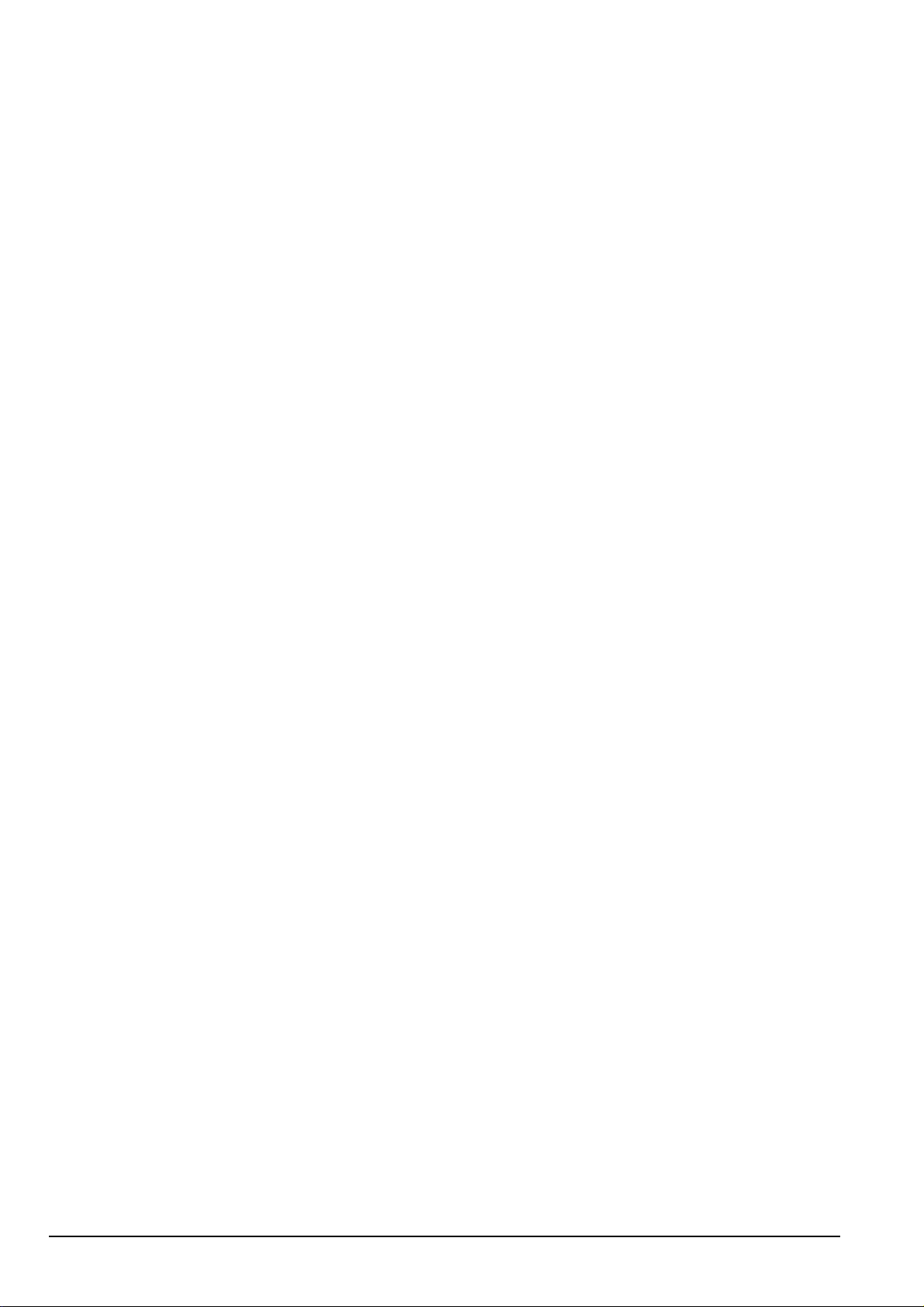

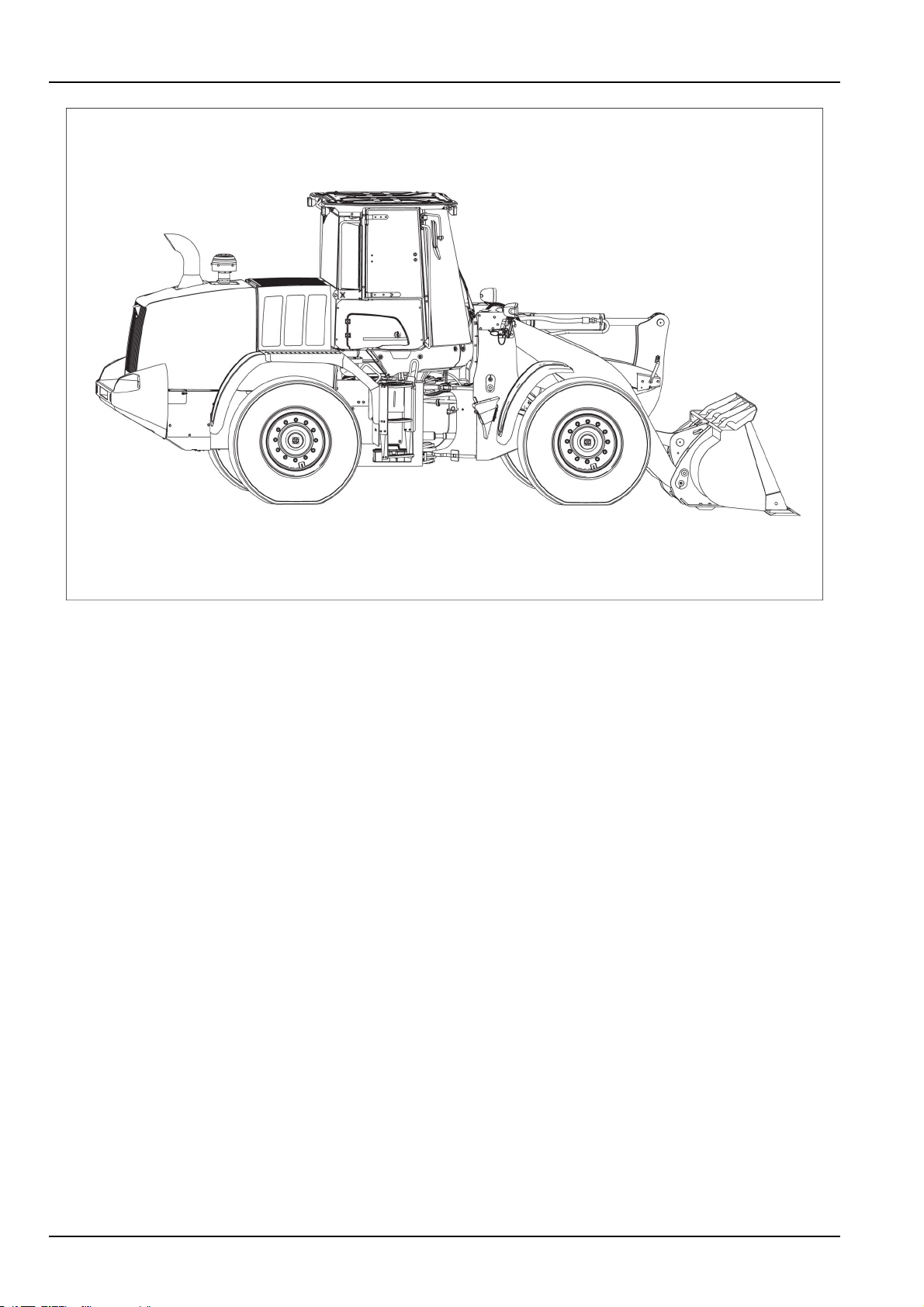

1-GENERALINFORMATION

Intendeduse

Thiswheelloader,withstandardequipmentandattachmentsisintendedtobeusedfordiggingandgeneralearth

movingpurposessuchaslandleveling,truckloading,andmaterialrehandling.

DONOTusethismachineforanyapplicationorpurposeotherthanthosedescribedinthismanual,decals,orother

productsafetyinformationprovidedwiththemachine.Thesematerialsdenethemachine'sintendeduse.

Consultanauthorizeddealeronchanges,additionsormodicationsthatcanberequiredforthismachinetocomply

withvariousapplicationsand/orcountryregulationsandsafetyrequirements.

Beforepermittinganewoperatoronthismachine,makecertain:

•Thattheoperatorhasreceivedthenecessarytrainingtooperatethemachinecorrectlyandsafely.

•Thattheoperatorhasreadandunderstandstheinstructionsgiveninthismanual.

Allpersonswhowillbeoperatingthismachineshallpossessavalidlocalvehicleoperatingpermitand/orotherappli-

cablelocalageworkpermits.

•Travelwithafullbucketrolled-backandloweredasmuchaspossibletoensuremaximumvisibility,stabilityand

safetytoatravellingmachine.Operatethemachineataspeedadequatetotheworkingconditionsinthesiteand

slowenoughtoensurecompletecontrolatalltimes.

•Donotusethemachineforanotherpurposethanintendedbythemanufacturerandoutlinedinthismanual.

•Donotusethemachineonhigherspeedsthanallowedbytheloadandenvironment.Awetsurfaceorotherlow

adherenceconditionsmayincreasethebrakingdistanceorresultinvehicleinstability.Adaptyourtravelingspeed

accordingtotheloadofthevehicleandthecharacteristicsoftheroad.

