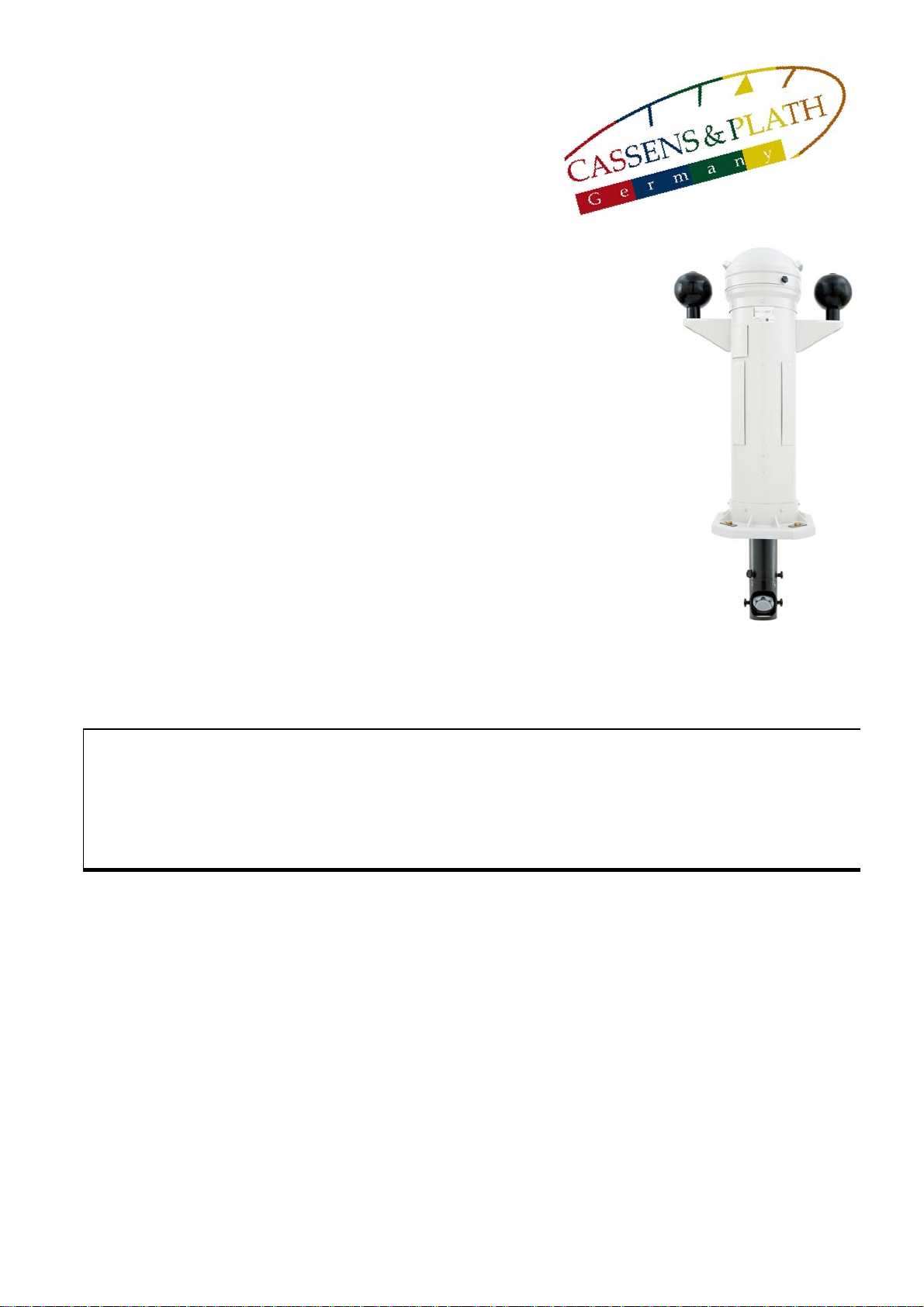

Introduction, General REFLECTA/1

Page A4 Mounting & Operations Manual

Alterations / Errors reserved

Cassens & Plath GmbH, Kompasshaus, Am Lunedeich 131, 27572 Bremerhaven, Germany, tel +49 471 4839990, fax +49 471 48399910

Intended Purpose

Apart from the gyro compass seagoing ships have to be equipped with a second heading source, the magnetic

compass. Furthermore the magnetic compass works more and more as back-up to drive the autopilot.

