclockwise until a

full coat is obtained.

If the finish is too sandy and dry, the

material flow may be too low for the

atomization air pressure being used.

Turn the fluid needle adjusting knob

counterclockwise to increase fluid flow.

If the finish sags, there is too much mate-

rialflowingfor the atomization air pressure

being used. Turn the fluid needle adjusting

knob clockwise to decrease fluid flow.

Pattern width can be altered by turn-

ing spreader adjustment valve, either

clockwise to decrease the width or coun-

terclockwise to increase the width.

Adjust inlet air pressure to provide a uni-

formdispersion of atomized paint through-

out the pattern. Keep air pressure as low

as possible to minimize bounce-back and

overspray. Excessive pressure will result in

split spray patterns. Inadequate pressures

will cause heavy centered patterns and

poor atomization.

CLEANING

For routine cleaning, it is not necessary

to remove cup from gun. Remove lid and

properly dispose of any excess paint. Pour

in a small amount of clean solvent. The

amountwill varywithdifferent coatingsand

solvents. Reinstall lid. Shake cup to wash

down the inside surfaces. Pull trigger to

allow some solvent to be flushed through

gun.Removelidand pour out dirty solvent.

Add a small amount of clean solvent and

repeat procedure. Wipe exterior of lid with

a clean cloth and clean solvent.

If a paint filter was used in the bottom of

the cup outlet, it should be removed and

cleaned at this time.

To clean air cap and fluid tip, brush exte-

rior with a stiff bristle brush. If necessary

to clean cap holes, use a broom straw or

toothpickif possible. If a wireorhard instru-

mentisused,extremecare must be used to

prevent scratching or burring of the holes

which will cause a distorted spray pattern.

To clean fluid passages, remove excess

material at source, then flush with a suit-

able solvent. Wipe gun exterior with a

solventdampened cloth. Never completely

immerse in solvent as this is detrimental

to the lubricants and packings.

PREVENTIVE MAINTENANCE

Spray Gun Lubrication

Apply a drop of spray gun lube at trigger

bearing stud and the stem of the air valve.

Theshank of thefluidneedle where itenters

the packing nut should also be oiled. The

fluid needle packing should be kept soft

and pliable by periodic lubrication. Make

sure the baffle and retaining ring threads

are clean and free of foreign matter. Before

assembling retaining ring to baffle, clean

thethreads thoroughly,thenadd two drops

of spray gun lube to threads. The fluid

needle spring and air valve spring should

be coated with a very light grease, making

sure that any excess grease will not clog

the air passages. For best results, lubricate

the points indicated, daily.

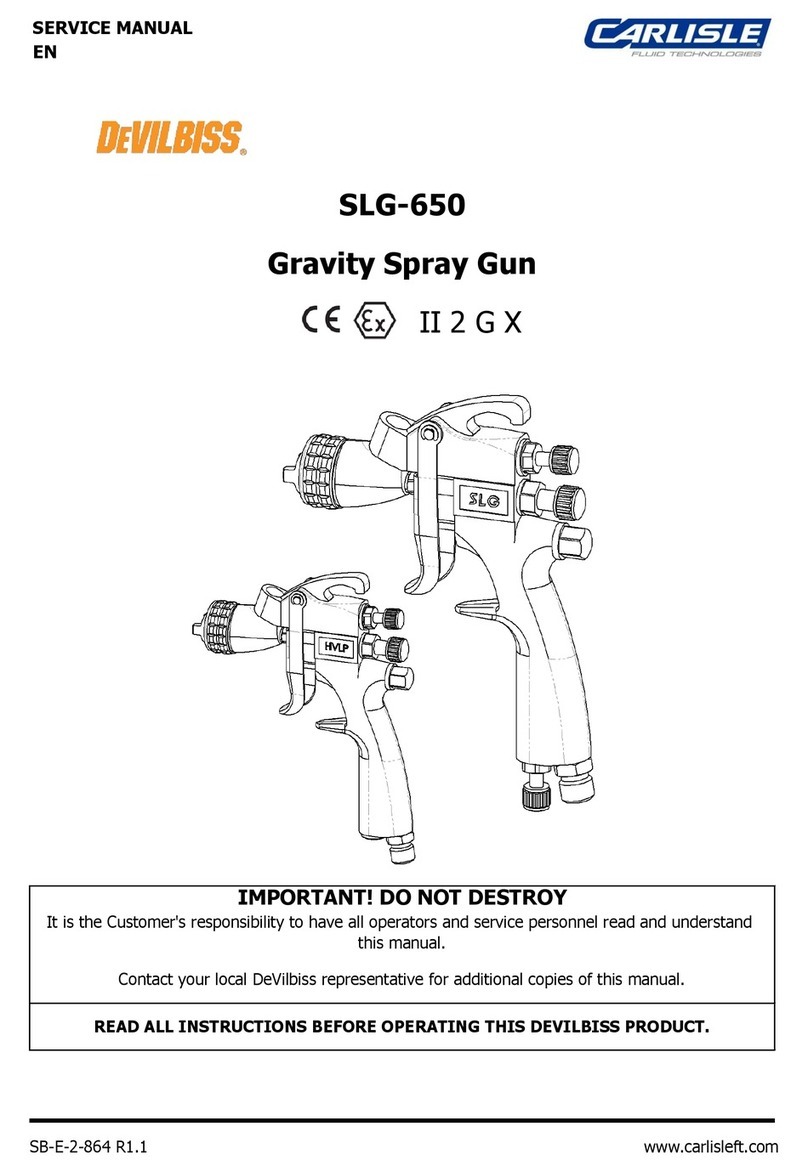

A. Trigger Points

B. Packing

C. Adjusting Valve

D. Baffle/Air Cap Threads

Fluid Tip

Size (mm) Applications

1.0 General purpose, light to medium

viscosity material.

1.3 Top coats.

1.5 Top coats and primer sealers.

1.8 Primers.

EN

SB-2-610-R1 (4/2018)2 / 3www.carlisleft.com