AFS-8036-13e Replaces: None

© 2013 CNH America LLC. All rights reserved. Printed in U.S.A.

Case IH is a registered trademark of CNH America LLC. Any trademarks referred to herein in

association with the goods and/or services of companies other than CNH America LLC are the

property of those respective companies.

CNH America LLC reserves the right to make improvements in design and changes in

specifications at any time without notice and without incurring any obligation to install

them on units previously sold. Specifications, descriptions and illustrative material herein

are as accurate as known at time of publication, but are subject to change without notice.

Availability of some models and equipment builds varies according to the country in which

the equipment is used.

Visit us on the web at www.caseih.com

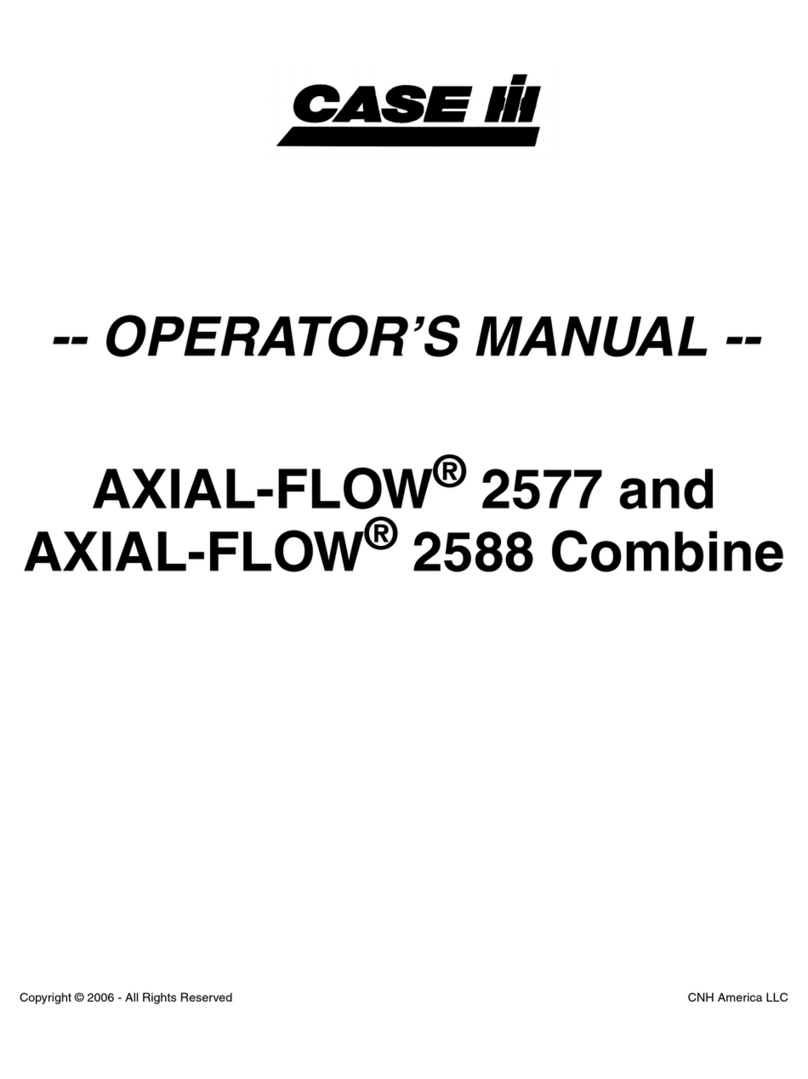

7 - OVERLAP/BOUNDARY CONTROL

7.1 Overlap/Boundary Control

Toolbox>Overlap

a) Turn overlap control on

b) Turn boundary control

on (requires a created

boundary)

c) Set % for out of bounds

d) Set % of overlap

for shutoff

e) Set start early

distance to 0 ft.

f) Set stop late

distance to 0 ft.

IMPORTANT! Product delay

must be measured and set

correctly before adjusting

start early/stop late values.

