Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

PC 111 Catalog No. 533-358 Printed in U.S.A. Form 33ZC-3SI Pg 1 10-99 Replaces: New

Book 1 4

Tab 11a 13a

Mounting Instructions

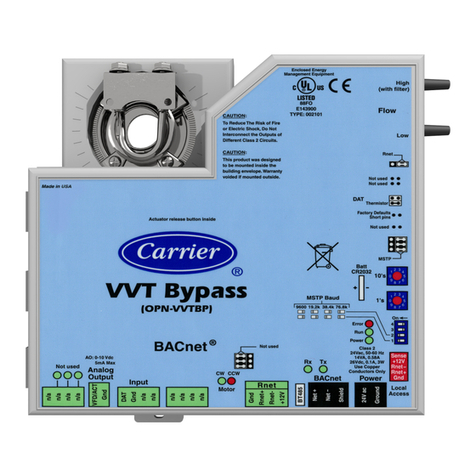

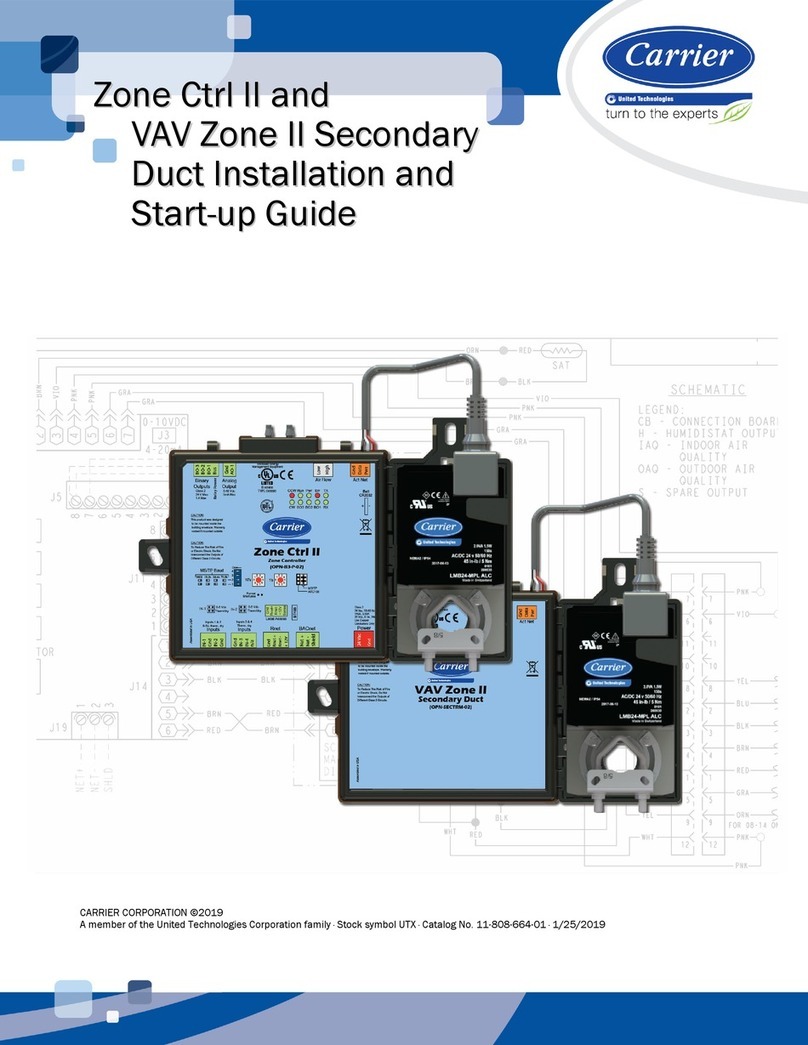

Part Numbers 33ZCVAVTRM, 33ZCFANTRM, 33ZCSECTRM

GENERAL

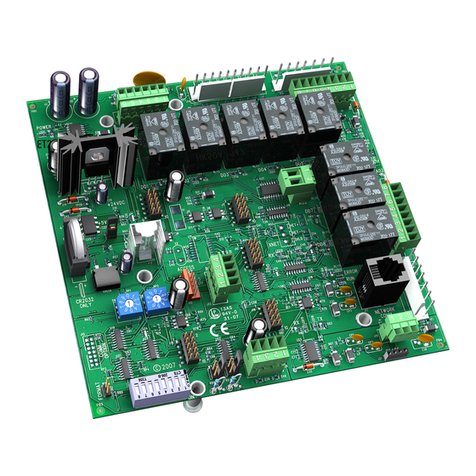

The VAV Fan Terminal Zone Controller (33ZCFANTRM)

