index

The manual in language is available at

www.castellarisrl.com Use and maintenance manual:

www.castellarisrl.com

Manuale de uso y mantenimiento: www.castellarisrl.com

USE AND MAINTENANCE MANUFACTURE:

www.castellarisrl.com

1. DESCRIPTION OF THE GENERAL CHARACTERISTICS OF MACHINERY 3

1.1. Purpose of the manual ......................................................................................................3

1.2. Identification of machinery ...............................................................................................3

1.3. Description of machines and technical data ........................................................................3

1.4. Subjects to whom the manual is addressed ........................................................................4

1.5. Intended and unforeseen uses of machinery.......................................................................4

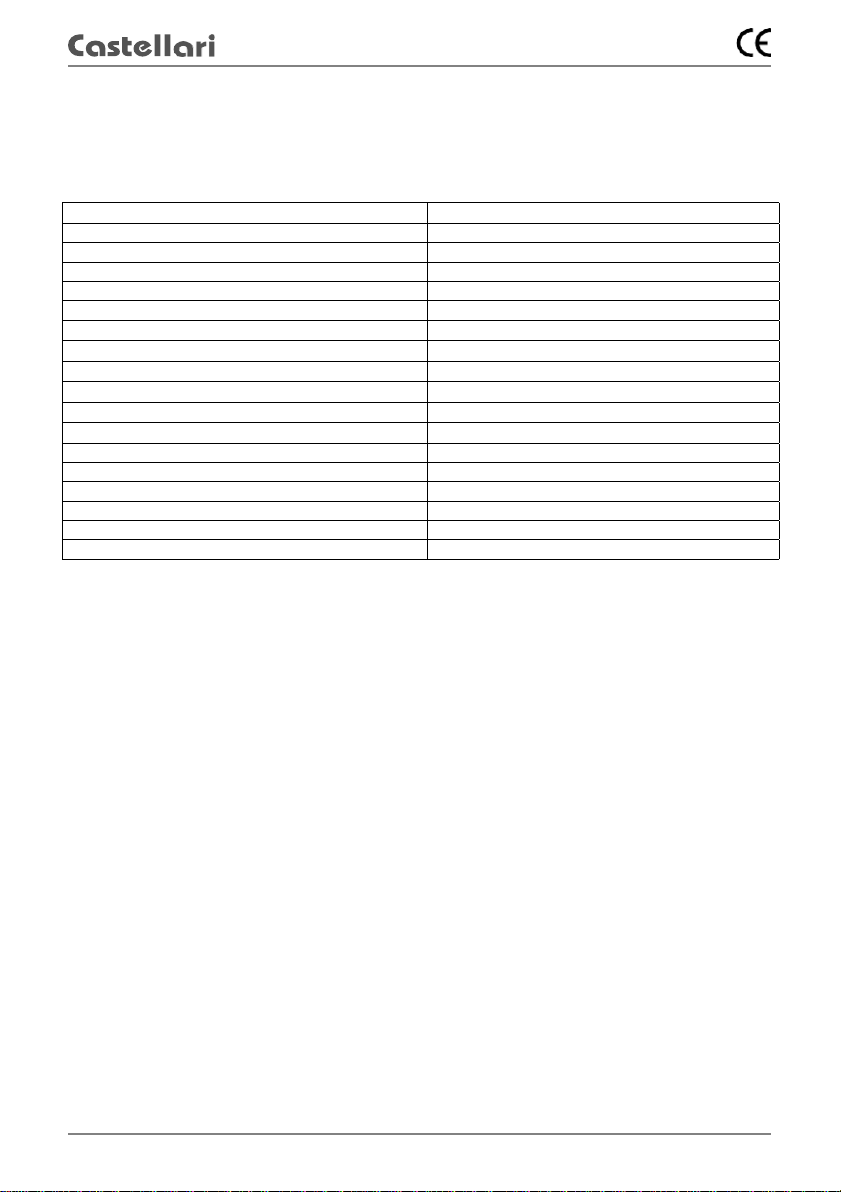

1.6. Risks arising from the use of machines ...............................................................................4