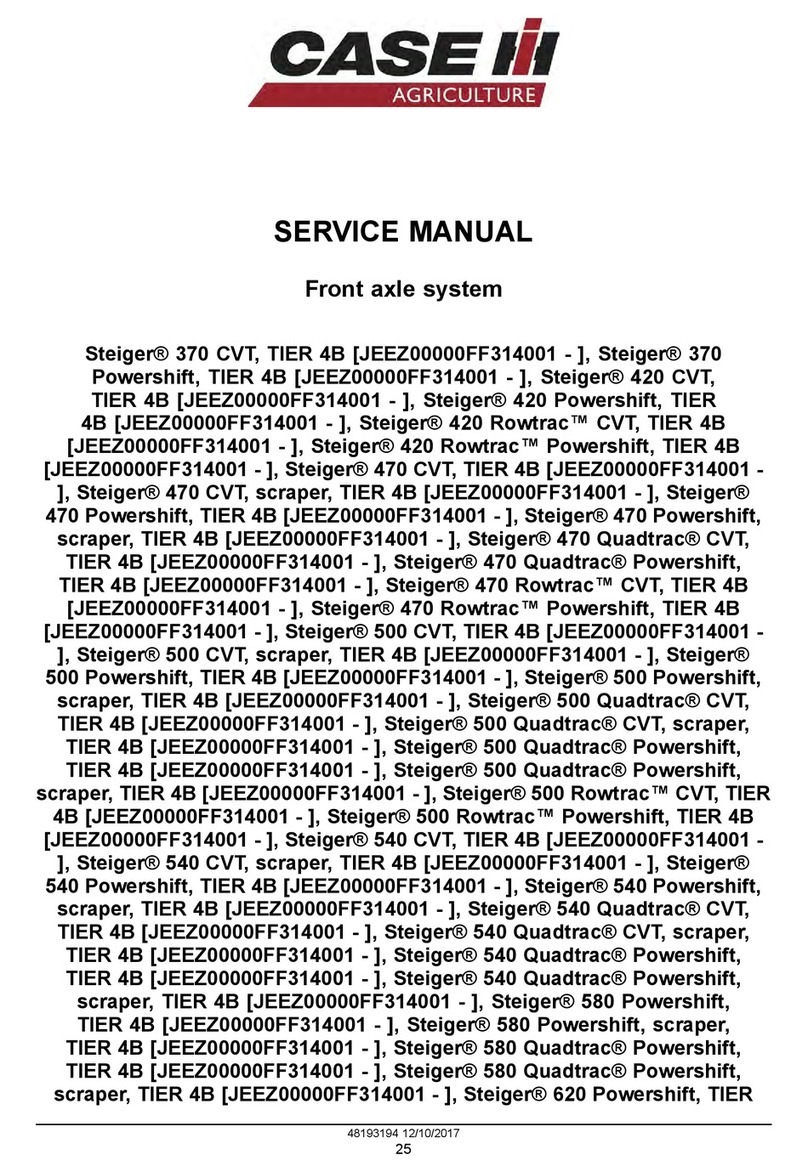

7.2 Product Delay Adjustment

Work Condition>Control>Liquid

Before making any adjustments to the Product

Delay, make sure GPS offsets & Bar Distance are

entered correctly.

To check performance:

Note: Prime can be used to perform this calibration (start at

step g), but may not be available on the run screens. The NH3

calibration screen will be used to check the product delay in

this case. Instructions below are for using the liquid calibration

method to check product delay.

a) Select Work

Condition>Liquid Cal

b Select Liquid Op Mode

– [Anhydrous] (Accept

Safety Warning if agreed)

c) Press Master Control –

‘Apply’ Button

d) Press ‘Next’, twice

e) Press the Start button

once to prime the system,

Press ‘Stop’

