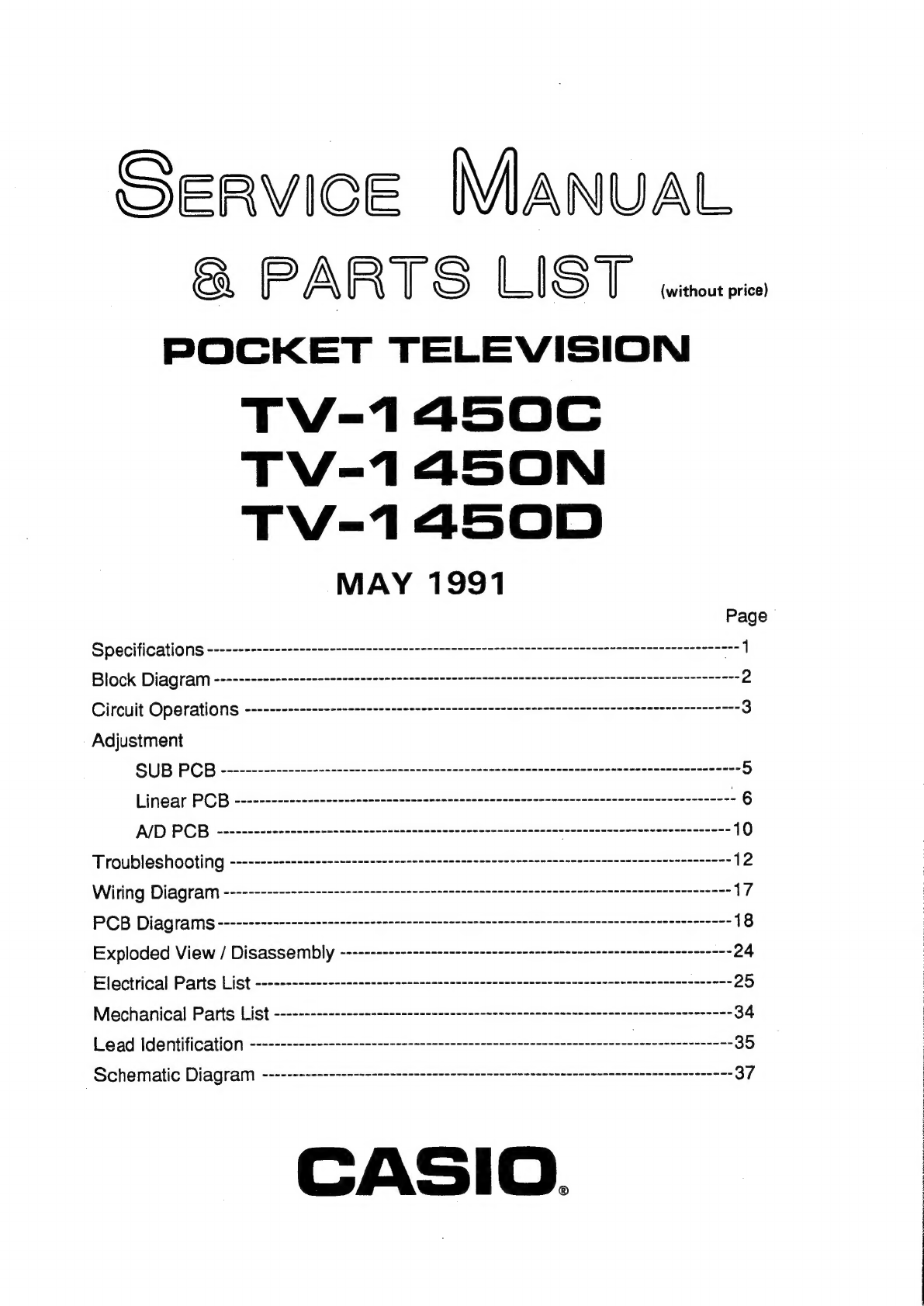

Seavice

MANUAL

&

PARTS

LIST

soo

POCKET

TELEVISION

TV=-1450C

TV=-1450N

TV=-1450D

MAY

1991

Page

Specifications

---------------------------------2-ecn

cc

nnnn

nnn

nnnn

ncn

cn

nnn

nccn

ne

nananncnnnnncncencnns

|

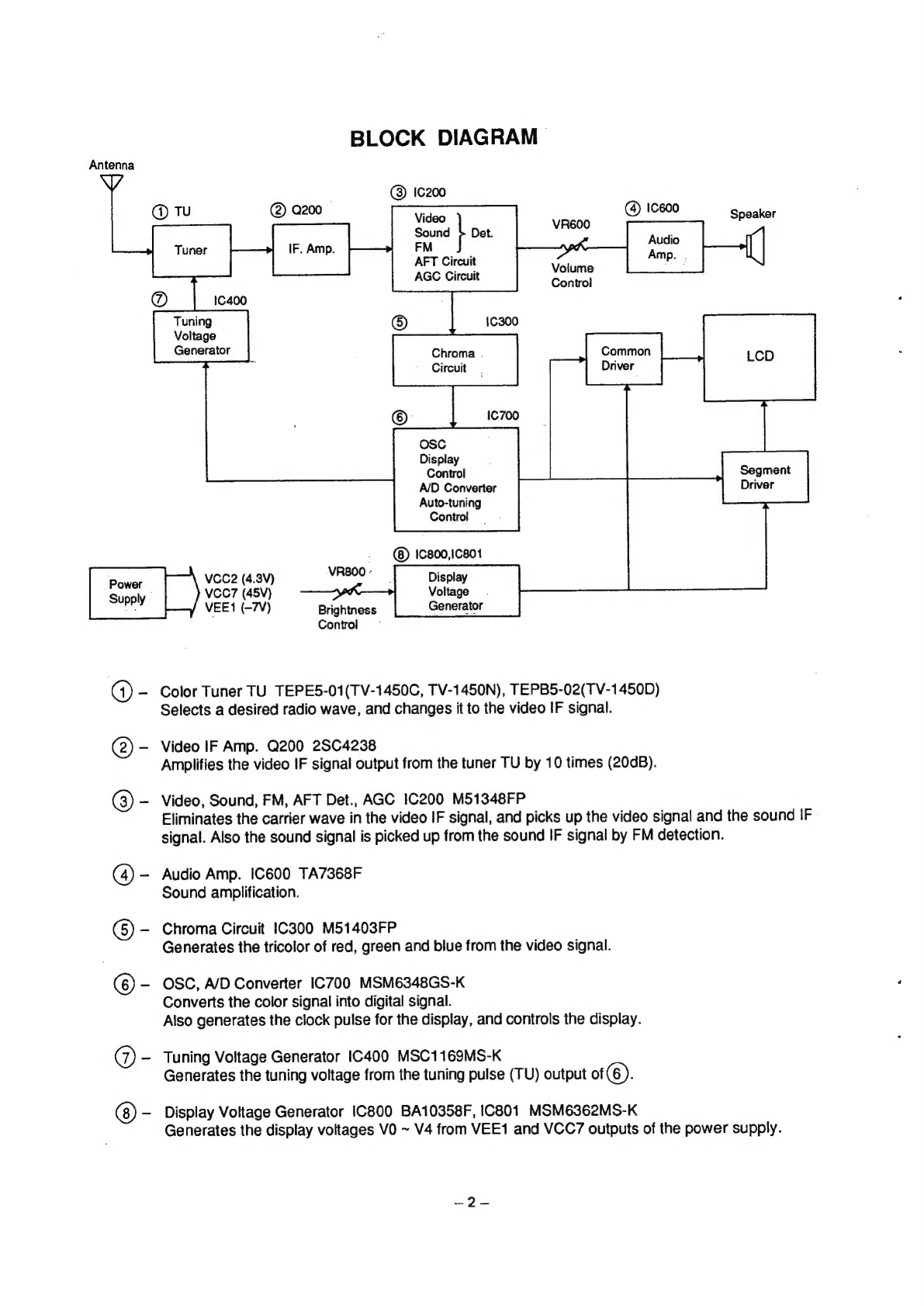

Block

DiaQram

--------------en20n=--nnnn

nnn

nnn

nn

nnn

nnn

nnn

nnn

nro

rn

rn

nnn

nnnnnannn

a

mir

2

Circuit

Operations

----------------------------nnnennnnn

nnn

nnn

nner

nen

nnnn

enon

nnn

onnonmnnnnnnnnnn

sane

3