provides dedicated control functions for series fan or parallel

fan powered terminals, single duct terminals with 3 stages of

heat, or as a primary controller for dual duct or zone pressure

control applications. The VAV Fan Terminal zone controller is

part of the Carrier ComfortID System.

The Single Duct Air Terminal Zone Controller

(33ZCVAVTRM) provides dedicated control functions for sin-

gle duct terminals with modulating heat or up to 2 stages of

heat. The single duct air terminal zone controller is part of the

Carrier ComfortID system.

With the addition of a secondary terminal and the

33ZCSECTRM secondary terminal zone controller accessory,

either dual duct or zone pressurization applications can be sup-

ported. This accessory is only used with the 33ZCFANTRM

controller.

TOOLS REQUIRED

•1/4-in. nut driver

• 8-mm wrench or socket

• No. 1 Phillips head screwdriver

INSTALLATION

Location — The zone controller must be mounted on the

air terminal’s damper actuator shaft. For service access, there

should be at least 12 in. of clearance between the front of the

zone controller and adjacent surfaces.

Mounting — Perform the following steps to mount the

zone controller:

1. Visually inspect the damper and determine the direc-

tion in which the damper shaft moves to open the

damper — clockwise (CW) or counterclockwise

(CCW).

If the damper rotates CCW to open, it does not require

any configuration changes.

If the damper rotates CW to open, then the damper

actuator logic must be reversed. This is done in the

software when performing system start-up and damper

calibration test. Do not attempt to change damper rota-

tion by changing wiring. This will upset the damper

position feedback potentiometer readings.

2. Rotate the damper shaft to the fully closed position.

3. Press the release button on the actuator and rotate the

clamp in the same direction that was required to close

the damper in Step 2.

4. Press the actuator release button and rotate the actuator

back one-position of graduation. Release the button

and lock the actuator in this position.

5. Mount the control to the terminal by sliding the

damper shaft through the actuator clamp assembly.

Secure the control by installing the screw provided

through the grommet in the anti-rotation tab. Be sure

the floating grommet is in the center of the slot. FAIL-

URE TO CENTER THE GROMMET MAY CAUSE

THE ACTUATOR TO STICK OR BIND.

6. Tighten the actuator clamp assembly to the damper

shaft. Secure by tightening the two 8-mm nuts.

7. If the damper has less than 90 degrees of travel

between the fully open and fully closed positions, then

a mechanical stop must be set on the actuator. The

mechanical stop prevents the damper from opening

past the maximum damper position. To set the

mechanical stop, perform the following procedure:

a. Press the actuator release button and rotate the

damper to the fully open position.

b. Using a No. 1 Phillips screwdriver, loosen the

appropriate stop clamp screw and move the stop

clamp so that it contacts the edge of the cam on

the actuator.

c. Secure the stop clamp in this position by tighten-

ing the screw.

8. Verify that the damper opens and closes. Press the

actuator release button and rotate the damper. Verify

that the damper does not rotate past the fully open

position. Release the button and lock the damper in the

fully open position.

9. Remove the cover from the zone controller. Install

two lengths of field-supplied 1/4-in. pneumatic tubing

(rated for the application) from the pressure transducer

to the velocity pressure pick-up tubes. Be careful to

avoid sharp bends in the tubing, because malfunctions

may occur if the tubing is bent too sharply. For best

operation, use at least 2 ft of tubing. Connect high side

to the P1 port of the airflow transducer. Replace cover.

IMPORTANT: This document contains zone con-

troller mounting information only. Refer to the

Installation, Start-Up, and Configuration manual for

zone controller wiring and tubing installation. Refer

to the Installation, Start-Up, and Configuration

manual for configuration procedures.

Single Duct Air Terminal Zone Controller

VAV Fan Terminal Zone Controller

Secondary Terminal Zone Controller