•Alwayschecktheconditionsandcarryingcapacityofbridgesandrampsbeforedrivingoverthem.

•Donotusethemachinewithoutwearingtheseatrestraintsystemduringactivitieswhererolloverortip-overhazard

exist.TheROPScaborROPSstructurewillonlybefullyeffectivewhenthedriverremainsattachedtotheseat.

•Donotuseequipmentmountedonthemachinewhichisnotcorrectlymatchingandrmlyxed.Suchequipment

mayincreasetheriskofroll-overandhitthemachinewhencomingloose.

•Donotusethemachinebeyonditslimitsofdynamicstability.Highspeed,abruptmaneuversandfastandshort

corneringwillincreasetheriskofroll-over.

•Takethenecessaryprecautionstoalwaysbeawareofthepossiblepresenceofbystanders.Donotworkifby-

standersarewithintherangeoftheoperationofthemachine.Keeppeopleawayfromthemachineduringwork;

bystandersmustleavetheworkingarea.

•Donotallowridersonthemachine.Donotallowpeoplestandingontheaccesswayorsteptothecabwhenthe

machineismoving.Yourviewtotheleft-handwillbeobstructedandariderriskstofallfromthemachineduring

unforeseenorabruptmovements.

•Alwaysstayclearfromimplementsoperatingarea.Whenoperatingliftcontrolsensurebystandersarenotnear

operatingareas.

•Amachinehasonlyoneoperatorstationandisaonemanoperatedvehicle.Otherpeopleonoraroundthemachine

duringnormaloperationarenotallowed.

•Themachineisintendedtobeusedundernormalconditionsfortheapplicationsdescribedinthismanual.Ifthe

machineisusedforotherpurposesorindangerousenvironments,forexampleinaammableorexplosiveatmos-

phere,specialsafetyregulationsmustbefollowedandthemachinemustbeequippedforuseintheseenvironments.

1-4