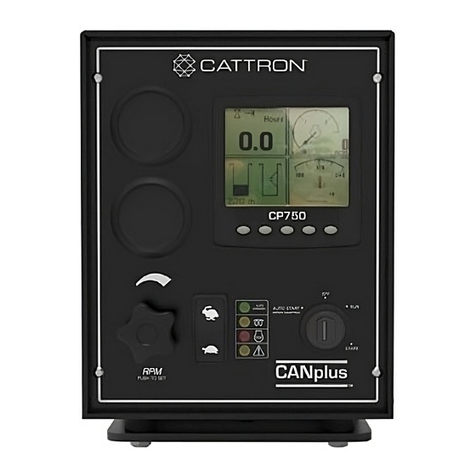

CANplusTM CP750-E

Installation Manual

Revision A

1.1.1 INTRODUCTION----------------------------------------------------------------------------------------------------------- 4

2MECHANICAL MOUNTING--------------------------------------------------------------------------------------------- 5

2.1 ALUFLEX™PANELS ------------------------------------------------------------------------------------------------------ 5

2.1.1 MOUNTING TEMPLATES ------------------------------------------------------------------------------------------------ 5

3CONNECTOR PINOUTS------------------------------------------------------------------------------------------------- 8

3.1 D21 TO ENGINE PIN OUT ------------------------------------------------------------------------------------------------- 9

3.2 AUTOSTART SWITCHES ------------------------------------------------------------------------------------------------ 10

3.3 TRANSDUCERS 1AND 2 ------------------------------------------------------------------------------------------------ 10

3.4 AUXIO -------------------------------------------------------------------------------------------------------------------- 10

3.5 MODBUS------------------------------------------------------------------------------------------------------------------- 11

4TYPICAL WIRING ------------------------------------------------------------------------------------------------------- 12

4.1 POWER AND GROUND -------------------------------------------------------------------------------------------------- 12

4.2 ECU POWER OUT ------------------------------------------------------------------------------------------------------- 12

4.3 STARTER POWER OUT ------------------------------------------------------------------------------------------------- 12

4.4 RESISTIVE SENDERS---------------------------------------------------------------------------------------------------- 12

4.5 CAN BUS TERMINATION ----------------------------------------------------------------------------------------------- 12

5TESTING ------------------------------------------------------------------------------------------------------------------- 13

6CERTIFICATIONS ------------------------------------------------------------------------------------------------------- 14

6.1 FCC PART 15 CERTIFICATION ---------------------------------------------------------------------------------------- 14

6.2 INDUSTRY CANADA CERTIFICATION --------------------------------------------------------------------------------- 15

7TECHNICAL SUPPORT ----------------------------------------------------------------------------------------------- 16