to stop operation

g) Start the stopwatch and

at the same time Press

the ‘Start’ button

h) Stop the stopwatch when product is rst observed leaving the

application point

i) The elapsed time displayed on the stopwatch is the

Product Delay

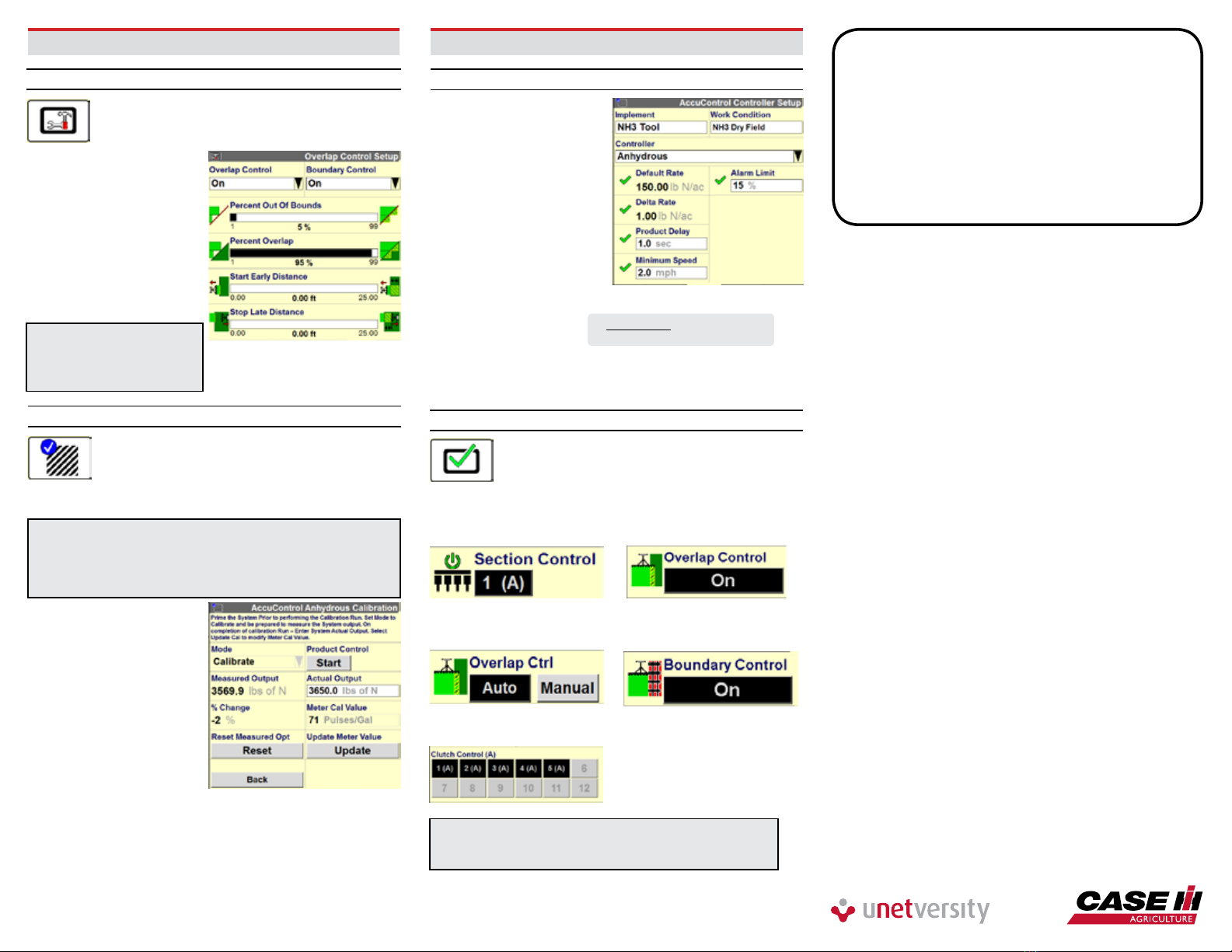

7 - OVERLAP/BOUNDARY CONTROL – continued

7.3 Running Overlap/Boundary Ctrl

NOTE! The following windows can be located

on the Run screens.

Disengages drive section master

valve and/or all boom valves for that

drive section. “On” when the button

is black (1), and “Off“ when the button

is grey (2)

Quickly switch between Auto and

Manual section control

Enables/Disables Overlap Control

(disable before backing, enable after

driving forward), except AccuGuide

complete tractors

Enables/Disables Boundary Control

Disengage individual section valves

NOTE! (A) must be present for Auto Overlap and Boundary

Control to function. If (M) is present, Auto Overlap and

Boundary control will not work!

7.2 Product Delay Adjustment - continued

j) Exit the calibration

without updating the

calibration number

by pressing ‘Back’

k) Press ‘Control’ Tab

l) Enter the measured

time as the Product

Delay gure

m) Throughout the season

check for proper overlap

operation especially when

experiencing different

ambient temps

n) If exact measurement of

error is determined use this

formula to convert this

distance to a new

Product Delay (PD)

o) Adjust Start Early/Stop Late distance for intentional

overlap. If a negative number seems to be required for

SE/SL, re-measure & adjust Product Delay

TIPS

1. A data card must be inserted in to the display.

2. Check GPS Offset, Bar Distance, Product Delay, and

check that a product is assigned to a layer for Overlap

& Boundary control to function properly.

3. “(A)” must be present in a window for Auto mode.

4. Disable Overlap Ctrl before backing into corners,

etc. Re-enable after moving forward (not required for

AccuGuide Equipped Tractors).

= new PD (sec)

Ft. of error

mph X 1.46