1.6.1. Noise risk 4

1.6.2. Vibration risk 5

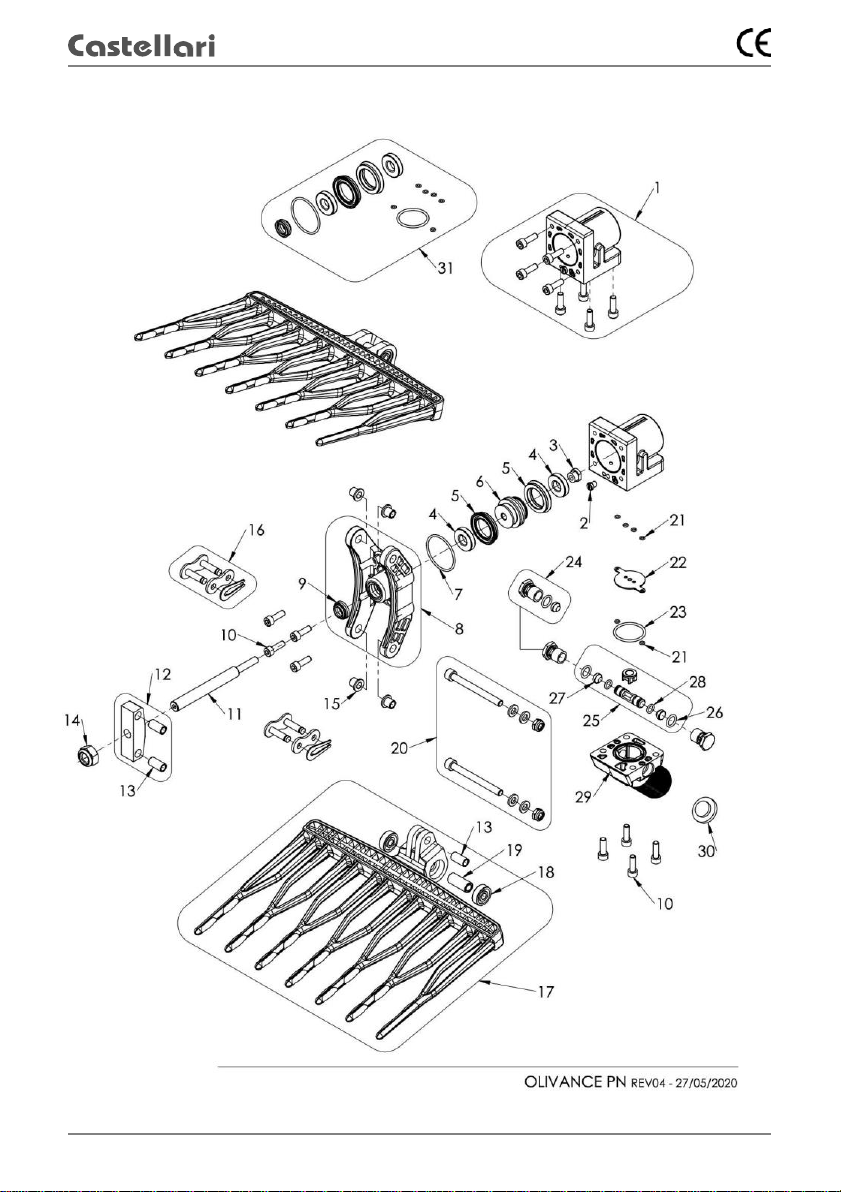

1.7 Olivance PN Components ..................................................................................................6

