CPLOWAMB

LEFT

COIL

MOTORMASTER

tt

=

—

eLECTRICAL

BLOWER

ACCESS ACCESS

PANEL

PANEL

COMPRESSOR

ACCESS

PANEL

MODELS

A48ES-A,

48EZ-A,

48VL-A,

48VT-A

50ES-A,

50EZ-A,

48VL-A,

48VT-A

§74D--A,

674D--A,

577C--A,

677C--A

704D--A, 604D--A, 707C--A,

607C--A

PGDS,

PODS,

PGD4

PADS,

PHD3,

PAD4,

PHD4

PY3G,

PA3G

WPGS3,

WPA3,

WPH3

A11089

oS

a

Se

=S

mae

SSS

|

BeESS

SSSSSSS

|

222222

SSSSSPS

SSS

Sass

SSSS8S85

|

SS

aes

SSSSSSS

|

SSeS

See

SSSSS25

|

See

ess

SSSS3SS3S3

|

SeSeess

SSSiSS3

|

See

eSes

Motormaster

If

SSSSSSS3

|

SSS

eee

SSSSSS8

|

222222

SSQSS8SS|

Seo

SeSes

SSSSS538

|

SSeeees

SSSSSS88

|

Spe

aees

SSS

S|

SSeS

Ss

SSSSS838|

2BeesteZ

SSSSS323|

2eSeee=

SSSSSS8

|

222222

SSSS8S2

|

SSeS

Sese

SSSSSS35)

|

Sree

Sseesee

SSSSSS838

|

2Geeaeee

SSSSSSS

|

SSeeeses

SSSSSS83)

|

2eeeee

SSSESS

2

|

Sree

eae

SSSSS383

|

2ereees

SSSSSSS8|

ZB2Z22Z222

SSS8

|

Sees

.

SSSSSS

ZZZE

Electrical/

SSNS

Ze

Compressor

ASS

Coil

Access

OS

Panel

Models

50ZHB,

50ZPB,

PHJ3,

PAJ3,

PH3Z,

PA3Z,

WJH3,

WJA3

A11090

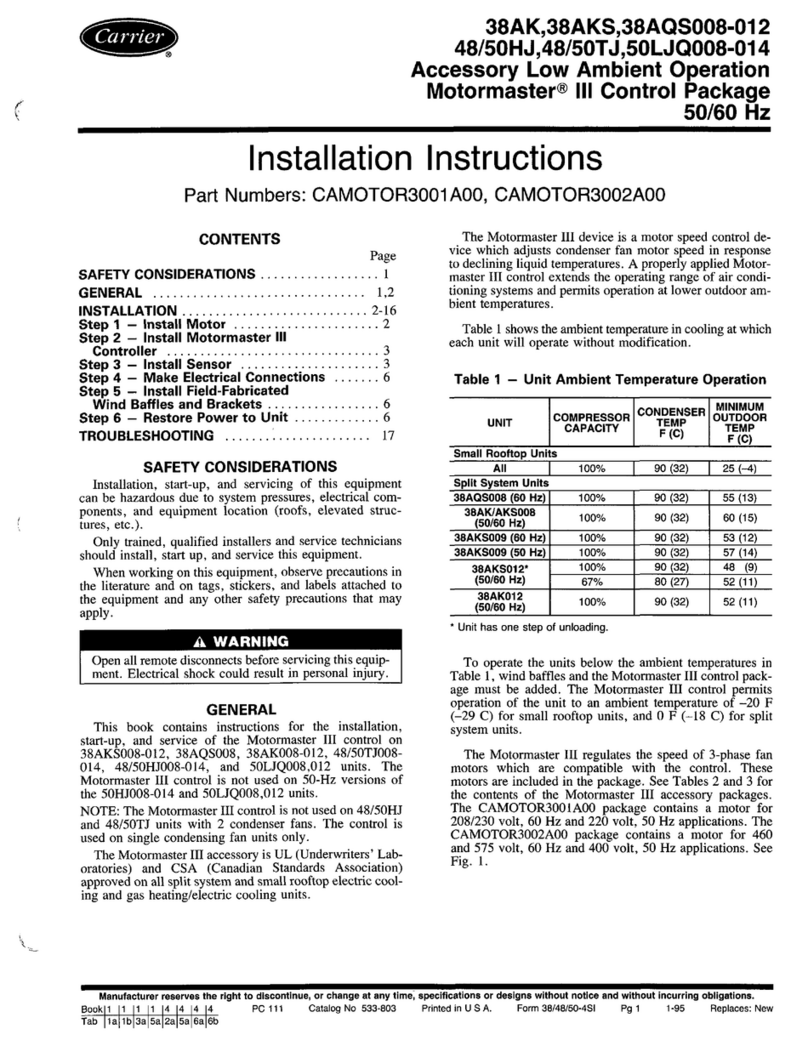

Fig.