Magnetic compasses have to be installed in a sufficient distance to any magnetic iron as well as to the different

navigational instruments. Therefore the preferred location is the compass bridge. To read the heading at the

helmsman´s position inside the wheelhouse one makes use of a reflection arrangement. This is an optical

arrangement consisting of magnification lenses and mirrors. According to SOLAS regulations the remote

reading has to be independent of electrical means.

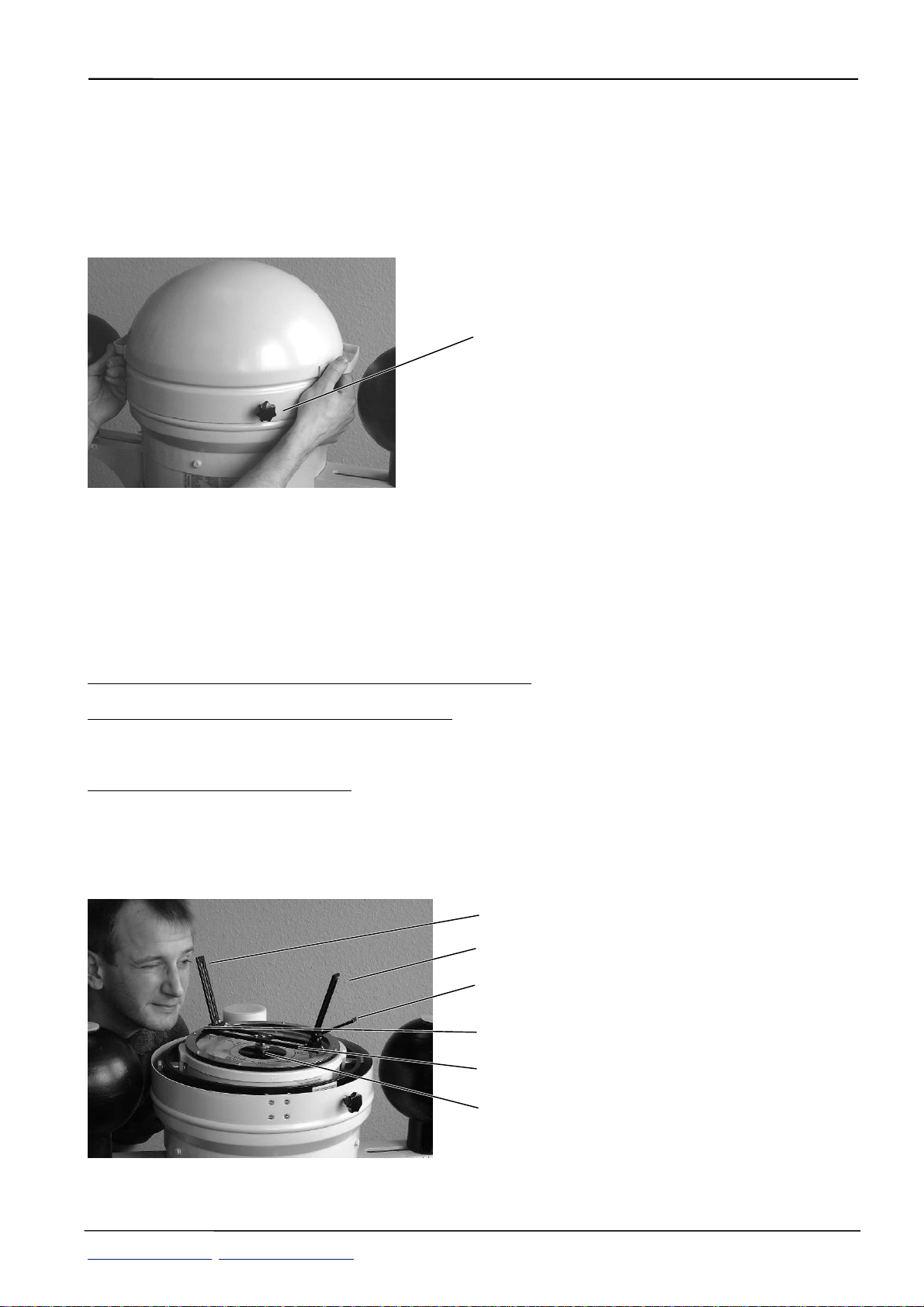

The magnetic compass is found within the compass binnacle. It is easy to remove and to replace with another

one. Spare magnetic compasses are obligatory according to SOLAS.

A divided verge ring on top of the compass allows taking bearings of coastal or heavenly objects. A vane type

azimuth device with a swivel black mirror is included in the range of delivery to allow compass and relative

bearings.

In spite of the distance to any magnetic source a deflecting influence -the deviation- cannot be totally excluded.

For correction of these residual errors the compass binnacle possesses an adjusting arrangement.

Installation of magnetic compasses and the requirements for their location are laid down in basic national and

international regulations. These are IMO A.382(X) and SOLAS consolidated Edition, 1992, Chapter V,

regulation 12. The technical and design requirements for magnetic compasses are laid down in ISO

25862:2009(E) amendment: Directive 2010/68/EC + 2011/75/EC as well as in the relevant national documents.

REFLECTA fullfills all these regulations.