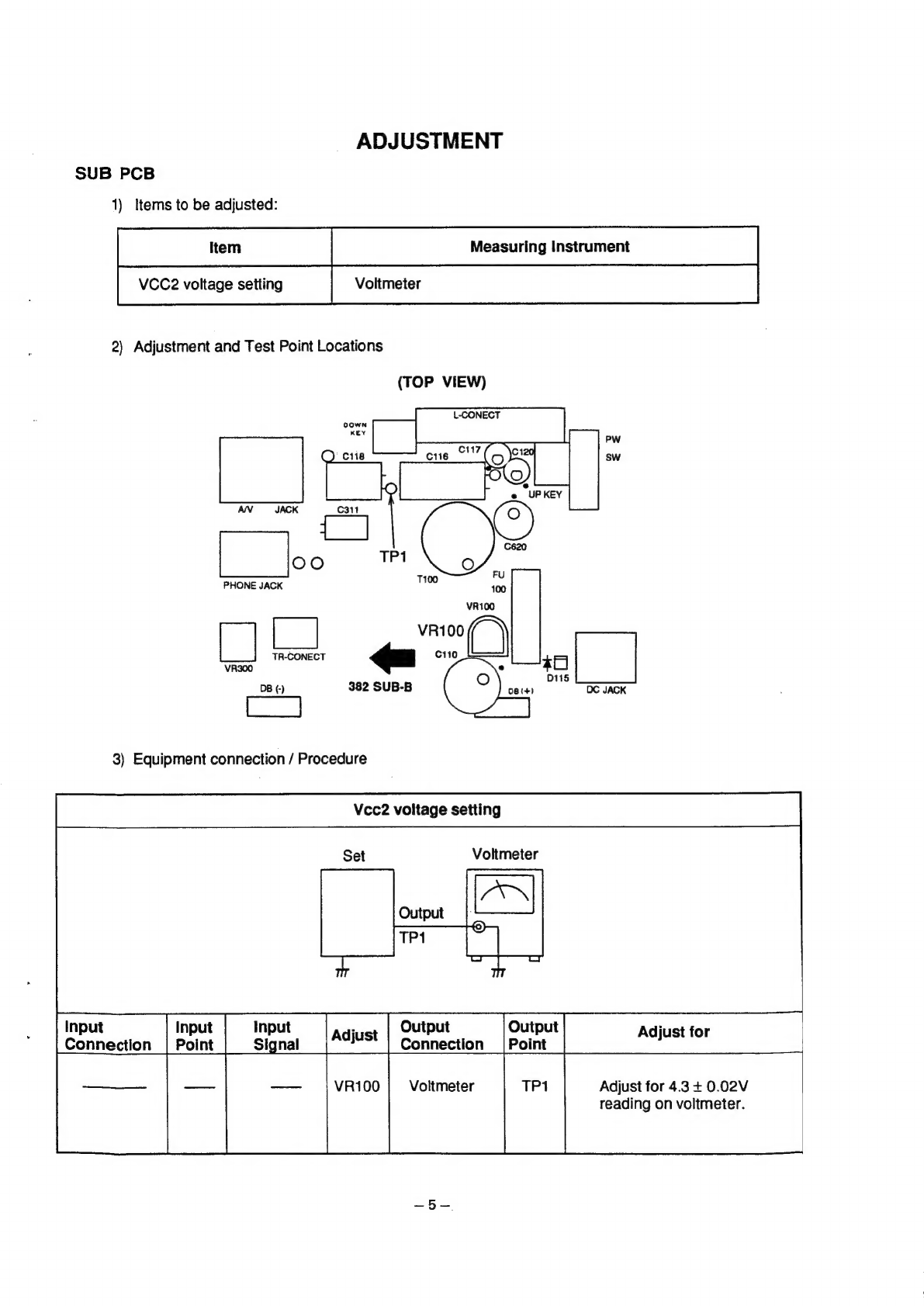

Adjustment

ee

a

Oo

a

a

5

Linear

PCB

------------------n2-n-n-nn-nennnnnnn

ence

nc

cenceneennnnncnnnnnnennnnnnencesccsenen

&

AID

PCB

~----------n--n-nnnnn

nnn

manne

nnn

n

nner

nner

nennncnnnccnncncnnncenanmmnnnnnnanans

10

Troubleshooting

------------------n-nn-n

nmr

nnn

nnn

nn

nner

nnn

nnn

nnn

nen

mn

nna

nnn

cn

emnnmnnnnns

12

Wiring

Diagram

-----------------------------n

enn

nnnn

nn

nn

nnnn

nnn

nnn

nnn

nnn

nnn

nmnnnnn

nnn

nnnn

on

17

PCB

Diagrams

----------------7--------nn

nn

nnnnn

none

nn

enn

nnnnnnnncennnnnnnnnnnnnrnnannnnnannnnenes

18

Exploded

View:/

Disassembly

==--<-s--2-+---=-sse

retire

mene

seen

eerce

ese

areeeen

eee

24

Electrical

Parts

List

-----------------------------

ns

-nn

nnn

nnn

nnn

nnn

nnn

nnn

nnn

nme

25

Mechanical

Parts

List

---------------~------------------

nnn

nn

nn

nnn

nnn

nn

nnn

ne

nnn

er

een

cnn

nnn

34

Lead

Identification

------------------------------------e---o2ncenecenccenceencees

eid

ceoeee

se

35

Schematic

Diagram

+S

37