2

-

Access

Panel and

Motormaster

Location

SENSOR

INTEGRAL

WIRE

TIE

3/8"

HEADER

TUBE,

CONDUCTIVE

GREASE

OR

RETURN

BEND

NOTE:

INSTALLED

SENSOR

MUST

BE

LEFT

UNINSULATED,

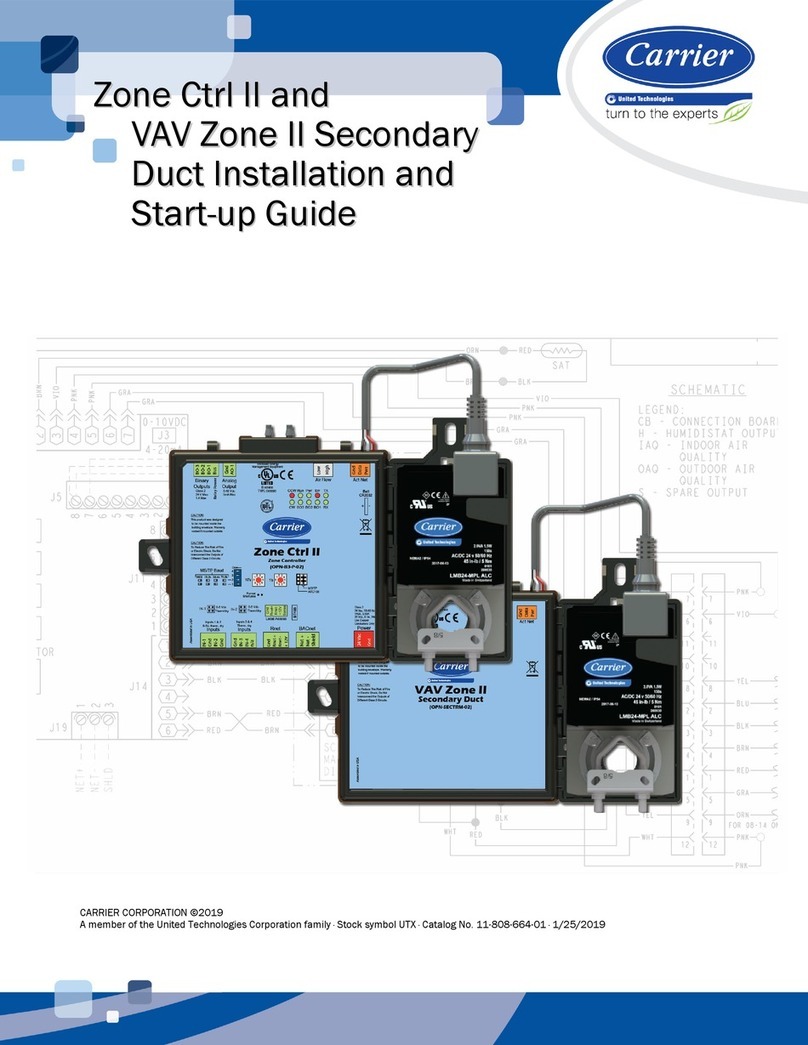

Sensor

Connection

Detaiis

A11106

Fig.