Technical Data

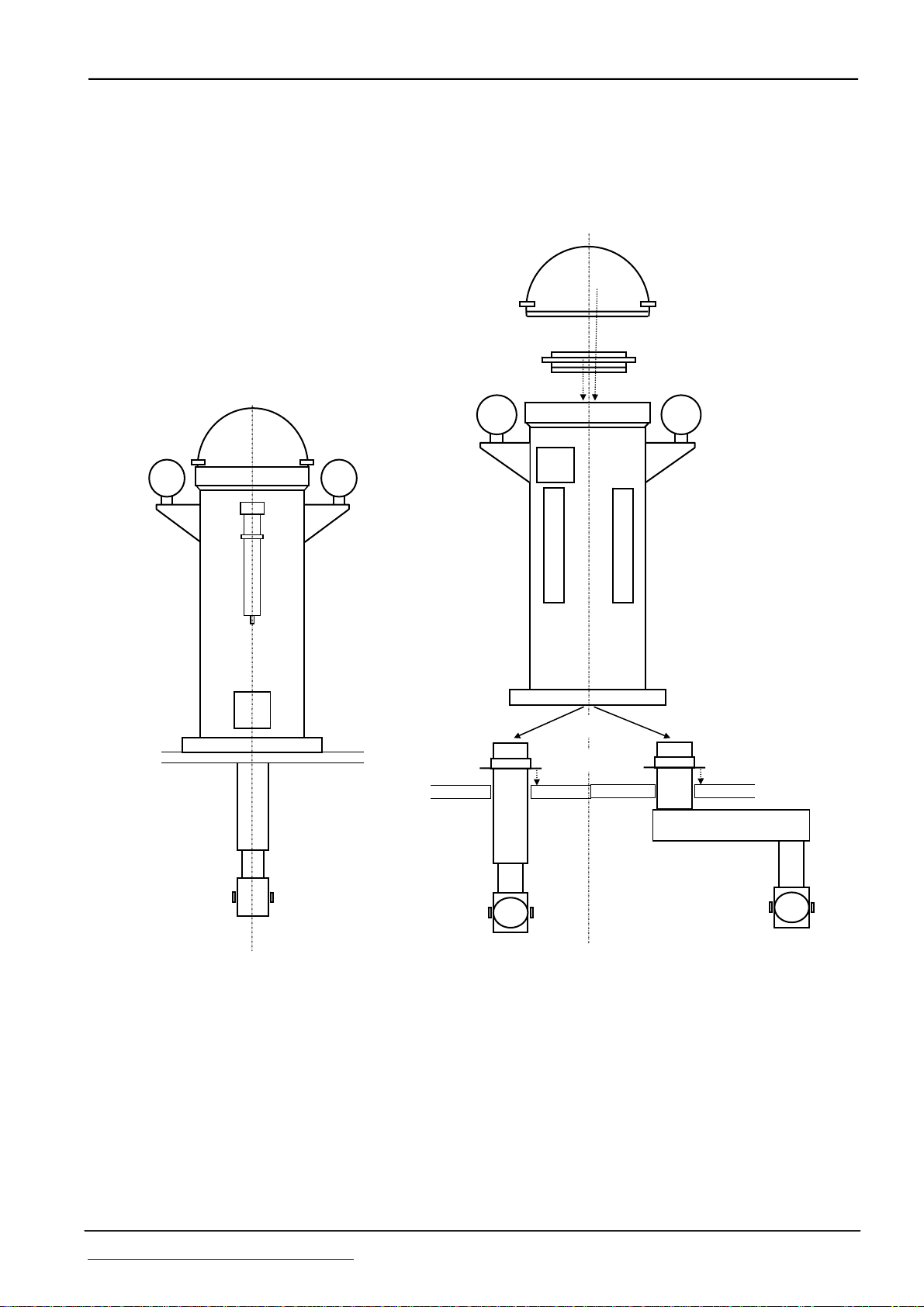

Compass Binnacle

Card height............................................. standard column 1200 mm, as option 910 mm up to 1800 mm

Total height.....................................................................................1380 mm in case of standard column

Maximum width measured over D-spheres..................................................................................880 mm

Weight of binnacle and compass complete....................................net 95 kg in case of standard column

Material of binnacle column..........................................................................seawater resistant light alloy

Built-in correctors.......................................................................................................................B+C, K, D

Correctors as option................................................................................................................................E

Correctors as option..............................................................................................................Flinder´s bar

Reflector/bearing compass type 11

Diameter of directional system..................................................................................................... 180 mm

Orientations of card printing from below for reflection reading .................................................N below N

Card division........................................................................................................................................1/1°

Magnet................................................................................................................................................Ring

Magnetic moment...............................................................................................................typically 4 Am2

Damping factor ....................................................................................................................... typically 3.3

Working temperature range............................................................................................. -30°C .... +65°C

Swirl error according to ISO 25862:2009(E)/2010/68/EC+2011/75/EC, 2013/52/EU........< 2,0°(at18µT)

Friction error according ISO25862:2009(E) 2010/68/EC+2011/75/EC, 2013/52/EU..........< 0.5°(at 6µT)

Directional error according ISO25862:2009(E) 2010/68/EC+2011/75/EC, 2013/52/EU ..< 0.5°(at 18µT)

Half period .......................................................................................................................................13 sec

Tilt freedom of card in compass bowl.............................................................................................+/- 10°

Rolling/pitching tolerance of compass in gimbal suspension........................................................+/- 180°

Weight................................................................................................................................................12 kg