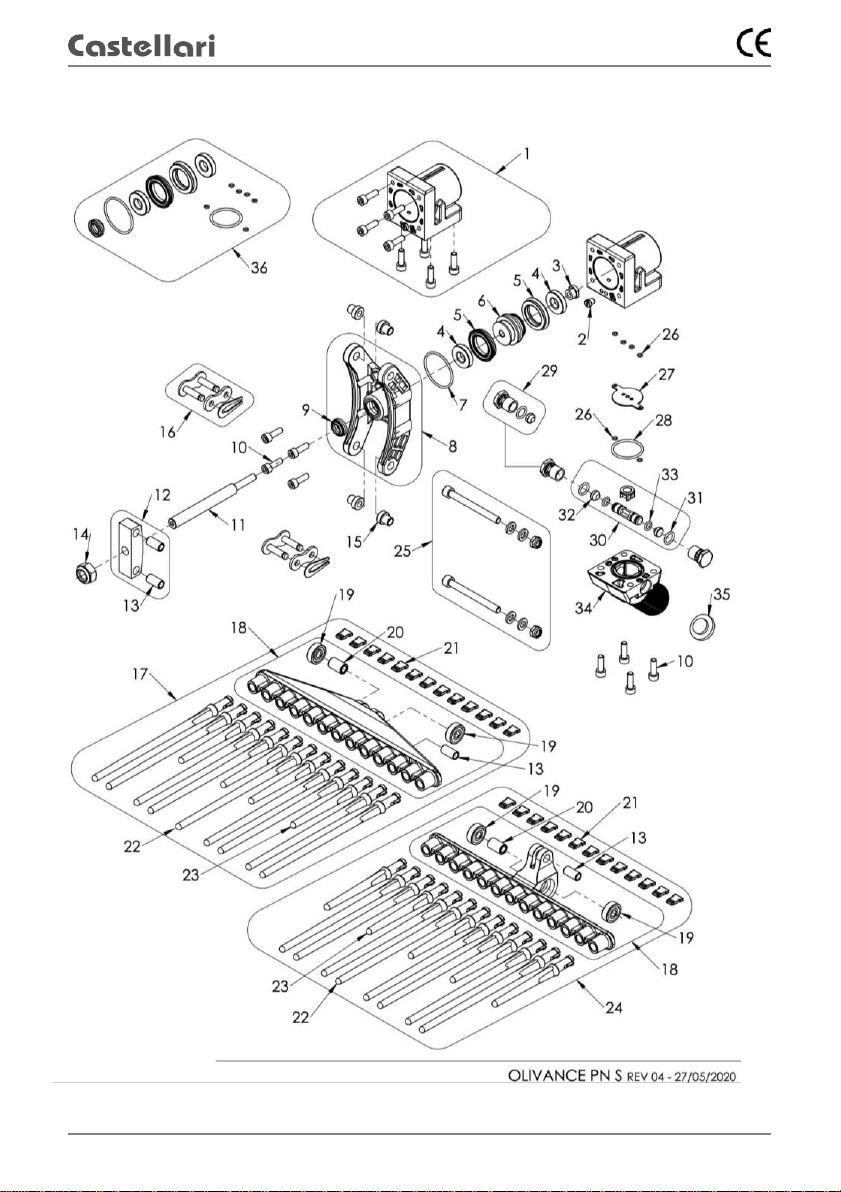

1.8 Components Olivance PN S................................................................................................8