3

-

Connection

Details

DESCRIPTION

AND

USAGE

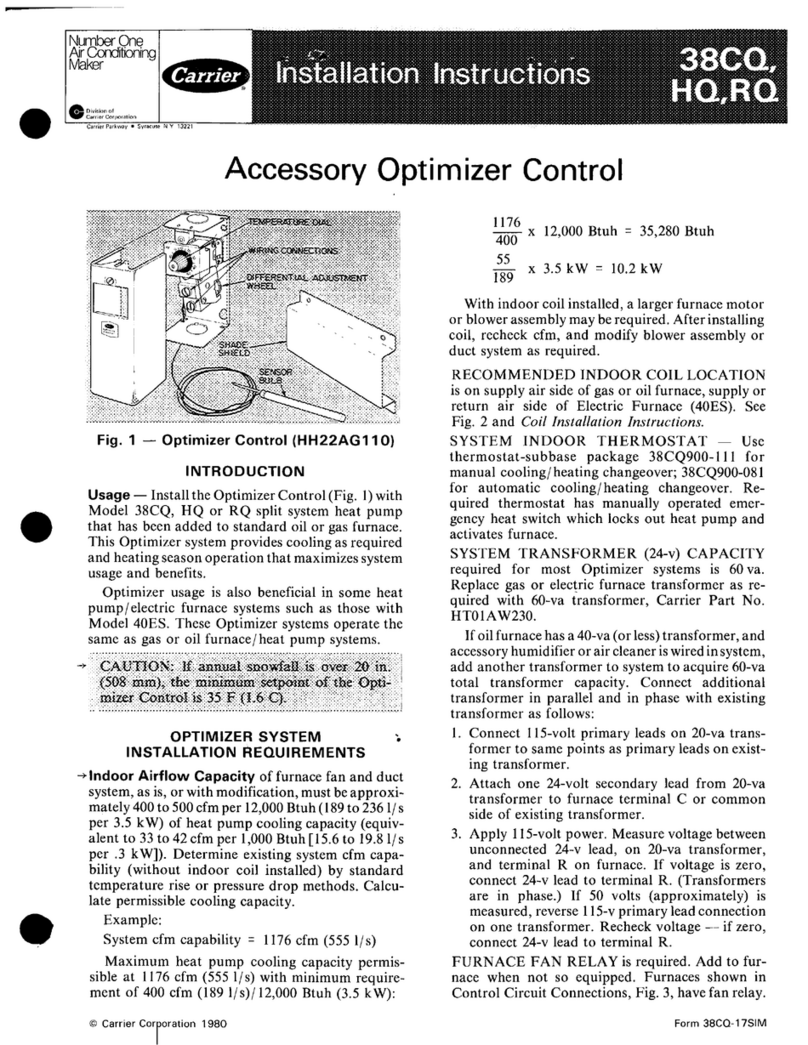

The

Motormaster

II

head

pressure

controller

is

a

cycle

control

device

activated

by

a

temperature

sensor

mounted

on

a

header

tube

of

the

outdoor

coil

(see Fig.

1).

It

is

designed

to

cycle

the

outdoor-fan

motors

to

maintain

the

saturated

condensing

temperature

within

normal

operating

limits

of

approximately

130

to

110°F

high

(54°C

to

43°C),

70

to

50°F

low

(21

to

10°C).

The

controller

maintains

working

head

pressure

at

low

ambient

temperatures

down

to

-20°F

(-29°C)

when

properly

installed.

INSTALLATION

1.

Disconnect

power

to

unit.

Install

lockout

tag.

2.

Remove

unit

electrical,

blower

and

compressor

access

panel.

(See

Fig.

2.)

3.

Disconnect

black

lead

from

the

outdoor-fan

motor

(OFM)

and

connect

to

Motormaster

control

(See

Wiring

Schematic,

Fig.

7

or

8).

4.

Using

a

knockout

punch

and

die

combination,

make

hole

in

the

access

panel

to

feed

MotormasterII

Control

wire

leads

to

the

side

of

its

mounting

location

(See

Fig.

2

and

Fig.

4

or

Fig.

5).

NOTE:

Field-supplied

conduit

must

be

used

between

controller

and

access

panel

(or

wire

into

unit

entrance).

Created

hole

on

the

access

panel

must

be

sealed

to

comply

with

National

Electric

Code

(NEC).

5.

Mount

Motormaster

II

Controller

on

unit.

Refer

to

Fig.

2

and

Fig.

4

or

Fig.

5,

The

controller

must

be

mounted

vertically

with

the

leads

at

the

bottom.

Using

the

Mounting

Template

(Fig.

9)

as

a

guide,

drill

mounting

holes. To

ensure

electrical

ground,

insert

star

washers

(supplied

with

the

controller)

under

the

heads

of

mounting

screws.

6.

Determine

sensor

location

by

referring

to

Fig.

10-41.

Route

sensor

wire

through

bottom

of

Motormaster

II

Controller

(Fig.

1) to

sensor

location

specified.

Prior

to

installation,

apply

conductive

grease

supplied

with

accessory

to

contact

surface

of

sensor.

4&

CAUTION

COMPONENT

DAMAGE

HAZARD

Failure

to

follow

this

caution

may

result

in

component

damage.

Sensor

assembly

is

delicate.

Handle

with

care.

7.

Attach

sensor

to

tube

as

shown

in

Fig.

3.

Installed

sensor

must

be

left

uninsulated.

8.

Power

wiring

must

comply

with

all

local

and

National

Electrical

Code

(NEC)

and

International

Electric

Code

(IEC)

requirements.

Refer

to

Fig.

7

and

8

for

power

wiring

connections.

Coil

up

all

excess

wire

and

secure.

(Yellow

and

blue

wires,

from

controller,

must

run

to

unit

contactor

and

connect

on

the

load

side.)

4&

CAUTION

UNIT

OPERATION

AND

COMPONENT

DAMAGE

HAZARD

Failure

to

follow

this

caution

may

result

in

improper

unit

operation

or

component

damage.

All

wires

must

be

secured

so

that

they

are

not

in

contact

with

unit

tubing.

9,

To

prevent

wind

cross-currents form

causing

abnormally

low

condensing

temperatures,

louvered

panels

are

required

on

some

models.

See

Table

1

and

2

for

models

requiring/not

requiring

louvered

panels.

10.

Screw

back

ail

access

panels

11.

Reconnect

power

to

the

unit.

The

Motormaster

II

head

pressure

controller

is

equipped

with

an

alternate

operating

mode.

When

this

mode

is

selected,

the

controller

shifts

the

fan

cycle

sequence

to

effectively

raise

the

average

condensing

temperature

approximately

20°F

(-6.7°C)

higher

than

the

standard

operating

mode.

In

this

alternate

mode,

the

outdoor

fan

begins

cycling

at

higher

outdoor ambient

temperatures.

This

mode

should

only

be

used

if

the

evaporator

coil

shows

signs

of

frosting

at

low

outdoor ambient

temperatures.

To

select

the

alternate

operating

mode,

move

the

jumper

wire

on

the

Motormaster

II

control

board from

reset

T1

to

T2.

Refer

to

Fig.

6

for

thermistor

resistance

vs.

temperature.

2