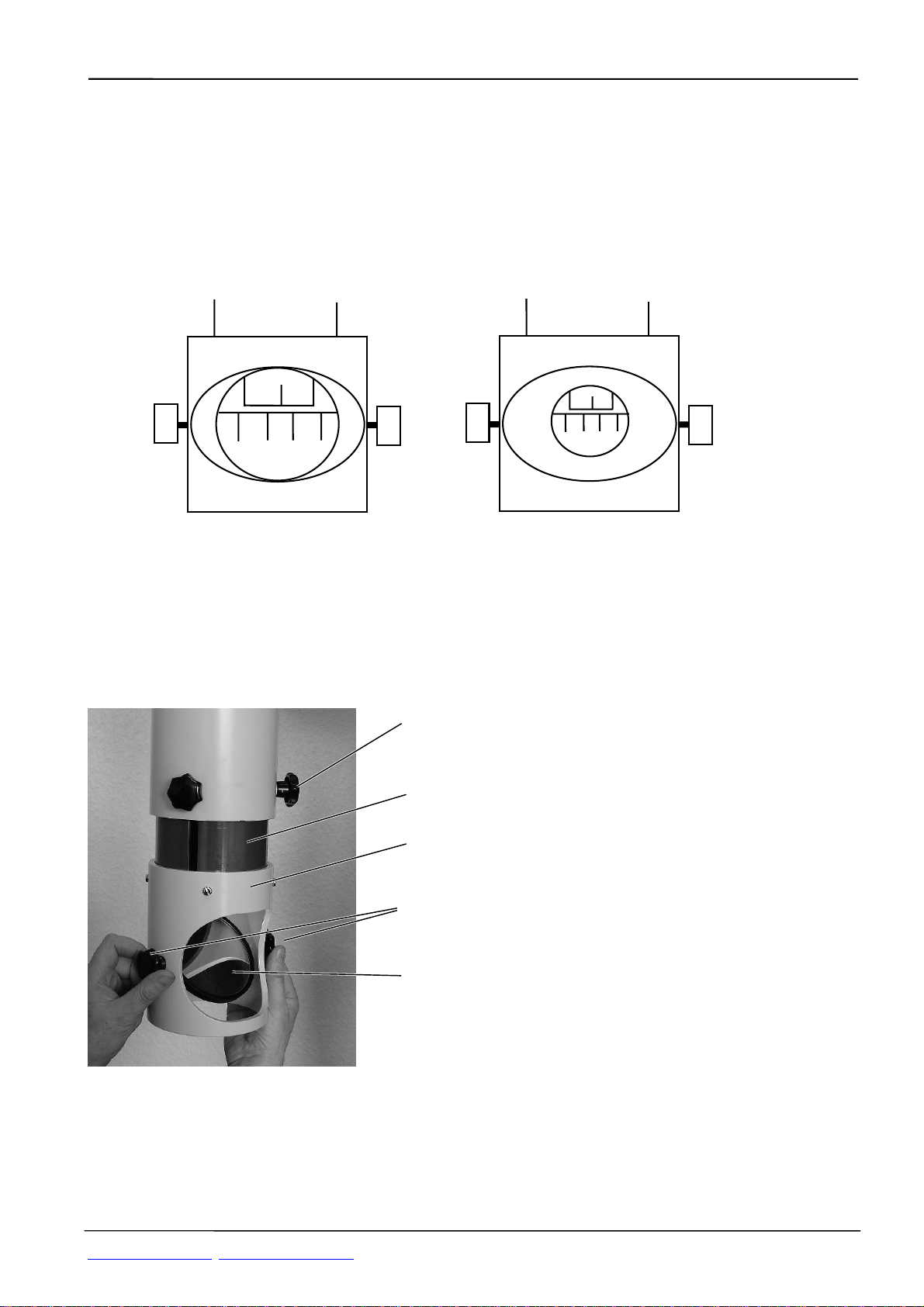

Reflection arrangement

Type CUTUBE .....................................................................................length 1200 mm to be cut by yard

Type FIXTUBE................................................................................... ready adjusted in length at delivery

Diameter of tube........................................................................................................................... 140 mm

Material...............................................................................................................................................PVC

Extension length of mirror head.................................................................................................... 150 mm

Turning range of mirror head..............................................................................................................360°

Swivel range of reflection mirror, black and white..............................................................................360°