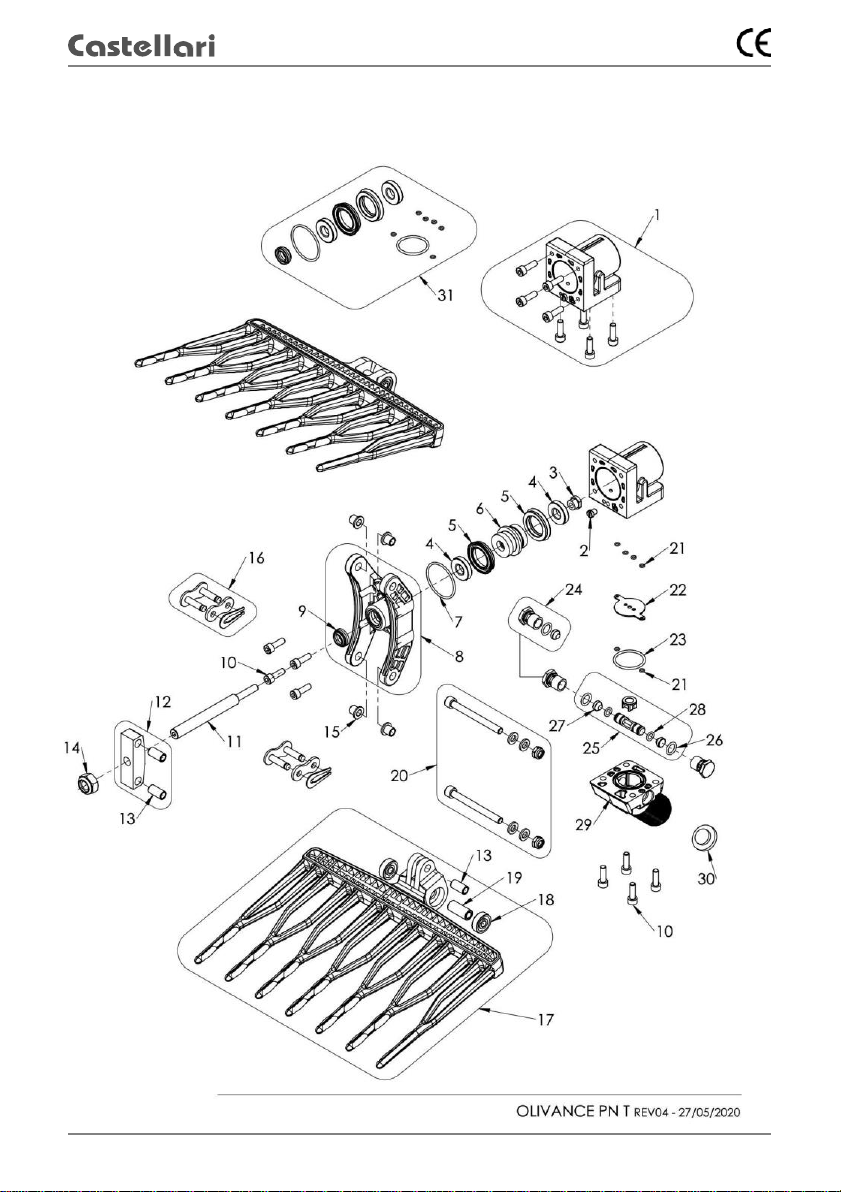

1.9 Olivance PN T Components.............................................................................................. 10

1.10 Olivance PN X Components ............................................................................................. 12

1.11 Olivance PN XT Components............................................................................................ 14

2. SAFETY AND PREVENTION 16

2.1. Safety signals (pictograms).............................................................................................. 16

2.2. General safety standards................................................................................................. 16

2.3. Safety in use and maintenance ........................................................................................ 16

2.3.1. Safety in use 16

2.3.2. Maintenance safety 16

2.4 Ecology and pollution...................................................................................................... 17

2.4.1. Waste management 17

3. use 17

3.1. Handling and transport ................................................................................................... 17

3.2. Before use...................................................................................................................... 17

3.3. Assembly and connection................................................................................................ 17

3.4. Use of machines ............................................................................................................. 17

4. MAINTENANCE AND CLEANING 18

4.1. Routine maintenance...................................................................................................... 18

4.2. Cleaning and lubrication of machines ............................................................................... 18

4.3. Set-aside........................................................................................................................ 18

4.4. Dismantling of machinery................................................................................................ 18

4.5. Solving common problems (see website).......................................................................... 19

4.6. Spare parts..................................................................................................................... 19

5. WARRANTY CONDITIONS 19

5.1. Exclusion from warranty ................................................................................................. 19

6. DECLARATION OF CONFORMITY 19